Supplied By www.heating spares.co Tel. 0161 620 6677

Publication No. 5102696 9InstallationRequirements

1.9 The System

Beforeinstallinganewboilertoanexistingsystemtreatthe

systemwithanappropriatedescaling/flushingagentasper

the instructions supplied with the treatment package. It is

recommendedthatanycorrosioninhibitorsanddescalers/

flushing agents used are manufactured by Fernox or

BetzDearborn.

If plastic pipe is used for the central heating circuit there

mustbearunofatleast2mofuninsulatedcopperpipefrom

theboiler flowandreturn connections.

TheboilermustbeusedonIndirectFullyPumpedsystems

only, which may be sealed or open vented - See Page 12

forpumprequirements.

Thesystemshouldbedesignedsothatthemaximumstatic

headdoesnotexceed30.5m(100ft)andaminimumof150

mm(6in).Theflowpipefromtheboilermustalwaysbelevel

toorhigherthanthereturn pipe.

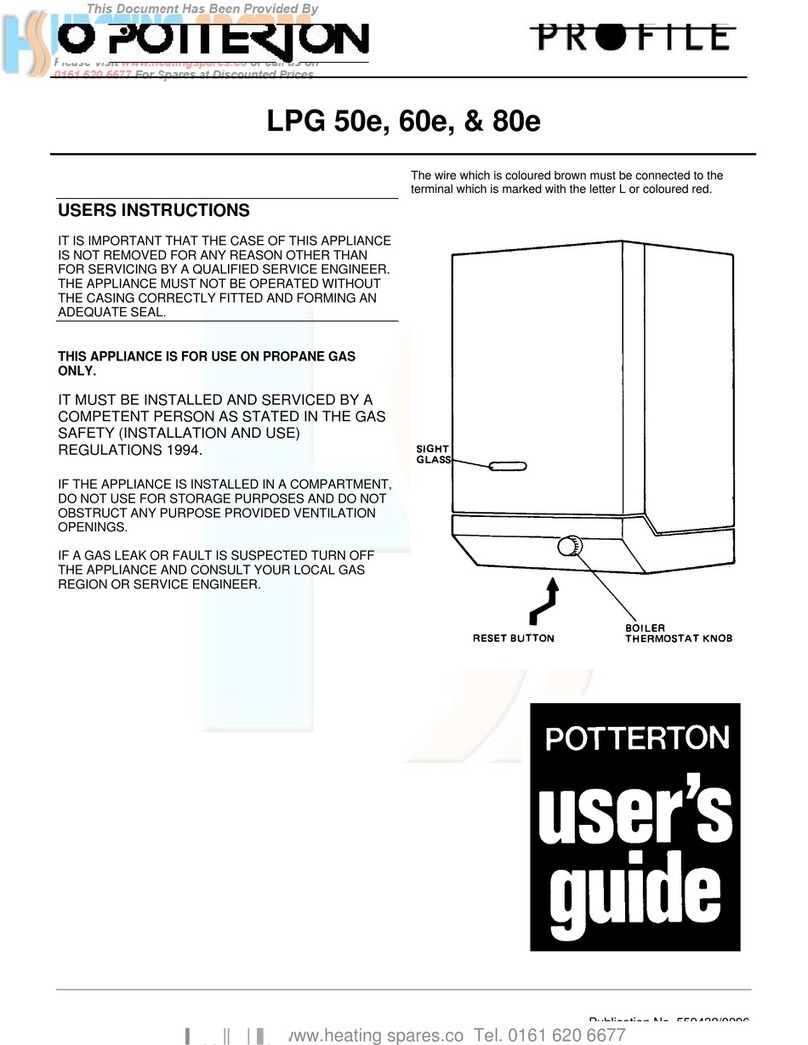

On all systems the pump live connection should be wired

tothe boiler terminal block,itwill then becontrolledbythe

pumpover-run.Thiswillensurethatthepumpwillcontinue

torunafterboilershutdownifthewatertemperatureishigh,

thus preventing nuisance operation of the overheat

thermostat.

Itisimportantthatwhereelectricallyoperatedzonevalves

are used the boiler is wired so it does not cycle when the

zone valves are closed. Also, systems fitted with controls

thatclosebothhotwaterandcentralheatingcircuitswhile

theboiler isstillhot, mustbefitted withaby-pass circuitto

dissipate the residual heat from within the boiler.

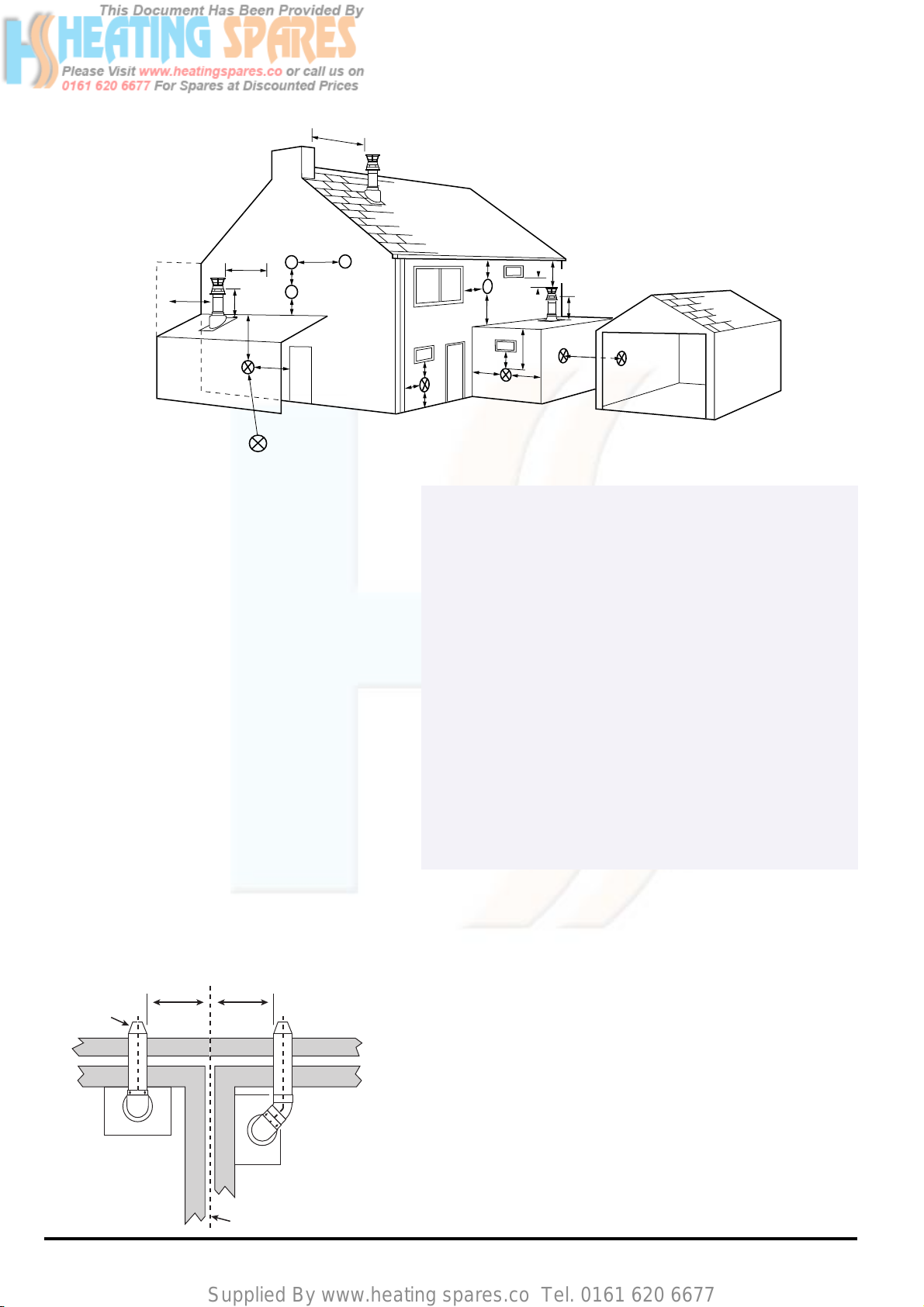

IfathreeportvalveisusedasshowninFig.5aby-passis

not necessary since one circuit is always open.

Where a pair of two port valves are used, a by-pass is

necessary. The total length of the by-pass circuit taken

fromtheboilerconnectionsshouldbegreaterthan4metres

of22mmpipe.Itshouldbefittedwithalockshieldvalveand

beadjustedtomaintainaminimumflowthroughtheboiler

of 4.5 litres/min (1 gal/min).

Systems fitted with controls which allow the boiler to

operatewhenboththehotwaterandcentralheatingcircuits

areclosed(i.e.mechanicallyoperatedthermostaticcontrol

valves)mustbefittedwithaby-passcircuit(2mmin.length

of22mmdia.pipe)andcapableofmaintainingaminimum

waterflowratethroughtheboilerof9litres/min(2gal/min).

A suggested method of meeting these requirements by

usingabathroomradiatorfittedwithtwolockshieldvalves

is shown in Fig. 5. Additional system information can be

foundintheControlSystems,pipeworkandWiringGuide.

Drain off taps should be fitted in the pipework close to the

boiler and in the low points of the system.

Note:Althoughthesystemcanbeemptiedusingthedrain

off taps installed in the pipework around the system, to

empty the boiler it is necessary to remove the drain off

screwpositioned ontheheatexchanger.

Sealed Systems

Note: If the sealed system kit is

Not

being used the

installation must comply with the following requirements.

Installation

The installation must comply with the requirements of BS

6798:1987andBS5449:Pt1.TheBritishGaspublication

"BritishGasSpecificationforDomesticWetCentralHeating

Systems" should also be consulted.

PressureReliefValve

Anon-adjustablespring-loadedpressurerelief valve,preset

tooperateat3bar(45lbf/in²)shallbeused.Itmust comply

withBS 6759: Pt1. and includeamanual testingdevice.It

shall be positioned in the flow pipe either horizontally or

verticallyupwardsandclosetotheboiler.Noshut-offvalves

aretobeplacedbetweentheboilerandthesafetyvalve.The

valve should be installed with a discharge pipe which

permitsthesafedischargeofsteamandhotwatersuchthat

nohazardto persons or damage to electricalcomponents

is caused.

PressureGauge

A pressure gauge incorporating a fill pressure indicator,

coveringtherange0-4bar(60lbf/in²)shallbefittedtothe

system.Itshouldbeconnectedtothesystem,preferablyat

thesamepointastheexpansionvessel.Itslocationshould

be visible from the filling point.

ExpansionVessel

AdiaphragmtypeexpansionvesseltoBS4814:Pt1.shall

befittedclosetotheinletsideofthepump.Theconnecting

pipework should not be less than 15 mm. Pipework

connecting the expansion vessel should not incorporate

valves of any sort. Methods of supporting the vessel are

supplied by the vessel manufacturer. The nitrogen or air

charge pressure of the expansion vessel shall not be less

than the hydrostatic head, (height of the top point of the

systemabovetheexpansionvessel).Tosizetheexpansion

vesselit is first necessarytocalculate the volume ofwater

inthesysteminlitres. Thefollowing volumesmay beused

asaconservative guide to calculating the system volume.

BoilerHeatExchanger: 2.1 litres

SmallBorePipework: 1 litre per kW of system

output

MicroBorePipework: 7 litres

SteelPanelRadiators: 8 litres per kW of system

output

LowWaterCapacityRadiators: 2 litres per kW of system

output

HotWaterCylinder: 2 litres