Mower

CAT 310

plus front

( Type PTM 342 : + . . 01001 )

GB Excerpt from

operating manual Nr. 342960GB.pdf

Table of contents

Snap Connector (1).......................................................................................................................... 4

Attaching problems .......................................................................................................................... 4

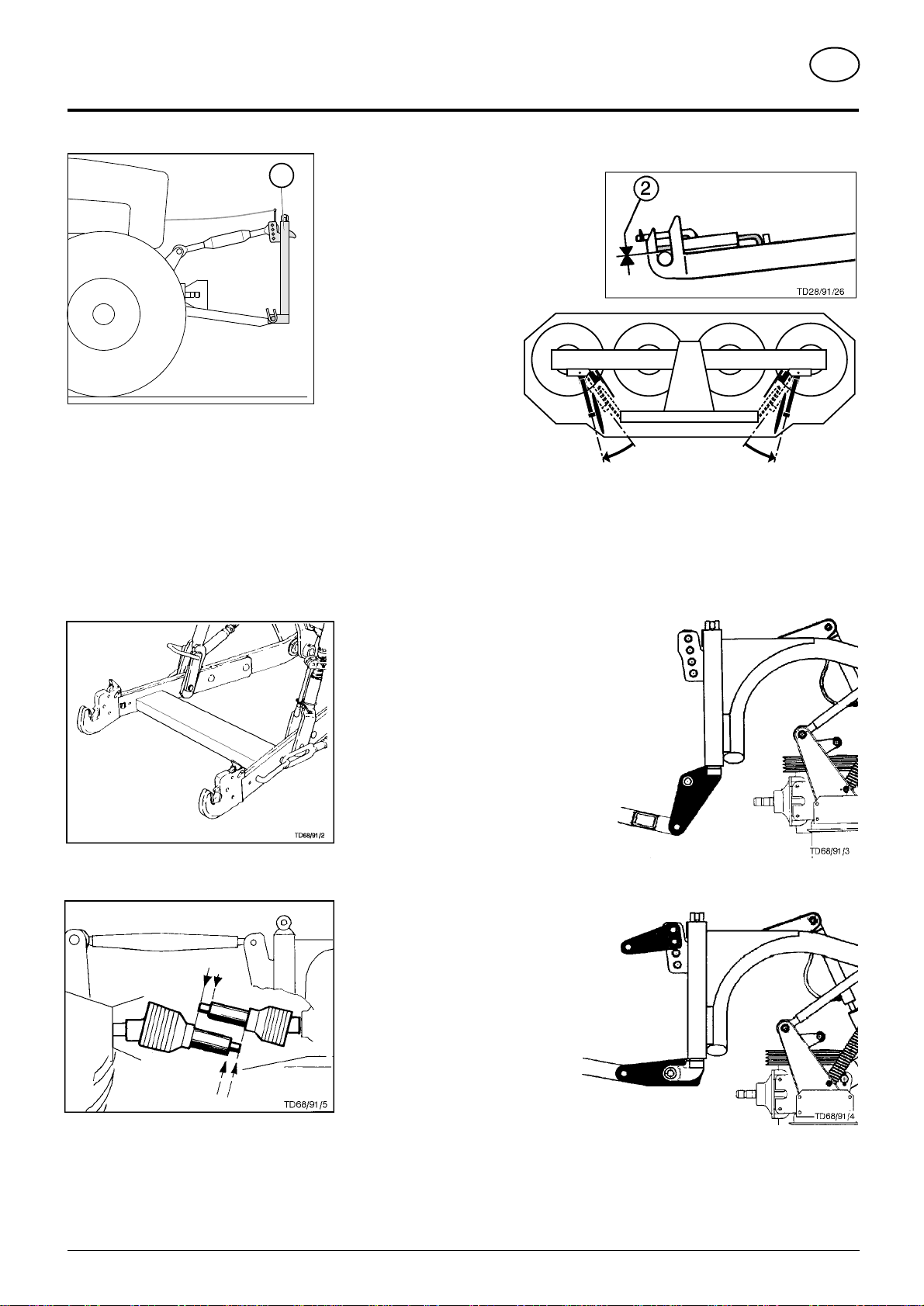

Connecting to tractor........................................................................................................................ 5

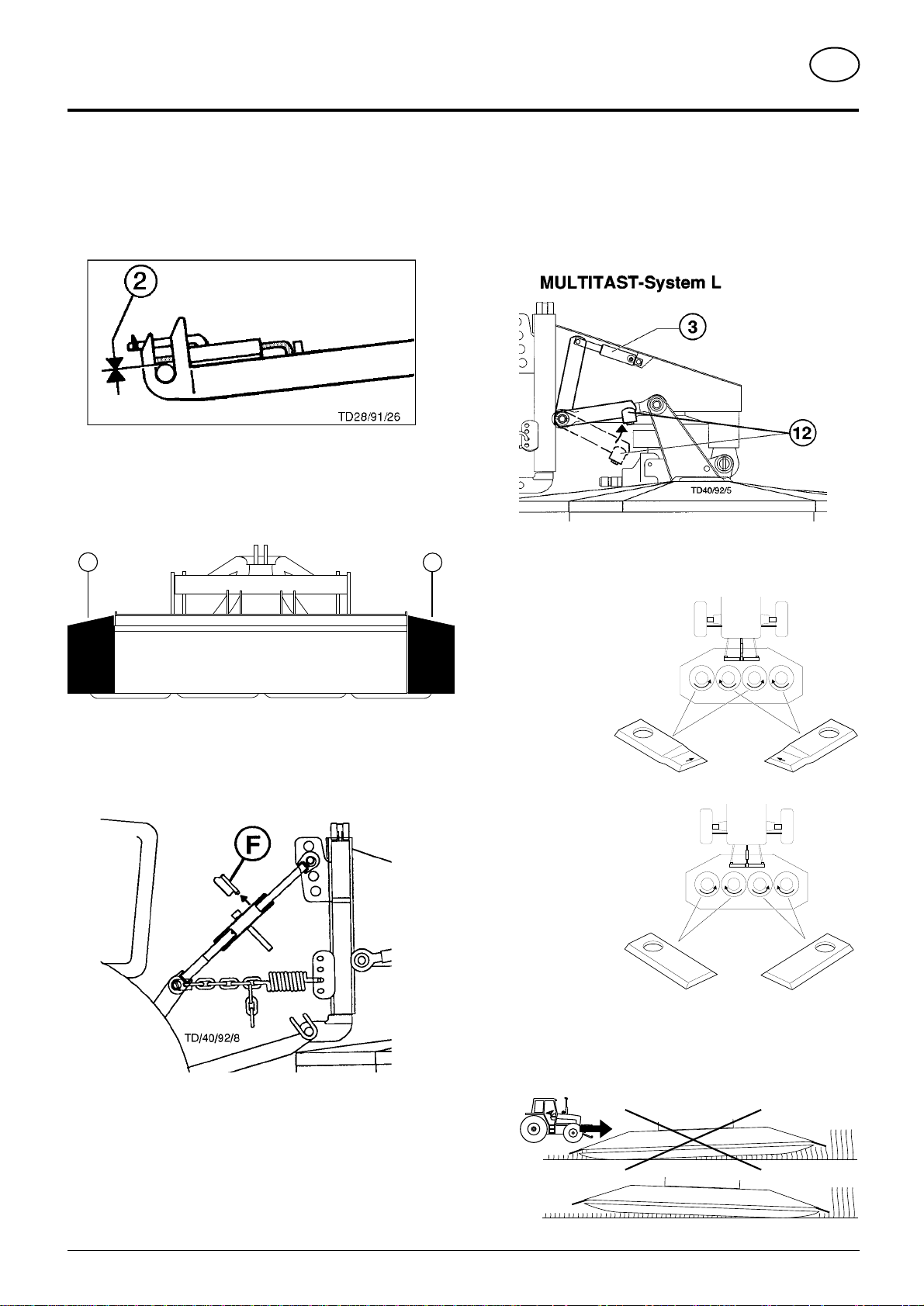

Adjusting(8i the MULTITAST-System L ............................................................................................ 5

Spring tensioning ............................................................................................................................. 5

Adjusting the upper link.................................................................................................................... 5

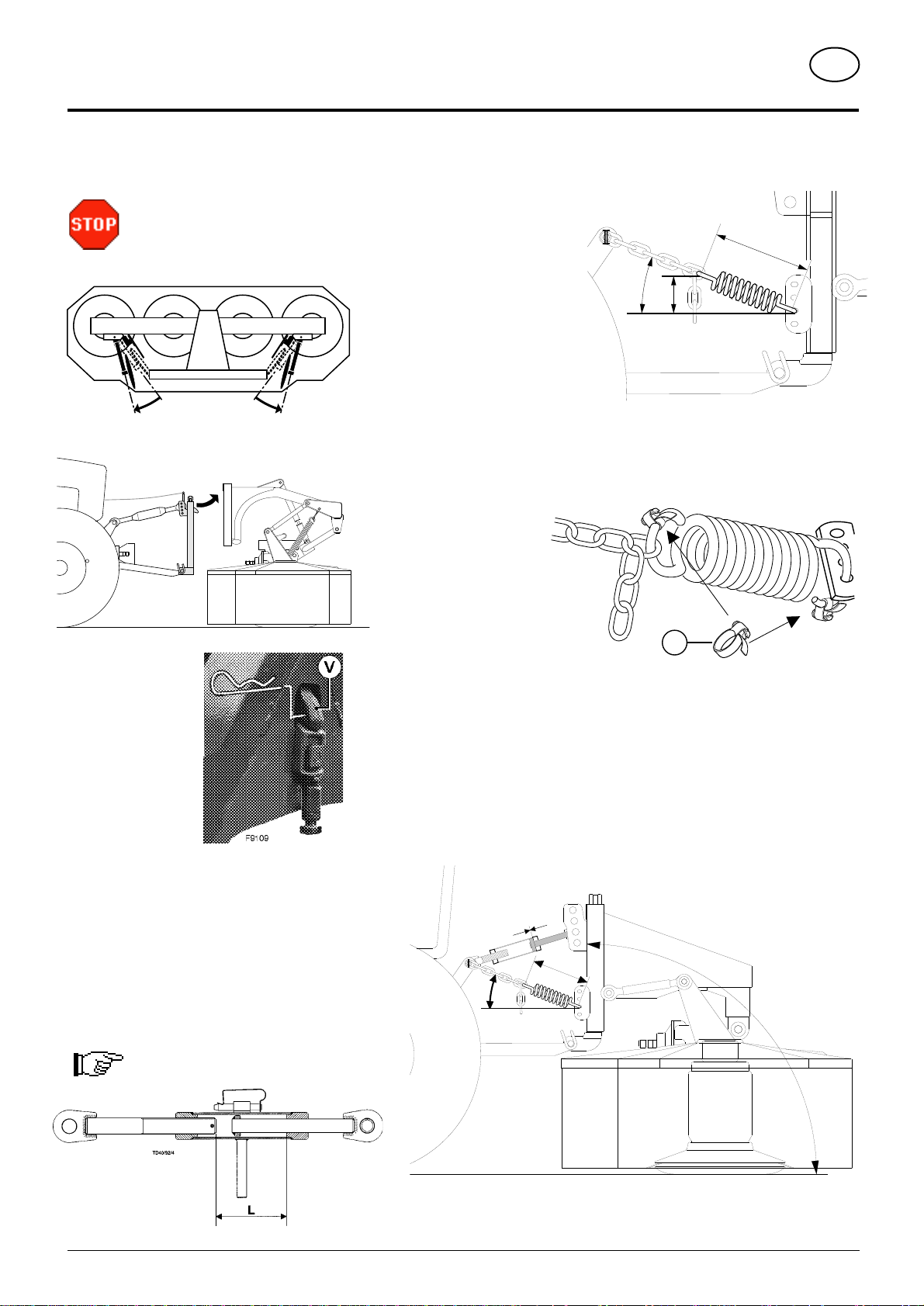

Adjustment of the damped steering mechanism (DSM) .................................................................. 3

Function of the damped steering mechanism .................................................................................. 3

Problems which may arise during operation and their correction .................................................... 3

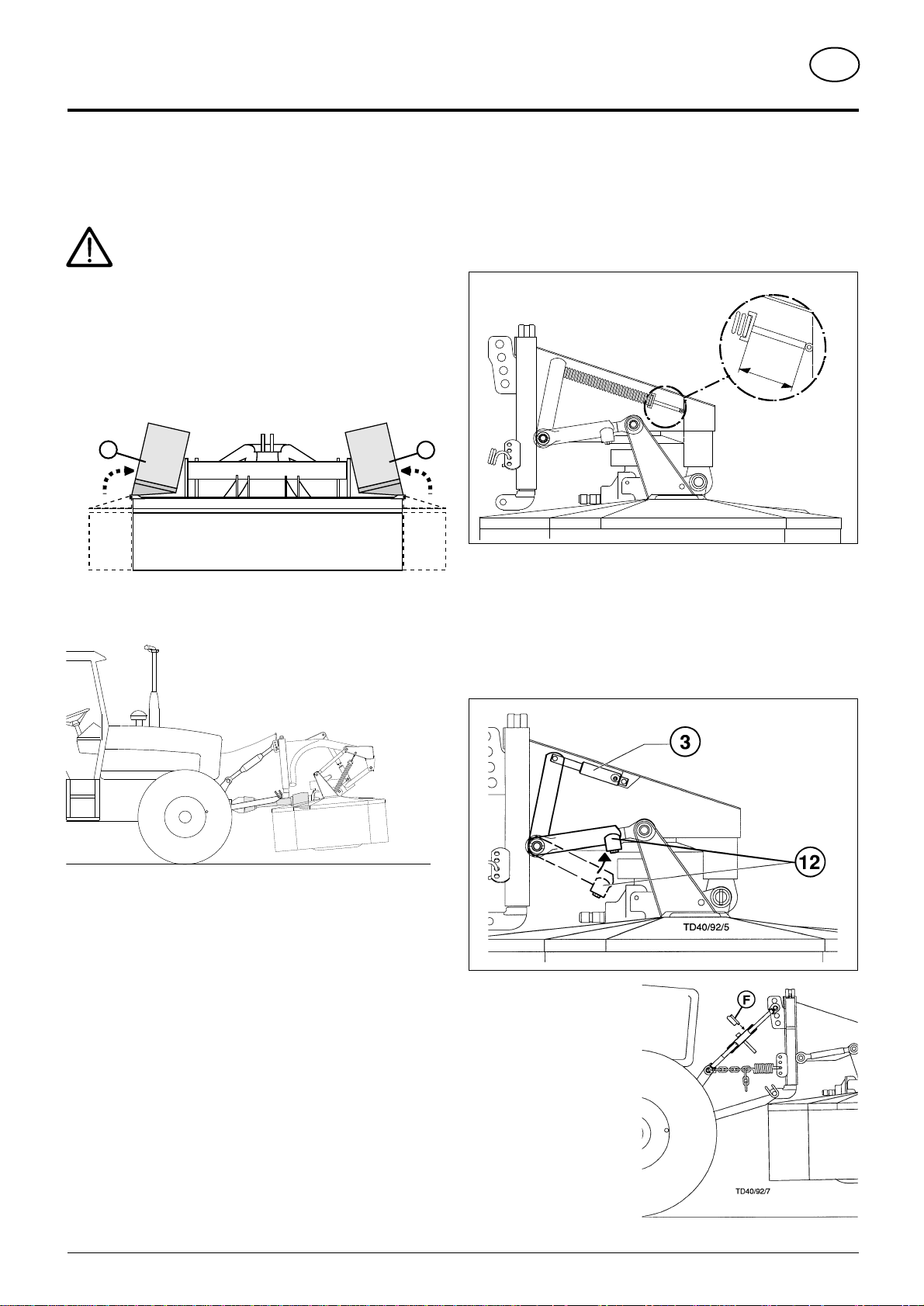

Mowing............................................................................................................................................. 9

Hints ................................................................................................................................................. 9

Double cut ........................................................................................................................................ 9

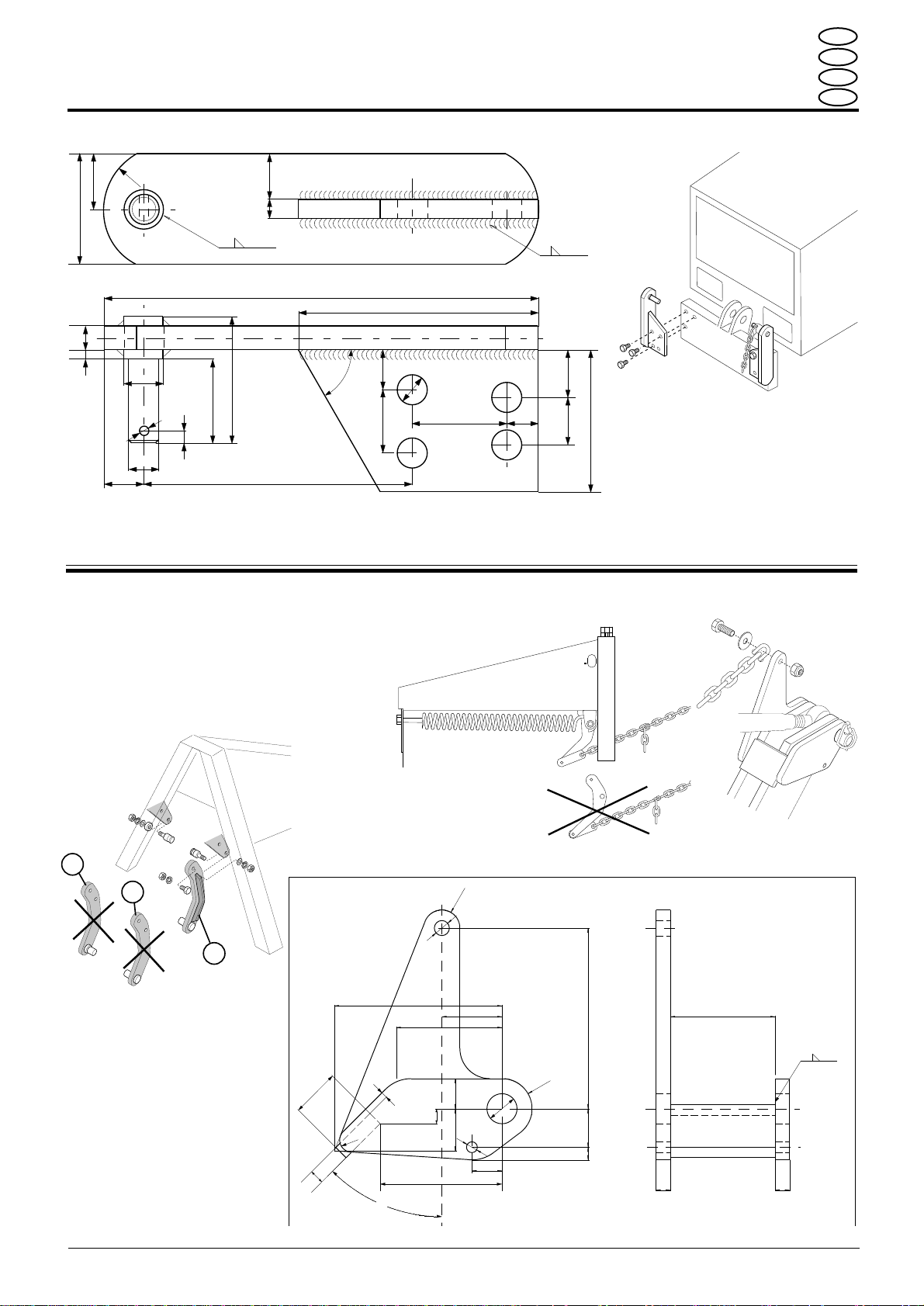

Swath makers (CAT 270 plus front Masch.Nr.: .. . - 03690) ....................................................... 12

Swath makers (CAT 310 plus front Masch.Nr.: .. . - 01390) ....................................................... 12

Swath makers (CAT 270 plus front Masch.Nr.: .. . + 03691) ...................................................... 13

Swath makers (CAT 310 plus front Masch.Nr.: .. . + 01391) ...................................................... 13

Maintenance................................................................................................................................... 15

Safety points .................................................................................................................................. 15

Pay attention to correct assembly! ................................................................................................. 15

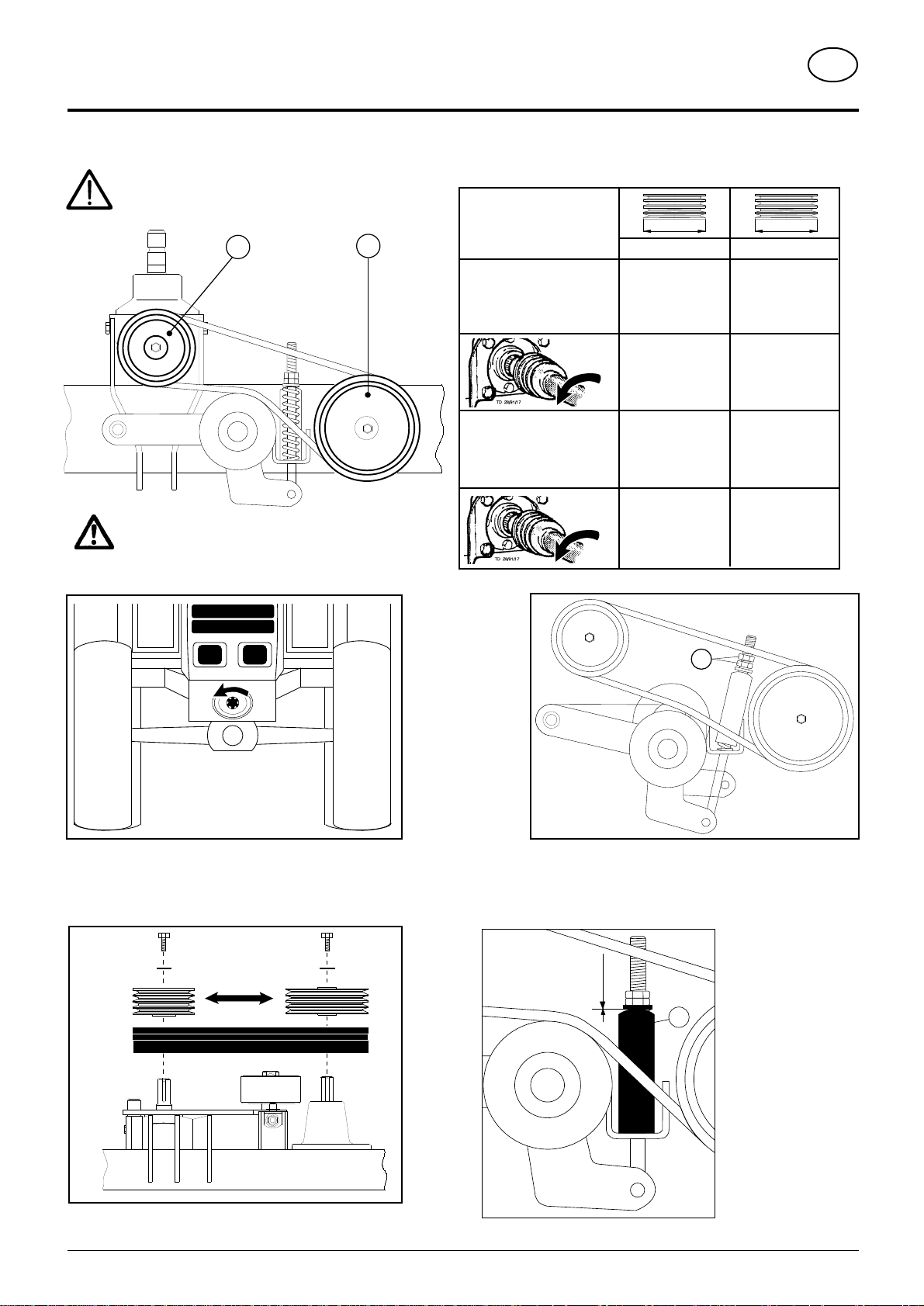

Changing the cutters ...................................................................................................................... 15

Checking the mowing blade suspension ........................................................................................ 15

Mower disc ..................................................................................................................................... 15

Winter storage................................................................................................................................ 15

Lubrication chart ............................................................................................................................ 15

Shorten upper link............................................................................................................................ 1