54

Installation on Mitron or flue-pipe in fibro-cement (see pic. 3)

• Work as described above and make sure that the unit is correctly xed.

Installation on a Poujoulat stainless steel chimney pipe (see pic. 4)

• Use the steel plate PAM described in «Aspirotor accessories» on page 25.

Pic. 3

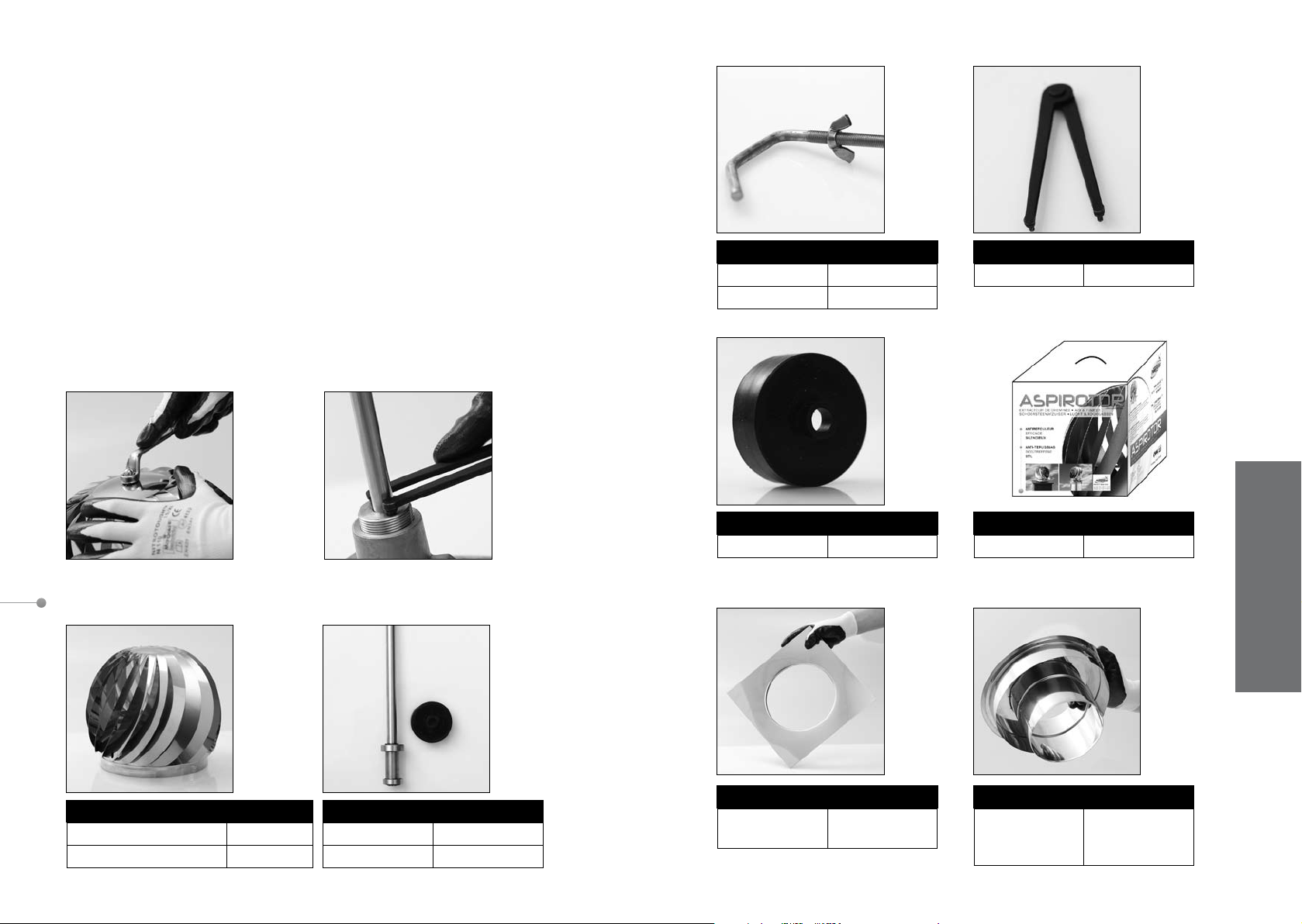

Pic. 5

Pic. 4

Pic. 6

4. APPLICATIONS

ADVICE

It is advisable to t an Aspirotor on any chimney situated in a high pressure area to prevent down draught.

It is especially advised in the following cases:

• Placing a chimney through the roof

• If the chimney is too small (- 2.5m for gas and – 4m for any other fuels)

• In cases where the building next to the chimney is higher than the chimney itself

• Etc...

A chimney that is not functioning well can be identied by:

• Downdraught

• Stoves: Window is turning black

• Boilers: Lots of tar in the burner

• Natural draught: Back draught of cold air into the building

FUELS

Due to the materials used, the Aspirotor is completely weather resistant. Technically speaking, the unit can be

used for any fuels.

Note: For the usage of different fuels, please verify local laws and regulations for any restrictions.

5. MAINTENANCE

Note: Always wear gloves during maintenance.

Good maintenance will certainly increase the lifespan of the Aspirotor unit. The unit should be maintained

once a year or twice a year if wood is used.

Maintenance: Chimney access and cleaning the appliance (see pic. 5 and 6)

1. Loosen the bolt on the supporting frame to be able to turn the unit one side. This will give you access

to the chimney.

2. Once the chimney is cleaned, the appliance can be cleaned depending on the amount of dirt or tar.

3. Cleaning the blades

Be careful cleaning the blades as you can cut yourself. (Always wear gloves to prevent accident).

Don’t use any aggressive cleaning products.

4. Cleaning the axis and the bearings

Make sure the axis can still spin freely on the bearings.

If necessary, replace the rubber cap.

5. Close the appliance and tighten up the bolt.

LIMITATIONS FOR USE

The Aspirotor shouldn’t be used in the following cases:

• If National laws or regulations prohibit the usage

• For boilers of type «C».

• If exhaust temperature is more than 250°C.

• If wind speed is more than 150km/h.

ENGLISh