SAFETY RULES (PRUNER ATTACHMENT)

WARNING: Always disconnect spark

plug wire and place wire where it cannot contact

spark plug to prevent accidental starting when

setting up, transporting, adjusting or making re-

pairs except carburetor adjustments.

Because a pruner is a high-speed wood-cutting

tool, special safety precautions must be ob-

served to reduce the risk of accidents. Careless

or improper use of this tool can cause serious or

even fatal injury.

PLAN AHEAD

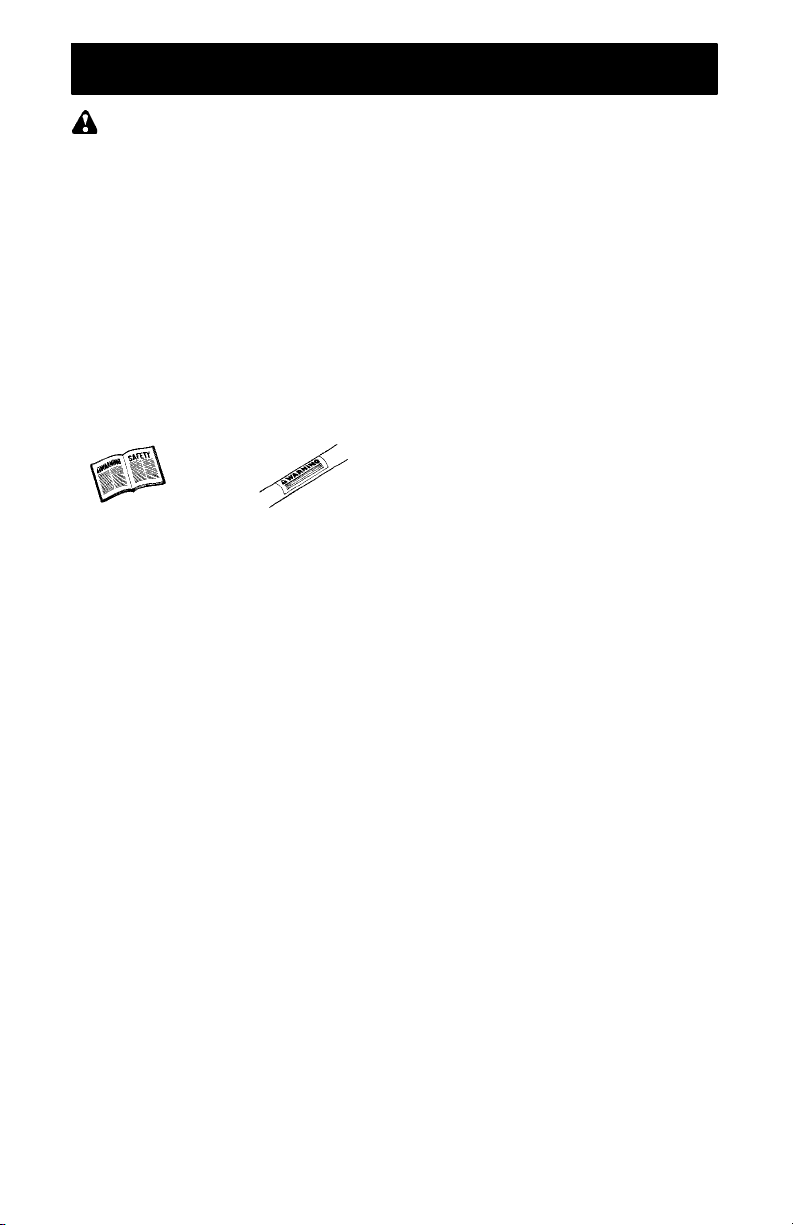

SRead this manual carefully until you

completely understand and can follow all

safety rules, precautions, and operating

instructions before attempting to use the unit.

SRestrict the use of your pruner to adult users

who understand and can follow safety rules,

precautions, and operating instructions found

on the unit and in this manual.

SAFETY INFORMATION

ON THE UNIT

INSTRUCTION

MANUAL

PRUNER SAFETY

SKeep all parts of your body away from the

chain when the engine is running.

SDo not handle or operate a pruner when you

are fatigued, ill, or upset, or if you have taken

alcohol, drugs, or medication. You must be in

good physical condition and mentally alert. If

you have any condition that might be

aggravated by strenuous work, check with

doctor before operating a pruner.

SOperate pruner only in a well-ventilated

outdoor area.

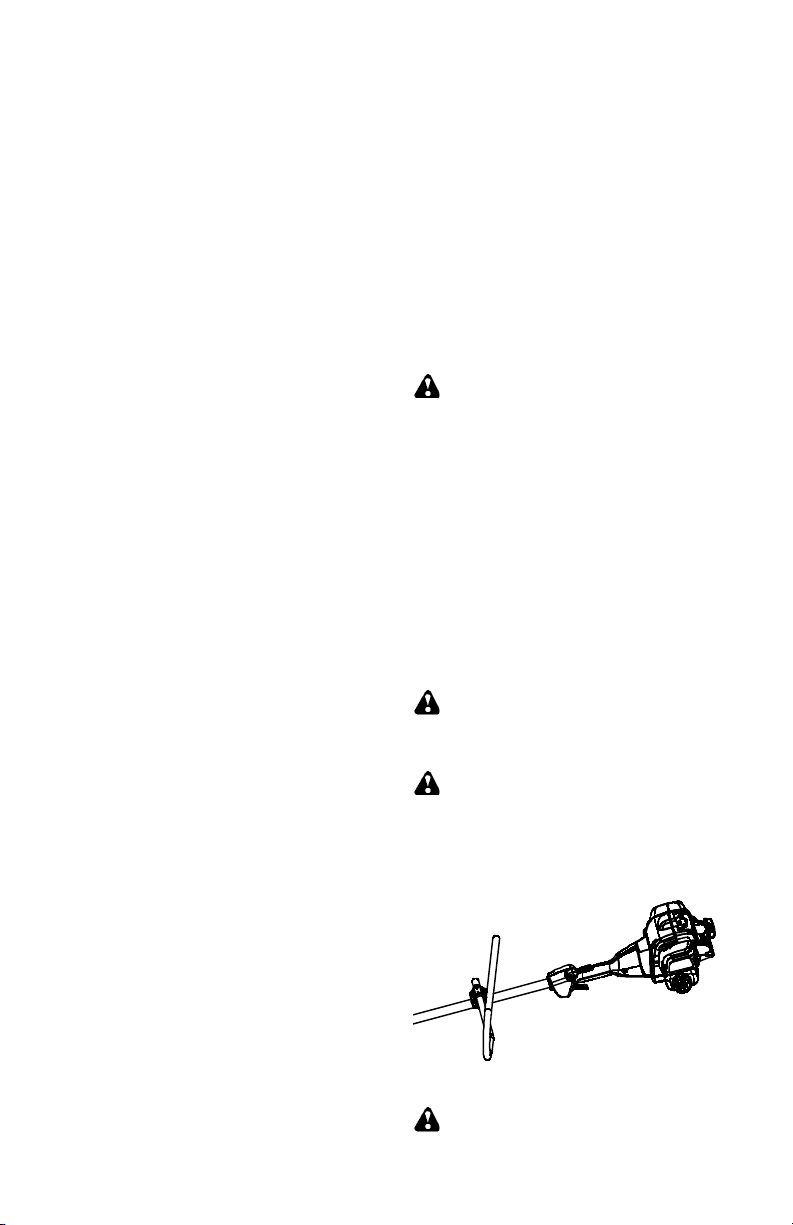

SDo not use a pruner to cut down trees or any

portion of the tree trunk.

SOnly use for pruning limbs or branches

overhead not greater than 6 inches (15 cm)

in diameter.

SDo not cut small brush and saplings with the

pruner. Slender matter may catch in the

chain and be whipped toward you, pulling

you off balance.

SMake sure the chain will not make contact

with any object while starting the engine.

Never try to start the unit when the guide

bar is in a cut.

SDo not put pressure on the pruner at the end

of the cut. Applying pressure can cause you

to lose control when the cut is completed.

SDo not run the unit at high speed when not

pruning.

SIf you strike or become entangled with a

foreign object, stop the engine immediately

and check for damage. Have any damage

repaired by an authorized service dealer

before attempting further operations.

SDo not operate a pruner that is damaged,

improperly adjusted, or not completely and

securely assembled. Always replace bar

and chain immediately if it becomes

damaged, broken or is otherwise removed.

SAlways stop the unit when work is delayed

or when walking from onecutting location to

another. Stop the engine before setting the

unit down.

SUse only in daylight or good artificial light.

SUse only for jobs explained in this manual

(or manuals for optional attachments).

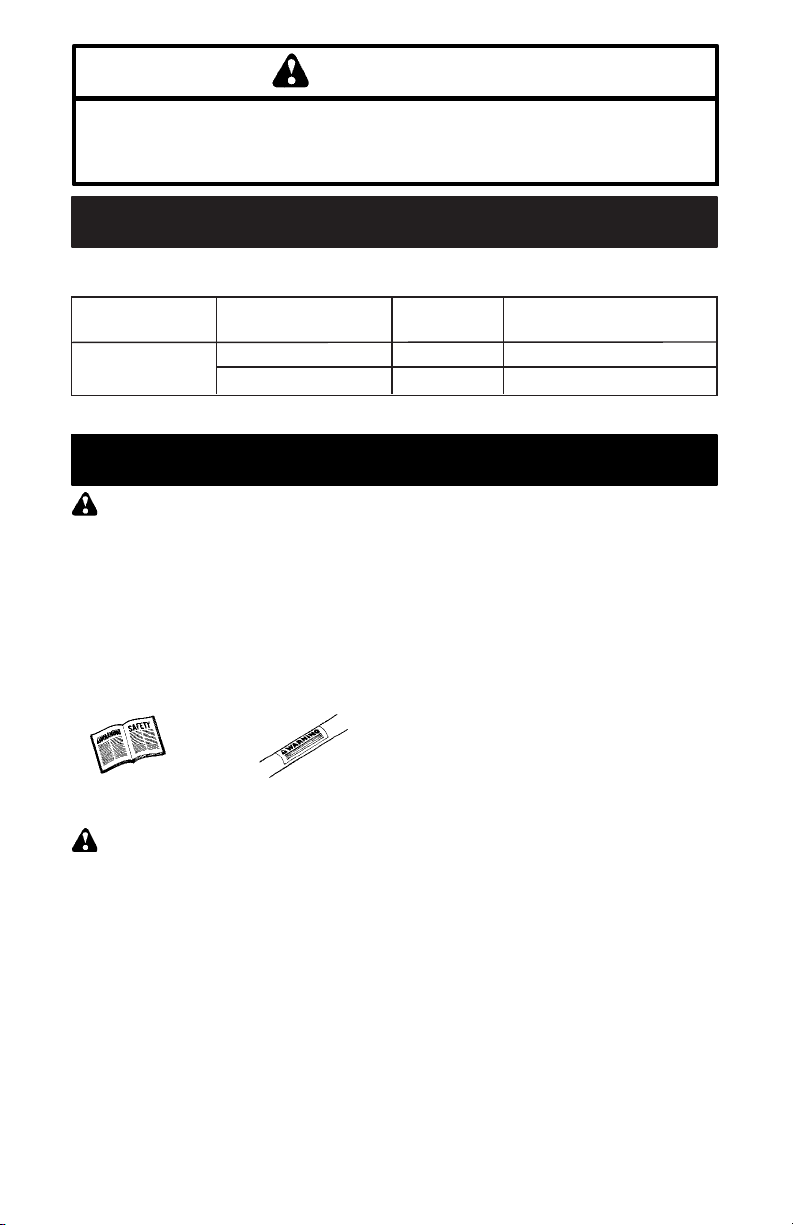

SInspect area before starting unit. Remove

all debris and hard objects such as rocks,

glass, wire, etc., that can ricochet, be

thrown, or otherwise cause injury or dam-

age during operation.

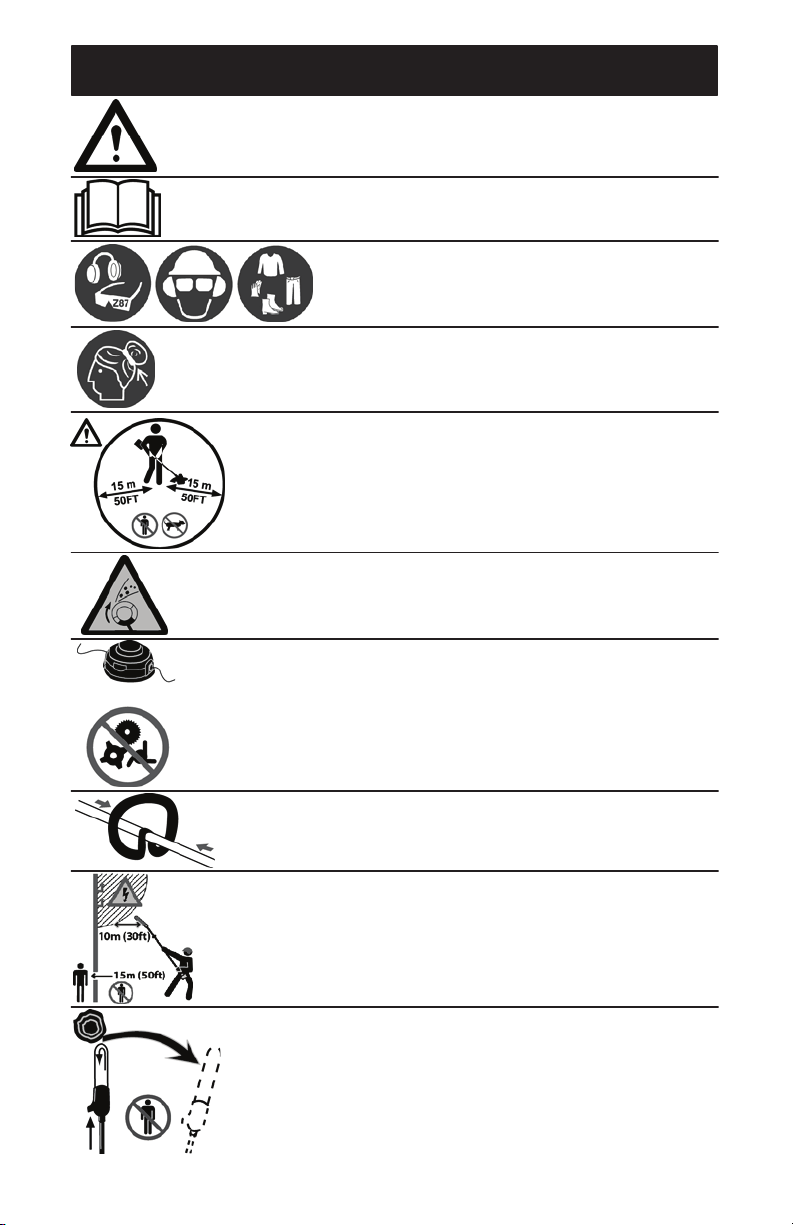

SKeep children, bystanders, and animals 50

feet (15 meters) away. Bystanders should be

encouraged to wear safety glasses. Stop

unit immediately if approached.

SAlways wear hearing protection.

SDress properly. Always wear safety

glasses or similar eye protection when

operating, or performing maintenance, on

your unit (safety glasses are available).

Eye protection should be marked Z87.

SAlways wear face or dust mask if operation

is dusty.

SAlways wear heavy, long pants, long

sleeves, boots, and gloves. Wearing safety

leg guards is recommended.

SAlways wear foot protection. Do not go

barefoot or wear sandals.

SSecure hair above shoulder length. Secure

or remove loose clothing or clothing with

loosely hanging ties, straps, tassels, etc.

They can be caught in moving parts.

SBeing fully covered also helps protect you

from debris and pieces of toxic plants

thrown by the tool.

SAlways keep engine on the right hand side

of your body.

SHold the unit firmly with both hands.

SKeep all parts of your body away from muffler

and attachment. Keep engine below waist

level. A hot muffler can cause serious burns.

SKeep firm footing and balance. Do not

overreach or use from unstable surfaces

such as ladders, trees, steep slopes,

rooftops, etc.

MAINTAIN YOUR UNIT IN GOOD

WORKING ORDER

SDisconnect the spark plug before

performing maintenance except idle speed

adjustments.

SLook for and replace damaged or loose

parts before each use. Look for and repair

fuel leaks before use. Keep in goodworking

condition.

SMake certain the chain stops moving when

the throttle trigger is released. For correction,

refer to IDLE SPEED ADJUSTMENT.

SReplace parts that are chipped, cracked,

broken, or damaged in any other way

before using the unit.

SNever modify your unit in any way.

SKeep the handles dry, clean, and free of oil

or fuel mixture.