Powered by Safety®i

01.4IB.48040C

Ch 1 General Information ..................................................................................................1

A. Scope ...............................................................................................................................................................2

B. purpoSe ............................................................................................................................................................2

c. ApprovAlS And certificAtionS ..............................................................................................................................2

1) Safety Information .................................................................................................................................................................. 2

2) FCC Statement ......................................................................................................................................................................... 2

3) EMC Directive ........................................................................................................................................................................... 2

d. inStruction BulletinS AvAilABle electronicAlly ....................................................................................................3

Ch 2 Safety .......................................................................................................................4

A. SAfe Work condition .........................................................................................................................................4

B. SAfety GuidelineS ...............................................................................................................................................4

c. GenerAl ............................................................................................................................................................5

d. Specific .............................................................................................................................................................5

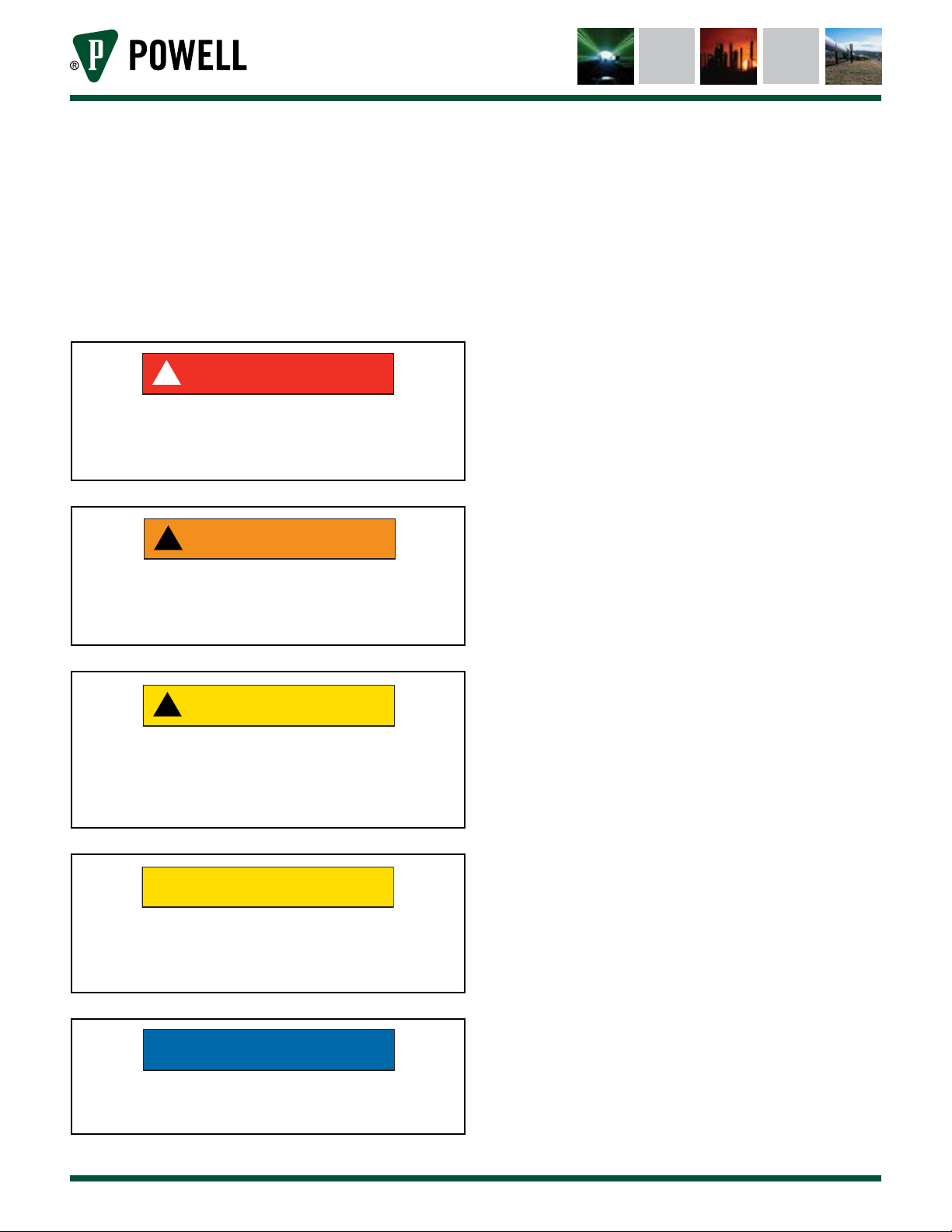

e. SAfety lABelS ....................................................................................................................................................5

Ch 3 Equipment Description ............................................................................................6

A. GenerAl ............................................................................................................................................................6

B. SenSing SyStem Overview ......................................................................................................................6

c. SpecificAtionS ....................................................................................................................................................8

d. HArdWAre deScription .................................................................................................................................... 10

Ch 4 Installation .............................................................................................................13

A. Select AlocAtion of intereSt ........................................................................................................................... 13

B. Secure proBe to loi ....................................................................................................................................... 14

c. route fiBer-optic proBe ................................................................................................................................. 16

d. Mount G3 converSion Module ....................................................................................................................... 18

1) Mount DIN Rail .......................................................................................................................................................................18

2) Attaching G3 Conversion Module to the DIN Rail .........................................................................................................19

e. connect netWork And poWer WirinG ............................................................................................................... 21

1) Power Requirements .............................................................................................................................................................21

2) Remove Terminal Connector ..............................................................................................................................................21

3) Connect DC Power Wiring ...................................................................................................................................................21

4) Connect Communication Wiring (Two Wire RS-485 MODBUS) .................................................................................22

5) Grounding ...............................................................................................................................................................................22

6) Connect Communication Wiring (MODBUS TCP/IP and ETHERNET I/P) ..................................................................23

7) Relay Output ...........................................................................................................................................................................23

8) Network Topologies ..............................................................................................................................................................23

9) Fiber Connection / Termination at G3 Conversion Module .........................................................................................24