Page 1of 4

Content

These general service notes

and the Step Test Procedures

address the most common

questions about Kwikee

electric steps. Due to the

number of variable conditions,

you may experience

symptoms other than those

covered.

*IMGL controls are on 2006 or

newer model year steps. The

service procedures outlined in

this document are for IMGL

controls only.

12 volt automotive batteries

contain sulfuric acid which

can cause severe burns. Avoid

contact with the skin, eyes,

and clothing. 12 volt

automotive batteries produce

hydrogen gas which is

explosive; keep cigarettes,

open flames, and sparks away

from the battery at all times.

NOTE

© Co

ri

ht PowerGear Issued Ma

, 2011 #82-ST0500, Rev. 0C 7/20/12

KWIKEE STEP TESTING PROCEDURES for CONTROL #

909510000, 1510000140, 1510000158 or any IMGL

(Integrated Motor/Gearbox/Linkage)* STEP CONTROL

If the power wire to the step is disconnected from its source and reconnected, a spark is common. This is

caused by the momentary charging of the control unit and does not necessarily indicate the system is

staying on, which would cause a drain on the battery.

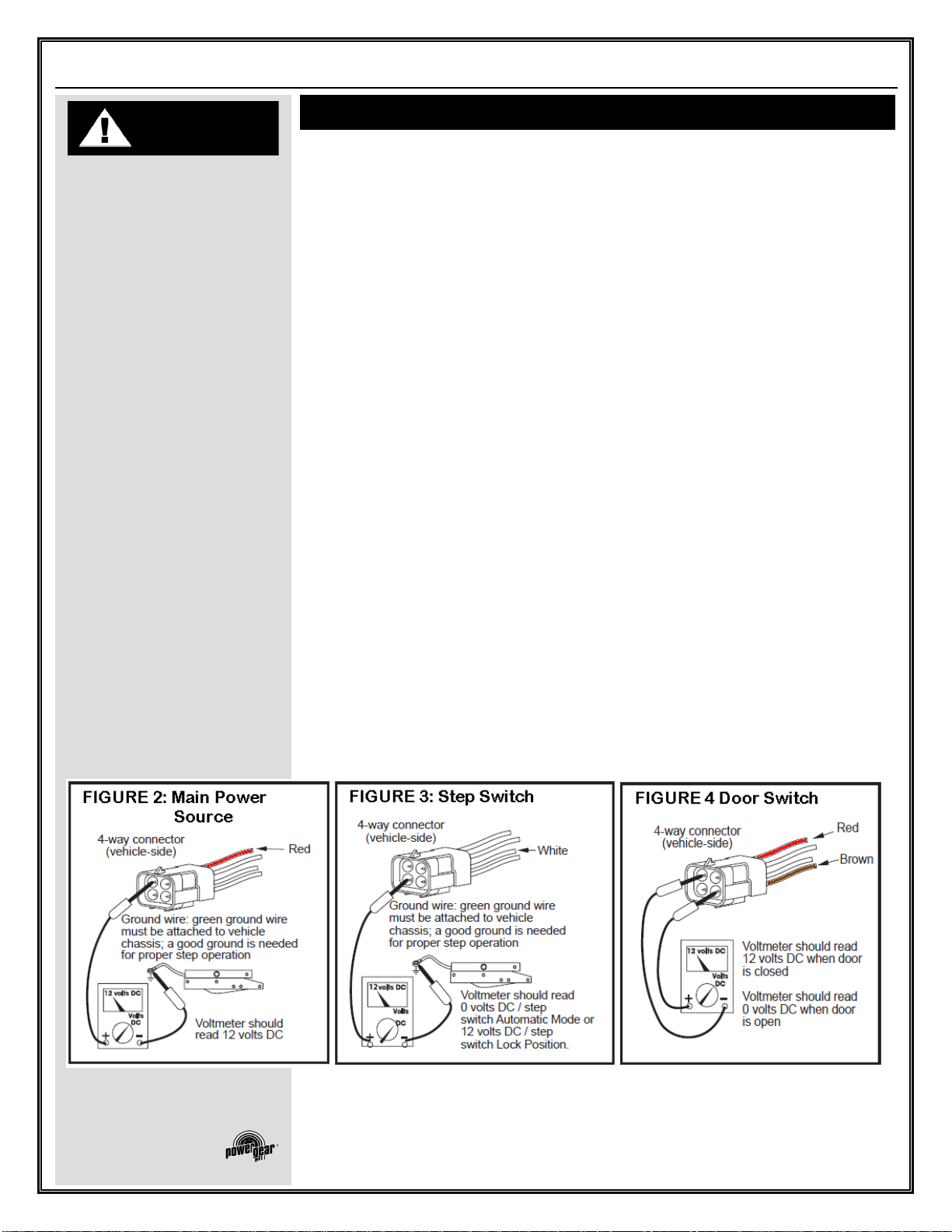

To determine if a control unit is not shutting off, remove the four-way connector to the chassis and the

two-way connector between the step motor and the control unit. Place a voltmeter between the red and

yellow motor wires at the two-way connector from the control unit. Reconnect the four-way Connector.

Refer to OEM Owner’s Manual (or OEM Requirements) and place the step switch in the appropriate

position for the step to remain in the extended position. If any voltage registers on the meter for more

than 5 seconds, the control unit is not shutting off and may be defective. When doing this test, switch the

voltmeter leads back and forth between the red and yellow motor wires to be sure no voltage registers.

If any voltage registers for more than 5 seconds, disconnect the four-way connector to keep the step

motor from overheating. If zero voltage is present, the control unit has shut off and is normal.

If the step does not work or operates erratically (for example, extends part way and shuts off) the first

item to check is the vehicle battery. Low supply voltage may cause erratic operation of the step. Poor

ground connections may also cause erratic operation of the step. Check battery voltage and condition. A

battery in good condition and properly charged will have a no load voltage of approximately 12.6 volts.

Check the voltage at the battery and at the four-way connector at the control unit. Insure that all battery

and step control unit connections are clean and secure. Recharge or replace the battery as necessary

and retest the step for proper operation.

The step may also operate erratically if it is operating directly from a converter and the converter output

is not adequate or properly filtered for clean DC voltage. The converter must be capable of producing a

minimum of 30 amps for proper step operation.

The step will not function if the ground to the control unit lost between the step control unit and the

vehicle chassis (the long green ground wire) or between the vehicle battery and the ground (negative

battery cable). Make sure the battery terminals and all wire connections are clean and tight. Verify that all

wires meet the minimum requirements specified in FIGURE 1 on PAGE 2.

General Service Note

KWIKEE STEP TESTING

PROCEDURES

1217 E. 7

St.

Mishawaka, IN 46544

www.powergearus.com

Troubleshooting and Test Procedure

The step test procedures outlined in this tip sheet are provided to troubleshoot and test all Kwikee IMGL

automatic electric step functions. The procedures are designed to initially check the basic functions of the

step separately from the RV wiring to determine whether or not the step is malfunctioning. The

procedures test various components of the step until the source of the malfunction is located. Using the

procedures will shorten and reduce the time spent troubleshooting.

Some portions of the test procedures require additional equipment. This equipment includes:

A voltmeter

A well charged 12V DC automotive battery

4-way connector/pigtail (Part #909306000, available from Kwikee)

** Read the entire procedure prior to testing **

TESTING THE STEP:

1. Inspect the step for visible damage that might restrict step operation.

2. Obtain a 4-way pigtail connector (part #909306000) from Kwikee.

3. Disconnect 4-way connector on underside of step and connect the step-half of the connector to the

four-way connector pigtail. See FIGURE 1 on PAGE 2.

4. Set a fully charged 12V DC automotive battery beside the step.

NOTE: Do not allow the battery terminals to come in contact with the step.

Complete a ground for the step tests by connecting a 10 gauge wire from the negative (-) battery

post to the green ground wire of the control unit.

WARNING

IMGL Control

Pre IMGL Control