Page 3of 7

3010002679 Rev 0C Owner’s Manual In Wall Slide Out System

•Always make sure that the

slideout room path is clear

of people and objects

before and during

operation of the slideout

room.

•Always keep away from

the slide rails when the

room is being operated.

The gear assembly may

pinch or catch on loose

clothing causing personal

injury.

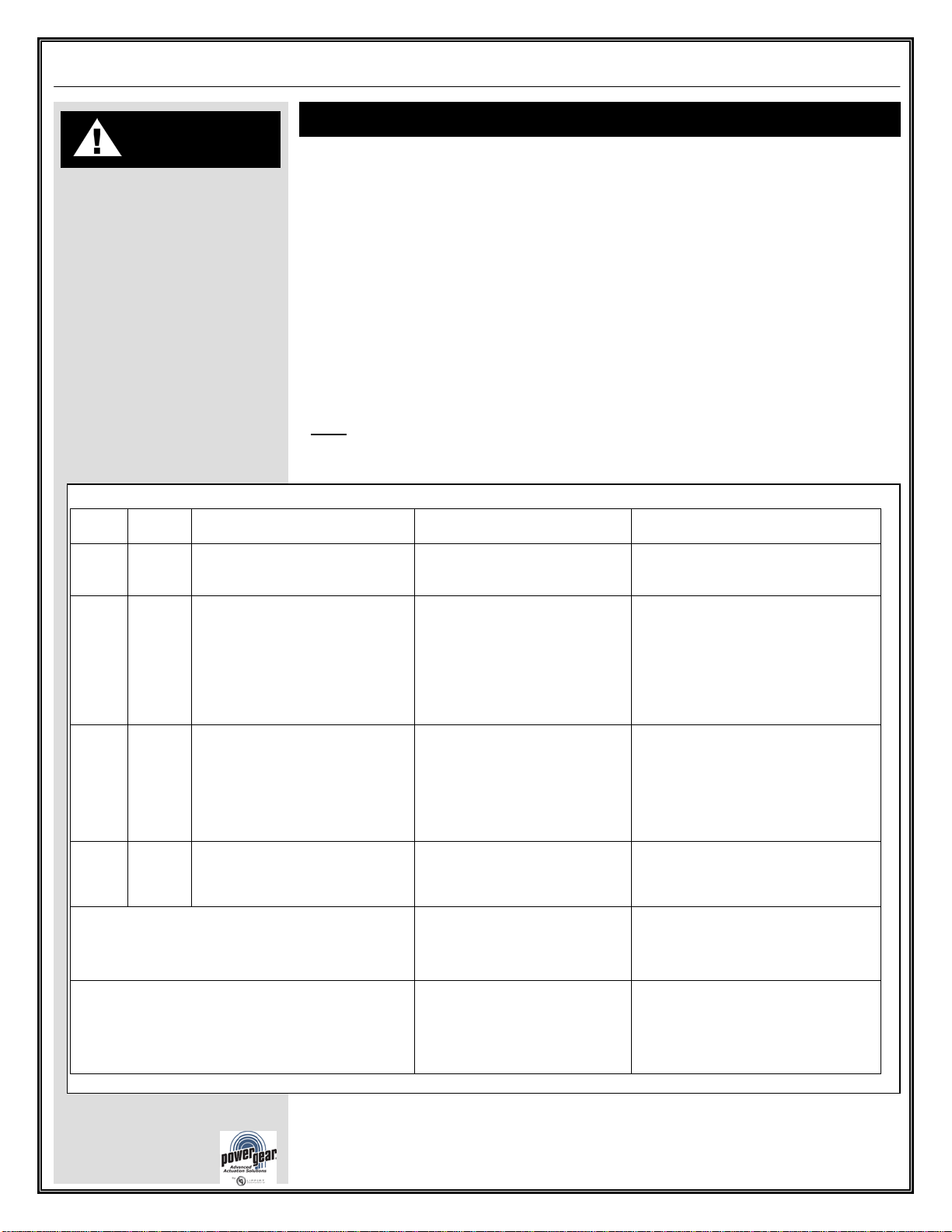

Fault Diagnostics/Troubleshooting

This control has the ability to detect and display several faults. When a fault is detected, the

room movement will stop and two (2) different LED’s will flash in a pattern.

•The FAULT CODE LED (FIGURE 4, page 2) will flash RED a number of times

corresponding to a specific fault code. Refer to the FAULT CODES chart on to best

determine what caused the fault.

•The ROOM MOVEMENT LED (FIGURE 4, page 2) will flash GREEN a number of

times corresponding to which motor had the associated fault.

For example: if you are seeing four (4) REDflashes and two (2) GREEN

flashes, it means that there is a motor fault on motor 2.

There are two (2) types of faults, MINOR and MAJOR, and fault must be cleared in order for

the room to operate.

•MINOR faults can be cleared by pushing and releasing the IN or OUT buttons on

the wall touchpad (FIGURE 4, page 2).

•MAJOR faults must be cleared by pushing and releasing the SET STOPS/CLEAR

FAULTS button located the back of the wall touchpad (FIGURE 2, page 2).

Note: For major faults, the control must be overridden by following the EMERGENCY

RETRACT MODE in the OVERRIDE MODES (page 4). The control will then have to be re-

programmed by an O.E.M. authorized dealer when the problem is repaired.

Description Possible Cause Possible Solutions

1 Major Stops not programmed

•Stops were cleared

•Stops were improperly set

Stops need to be programmed by an

authorized service facility.

2 Minor System Fault •Obstruction present

•Excessive system drag

Run room in opposite direction. If

room continues to move in the

opposite direction, remove

obstruction, excessive weight in room

or repair of damaged component. If

room stops moving in opposite

direction, observe fault code and

4 Major Motor Fault •Bad or loose connection

•Defective harness

•Open or shorted motor

•Check all connections at control

box and motor.

•Check the harness for broken

wires.

•Put 12.0 VDC direct to the

motor. If it does not run replace

6 Minor Excessive Battery Voltage Supply voltage to control box is

17.0 V DC or greater.

Check 2-pin power connector at

control box. If the voltage is 17.0

VDC or higher, contact O.E.M. for

power and ground supplies.

Park brake LED flashing

•Parking brake not set (if

applicable)

•Ground signal lost at park

brake connector on control box

•Set parking brake (if applicable)

•Check for continuity to ground

on wire plugged into park brake

connector at control box.

Low voltage LED flashing Incoming voltage to control box

is below 12.0 VDC

Check 2-pin power connector at

control box. If the voltage is below

12.0 VDC, contact O.E.M. for power

and ground supplies.

Mishawaka, IN 46544

www.powergearus.com