Pulled to the left and rearward from its neutral

position,

it

determines

the reverse speed.

Tractor

speed in

either

direction

may be

increased

or

decreased at any time

with

or

without

the use of the

motion

control

pedal.

8. TRANSAXLE

SHIFT

LEVER

Use

this

lever to

select the transaxle speed range you wish to use.

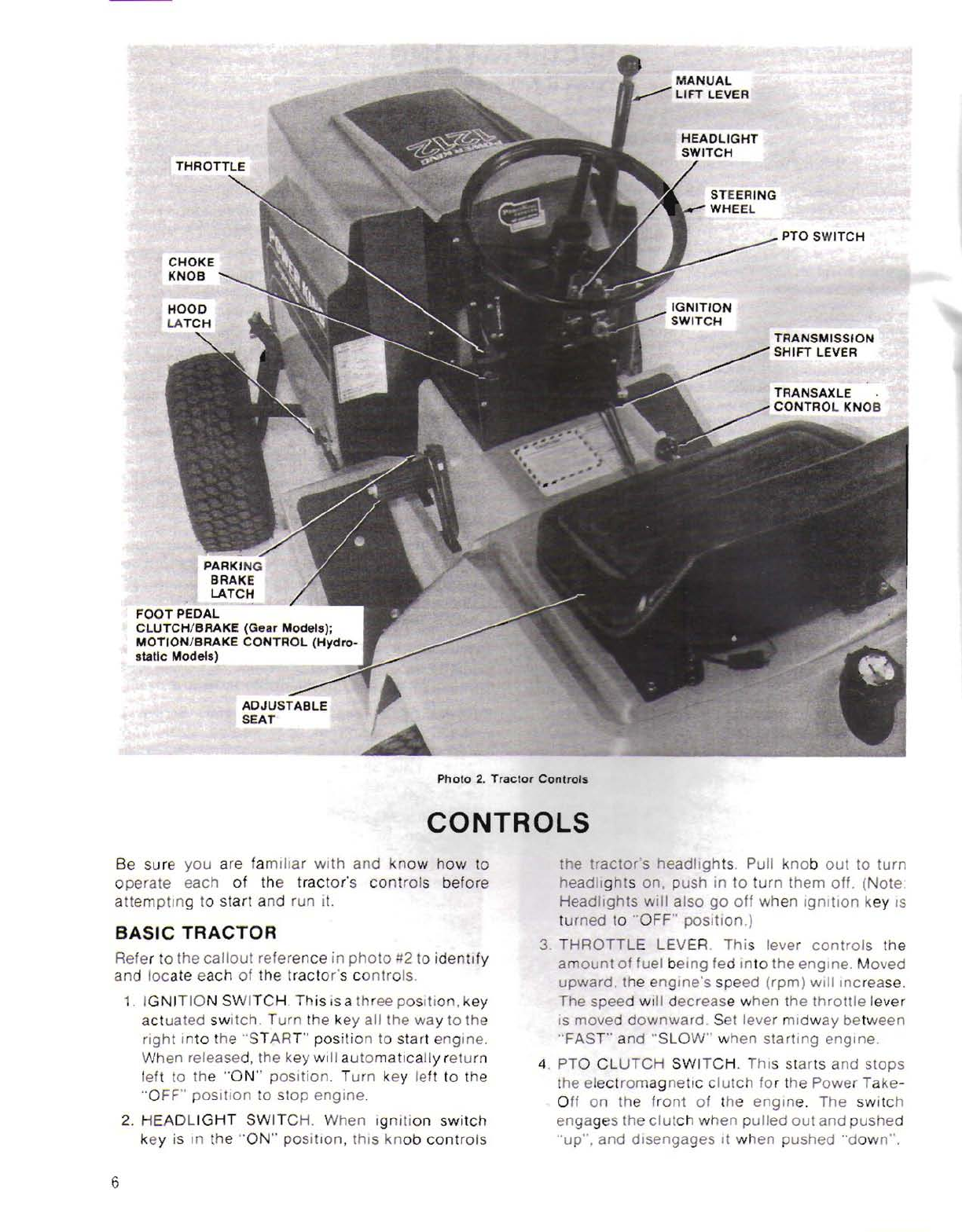

5.

CHOKE

KNOB.

By cable extension this

knob

can

rols

he

uel-air

mixture

in the engine's

carbure:or.

The

knob

should

be pulled

out

when

--a1

the

engine

and then pushed in

shortly

a::er

engine

begins

to run.

-. STEERING WHEEL.

Controls

the

front

wheels

of

the

tractor

for

steering.

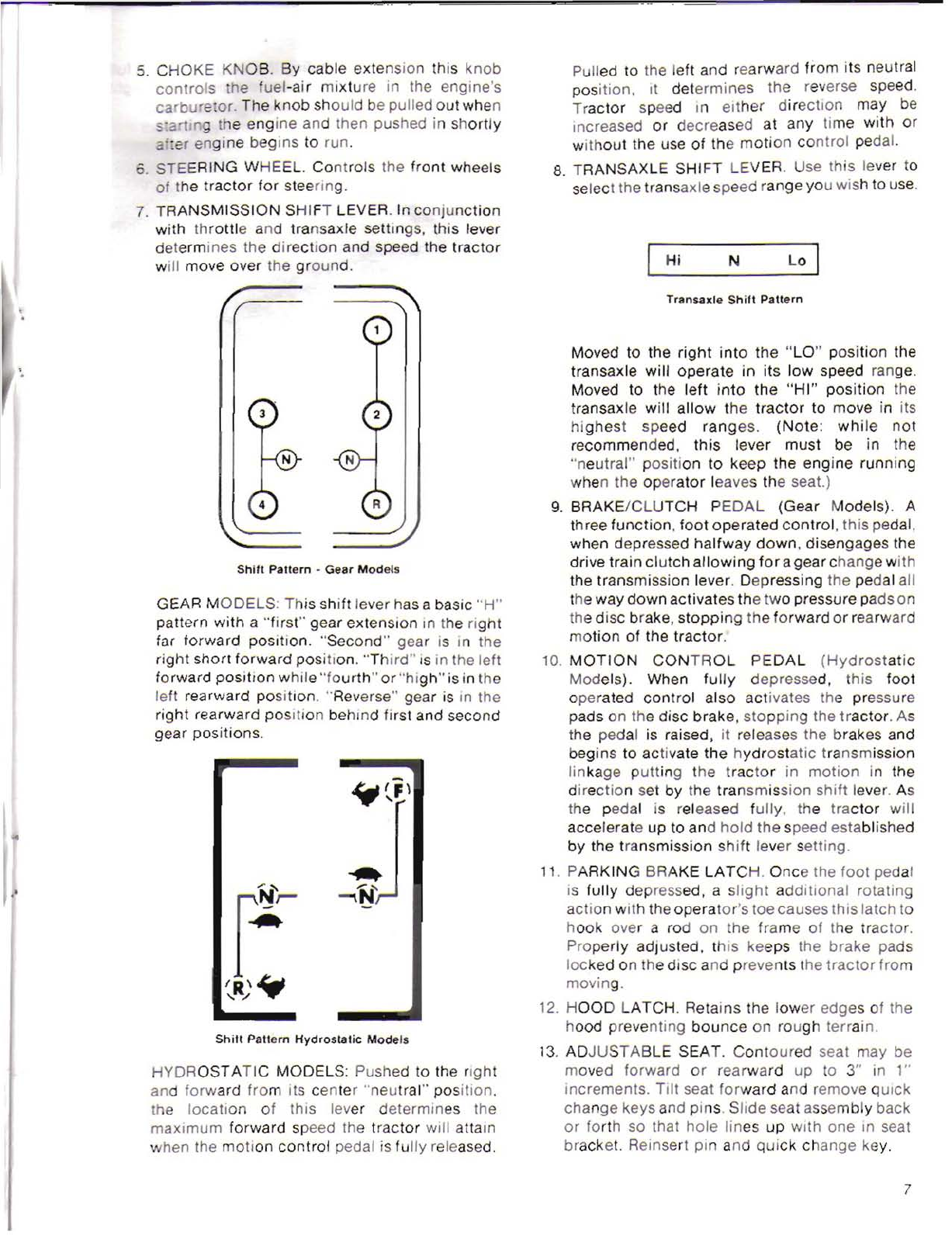

7.

TRANSMISSION

SHIFT LEVER. In

conjunction

with

throttle

and transax/e settings, this lever

determines

the

direction

and speed the

tractor

will move

over

the

ground.

Hi

N

Lo

Shift

Pattern

-

Gear

Models

Transaxle

Shift

Pattern

Moved to the

right

into

the

"LO"

position

the

transaxle will

operate

in

its

low

speed range.

Moved to the

left

into

the

"HI"

position

the

transaxle will

allow

the

tractor

to

move

in its

highest

speed

ranges.

(Note:

while

not

recommended,

this

lever must be in the

"neutral"

position

to

keep

the

engine

running

when the

operator

leaves the seat.)

9.

BRAKE/CLUTCH

PEDAL

(Gear Models). A

th

ree

function,

foot

operated

control,

this

pedal,

when depressed

halfway

down,

disengages the

drive train

clutch

allowing

for

a

gear

change

with

the transmission lever. Depressing

the

pedal all

the

way

down

activates

the

two

pressure padson

the

disc

brake,

stopping

the

forward

or

rearward

motion

of

the tractor.

10.

MOTION

CONTROL

PEDAL

(Hydrostatic

Models). When fUlly depressed,

this

foot

operated

control

also activates the pressure

pads on the disc brake,

stopping

the

tractor.

As

the pedal is raised, it releases the brakes and

begins to activate

the

hydrostatic

transmission

linkage

putting

the

tractor

in

motion

in the

direction

set

by

the

transmission

shift

lever. As

the pedal is released fully, the

tractor

will

accelerate

up

to

and

hold

the

speed established

by

the

transmission

shift

lever setting.

11.

PARKING

BRAKE

LATCH.

Once

the

foot

pedal

is

fully

depressed, a

slight

additional

rotating

action

with

the

operator's

toecauses

this

latch to

hook

over arod

on

the frame

of

the tractor.

Properly adjusted.

this

keeps the

brake

pads

locked

on the

disc

and

prevents the

tractor

from

moving.

12.

HOOD

LATCH.

Retains the

lower

edges of the

hood preventing

bounce

on

rough

terrain.

13.

ADJUSTABLE

SEAT.

Contoured

seat may be

moved

forward

or

rearward

up

to

3"

in 1"

increments.

Tilt

seat

forward

and remove

quick

change

keys and pins.

Slide

seat assembly back

or

forth so that

hole

lines

up

with

one

in seat

bracket. Reinsert pin

and

quick

change

key.

N

Shift

Pallern

Hydrostatic

Models

HYDROST

ATIC

MODELS: Pushed to the right

and

forward

from

its

center

"neutral"

position.

the

location

of

this lever

determines

the

maximum

forward

speed the

tractor

will attain

hen the

motion

control

pedal is

fully

released.

GEAR

MODELS:

This

shift

lever has abasic

"H"

pattern

with

a

"first"

gear

extension

in the

right

far

forward

position.

"Second"

gear is in the

right

short

forward

position.

"Third"

is in the left

forward

position

while

"fourth"

or

"high"

is in the

left rearward

position.

"Reverse" gear is in the

right

rearward

position

behind

first and second

gear

positions.

7