Power Master PM-SBC-2012 User manual

SWITCH-MODE BATTERY CHARGER

(MICROPROCESSOR SYSTEM)

USER MANUAL

FOR ALL PATTERNS 1 AND 3 OUTPUTS

1

CONTENTS

Introduction............................................................................................................2

Technical Features.................................................................................................2

Advanced Charging Technique ............................................................................3

Safety Devices.........................................................................................................3

Options....................................................................................................................4

Safety Instruction...................................................................................................4

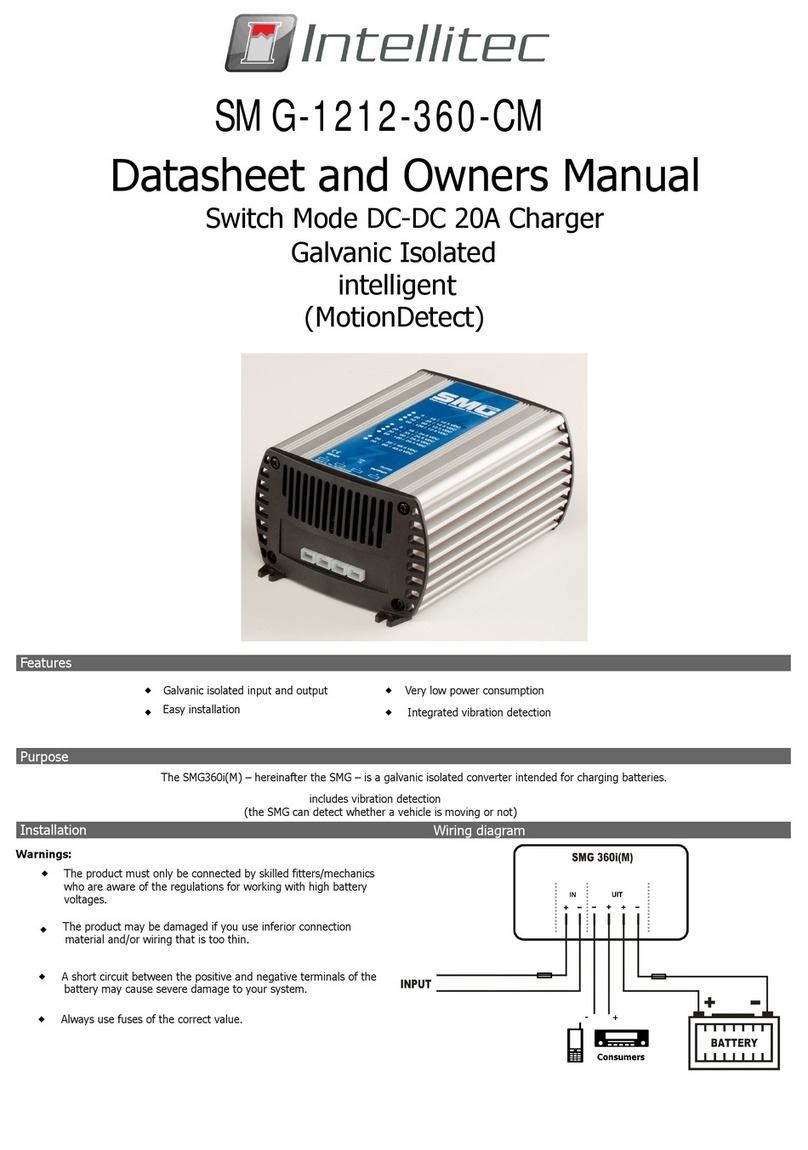

Installation..............................................................................................................5

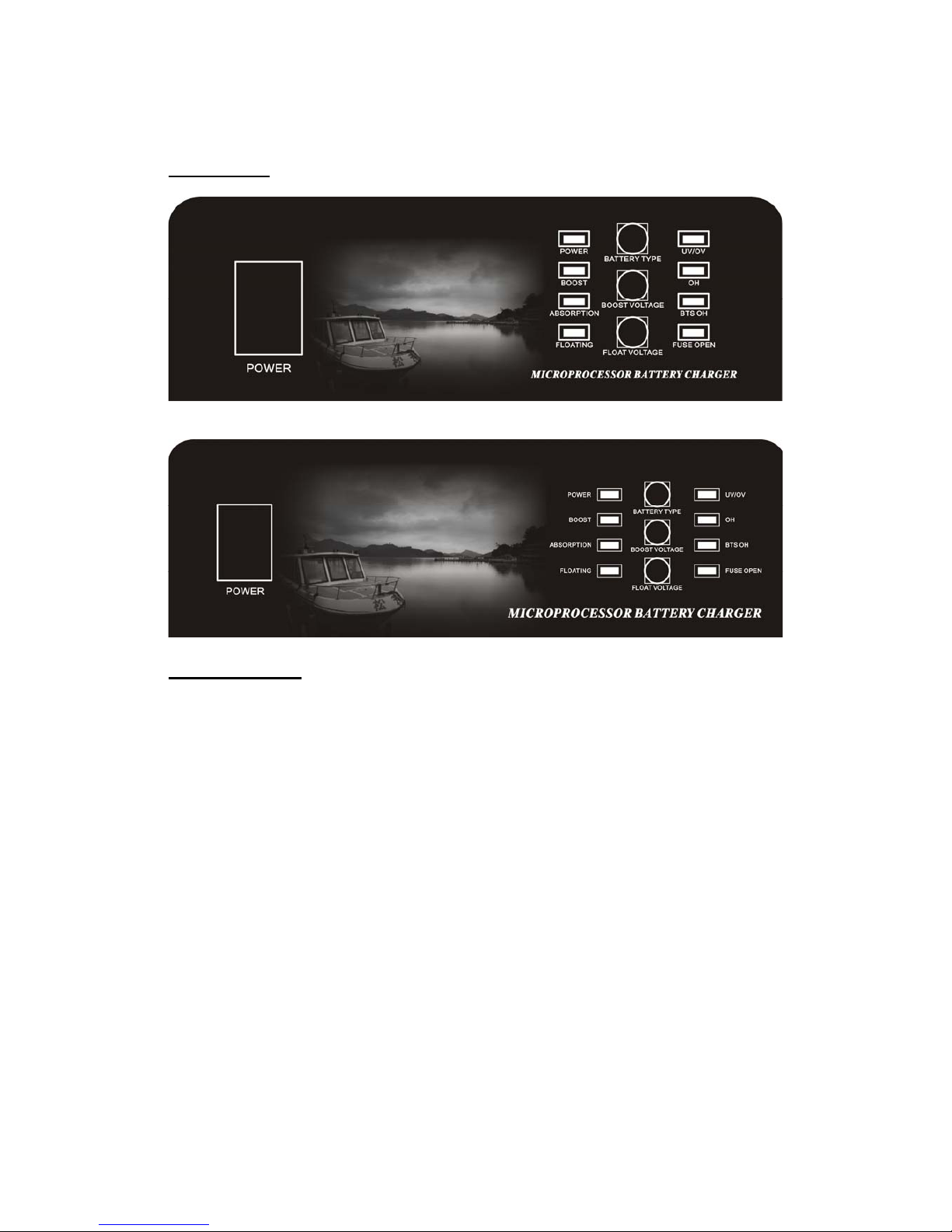

Front Panel.............................................................................................................7

LED Indicators.......................................................................................................7

Switches Section (4 Battery Types and 1 User Define) .......................................7

Instruction of Charging Curve Selection.............................................................8

DC Power Supply...................................................................................................9

BTS/Remote Control ...........................................................................................10

Trouble Shooting Guide......................................................................................10

Specification .........................................................................................................11

2

Introduction

Power Master Battery Charger is small and lightweight charger that offers charging

patterns which are perfectly adapted to each battery technology (liquid electrolyte, gel

electrolyte, lead calcium, etc... ). A charging pattern may be factory set to suit your

specific application. To prolong the life of your batteries and conserve their initial

capacity, the charger is programmed with 5 three-state charging patterns:

zBOOST Charge/FAST Charge :Restores battery capacity until 80 % in a short

space of time.

zABSORPTION Charge/BALANCE Charge : Complements of charge until 100 %

of battery capacity

zFLOATING Charge/TOP-UP Charge : Compensates for constant battery drain,

while keeping the battery fully charged.

Power Master Battery Charger is the only charger on the market to allow the battery to

be connected and used constantly, while still offering a real BOOST (high voltage)

charge over short period. The charger switches back to top-up mode automatically.

In accordance with EC standards, the Power Master Battery charger is fitted with a PFC

(Power Factor Corrector) which limit peak current draw from the input power required

from the generator or Mains supply to be reduced.

Technical Features

-Management and control by microprocessor

-Charging curve of 3 states IUU type

- UNIVERSAL input voltage 90V to 250Vac (item 12V/40A, 12V/60A, 24V/30A,

24V/50A)

- Input voltage 230V ~ +10%/-15% (item 12V/20A, 24V/15A )

- Frequency 50/60Hz

- Output voltage Ubat ±1% ; output current Ibat ±10%

- Operating temperature -10 to + 45°C; storage temperature -20 to +70°C

- Charging curve selection by rotate switch for 5 different batteries types

- Sensor used to balance charging voltage according to temperature gaps (-27mV/°C)

- Automatic air vented cooling

- Protection Index IP 235

3

Advanced Charging Technique

Charging curves of the 3-state IUU type, with a boost phase and a floating phase.

The 3-state charging characteristic, used on boats everywhere, saves on charging time. In

addition, the charger can be adapted to all types of battery thanks to its 5 integral

charging curves supervised by a micro controller. Charge cycle starts on with the mains

power-up of product.

Boost Phase

Charging continues at constant current (charger Inom) until the battery reaches the

maximum boost voltage. This voltage is maintained until the charging current falls to

Inom/8 ~Inom/10 boost charge over short period (12 hours) from the mains power-up of

product. This phase makes it possible to supply the maximum amount of energy in the

least possible time.

Floating Phase

The charger supplies just the current necessary to keep the battery at a constant and stable

voltage (floating voltage). This charging mode allows 12-volt equipment to be used

continuously (water pump, refrigeration, auto pilot, radio, lights, etc.) without the

batteries discharging.

It means that the on-board circuit can be used while keeping the battery charge level

constant. WITHOUT BATTERY AND IN SPECIAL CIRCUMSTANCES, THE

POWER MASTER CHARGER SUPPLIES STABLE VOLTAGE.

General form of the charging curve (five possible levels according to battery type)

Top-up ChargeBalance Charge

Fast Charge

CURRENT

VOLTAGE

CAPACITY Ah

BOOTS ABSORPTION FLOATING

Charging Current

The nominal current shown in case of nominal voltage is the mean current supplied by

the charger.

Safety Devices

Electronic protection against:

- Output short-circuits

- Battery discharge in the event of mains failure

4

Disjonction protection against:

- Battery overvoltage or undervoltage

- Battery or charger overtemperature

Protection by fuses against :

- Mains input overload

- Battery polarity inversion

Anti-corrosion

Casing in aluminum with anti-corrosion paint.

Anti-impact

Resistance to impacts in normal use thanks to the 2 mm-thick casing (1,5mm for the

cover).

Ventilation

If the internal charger sensor exceeds 60°C, fan starts

Options

1. Battery Temperature Sensor (BTS):

Sensor is used to balance charging voltage according to temperature gaps, compared

with reference temperature 25°C. If temperature exceeds 45°C, charging stops and

LED of BTS OH flashes. Charging restarts when temperature is less than 45°C.

Procedure of connecting BTS is:

1. Disconnect the charger from the mains (MANDATORY). To avoid short-circuit,

disconnect the batteries.

2. Extract fixing screw from wires cover and remove it

3. Connect the sensor connector to the green terminal on the card (see figure A)

4. Connect charger to the mains

5. Fix the temperature sensor(s) on corresponding battery(ies) with double-sided

adhesive tape supplied with sensor.

To disconnect sensor from the charger, charger must be disconnect from the mains

before (even if the charger indicates a default).

CAUTION: In case of fault, charger switches off automatically. Disconnect charger from

mains then wait for approximately 10 minutes before starting it again.

2. Remote Control: It can be connected to the Power Master charger. All operating

controls and displays are available on the remote control unit.

Safety Instruction

A battery can generate gas in the case of high overcharge, that can be explosive.

Attention must be paid to produce no spark or flame near a battery on charge, arrange for

a well-ventilated room.

Power Master charger limits overcharges and reduces this risk.

zExcessive discharges are among the principal causes of premature wear.

Power Master charger prevents such excessive discharge. After every discharge,

(especially higher than 50%), recharging should not be deferred for a long time.

zLow and permanent overcharge is another cause of premature wear. The Power

5

Master Charger delivers the current necessary for battery charge and adapts itself to

supply the optimum end of charge.

zThe accidental and violent overcharge or higher end of charge current produces early

destruction by excessive rise of temperature. The temperature should not exceed 50°C.

By the regulation of the current, the Power Master protects the battery from the

temperature rise at the end of charge.

It is advisable to

zPut batteries in a well ventilated area

zNot to smoke near batteries

zTake the battery manufacturer prescriptions into consideration

Accidental Leakage Current between Line And Earth

zConnections will be realized by an electrician or a professional installer.

zThe charger must be connected to a system having a two-pole differential circuit

breaker with 30 mA sensitivity.

Accidental Leakage Current Between Charge Circuit and Earth

zTo detect accidental leakage currents to earth, you must use a safety device outside

the charger.

zThe rating and nature of the protection must be ensured by the installer.

zSpecial precautions are recommended on any installation where there is a danger of

electrolytic effects.

zRegulations require the presence of a battery cut-out on the output + pole and on

the output – pole.

Precautions Regarding Lightning Strike

In geographic zones exposed to a high risk of lightning strikes, it may be recommended

fitting a lightning conductor on the inlet side of the charger. Power Master will not take

charge of damaged caused by lightning strike.

Precautions Regarding Electromagnetic Interference

zMake sure the length of the cables and screening connections are kept as short as

possible.

zSeparate the power supply cables from output cables.

zCables must only carry the charger power supply. Branch or bridging connections in

order to supply another equipment are too be banned.

Installation

The location of the Power Master charger must be chosen by the following criteria:

Protection from unauthorized handling.

Dry dust free room, no condensation, no rodents.

Keep ventilation holes free. The ventilation of the Power Master is designed in such a

way that it will work most efficiently when mounted horizontally.

Before any connection, put the switch on the right charging curve.

1. Connect the positive battery on terminal marker +BAT 1 and open the entry of the

upper case to tighten it with screws.

6

2. Connect the negative battery cable to terminal marker –BAT and open the entry of the

upper case to tighten it with screws.

3. Do the same for batteries number 2 and 3 for +BTA 2 and +BTA 3. For a 3 outputs

charger, refer to the table below to choose conductor section.

BTS3BTS2BTS1

-BAT+BAT1+BAT2+BAT3

Battery fuse board:

Model No. 12V/20A 12V/40A 12V/60A

FUSE Atofuse (car) 1 x 25A 2 x25A 2 x 30A

Model No. 24V/15A 24V/30A 24V/50A

FUSE Atofuse (car) 1 x 15A 2 x15A 2 x 30A

WARNING: Check carefully the tightness of the battery connections to the charger (risk

if not properly tightened). Power Master will not take charge of damage caused by a

bad tightness of connections.

Don’t connect a charge distributor on an Power Master charger, 1 or 3 outputs.

4. Put the AC plug in the rear panel. The charger operates on sector 90V to 250 Vac -

50/60 Hz. Use preferably cable H07rn-F with 3 conductors. Earth lead to be

connected to the terminal on the unit.

Length 5m 10m 15m Sector flex section (5m)

Current 220V 110V

Puissance

(W)

30A 6 mm210 mm216 mm21.5 mm22.5 mm2750

40A 10 mm216 mm225 mm21.5 mm21.5 mm2500

50A 16 mm225 mm235 mm21.5 mm22.5 mm21200

60A 25 mm225 mm235 mm21.5 mm22.5 mm2750

Main fuse board:

Model No. 12V/20A, 12V/40A, 12V/40A,

24V/15A, 24V/30A, 24V/50A

Temporized glass fuse 6.3x32mm 16A

7

Front Panel

15A/24V, 20A/12V

30A/24V, 40A/12V, 50A/24V, 60A/12V

LED Indicators

POWER: It is lit when the AC power has been input through the AC plug.

BOOST: It is lit as long as the battery is not fully charged at set voltage.

ABSORPTION: It is lit as long as the battery is not fully charged at set voltage.

FLOATING: It is lit when the battery is fully charged.

UV/OV:

Under Voltage---Deep battery discharge Ubat < 10V for 12V system and < 20V for 24V

system. If Ubat stays < 10V for 12V system and < 20V for 24 system

during more than 5 minutes, charger shuts down. To restart the charger:

disconnect the mains, wait few minutes and reconnect the charger on

mains.

Over Voltage--- Battery overcharge Ubat >16V for 12V system and > 32V for 24V

system. If Ubat >16V for 12V system and > 32V for 24V system

during more than 5 minutes, charger shuts down. To restart the charger:

disconnect the mains, wait few minutes and reconnect the charger on

mains.

OH: Over Heat---It is flashing when the heatsink of the charger reaches > 70℃. The

charger shuts down when the charger is > 80℃.

BTS OH: Battery Temperature Sensor Over Heat--- It is flashing when the BTS reaches

> 45℃. The charger shuts down when the battery temperature is > 50℃.

8

FUSE OPEN: Fuse is broken.

Switches Section (4 Battery Types and 1 User Define)

The great advances realized by manufacturers of batteries put at the disposal of users

batteries without maintenance, so it means a certain tranquillity for the user but impose,

however on the charger system, an exacting precision.

Every battery is designed according to particular technology and therefore calls for a

particular charging curve.

With Power Master battery charger, you can achieve this perfect match between battery

and charger using a switch, which is simply positioned according to the required,

charging curve.

Note: Do indicate the type of your battery when buying the charger, and position the

switch correctly before use.

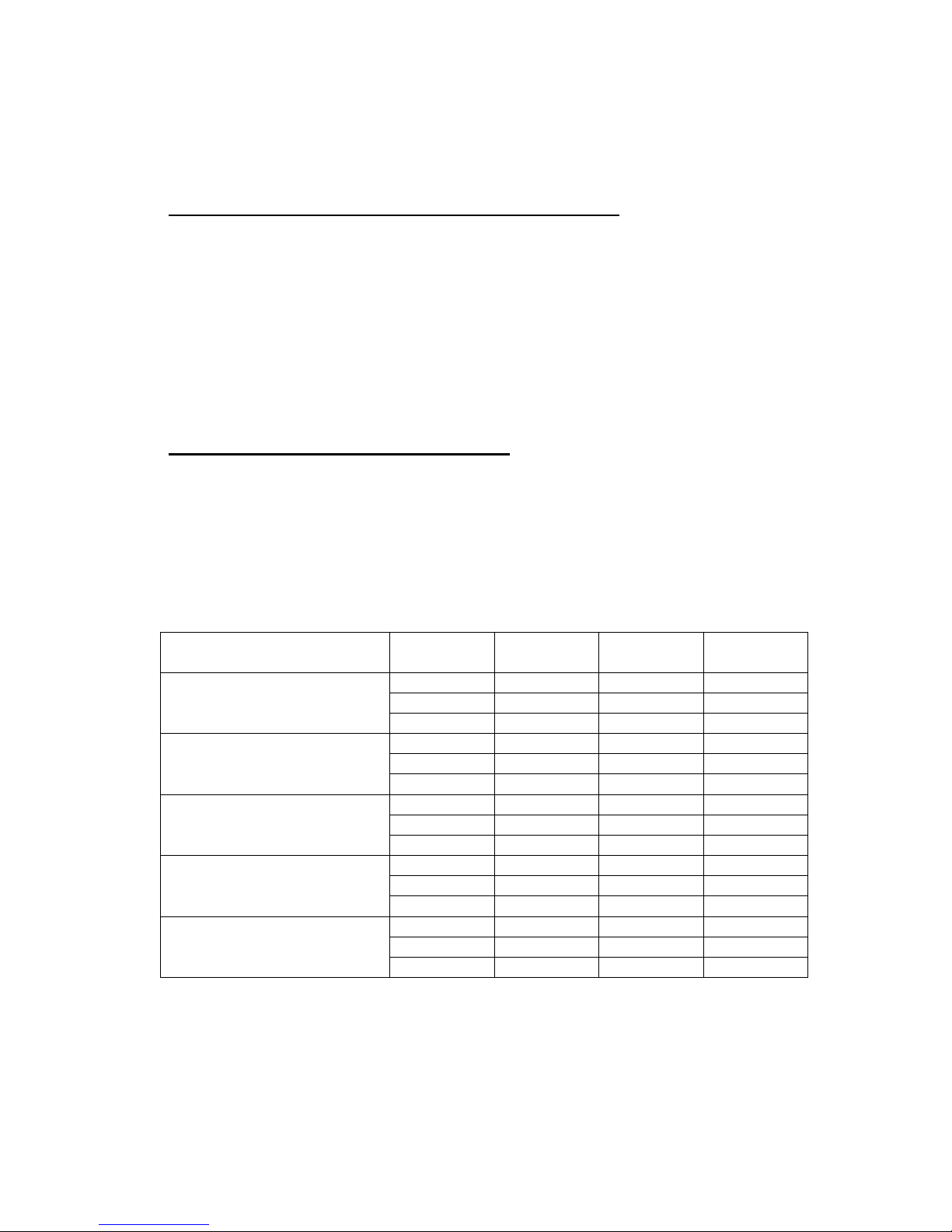

Instruction of Charging Curve Selection

The user can very easily adapt the Power Master charger to the type of battery by rotate

switch used.

To modify configuration carryout the following steps:

STEP 1: Disconnect charger from the mains. To avoid short-circuit, disconnect the

batteries.

STEP 2: According to 4 different battery types and desired charge current (30%, 70% and

100%), choose the rotate switch from 1 to C. If the used battery is not in 4 listed

battery types, User Define is available.

Battery Type U Boost U Float Charge

Current Rotate

Switch

14.4V 13.5V 100% 1

14.4V 13.5V 70% 2

Sealed lead, maintenance-free

gel type 14.4V 13.5V 30% 3

14.2V 13.8V 100% 4

14.2V 13.8V 70% 5

Classical lead open

14.2V 13.8V 30% 6

14.6V 14.0V 100% 7

14.6V 14.0V 70% 8

Lead calcium

(standard charge ) 14.6V 14.0V 30% 9

16.0V 13.8V 100% A

16.0V 13.8V 70% B

Lead calcium *

DEEP DISCHARGE 16.0V 13.8V 30% C

──100% D

──70% E

User Define

──30% F

User Define: Use the switches of the BOOST VOLTAGE and FLOAT VOLTAGE to

choose desired voltages from the following tables.

9

BOOST VOLTAGE Selection

Rotate

Switch Boost

Volt. Rotate

Switch Boost

Volt. Rotate

Switch Boost

Volt. Rotate

Switch Boost

Volt.

0 14.4V 5 14.9V A 15.4V F 14.3V

1 14.5V 6 15.0V B 15.6V

2 14.6V 7 15.1V C 15.8V

3 14.7V 8 15.2V D 16.0V

4 14.8V 9 15.3V E 14.2V

FLOAT VOLTAGE Selection

Rotate Switch Floating Volt. Rotate Switch Floating Volt.

0 13.5V 5 14.0V

1 13.6V 6 13.1V

2 13.7V 7 13.2V

3 13.8V 8 13.3V

4 13.9V 9 13.4V

STEP 3: Connect charger to the mains.

Example:

To use the Power Master charger of 12V/40A to charge a battery of Classical lead open at

desired charging current 28A, users should choose rotate switch of battery type to be “5”.

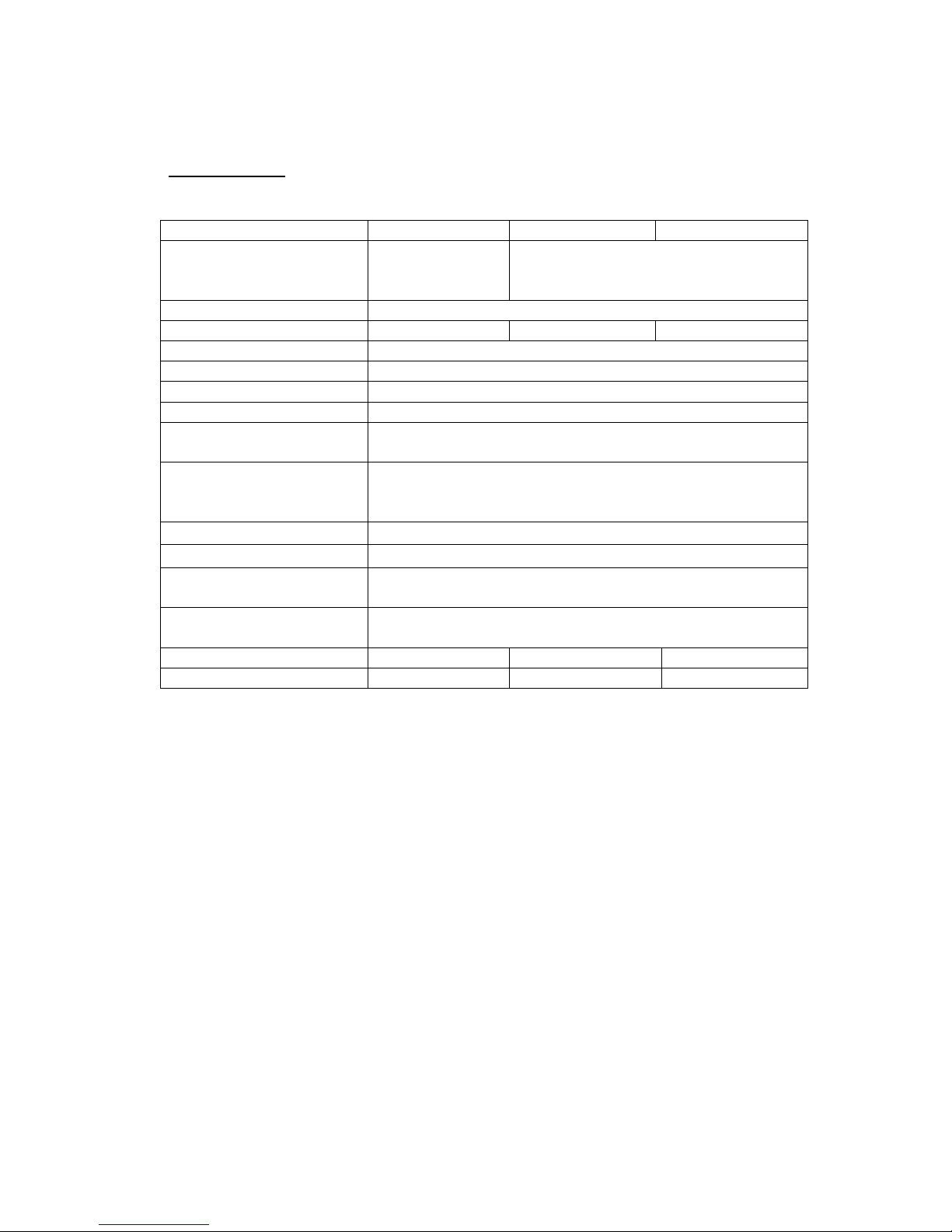

DC Power Supply

Power Master charger can not only charge the battery but also supply DC power directly.

The desired voltage can be set by the following steps.

STEP 1: Choose the rotate switch of BATTERY TYPE to be“0".

STEP 2: Use the rotate switch (0~F) of BOOST VOLTAGE to set the first two digits of

desired voltage. Refer to the below table for what 0~F represents.

Rotate

Switch Boost

Volt. Rotate

Switch Boost

Volt. Rotate

Switch Boost

Volt. Rotate

Switch Boost

Volt.

0 13.0V 5 16.0V A 16.0V F 16.0V

1 14.0V 6 16.0V B 16.0V

2 15.0V 7 16.0V C 16.0V

3 16.0V 8 16.0V D 16.0V

4 16.0V 9 16.0V E 16.0V

STEP 3: Use the rotate switch (0~9) of FLOAT VOLTAGE to set the decimal of desired

voltage. Refer to the below table for what 0~9 represents.

Rotate Switch Floating Volt. Rotate Switch Floating Volt.

0 0.0V 5 0.5V

1 0.1V 6 0.6V

10

2 0.2V 7 0.7V

3 0.3V 8 0.8V

4 0.4V 9 0.9V

Example:

To set the desired DC power supply of 14.3V, firstly, choose the rotate switch of battery

type to be“0"and then choose the rotate switch of boost voltage to be“1"; finally,

choose the rotate switch of float voltage to be“3".

BTS/Remote Control

It is a port for phone jack of the battery temperature sensor and upcoming remote control

to be connected.

Troubleshooting Guide

Problem and Symptoms Possible Cause Solution

No alternative current or

main fuse is melted down Check the fuse and replace

it

No output voltage and/or

intensity Main or generating unit too

weak Check the input voltage

Battery consumption > power

of the charger Reduce the consumption on

the battery

Charger delivers a weak

output voltage but a max.

intensity

One or several elements of

the battery present a

short-circuit

Check that there 's no

increase of battery

temperature

Battery is almost totally

charged Check that the charger is on

a floating mode

Intensity of charge is too

weak < 10% Alimentation is too weak Check the input voltage

Consumption on the battery

during the charge is too

important

Decrease the consumption

Time of charge is too short Choose a more powerful

charger

Battery temperature too weak Use a temperature sensor

Battery is never totally

charged

Defective battery Change the battery

Loss (emission of gas) Change the battery or check

the level of water

Battery is quickly empty

Sulfate on / stagnation

Charge / discharge several

time the battery or check

the charging curve or

replace the battery

Defective battery Replace the battery

Battery is hot/emission of

gas Temperature of the battery is

too high

Use a temperature sensor

and/or check the charging

curve

11

The charger is near to the

"switch off" temperature Ventilate the charger

Red LED DEFAULT

flashes Battery temperature is too

high (with a temperature

sensor)

Check the charging curve

and placed the battery in a

ventilated area

All LEDS are flashing but

the charger doesn’t charge

Default of the battery which

is in deep discharged or

polarity inversion of the

battery

Check the connection of the

battery, the polarity and

the output fuse

Problem and Symptoms Possible Cause Solution

All LEDS are flashing but

the charger doesn't charge DEFAULT

Check the battery

connections and the

connection of display, and

check the output fuse

No LED is lighting when

the charger is connected to

the main

DEFAULT

Check the main input, the

connection of display and

the fuses.

During the charge, all

LEDS are switched off

Stop because of the thermic

security or battery voltage <

9 V

( 18V for a 24V battery )

disconnect the charger, wait

20 minutes and connect to

the main

12

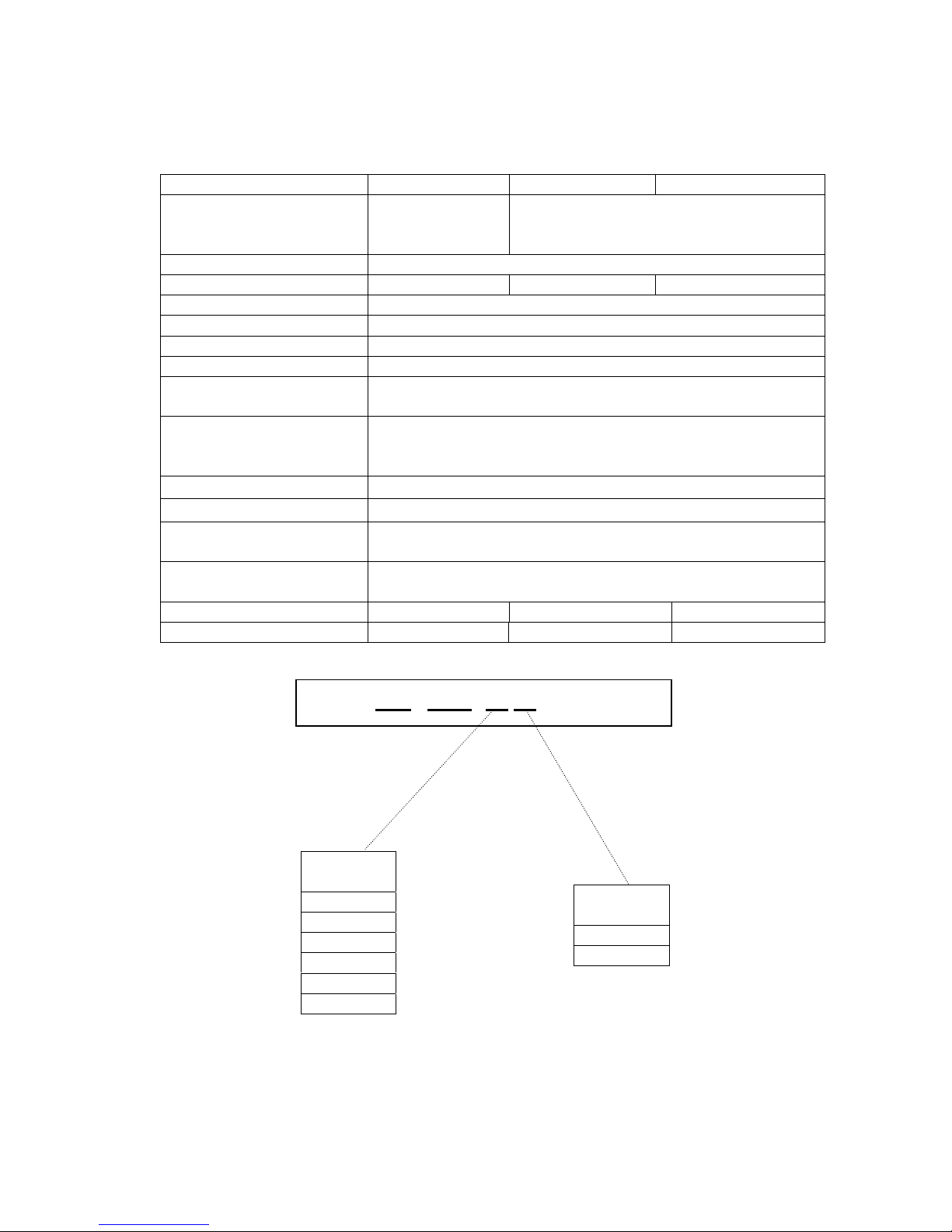

Specifications

Output: 12V

Model No. PM-SBC-2012 PM-SBC-4012F PM-SBC-6012F

Input Voltage Input voltage

230V ~

+10%/-15%

Universal input:

90V to 250V

Output Voltage 12V

Charging Capacity 20A 40A 60A

Frequency 50Hz/60Hz

Output Patterns 1 or 3

Input Voltage U bat +/-2%

Output Current I bat +/-10%

Charging Curve Type 3 states IUU type

(Boost Charge, Absorption Charge, Floating Charge)

Charging Curve Selection By SWITCH for 5 different battery types:

Classical lead open, sealed lead/gel, lead calcium

standard charge, lead calcium deep discharge, user define

Working Temperature -10℃~ +45℃

Storage Temperature -20℃~ +70℃

Protection Feature Against output short-circuit, battery discharge in the event of

mains failure, mains input overload, battery polarity inversion

Protection Options Battery or charger overtemperature

(Temperature sensor)

Dimensions 310x200x70 mm 400x250x80mm 400x250x80 mm

Weight 3 kgs 6 kgs 6 kgs

13

Output: 24V

Model No. PM-SBC-1524 PM-SBC-3024F PM-SBC-5024F

Input Voltage Input voltage

230V ~

+10%/-15%

Universal input:

90V to 250V

Output Voltage 24V

Charging Capacity 15A 30A 50A

Frequency 50Hz/60Hz

Output Patterns 1 or 3

Input Voltage U bat +/-2%

Output Current I bat +/-10%

Charging Curve Type 3 states IUU type

(Boost Charge, Absorption Charge, Floating Charge)

Charging Curve Selection By SWITCH for 5 different battery types:

Classical lead open, sealed lead/gel, lead calcium

standard charge, lead calcium deep discharge, user define

Working Temperature -10℃~ +45℃

Storage Temperature -20℃~ +70℃

Protection Feature Against output short-circuit, battery discharge in the event of

mains failure, mains input overload, battery polarity inversion

Protection Options Battery or charger overtemperature

(Battery Temperature Sensor)

Dimensions 310x200x70 mm 400x250x80mm 400x250x80 mm

Weight 3 kgs 6 kgs 6 kgs

CHARGE

CURRENT

15A

20A

30A

40A

50A

60A

OUTPUT

VOLTAGE

12VDC

24VDC

PM –SBC- 20 12

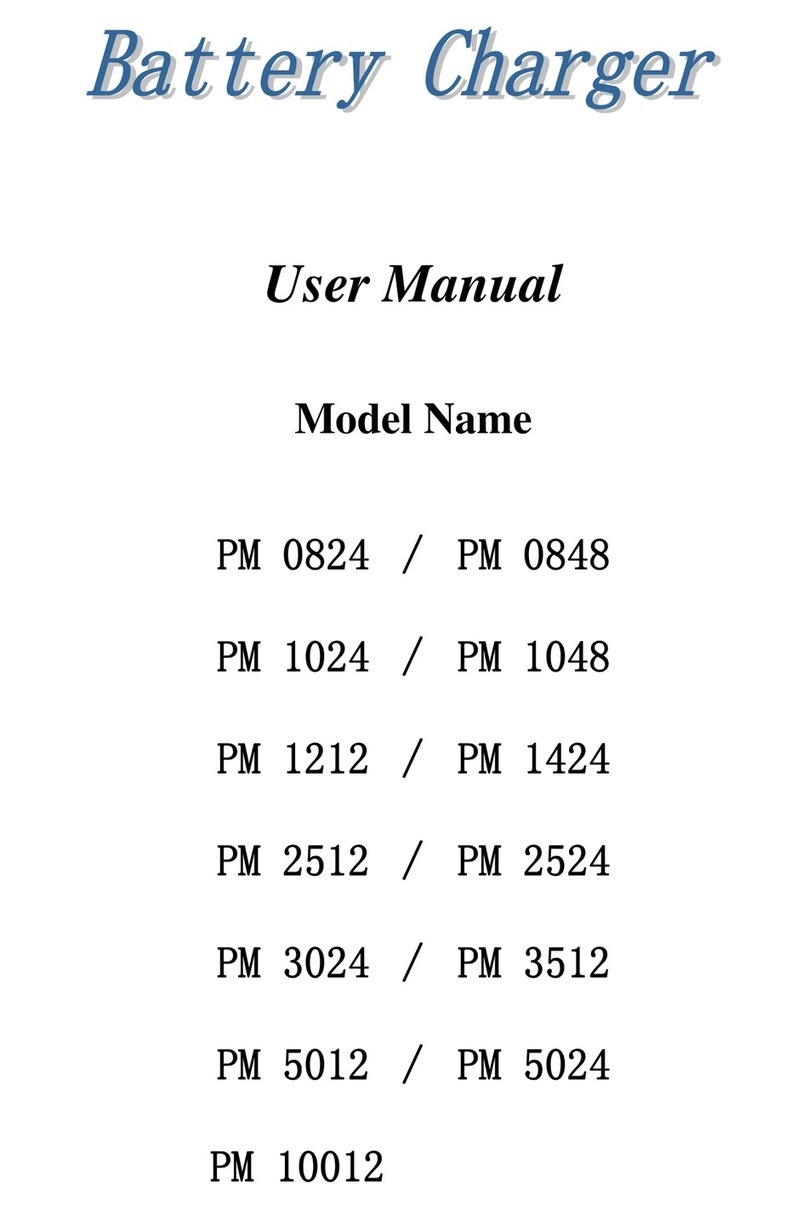

This manual suits for next models

5

Table of contents

Other Power Master Batteries Charger manuals