Document Operating and Maintenance manual, AC200

Reference No. 164571

Revision A

Date 23-JUL-2021

Author AK

Power Prove www.powerprove.com

Leicester. LE5 5LZ. United Kingdom sales@powerprove.com

a division of Cressall Resistors Ltd. +44(0) 116 249 1722 Page 1 of 12

Contents

1) Warnings ................................................................................................................................................................................................ 2

Prior to use ............................................................................................................................................................................................. 2

First use ................................................................................................................................................................................................... 2

During use............................................................................................................................................................................................... 2

2) Product specification ............................................................................................................................................................................3

3) Safety...................................................................................................................................................................................................... 4

General ....................................................................................................................................................................................................... 4

Protective earth bonding ......................................................................................................................................................................... 4

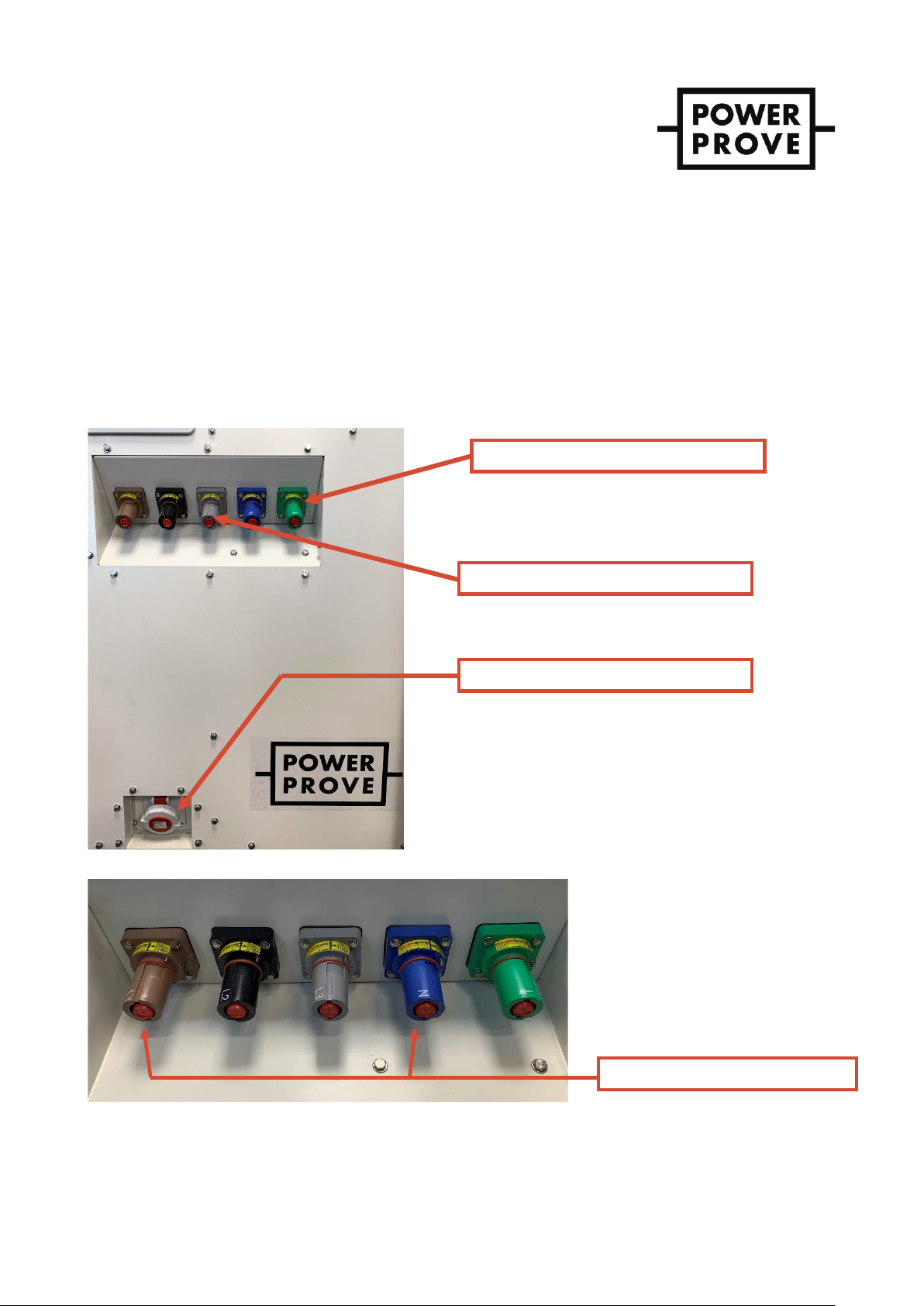

Power Connections ....................................................................................................................................................................................4

Ventilation ................................................................................................................................................................................................... 4

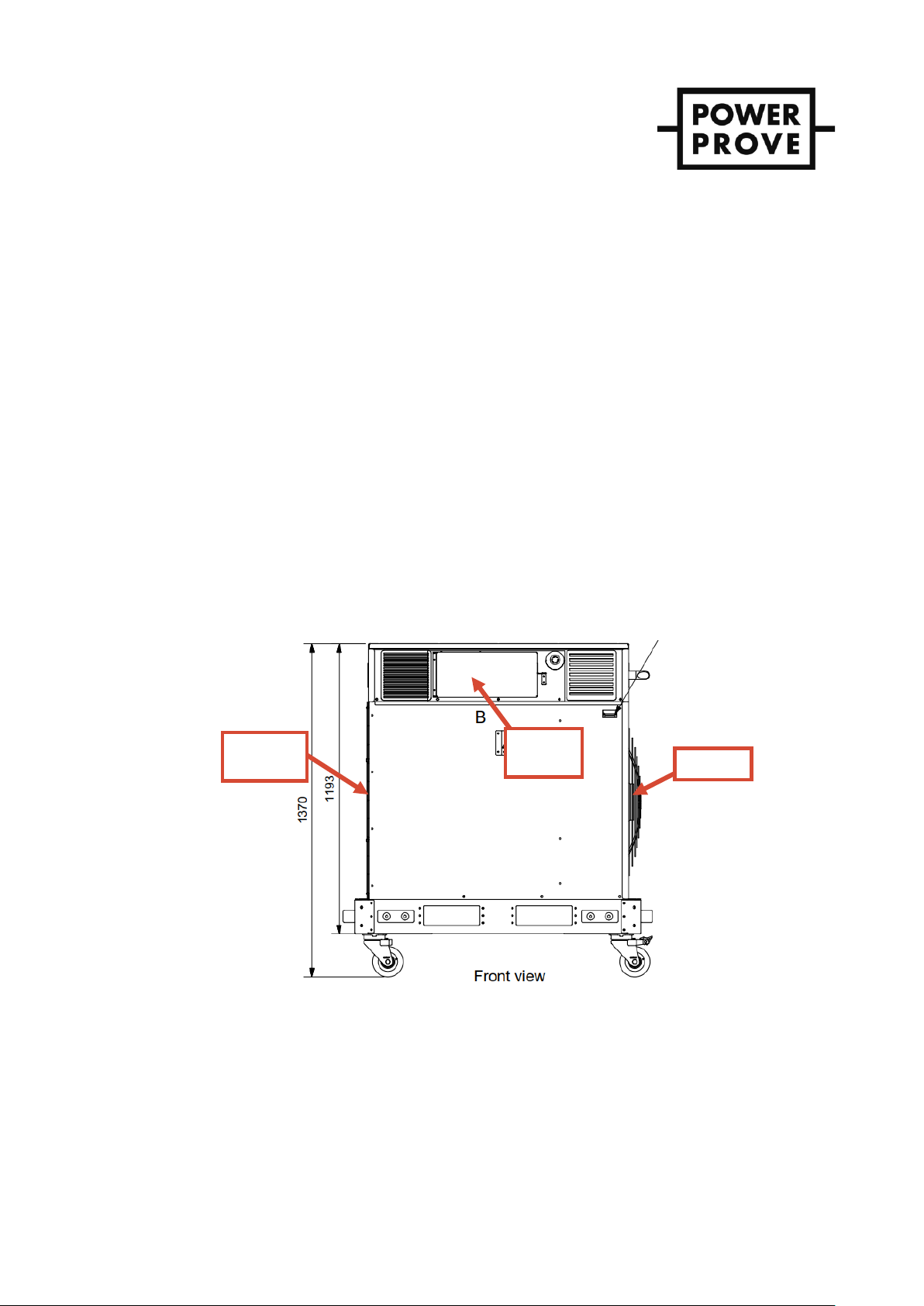

4) Operating Instructions ..........................................................................................................................................................................6

Connections ................................................................................................................................................................................................. 6

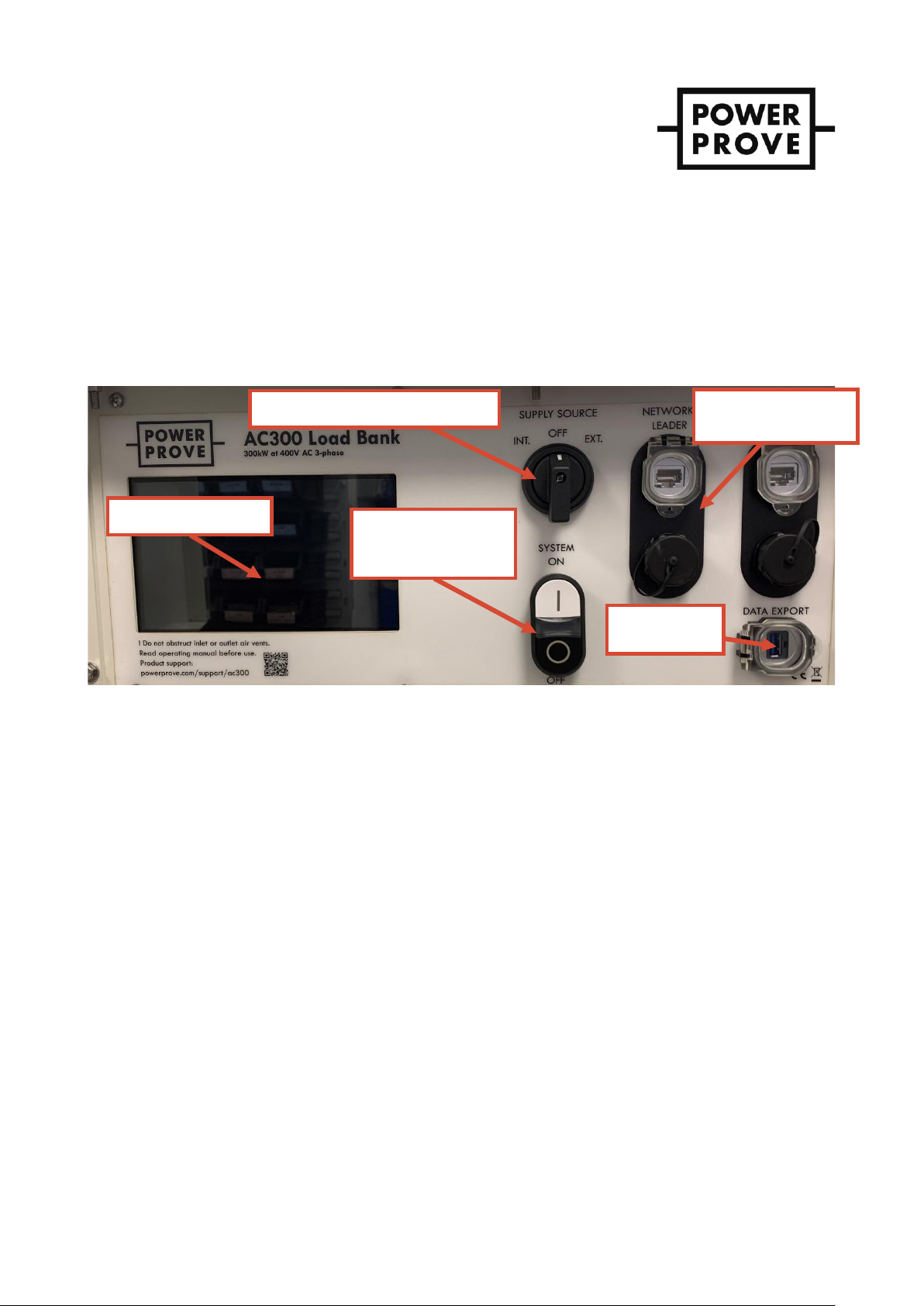

Controls........................................................................................................................................................................................................ 7

Pre-start-up.................................................................................................................................................................................................7

Start-up........................................................................................................................................................................................................ 7

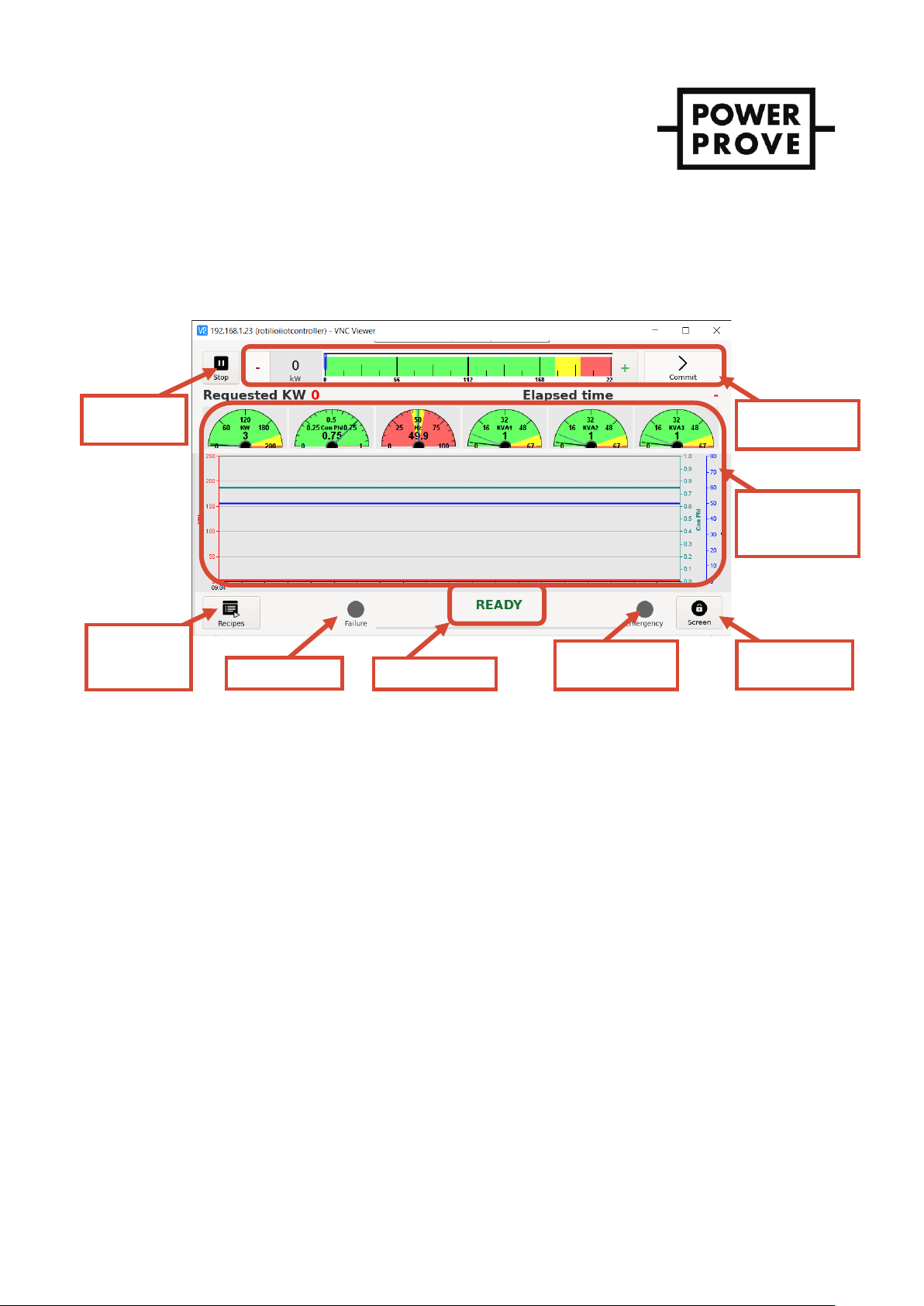

DIGILOAD HMI........................................................................................................................................................................................... 8

Applying & disconnecting load .............................................................................................................................................................. 8

Switching off and disconnection .............................................................................................................................................................9

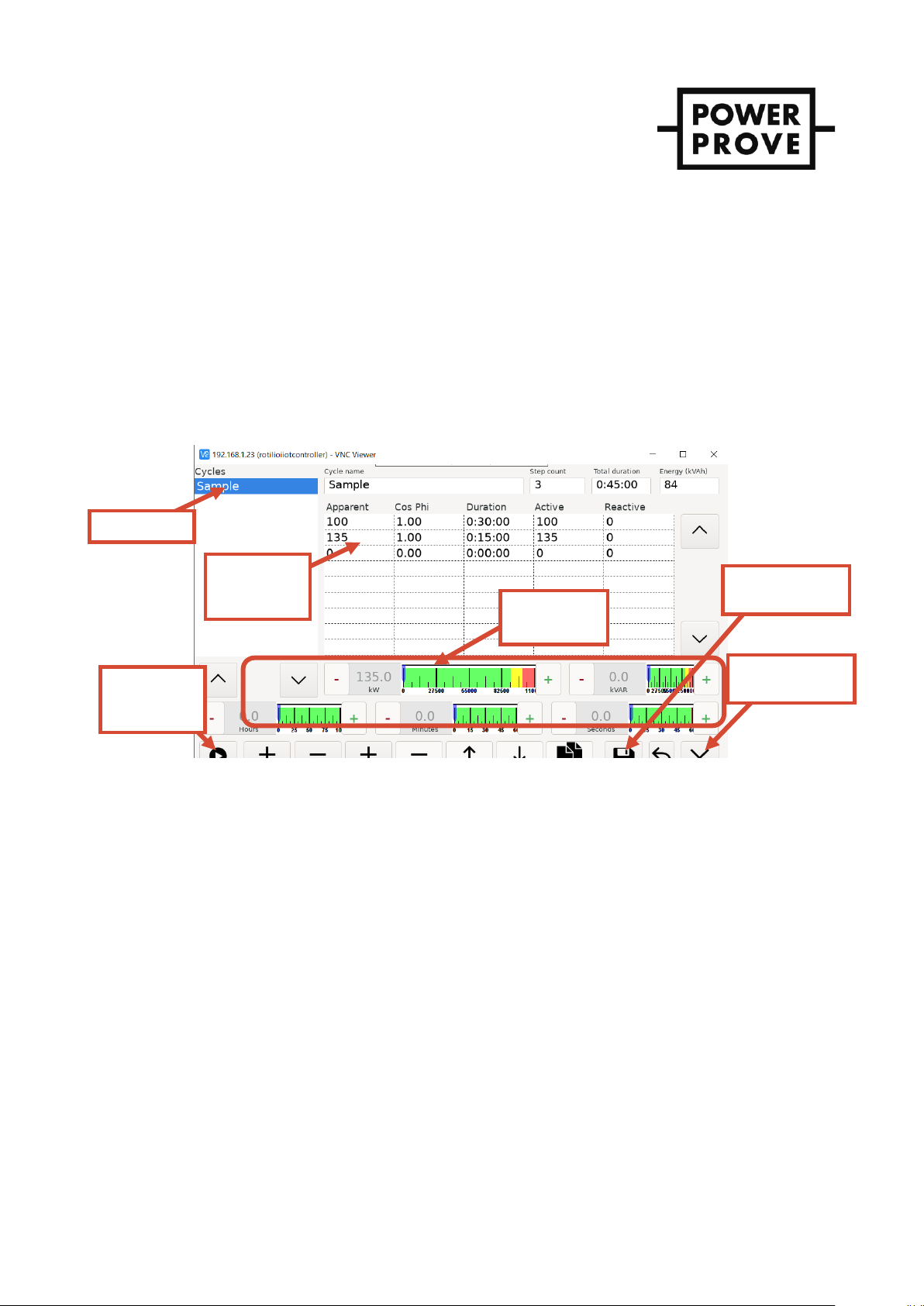

Load cycles ‘recipes’.................................................................................................................................................................................9

HMI Menus...................................................................................................................................................................................................9

Alerts menu............................................................................................................................................................................................. 9

Operating mode menu ......................................................................................................................................................................10

Power measurements menu...............................................................................................................................................................10

Lock screen................................................................................................................................................................................................11

Exporting test data over USB...............................................................................................................................................................11

5) Maintenance.........................................................................................................................................................................................12

6) Spares ...................................................................................................................................................................................................12

7) Waste Electrical & Electronic (WEEE) Disposal Instructions........................................................................................................12