Table of Contents

Introduction and Conventions......................................1

Product Introduction ....................................................2

Produce Washing Chemicals and Antimicrobials Error! Bookmark not

defined.

Explanation of Warning Messages...Error! Bookmark

not defined.

Danger................................................. Error! Bookmark not defined.

Warning ............................................... Error! Bookmark not defined.

Chemical Hazard ................................. Error! Bookmark not defined.

Operating Instructions..................................................5

Preparing the Produce Soak .......................................6

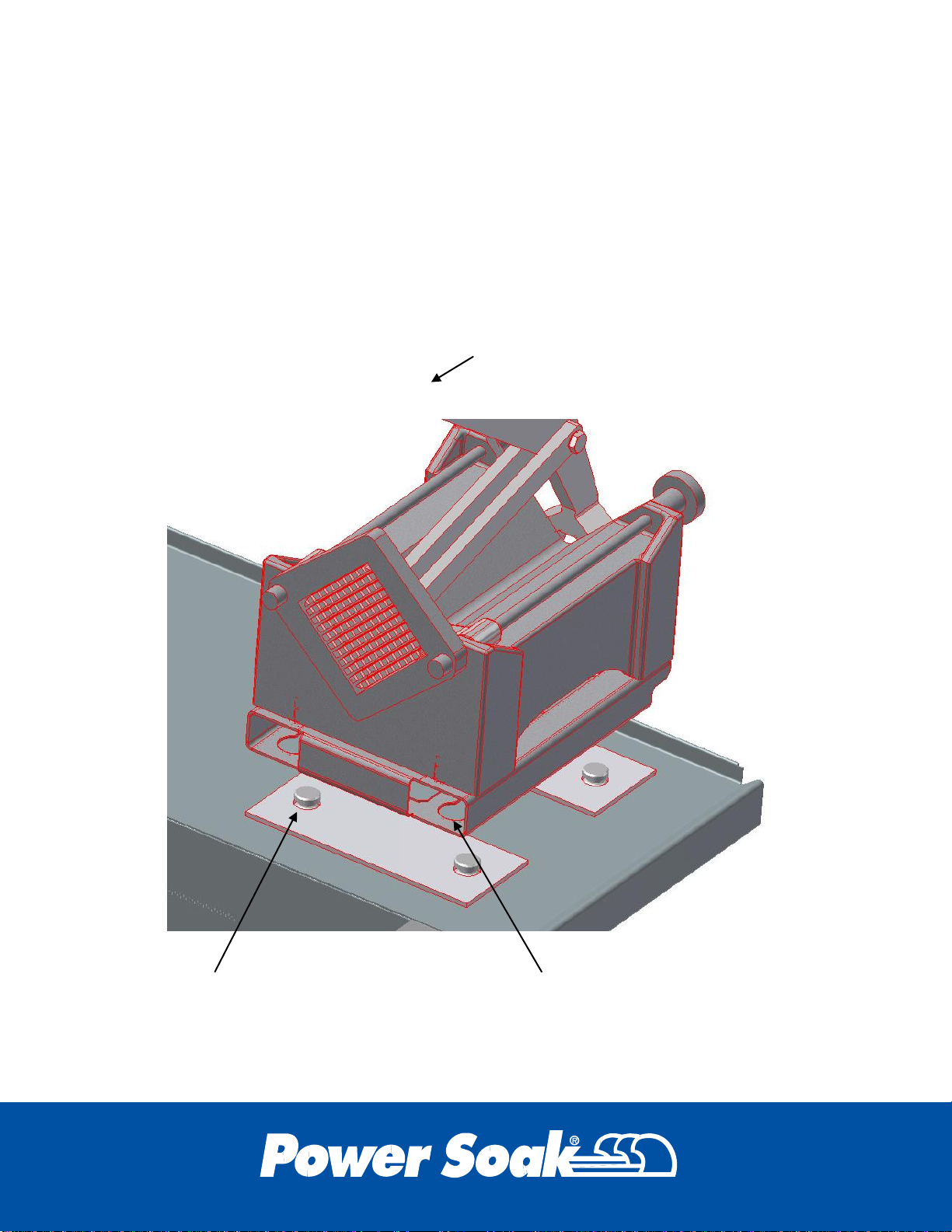

Placing the Wash Components............ Error! Bookmark not defined.

Rib sets............................................................................................7

Partitions.......................................... Error! Bookmark not defined.

Flow Guides..................................... Error! Bookmark not defined.

Filling the Produce Soak ........... Error! Bookmark not

defined.

Washing Tips .................................................................................19

Emptying the Produce Soak...... Error! Bookmark not

defined.

Preventive Maintenance ............................................23

Troubleshooting.........................................................25

Installation..................................................................29

Electrical Requirements.....................................................................31

Plumbing Requirements.....................................................................32