Finishing Touches

1. Using the 40mm galvanised nails, fit the bargeboards to the front and sides of the roof.

These may need cutting down with a saw depending on what size building you have.

2. Secure corner strips at each corner of your Power shed with 40mm nails (at least four per strip).

Extra strips are provided to cover any joins between side wall panels.

3. Secure the door pull to the door with 25mm screws.

4. Ensure there are no overhanging branches or debris on the shed as this can lead to water ingress.

Please be aware, this will need to be checked regularly as part of the maintenance of the shed.

Page 23

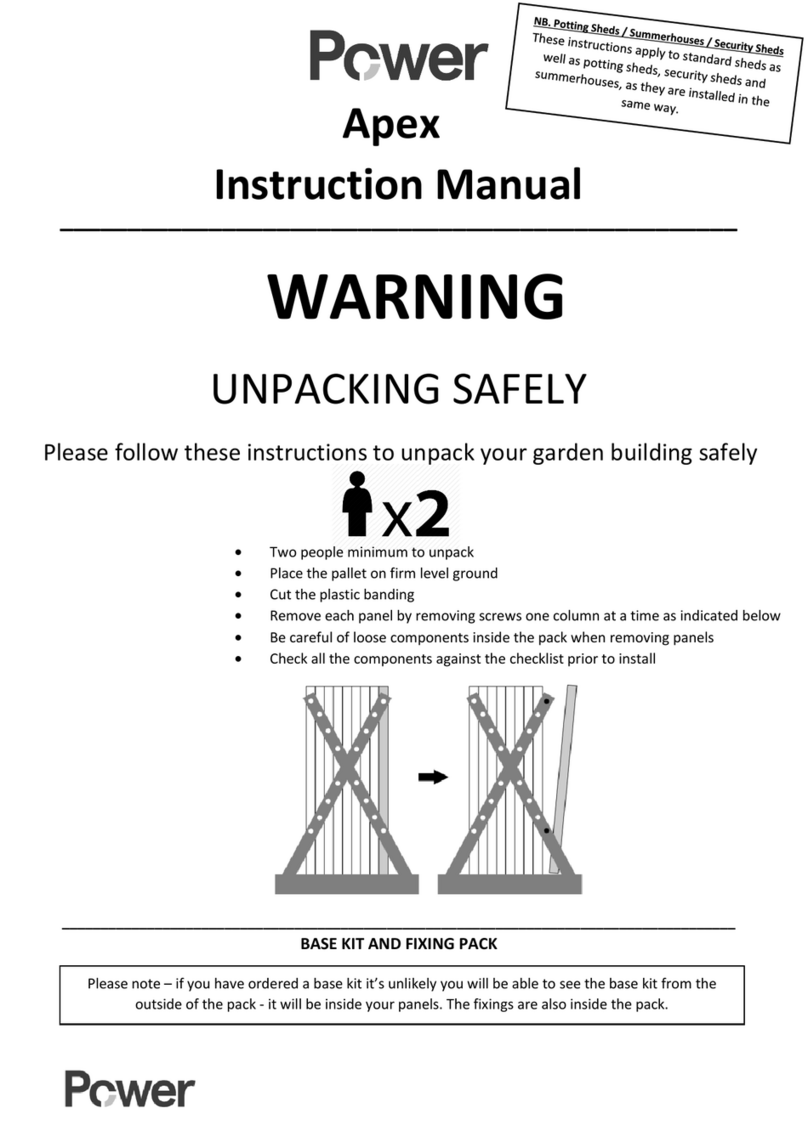

Watch the build a base video:

www.powersheds.com/faqs/how-do-you-assemble-the-power-sheds-base-kit/

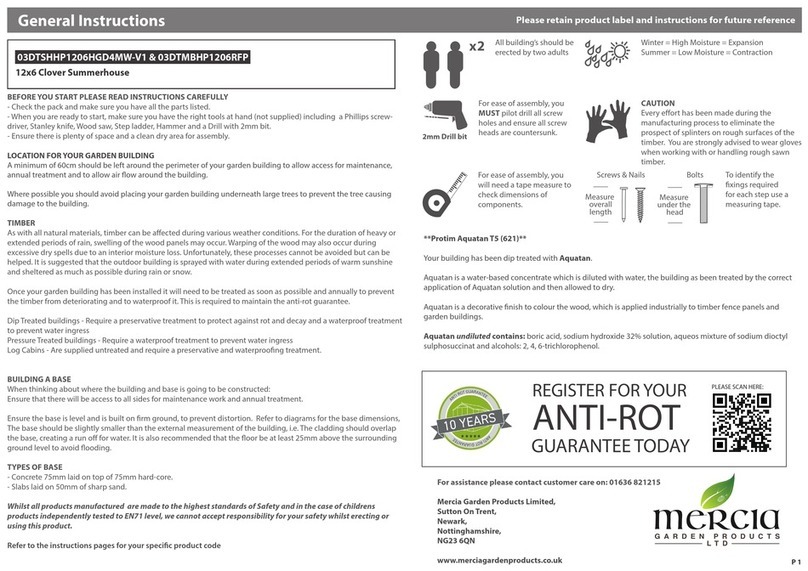

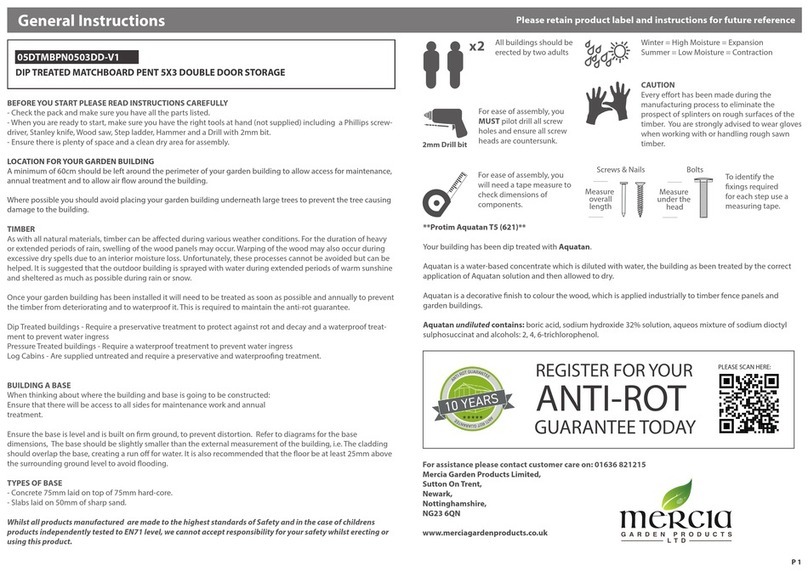

Timber

As timber is a natural product, it is prone to changes in appearance, including but not limited to movement, warping

and splitting, particularly in extreme weather conditions. There may be the occasional split, knot or similar visual

imperfections in the timber.

Whilst every effort is made to hand pick timber without visible knotholes or splits there may be occasions where

timber is selected in good faith that contains what appears to be a solid knot. Over the course of time/during

movement of the product, it may be that these small knot holes are then dislodged from the timber leaving a small

knot or crack.

Unfortunately, we cannot be held responsible for this maturing of the product and can only offer our best advice as

to how to deal with this situation in the unlikely event that it should occur. Our advice would be to apply some wood

filler to the area affected or in extreme circumstances to change the board over.

None of this should affect the structural integrity of the product.

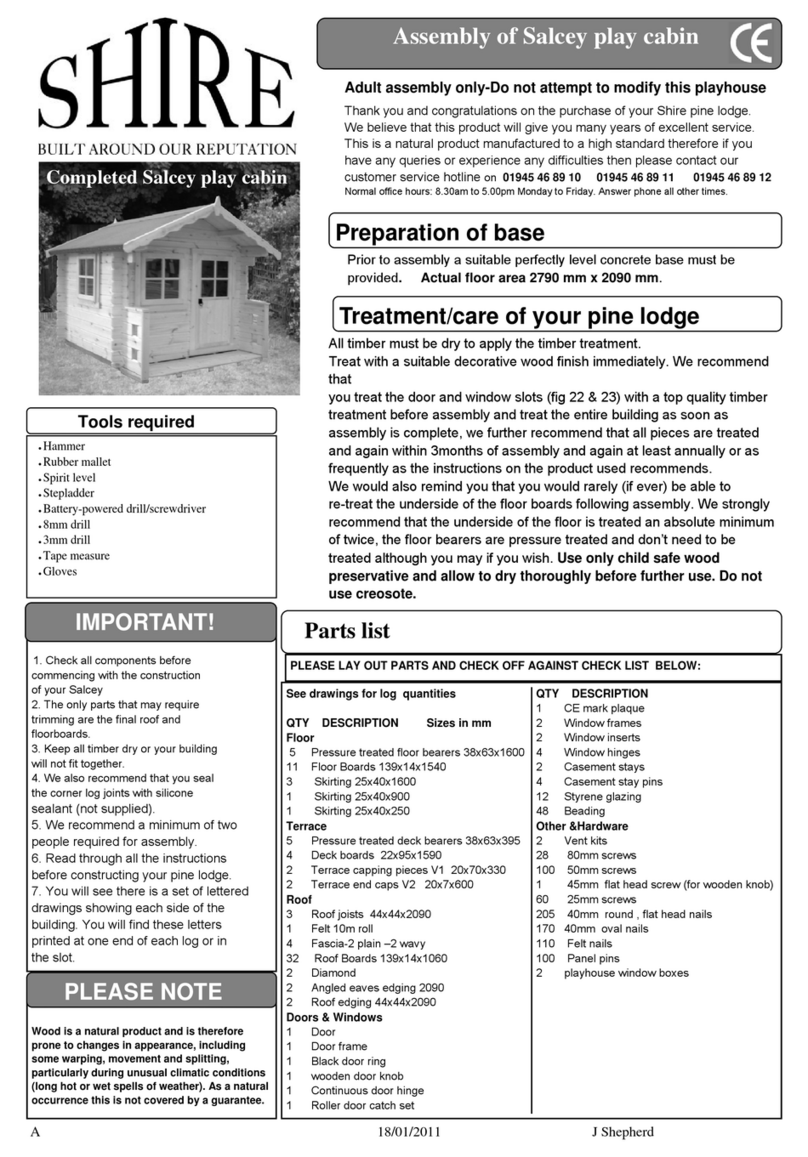

Firm & Level Base

All our garden sheds require a firm and level base.

When thinking about where the garden building and base is going to be constructed:

Ensure that there will be access to all sides for maintenance work and annual treatment.

Remember not to place the base too close to any walls or fences, as there may be a slight

overhang on the roof which may come into contact with the wall or fence.

Ensure the base is level and is built on firm ground, to prevent distortion.

Refer to PowerSheds.com for base dimensions.

Consider when placing the base next to trees or large bushes as this could cause problems

from overhanging branches. If these are likely to grow and come into contact with the

building in the future this could cause the felt to rip.

The base is slightly smaller than the external measurement of the building, i.e. The cladding should overhang the

base, creating a run for water.

It is recommended that the floor is at least 25mm above the surrounding ground level to avoid flooding.

If you have not chosen to purchase our Power Base, then other suitable bases would include a concrete base

(75mm of concrete on top of 75mm of hardcore) or a paving slab base (slabs laid on top of 50mm of sharp sand).

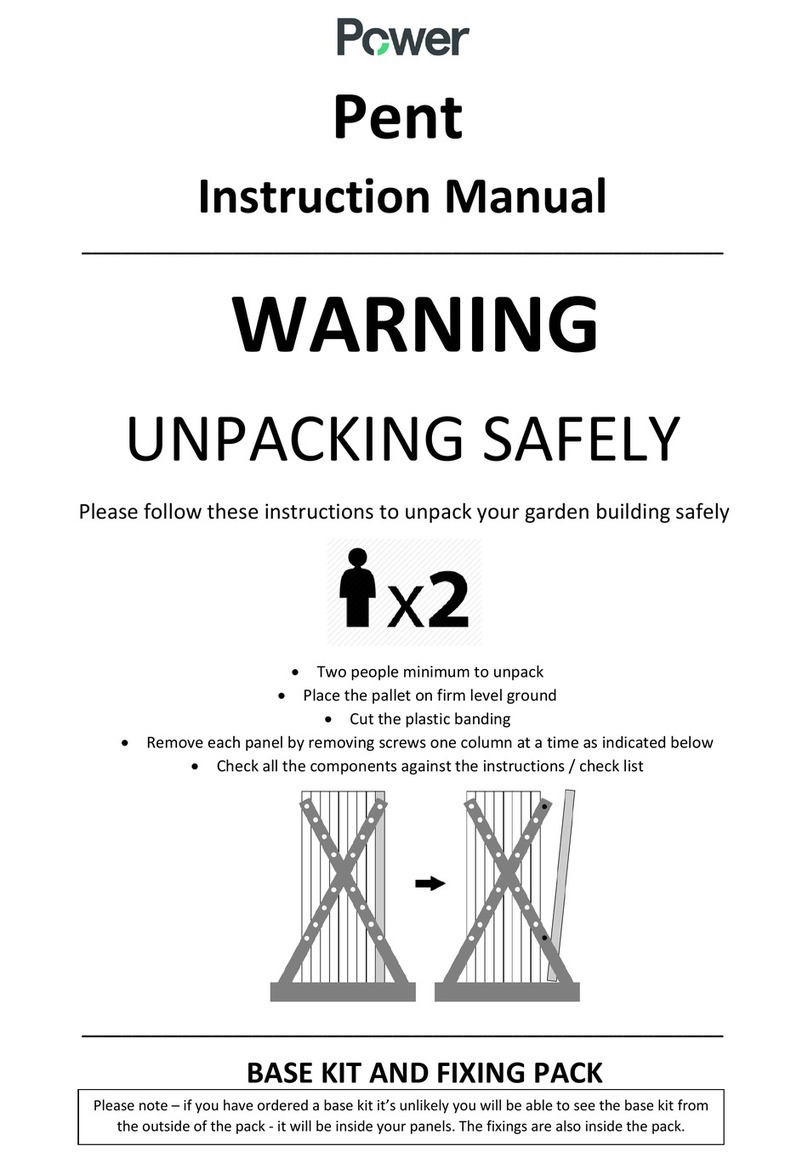

Power Base Kit

If you have ordered a Power Base Kit the instructions can be found in the small base kit fixing pack.

Please scan the QR code to watch our base kit installation video -

Page 4