Rev A.3 – 2013/01

Guide Overview

This guide is provided to help users get started using their Lifeti e Power® Wireless Sensor Syste

quickly and efficiently.

please see the following docu ents.

http://www.powercastsensors.co /files/WirelessSensorSyste

http://www.powercastsensors.co /files/WSG

Configuring Sensors

It is easiest to configure all the sensors for a deploy ent at one ti e. Aft

and configuring the ter inal interface, using the

gateway, one at a ti e. This will configure each sensor with the gateway’s network protocol settings;

2.4GHz syste s – Co Chan

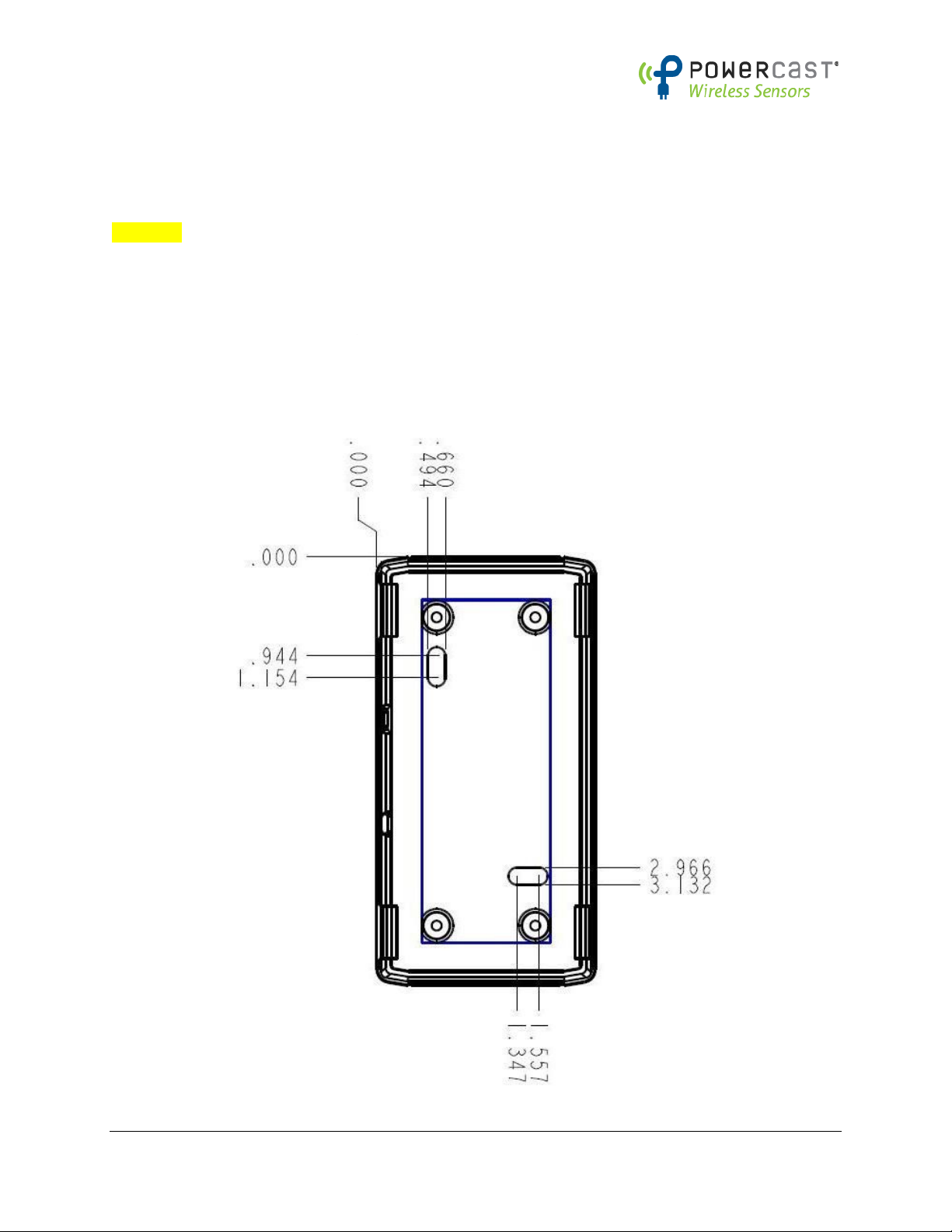

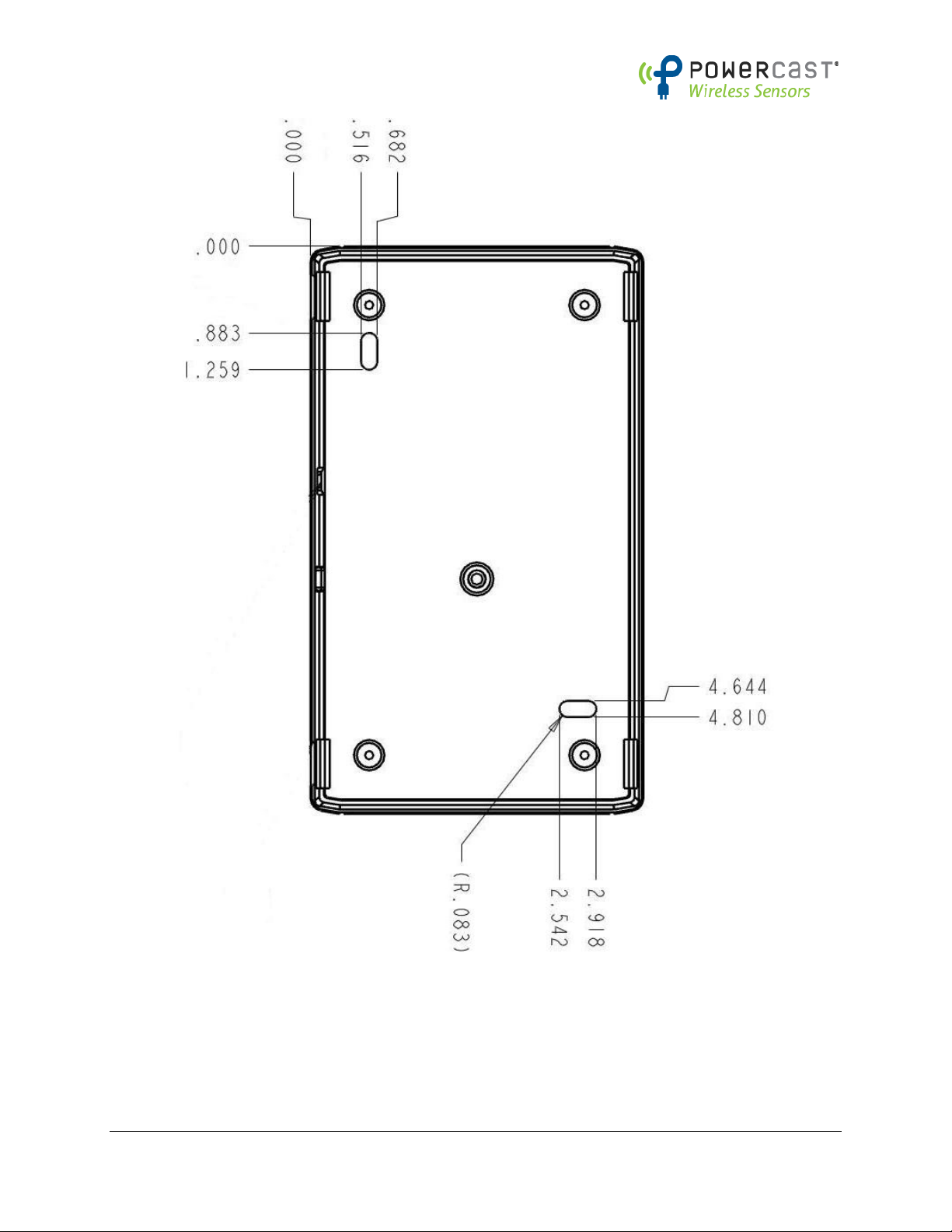

To configure sensors, each sensor ust be opened to expose the USB configuration port. To open the

enclosure, there are 2 slots on the right side. The slots are just large enough for a flat

Insert the screwdriver, applying light pressure to the tab, and then twist the screwdriver to release the

tab. CAUTION: Excessive

openin

g and closing, and only open enclosure when necessary.

WSN-1x 1

During configuration eac

h sensor is assigned an ID that is activated in the gateway. This nu ber should

be written on the

FCC label inside the sensor enclosure. You can also write the network protocol

settings for ore detail

ID).

Reattach the sensor back when configuration is co plete.

WSN Setup and Mounting Guide

www.PowercastSensors.co

This guide is provided to help users get started using their Lifeti e Power® Wireless Sensor Syste

uctions about the WSG Gateway and network configuration,

please see the following docu ents.

http://www.powercastsensors.co /files/WirelessSensorSyste

-UserManual.pdf

http://www.powercastsensors.co /files/WSG

-NetworkConfigurationGuide.pdf

It is easiest to configure all the sensors for a deploy ent at one ti e. Aft

er powering on the gateway

and configuring the ter inal interface, using the

S option, take

each sensor and plug the into the

gateway, one at a ti e. This will configure each sensor with the gateway’s network protocol settings;

15Mhz syste s –

To configure sensors, each sensor ust be opened to expose the USB configuration port. To open the

enclosure, there are 2 slots on the right side. The slots are just large enough for a flat

-

Insert the screwdriver, applying light pressure to the tab, and then twist the screwdriver to release the

enclosure could result in

broken tabs. Use care when

g and closing, and only open enclosure when necessary.

USB Configuration Port

h sensor is assigned an ID that is activated in the gateway. This nu ber should

FCC label inside the sensor enclosure. You can also write the network protocol

– Co Channel and Network ID; 915Mh

Reattach the sensor back when configuration is co plete.

PowercastSensors.co

WSN-12 1-T-N

Contains:

FCC ID: OA3MRF89XAM9A

IC: 7693A-89XAM9A

Node ID#

Example Sensor Label

Page 2

This guide is provided to help users get started using their Lifeti e Power® Wireless Sensor Syste

uctions about the WSG Gateway and network configuration,

er powering on the gateway

each sensor and plug the into the

gateway, one at a ti e. This will configure each sensor with the gateway’s network protocol settings;

To configure sensors, each sensor ust be opened to expose the USB configuration port. To open the

rewdriver.

Insert the screwdriver, applying light pressure to the tab, and then twist the screwdriver to release the

broken tabs. Use care when

h sensor is assigned an ID that is activated in the gateway. This nu ber should

FCC label inside the sensor enclosure. You can also write the network protocol

– Network