CONTENT

1.SAFETY PRECAUTIONS ................................................................................................................................................. 1

1.1SAFETY PRECAUTIONS.............................................................................................................................................................. 1

1.2IDENTIFICATION DESCRIPTION.................................................................................................................................................... 1

1.3ELECTRICAL SAFETY ................................................................................................................................................................. 1

1.4 OTHERS................................................................................................................................................................................ 3

2.PRODUCT DESCRIPTION ............................................................................................................................................... 4

2.1SERIAL NUMBER DESCRIPTION.................................................................................................................................................... 4

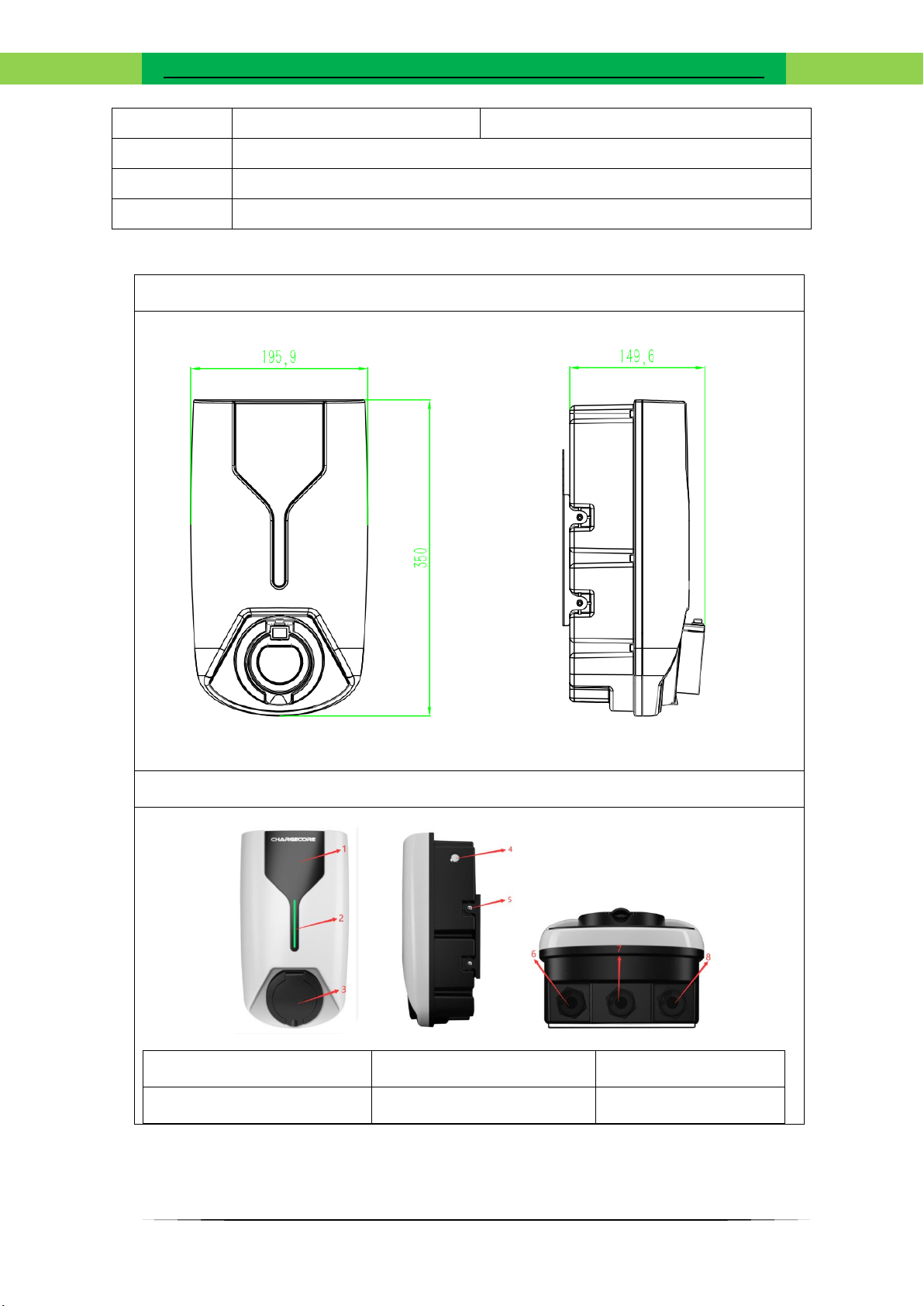

2.2 PHYSICAL DIMENSION .............................................................................................................................................................. 4

2.3 TECHNICAL PARAMETER ........................................................................................................................................................... 6

2.4 FEATURES........................................................................................................................................................................... 7

3.SYSTEM STRUCTURE .................................................................................................................................................... 9

3.1 ELECTRIC............................................................................................................................................................................... 9

3.2COMMUNICATION ................................................................................................................................................................... 9

4.INSTALL.......................................................................................................................................................................11

4.1INSTRUCTION........................................................................................................................................................................ 11

4.2 PREPARE............................................................................................................................................................................. 11

4.3INSTALLATION NOTES ............................................................................................................................................................ 13

5.OPERATION DEBUGGING ............................................................................................................................................15

5.1INSTRUCTIONS...................................................................................................................................................................... 15

6.AFTER-SALES SERVICE .................................................................................................................................................17

6.1AFTER-SALES SERVICE............................................................................................................................................................. 17

6.2DISCLAIMER......................................................................................................................................................................... 17

6.3MAINTENANCE...................................................................................................................................................................... 18

7.APPENDIX ...................................................................................................................................................................19

7.1 INDICATOR STATUS DESCRIPTION: ............................................................................................................................................ 19

7.2 GENERAL TROUBLESHOOTING INSTRUCTIONS............................................................................................................................. 19

7.3 TOXIC AND HAZARDOUS SUBSTANCES OR ELEMENTS IDENTIFICATION TABLE (ROHS) ........................................................................ 21