8

Note: All bare parts are greased in order to protect

them from corrosion. Before mounting the drill chuck

(10) onto the spindle (11), both parts must be

completely degreased using an environmentally

friendly solvent. This ensures optimal transmission of

power.

Mount the drill chuck onto the spindle.

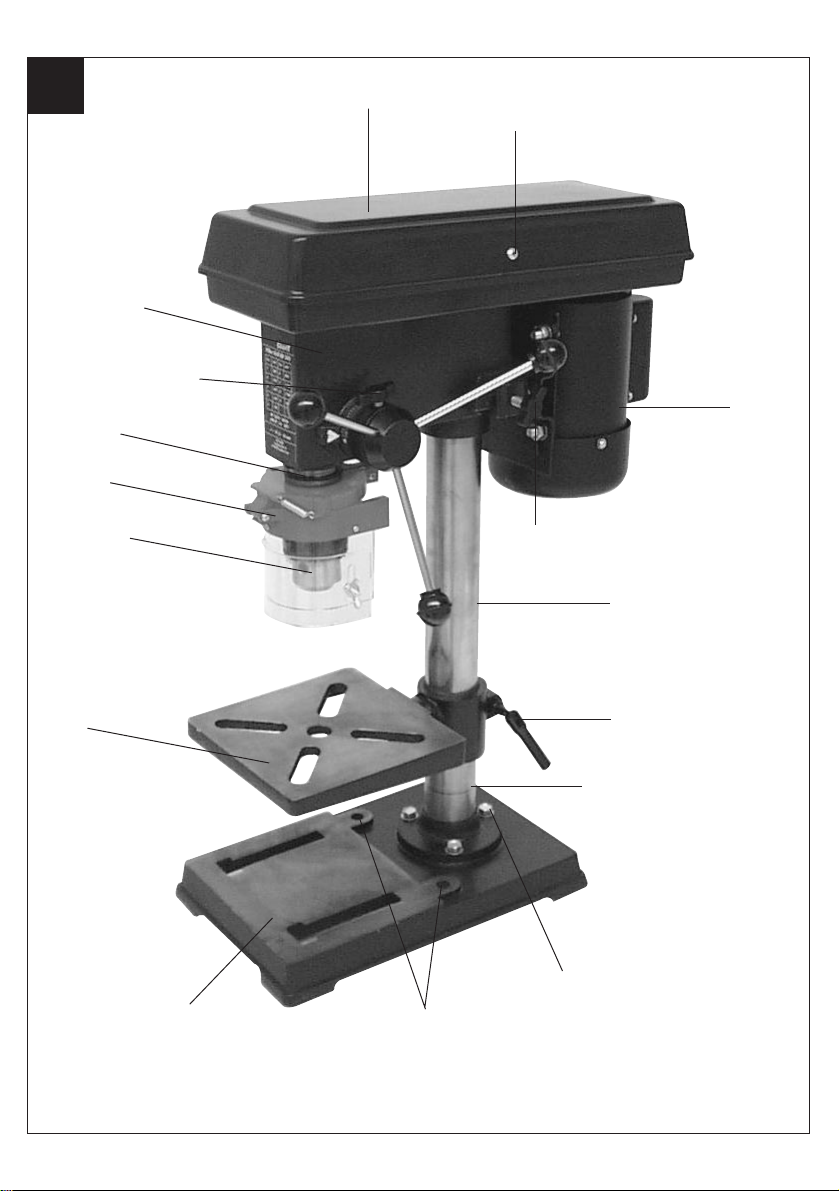

6.2. Installing the machine (Fig. 1)

Before the drill is started for the first time, it must be

solidly and fully mounted on the work area of a stable

workbench. Use both mounting holes (12) in the

base plate to do this. Ensure that the machine is

freely accessible for operation, adjustment and

maintenance.

Note: The fixing screws may only be tightened to a

point where they do not distort or deform the base

plate. Excessive tension can lead to fracture.

6.3. Hinged chip guard (Fig. 4)

Unscrew the three recessed head screws (21).

Push the transparent cover (23) into the groove of

the red mounting frame (24) and fasten it again with

the recessed head screws (21).

The height of the cover (23) is infinitely adjustable

and can be locked using the two thumb screws (22).

The chip guard (13) can be flipped upwards to

change drill bits; ensure, however, that the chip

guard (13) is back in its initial position before

restarting the machine.

6.4. Prior to starting

Ensure that the voltage of the mains supply complies

with the specifications on the rating plate. Connect

the machine only to a socket with the properly

installed earthing contact.

The table drill is equipped with a no-volt trip that is

designed to protect the operator from an undesired

restart following a drop in voltage. Should this occur,

the machine must be manually restarted.

7.0. Operation

Wear suitable, protective clothing (i.e.

rugged and tight-fitting) when working

with the table drill.

Always wear safety goggles!

Long hair should always be bound

back with a hair net or a cap!

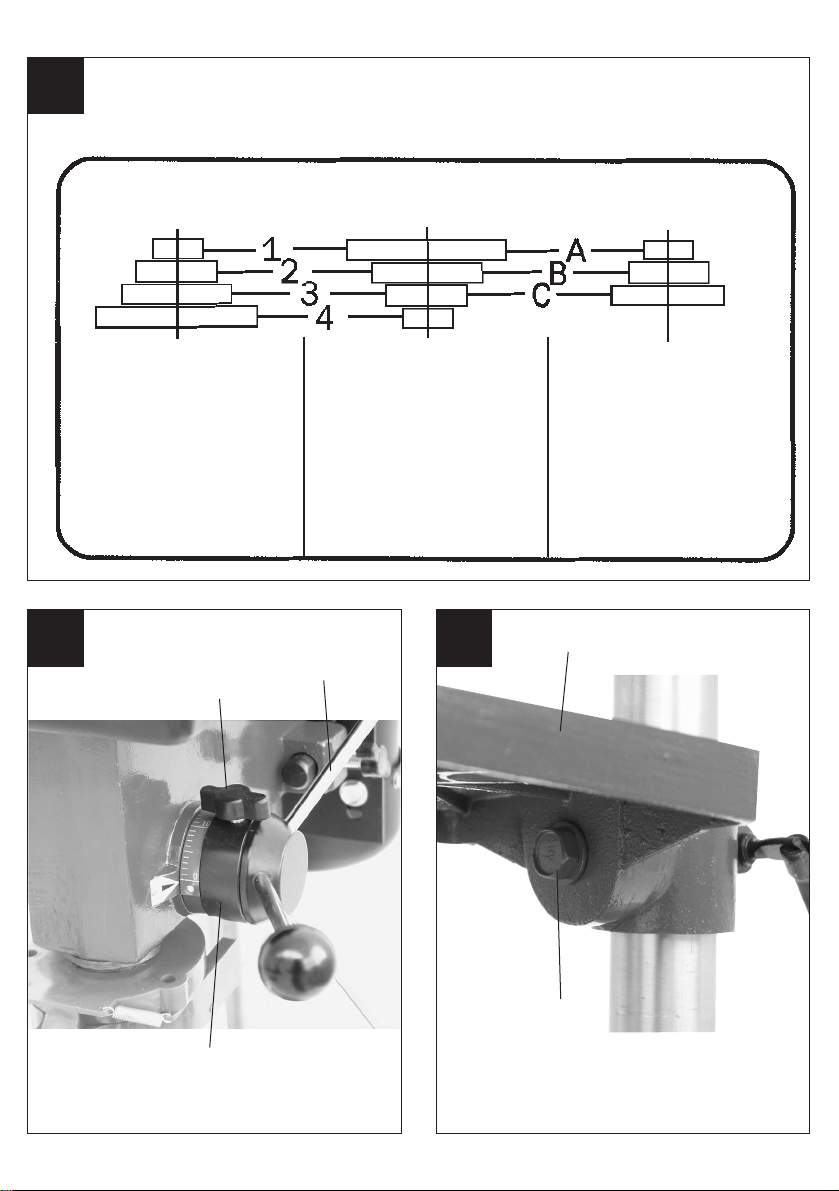

7.1. General (Fig. 2)

To switch on the machine, push in the green On

button „I“ (18); the machine starts up. To switch off,

press the red Off button „O“ (19); the device shuts

down. Ensure that you do not overload the device. If

the sound of the motor drops in pitch during

operation, it is being overloaded. Do not overload the

device to the point where the motor comes to a

standstill.

The machine is designed for continuous operation

with intermittent load (S6 50 %).

The machine may be operated under a full load for a

maximum of 5 minutes, at which time the machine

needs to idle for 5 minutes. This prevents the motor

from overheating.

7.2. Tool insertion (Fig. 1)

Ensure that the mains plug is pulled out before

changing tools. Only cylindrical tools with a

maximum shaft diameter of Ø 1.5 - 16 mm may be

clamped in the scroll chuck (10). Only use a tool that

is sharp and free of defects. Do not use tools whose

shaft is damaged or which are deformed or flawed in

any other way. Only insert accessories and

attachments that are specified in the operating

instructions or have been approved by the

manufacturer.

7.3. Handling the drill chuck (Fig. 1)

Your table drill is equipped with a scroll chuck (10).

In order to insert a drill bit, flip up the chip guard (13),

insert the drill bit, then tighten down the drill chuck

using the supplied chuck key.

Pull out the chuck key. Ensure that the clamped in

tool is firmly seated.

Caution! Do not leave the chuck key in the clamp

hole.

Doing so will cause it to shoot out, which could cause

injury.

GB