Operating

Select suitable drill bit, insert the shank into the drill chuck as far as

possible and tighten chuck with key supplied making sure that the

shank of the device is securely clamped centrally between the three

chuck jaws. Remove chuck key.

When drilling holes of all sizes it is advised to use a pointed punch to

mark the centre at which the hole is to be drilled as this will provide

a starting point for the drill tip. This procedure will prevent the drill bit

from skidding, ensure that the hole is drilled where intended and help

to prevent drill breakage when using small drills. When drilling,

particularly with small diameter drills, always try to ensure that load

applied to the drill is such that the drill bit is always at right angles to

the hole being drilled. Do not force the drill but allow it to cut.

When drilling always adopt a firm posture to be able to counteract

any sudden movement of the drill due to torque reaction. Such torque

reaction can occur when the drill stalls due to a too heavy load being

applied or the material being too hard or tough. The torque reaction

can occur when the drill breaks through the material being drilled,

particularly on sheet metal. Always use eye protection and hand

protection is advised, particularly when drilling holes in metals where

the material being removed from the hole is in the form of long sharp

strips. Do not tie the drill chuck key to the drill as the attaching device

i.e. string or chain could become entangled with the rotating chuck

and bit etc.

If using an abrasive device, drilling stone or performing any operation

where dust is created, it is recommended to use a breathing mask.

Always ensure that the material to be drilled is firmly fixed to prevent

its movement.

It is also recommended that when drilling holes of large diameter to

first pre drill a hole of smaller diameter as this will reduce effort

required to drill the hole and minimise torque reaction.

Dismantling & Assembly Instructions

Disconnect the tool from the air supply,

To remove the chuck use a cross head screwdriver and remove the

set screw (39-1) then unscrew the chuck from the anvil (37).

Use a 17mm spanner to undo the air inlet (42) and second silencer

(44) then with a small hook pull out the o ring (11) and silencer (43).

Unscrew clutch housing (36) using a 25mm open spanner then

remove the internal gear (34) pull out gear set (30, 29 & 28).

Pull out the motor assembly, tap the rotor (22) to loosen the

assembly, remove front plate (24) and bearing (25) from the front

plate (24) remove rotor blades (23) cylinder (20) then remove the

end plate (19) and push out the bearing (18) from the end plate (19)

using a4.1mm diameter roll stick take out screw (16) and remove

switch (17) them remove the valve (15) o`ring (14) and spring (13).

Unscrew cap screw (10) and remove button (9) pull out valve pin (6)

from pistol housing (1) then pick out parts (8, 8-1, 5, 6, 4 & 7) in

sequence.

Reassembly

Clean all parts and examine for wear and cracks, etc. and replace as

necessary. Look in particular for wear and cuts on O-rings, wear on

rotor blades and wear on bearing (18) and (25). Make sure that the

faces of end plates (24) and (19) that about cylinder (20) are flat and

free from burrs. The height of the rotor (22) must be lower than the

height of the cylinder (20) otherwise the motor will not run.

Lap on a flat fine grade of abrasive paper if necessary. Use only

manufacturer or authorized distributor supplied spare parts. Lightly

coat all parts with suitable pneumatic tool lubrication oil and

reassemble in the reverse order.

When assembling the gear sets (28,29, 30,31,32,33 & 34) use

lubricating oil on all the gear parts.

On completing assembly, ensure that all parts are locked tight and

the spindle rotates and the lever throttle. Connect tool to suitable air

supply and operate tool slowly for a few seconds and reset for

operation required. Refer to section on Operation Instructions.

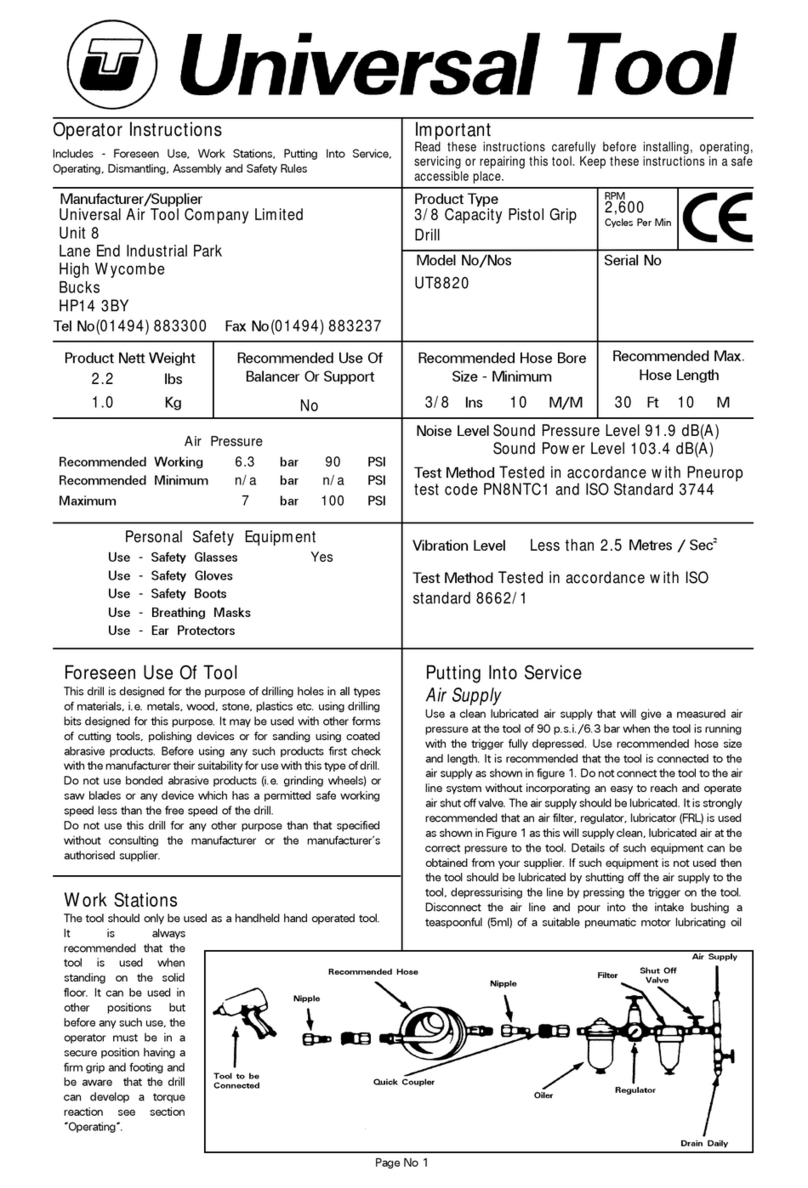

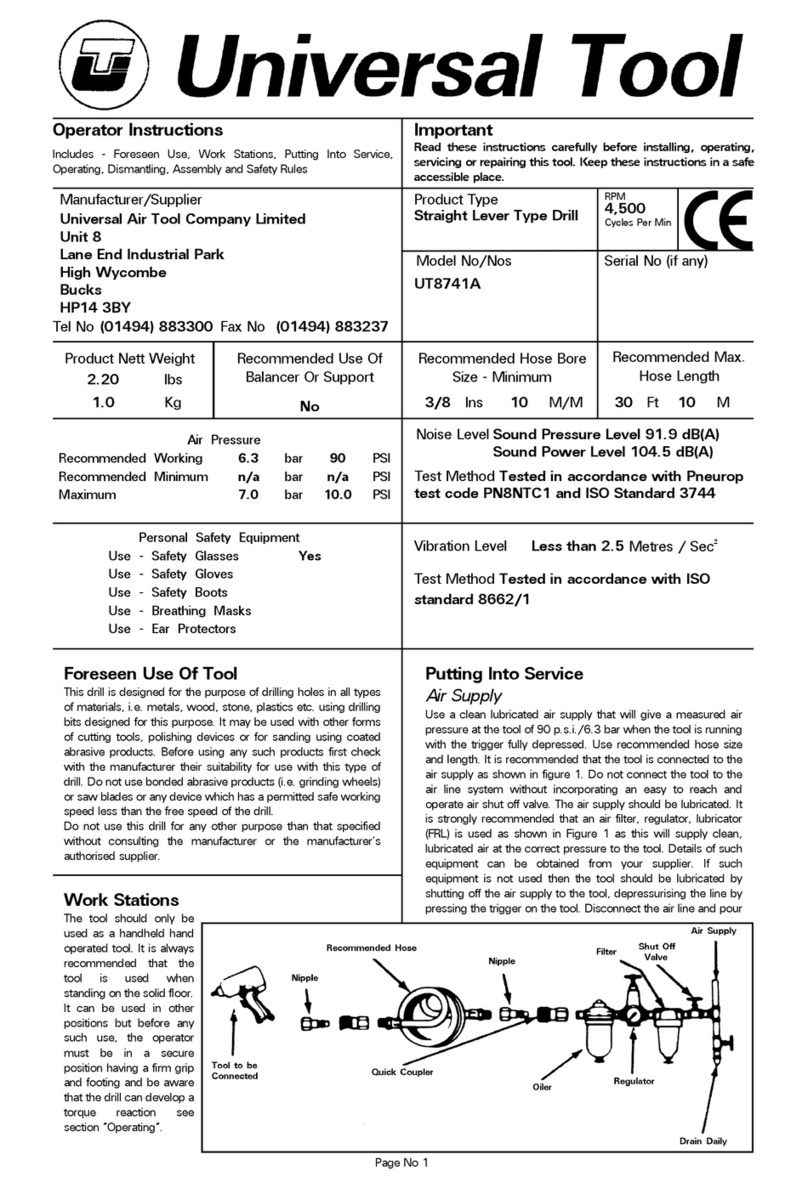

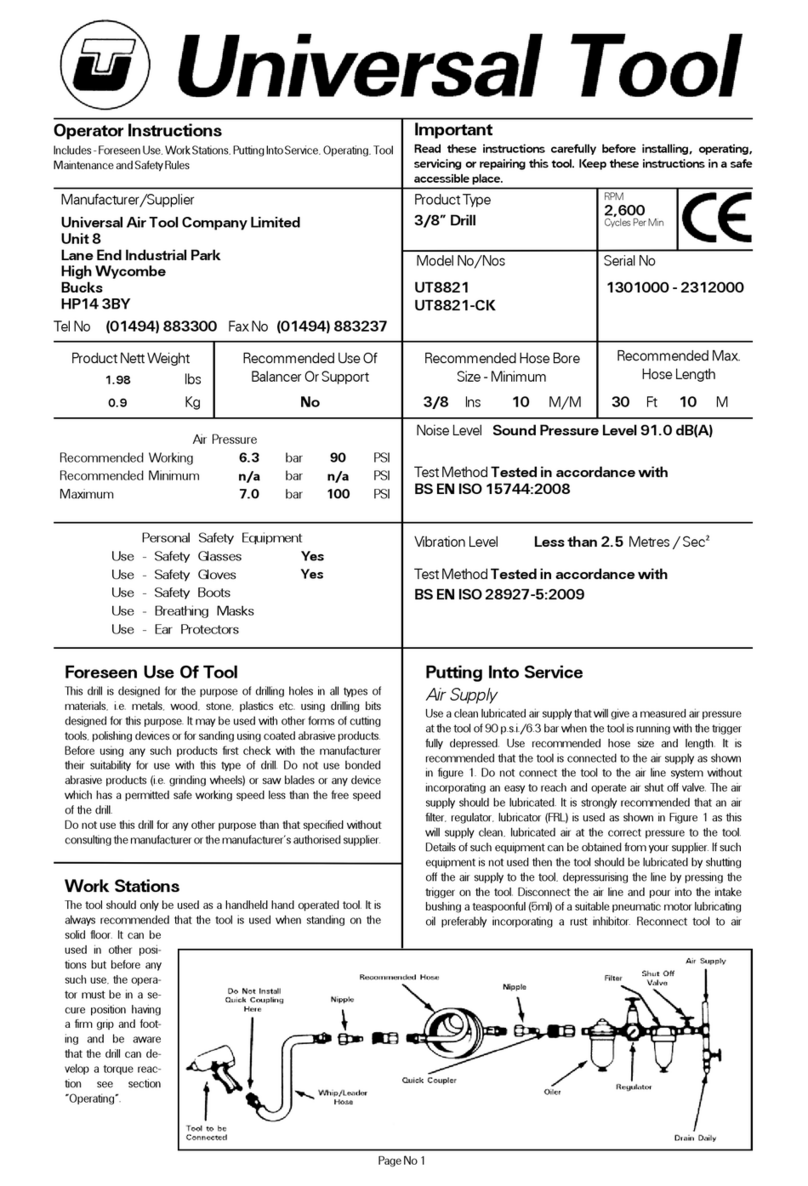

oil preferably incorporating a rust inhibitor. Reconnect tool to air

supply and run tool slowly for a few seconds to allow air to circulate

the oil. If tool is used frequently lubricate on daily basis and if tool

starts to slow or lose power.

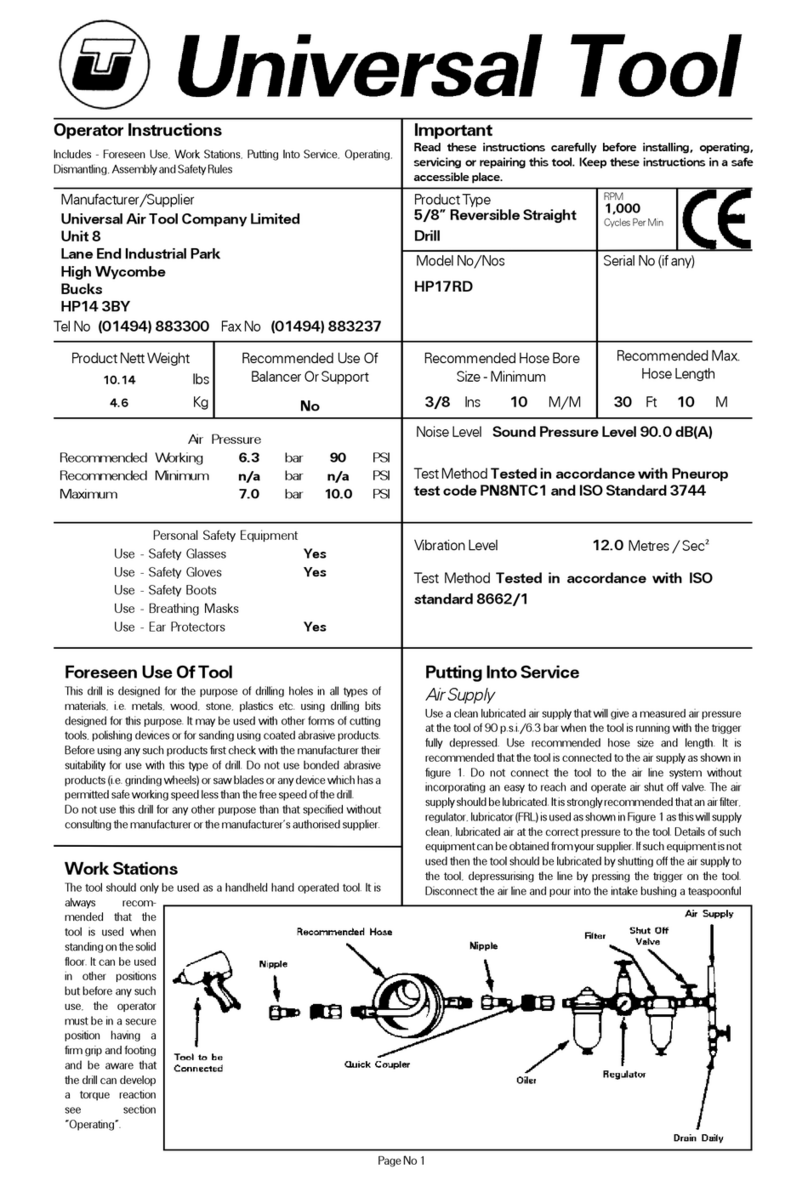

It is recommended that the air pressure at the tool whilst the tool is

running is 90 p.s.i./6.3 bar. The tool can run at lower and higher

pressures with the maximum permitted working air pressure of 100

p.s.i./7.0 bar.

Page No 2

Safety Rules When Using A Drill

1) Read all the instructions before using this tool. All operators must

be fully trained in its use and aware of these safety rules. All service

and repair must be carried out by trained personnel.

2) Always select a suitable cutting, abrasive device suitable for use

with this drill.

3) Always shut off the air supply to the drill and depress the trigger

to exhaust air from the feed hose before fitting, adjusting or removing

the device. Remove drill chuck.

4) Always adopt a firm footing and/or position and be aware of

torque reaction developed by the drill.

5) Use only correct spare parts.

6) Check hose and fittings regularly for wear. Do not carry the tool

by its hose and ensure that the hand is remote from the on/off valve

(trigger) when carrying the tool with air supply connected.

7) Do not exceed maximum recommended air pressure. Avoid low

air pressures as this will allow the drill to stall more easily and develop

torque reaction.

8) Use safety equipment as recommended.

9) The tool is not electrically insulated. Do not use where there is a

possibility of coming into contact with live electricity, gas pipes, water

pipes, etc. Check the area of operation before performing the

operation.

10) Take care against entanglement of moving parts of the tool with

clothing, ties, hair, cleaning rags, etc. This will cause the body to be

moved towards the work process and can be very dangerous.

11) Do not attempt to hold or guide the drill chuck when the tool is

running. Keep hands clear of the drilling process.

12) Use only compressed air at recommended conditions.

13) Do not attempt to fit attachments, i.e. for sawing, hedge cutting,

grinding, chain sawing, etc.

14) If the tool appears to malfunction remove from use immediately

and arrange for service and repair.

15) If an additional side handle is fitted to the tool ensure that it is

correctly positioned and fixed securely.

16) If the drill is used with a balancer or other suspension device

ensure that it is fixed securely.