3

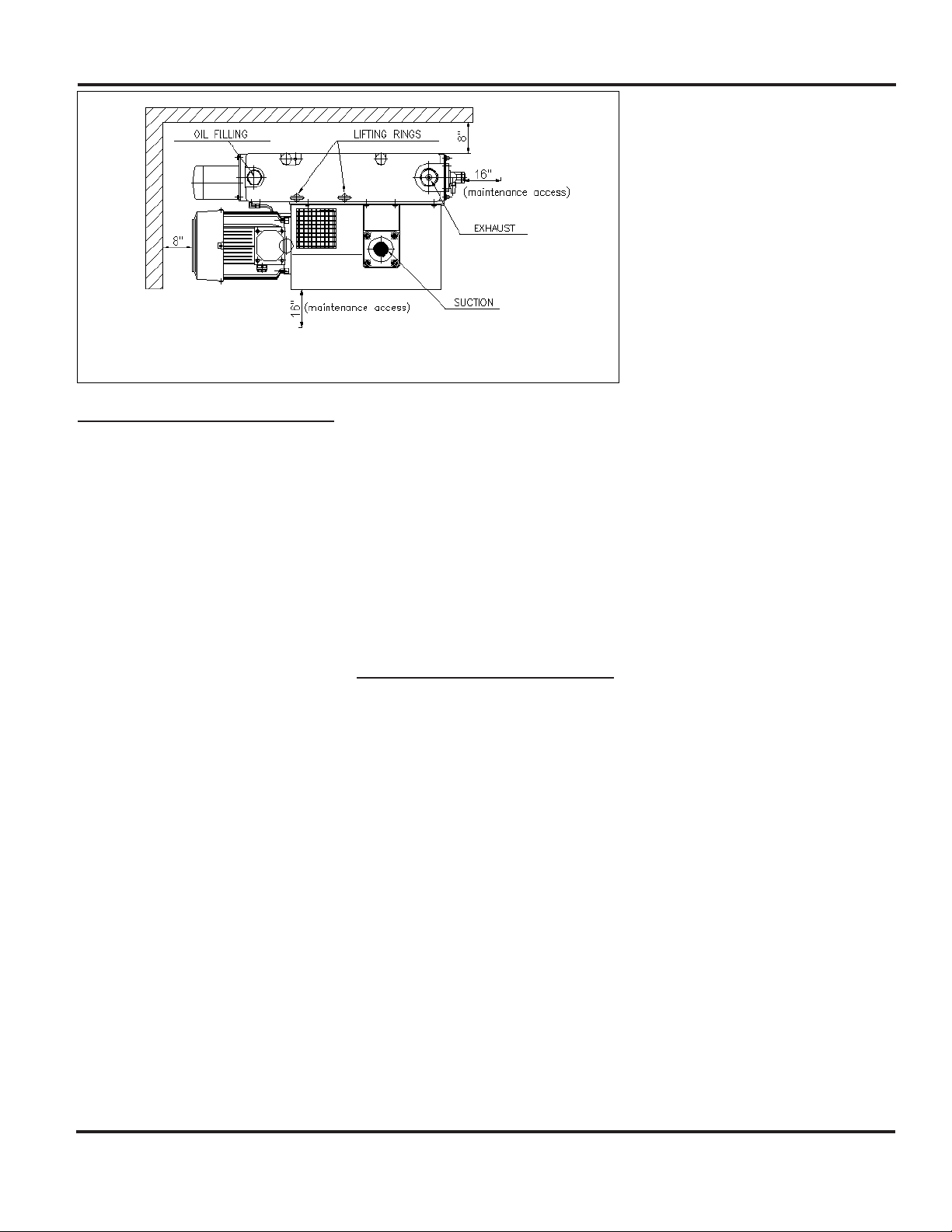

Installation (Cont.)

Place equipment as close to the work

area as possible to minimize piping

runs.

Each pump has rubber mounts to

reduce the vibrations transmitted to

the vacuum system. A flexible hose or

flexible connector should be used for

installation between the collection

tank and the pump intake.

INLET FILTRATION (available

separately)

Inlet filtration is required to prevent

solid particles from entering the vacu-

um pump. Powerex offers both paper

and polyester inline filters to 10

micron, which assure 99% particulate

free air. Certain applications such as

the pumping of solvents, alkaline solu-

tions or corrosive vapors may require

an additional carbon filter.

WIRING

Refer to the general safety manual. All

electrical hook-ups must be performed

by a qualified electrician. Installations

must be in accordance with local and

national electrical codes. Use solderless

terminals to connect the electrical

power source.

PIPING

Refer to the general safety manual.

1. Never use any piping, which is

smaller than the pump or tank con-

nection.

2. Make sure the piping is properly

placed to reach the pump connec-

tions. Ensure that the piping is not

strained or twisted during assembly

or after final hookup.

3. Anchor piping supports separately

from the pump to reduce noise and

vibration.

4. Install flexible hose or properly

designed bends at the vacuum

pump inlet and outlet to avoid

stresses caused by vibration and/or

temperature changes.

Operation

BEFORE STARTUP

1. Make sure all safety warnings,

labels and instructions have been

read and understood before contin-

uing.

2. Remove any shipping materials,

brackets, etc.

3. Confirm electric power source and

ground have been firmly connected.

4. Be sure all vacuum and/or pressure

connections are tight.

5. Ensure all fuses, circuit breakers, etc,

are properly sized.

6. Maker sure an inlet filter is present

and properly installed.

7. Close the tank drain valve.

8. Verify the pump has the proper oil

level.

9. Visually inspect the rotation of the

vacuum pump. If the rotation is

incorrect, have a qualified electri-

cian correct the motor wiring.

STARTUP AND OPERATION

1. Follow all procedures under

“Before Startup” before attempt-

ing to operate the vacuum pumps.

2. Switch on the electrical power

source and apply power to the sys-

tem.

3. Open the tank inlet valve complete-

ly.

4. Check for excessive vibration,

unusual noise or leaks during opera-

tion.

5. Close the tank inlet valve complete-

ly.

6. Check the vacuum gage to insure

that the designated vacuum setting

is reached.

Switch the power breaker to OFF if the

vacuum pump is not going to be used

right away. If the vacuum pump is

going to be out of use for 3 months or

more, see “Long Term Shutdown”

LUBRICATION

Check lubricating oil level before each

use. Refill as necessary using only

Powerex recommended oil. See

Maintenance section, Oil Change for

listing.

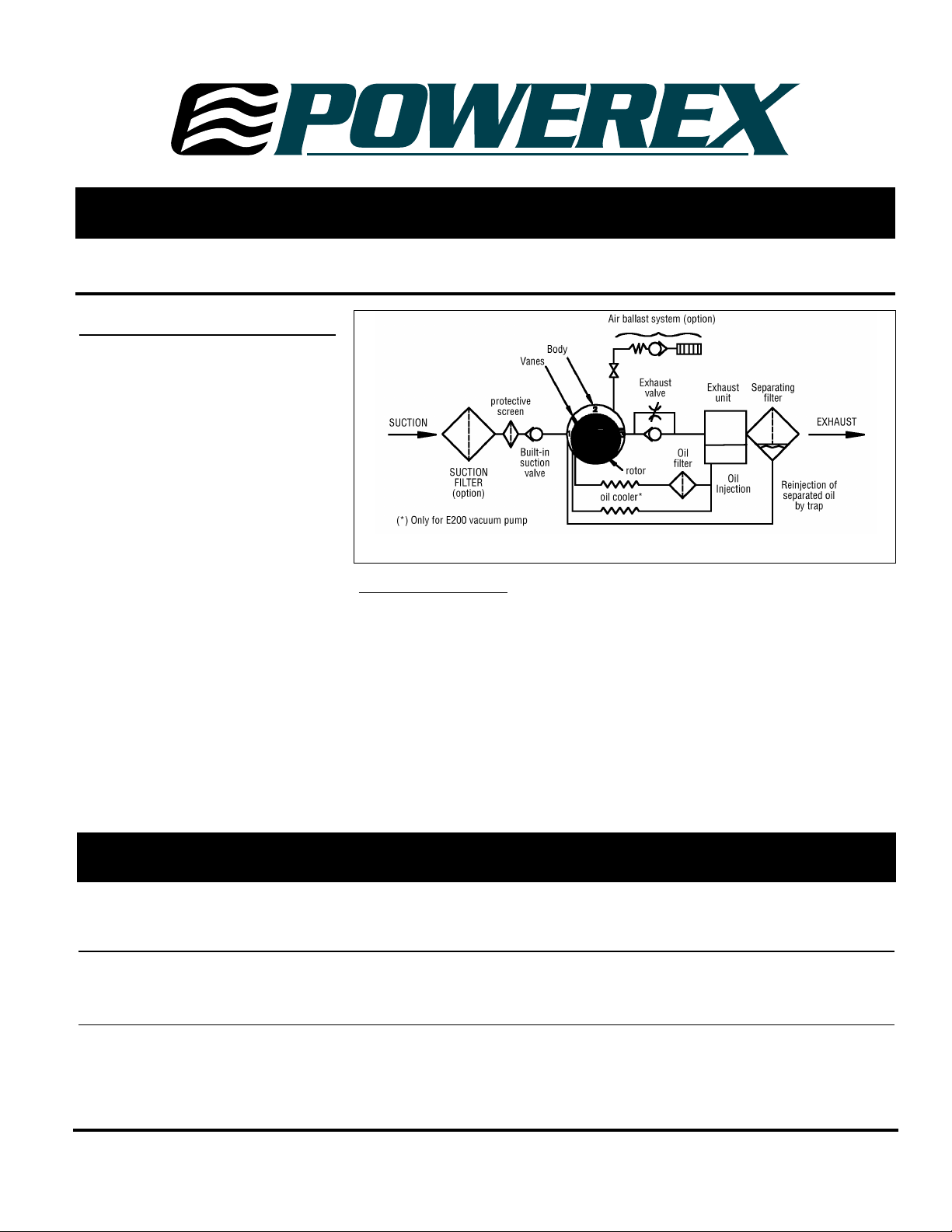

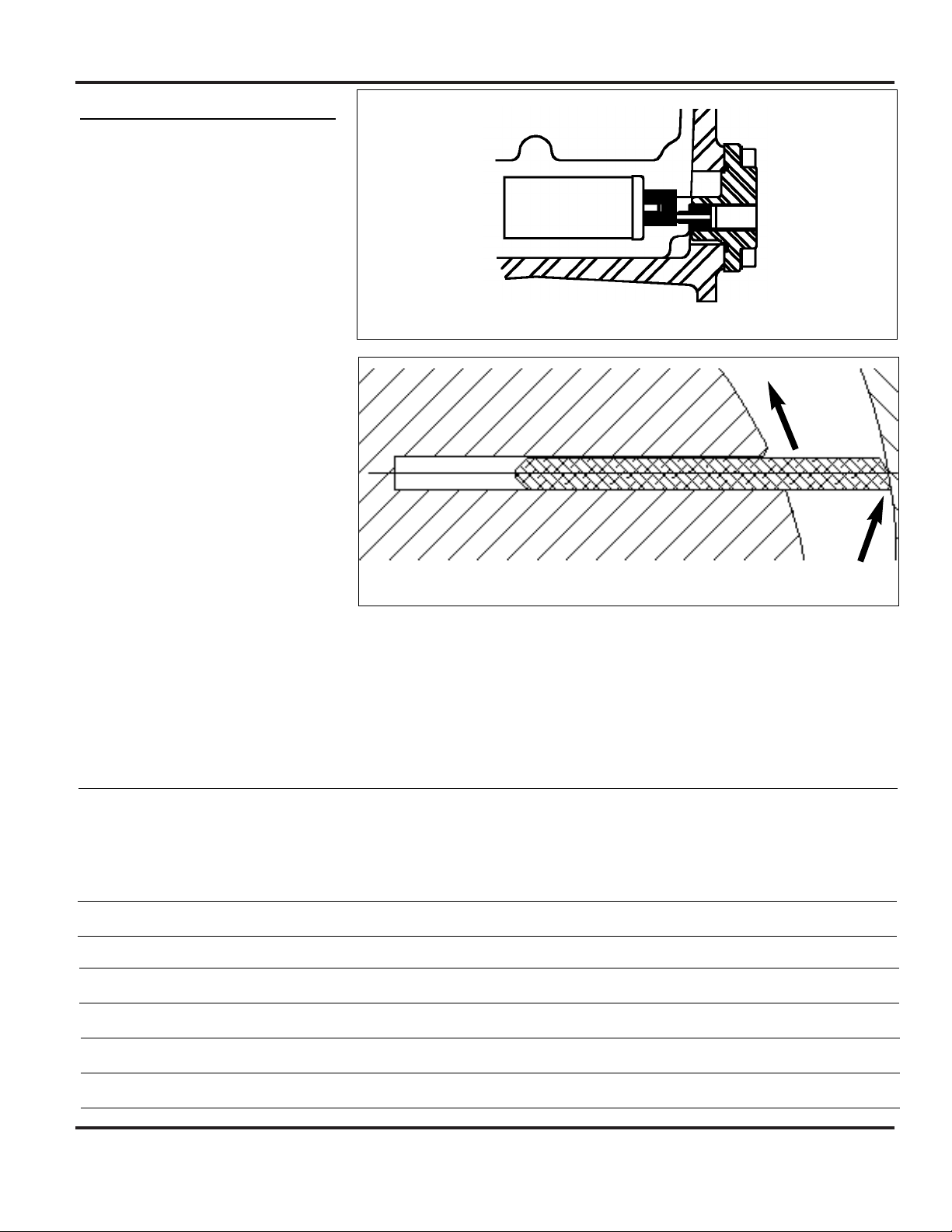

GAS BALLAST

A gas ballast device is provided on all

pumps to rid water emulsion in the

lubrication oil. The gas ballast is a quar-

ter turn ball valve located under the

metal shroud directly behind the intake

flange. To access the gas ballast valve,

turn the pump to OFF, remove the two

screws holding the small access plate in

place and remove the plate, open or

close the gas ballast valve as needed,

reinstall the plate, turn the pump to

ON.

Before using the gas ballast, allow the

pump to reach normal operating tem-

perature by running without load for

approximately 10 minutes. Open the

gas ballast valve (see procedure in pre-

ceding paragraph). Remove condensate

from the lubricating oil by operating

the vacuum pump for 30 minutes with

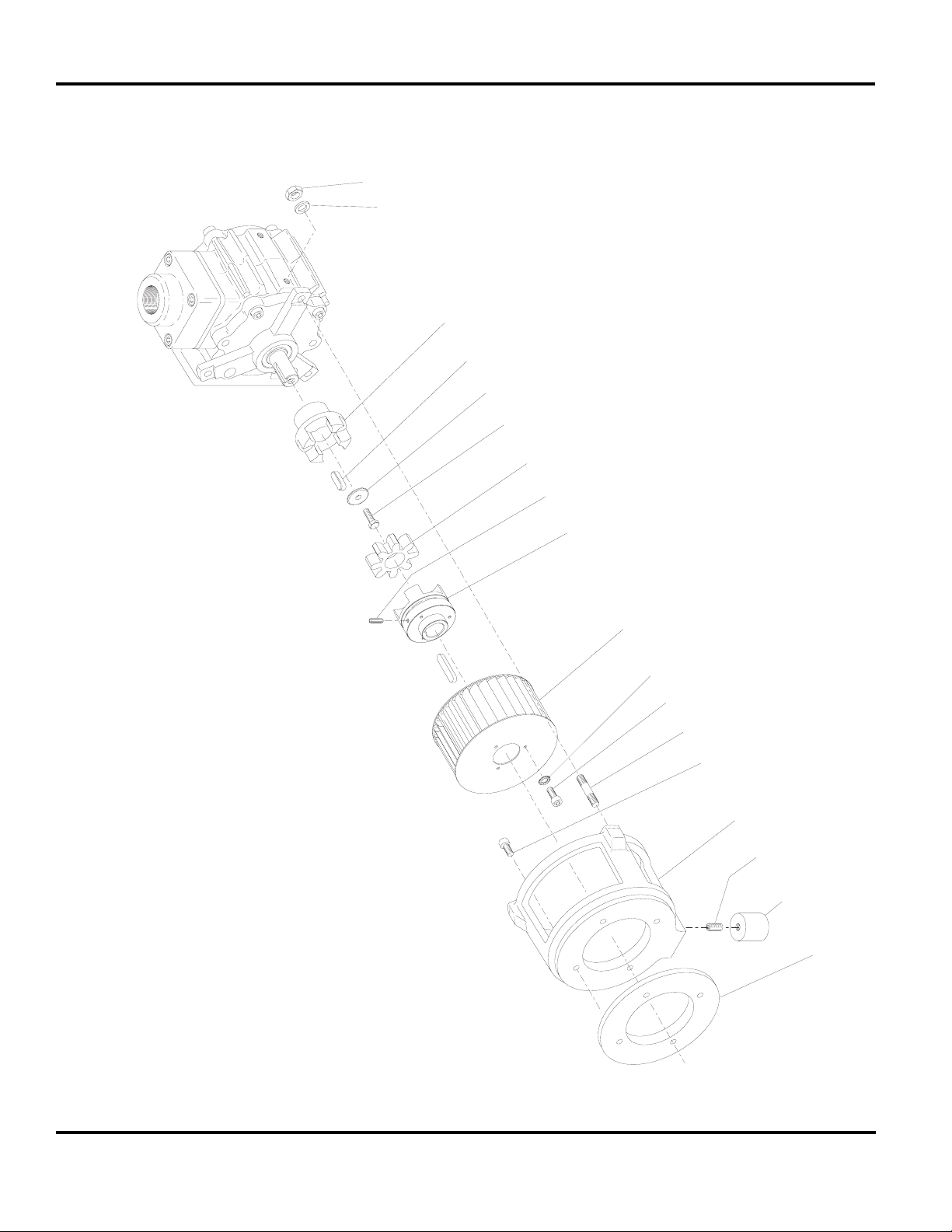

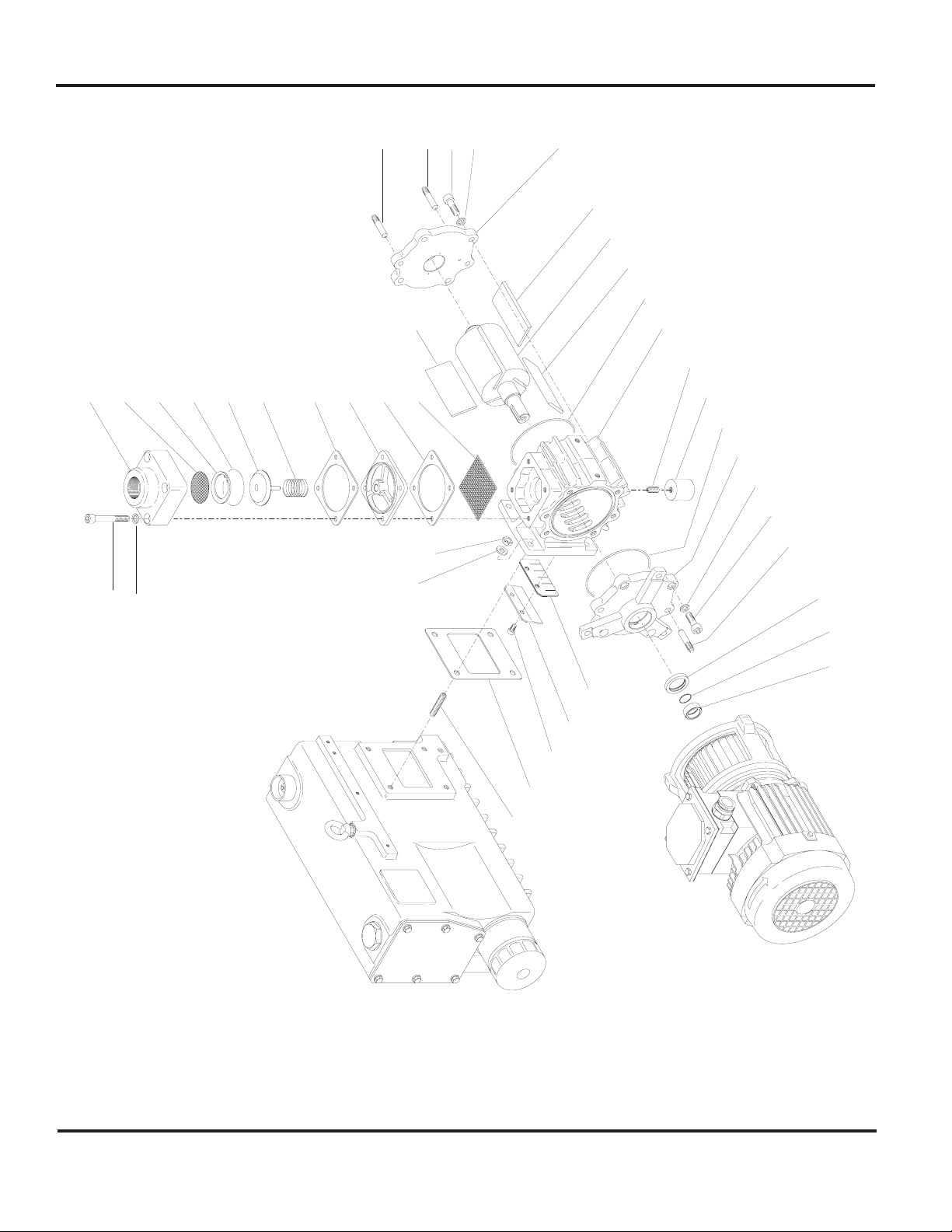

Rotary Vane Vacuum Pumps

Figure 3 - Installation