e3nmdlCsm-rev0712

www.versamatic.com Model E2 Non-Metallic Bolted • 8

Troubleshooting Guide

Symptom: Potential Cause(s): Recommendation(s):

Pump Cycles Once Deadhead(systempressuremeetsorexceedsair

supply pressure).

Increasetheinletairpressuretothepump.Pumpisdesignedfor1:1pressureratio

(Doesnotapplytohighpressure2:1units).

Air valve or intermediate gaskets installed incorrectly. Installgasketswithholesproperlyaligned.

Bent or missing actuator plunger. Remove pilot valve and inspect actuator plungers.

Pump Will Not Operate

/ Cycle

Pumpisoverlubricated. Setlubricatoronlowestpossiblesettingorremove.Unitsaredesignedforlube

Lackofair(linesize,PSI,CFM). Checktheairlinesizeandlength,compressorcapacity(HPvs.cfmrequired).

Check air distribution system. Disassembleandinspectmainairdistributionvalve,pilotvalveandpilotvalveactuators.

Dischargelineisblockedorcloggedmanifolds. Check for inadvertently closed discharge line valves. Clean discharge manifolds/piping.

Deadhead(systempressuremeetsorexceedsair

supply pressure).

Increasetheinletairpressuretothepump.Pumpisdesignedfor1:1pressureratio

(Doesnotapplytohighpressure2:1units).

Blockedairexhaustmufer. Removemuferscreen,cleanorde-ice,andre-install.

Pumpeduidinairexhaustmufer. Disassemblepumpchambers.Inspectfordiaphragmruptureorloosediaphragm

Pumpchamberisblocked. Disassembleandinspectwettedchambers.Removeorushanyobstructions.

Pump Cycles and Will

Not Prime or No Flow

Cavitation on suction side. Check suction condition (move pump closer to product).

Check valve obstructed. Valve ball(s) not seating

properly or sticking.

Disassemblethewetendofthepumpandmanuallydislodgeobstructioninthe

Clean out around valve ball cage and valve seat area. Replace valve ball or valve seat if damaged.

Use heavier valve ball material.

Valve ball(s) missing (pushed into chamber or

manifold).

Wornvalveballorvalveseat.Wornngersinvalveballcage(replacepart).Check

Resistance Guide for compatibility.

Valve ball(s)/seat(s) damaged or attacked by product. Check Chemical Resistance Guide for compatibility.

Checkvalveand/orseatiswornorneedsadjusting. Inspectcheckvalvesandseatsforwearandpropersetting.Replaceifnecessary.

Suction line is blocked. Removeorushobstruction.Checkandclearallsuctionscreensorstrainers.

Excessivesuctionlift. Forliftsexceeding20’ofliquid,llingthechamberswithliquidwillprimethepump

Suction side air leakage or air in product. Visuallyinspectallsuction-sidegasketsandpipeconnections.

Pumpeduidinairexhaustmufer. Disassemblepumpchambers.Inspectfordiaphragmruptureorloosediaphragm

Pump Cycles Running

Sluggish/Stalling,

Flow Unsatisfactory

Over lubrication. Setlubricatoronlowestpossiblesettingorremove.Unitsaredesignedforlube

Icing. Removemuferscreen,de-ice,andre-install.Installapointofuseairdrier.

Clogged manifolds. Cleanmanifoldstoallowproperairow

Deadhead(systempressuremeetsorexceedsair

supply pressure).

Increasetheinletairpressuretothepump.Pumpisdesignedfor1:1pressureratio

(Doesnotapplytohighpressure2:1units).

Cavitation on suction side. Check suction (move pump closer to product).

Lackofair(linesize,PSI,CFM). Checktheairlinesize,length,compressorcapacity.

Excessivesuctionlift. Forliftsexceeding20’ofliquid,llingthechamberswithliquidwillprimethepump

Airsupplypressureorvolumeexceedssystemhd. Decreaseinletair(press.andvol.)tothepump.Pumpiscavitatingtheuidbyfast

Undersizedsuctionline. Meetorexceedpumpconnections.

Restrictiveorundersizedairline. Install a larger air line and connection.

Suction side air leakage or air in product. Visuallyinspectallsuction-sidegasketsandpipeconnections.

Suction line is blocked. Removeorushobstruction.Checkandclearallsuctionscreensorstrainers.

Pumpeduidinairexhaustmufer. Disassemblepumpchambers.Inspectfordiaphragmruptureorloosediaphragm

Check valve obstructed. Disassemblethewetendofthepumpandmanuallydislodgeobstructioninthe

Checkvalveand/orseatiswornorneedsadjusting. Inspectcheckvalvesandseatsforwearandpropersetting.Replaceifnecessary.

Entrainedairorvaporlockinchamber(s). Purgechambersthroughtappedchamberventplugs.Purgingthechambersof

Product Leaking

Through Exhaust

Diaphragmfailure,ordiaphragmplatesloose. Replace diaphragms, check for damage and ensure diaphragm plates are tight.

Diaphragmstretchedaroundcenterholeorboltholes. Checkforexcessiveinletpressureorairpressure.ConsultChemicalResistance

Chartforcompatibility

withproducts,cleaners,temperaturelimitationsandlubrication.

Premature Diaphragm

Failure

Cavitation. Enlargepipediameteronsuctionsideofpump.

Excessiveoodedsuctionpressure. Movepumpclosertoproduct.Raisepump/placepumpontopoftanktoreduce

Install Back pressure device (Tech bulletin 41r). Add accumulation tank or pulsation dampener.

Misapplication(chemical/physicalincompatibility). ConsultChemicalResistanceChartforcompatibilitywithproducts,cleaners,temperature

and lubrication.

Incorrectdiaphragmplatesorplatesonbackwards,

installedincorrectlyorworn.

CheckOperatingManualtocheckforcorrectpartandinstallation.Ensureouter

worntoasharpedge.

Unbalanced Cycling Excessivesuctionlift. Forliftsexceeding20’ofliquid,llingthechamberswithliquidwillprimethepump

Undersizedsuctionline. Meetorexceedpumpconnections.

Pumpeduidinairexhaustmufer. Disassemblepumpchambers.Inspectfordiaphragmruptureorloosediaphragm

Suction side air leakage or air in product. Visuallyinspectallsuction-sidegasketsandpipeconnections.

Check valve obstructed. Disassemblethewetendofthepumpandmanuallydislodgeobstructioninthe

Checkvalveand/orseatiswornorneedsadjusting. Inspectcheckvalvesandseatsforwearandpropersetting.Replaceifnecessary.

Entrainedairorvaporlockinchamber(s). Purgechambersthroughtappedchamberventplugs.

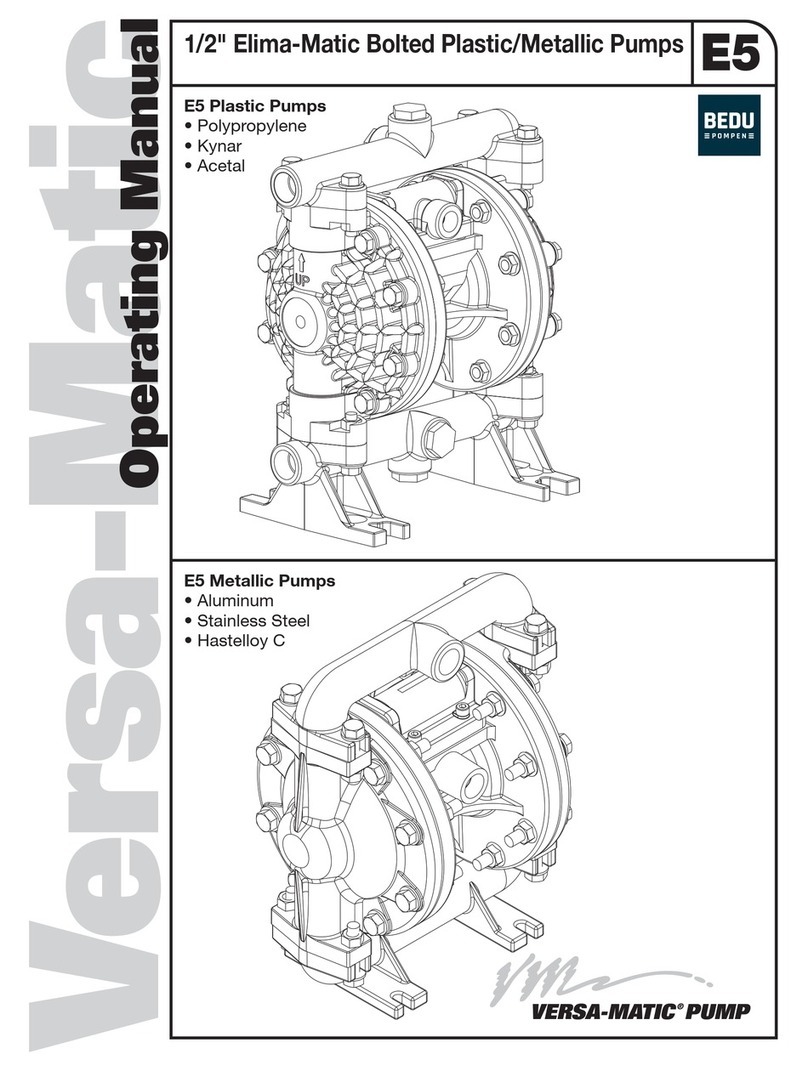

Composite Repair Parts Drawing

**MUFFLER OPTION

*OVERLAY OPTION

General Model Specic

3: EXP VIEW

北京崀润机电技术有限公司