5

Breather

cap

Operation

INITIAL START-UP

1. Pump is shipped with oil. Remove the oil cap

and check pump oil level. Add SAE 30 non-

detergent pump oil (Part #4043), if necessary.

Hand tighten breather cap.

2. Turn pressure relief knob to engine start

position.

3. The engine is shipped without oil. Refer to the

engine manual for oil capacity and viscosity

recommendations.

4. Turn the gasoline line valve to the ON position.

5. For cold engine, move choke lever to full choke

position. To restart a warm engine, move choke

lever to half choke or to RUN position.

6. Start the engine:

A) Using electric start –

Turn the engine switch to the ON position.

Push and hold the START button until the

engine starts.

NOTE: If the engine fails to start after 5

seconds, release the START button and wait

10 seconds before attempting to start again.

Cranking the electric starter for more than 5

seconds continuously can overheat and

damage the starter motor.

Release the START button when the engine

starts.

B) Using recoil start –

Turn the engine witch to the ON position.

Pull the starter grip lightly until you feel

resistance, then pull the starter cord out

briskly and rapidly.

Allow starter cord to return slowly.

7. When engine starts, move choke lever to RUN

position.

8. Once the engine has started, move the pressure

relief knob to the engine run position.

9. CAUTION! Unusual noise or vibration indicates

a problem. Do not continue to operate until you

identify and correct the source of the problem.

10. CAUTION! Do not attach air tools to open end

of the hose until start-up is completed and the

unit checks out OK.

11. Run the unit for 30 minutes, with ball valve open,

to break in pump parts.

12. Close the ball valve to shut off airflow. The

compressor is now ready for use.

13. After 50 hours of operation change the

compressor oil.

WARNING!

Never disconnect threaded joints with pressure in

the tank.

NOTE: Reduce tank pressure below 10 psi, then

drain moisture from tank daily to avoid tank

corrosion. Drain moisture from tank by opening the

drain petcock located at the bottom of the tank.

COMPRESSOR LUBRICATION

CAUTION! Do not operate without lubricant or with

inadequate lubricant. Use of compressor without

lubricant or inadequate lubricant voids all warranties.

Synthetic Lubricants

Synthetic lubricants are recommended after 50-hour

break-in. Compressor life is greatly increased with

the use of synthetic lubricants. CAUTION! If you will

be using synthetic lubricant, all downstream piping

material and system components must be

compatible.

Suitable Viton®, Teflon®, Epoxy (Glass Filled), Oil Resistant

Alkyd, Fluorosilicone, Flourocarbon, Polysulfide, 2-Component

Urethane, Nylon, Delrin®, Celcon®, High Nitrile Rubber (Buna N.

NBR more than 36 Acrylonite), Polyurethane, Polyethylene,

Epichlorohydrin, Polyacrylate, Melamine, Polypropylene, Baked

Phenolics, Epoxy, Modified Alkyds

( ®indicates trademark of DuPont Corporation)

Not Recommended

Neoprene, Natural Rubber, SBR Rubber, Acrylic Paint, Lacquer,

Varnish, Polystyrene, PVC, ABS, Polycarbonite, Cellulose

Acetate, Latex, EPR, Acrylics, Phenoxy, Polysulfones, Styrene

Acrylonitile (San), Butyl

Alternate Lubricants. You may use petroleum-based lubricant

that is premium quality, does not contain detergents, contains

only anti-rust, anti-oxidation, and anti-foam agents as additives,

has a flashpoint of 440°F (227°C) or higher, and has a auto-

ignition point of 650°F (343°C) or higher.

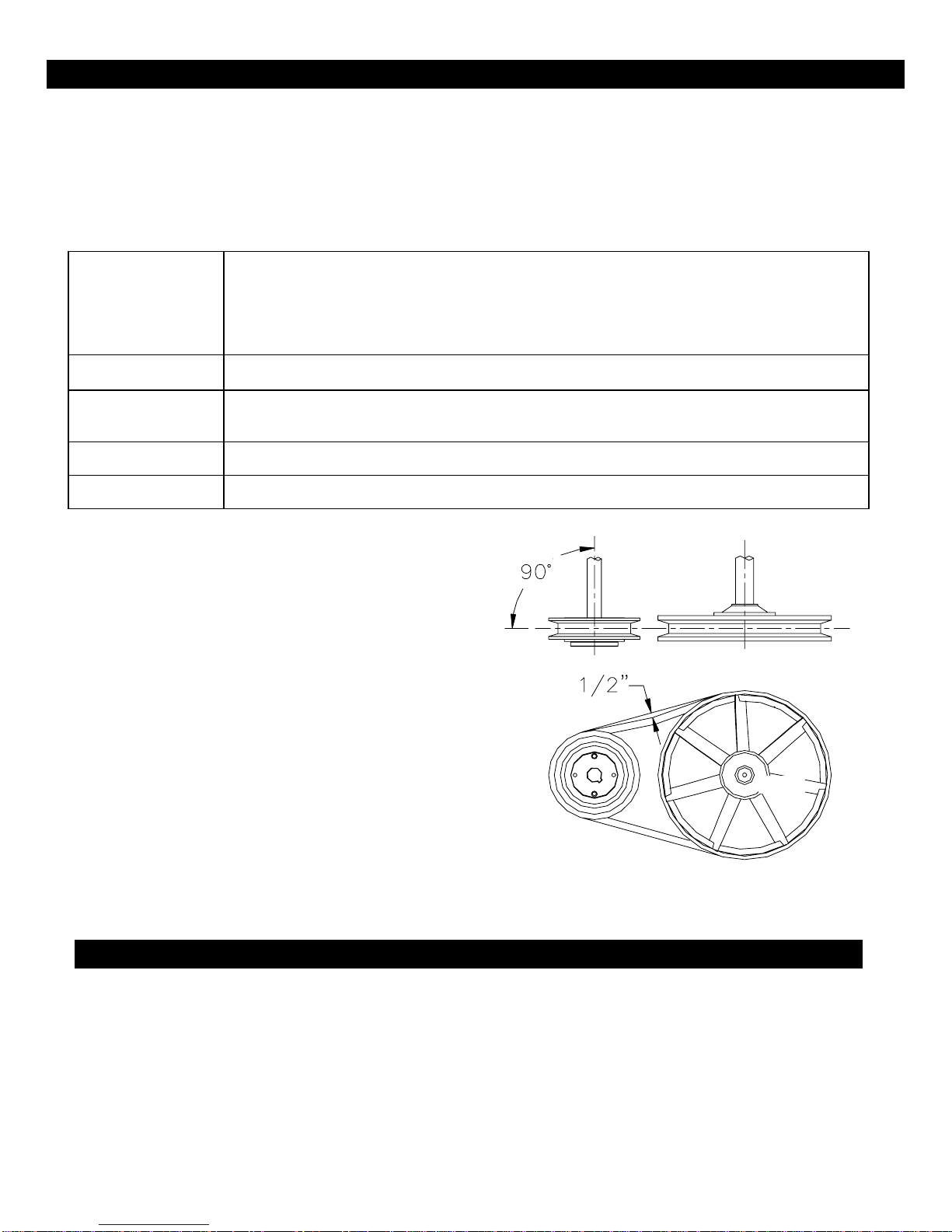

See the petroleum lubricant viscosity table below. The table is

intended as a general guide only. Heavy duty operating conditions

require heavier viscosities. Refer specific operating conditions to

Powerhorse Product Support at 1-866-443-2576

Temperature around

Compressor Viscosity Grade

ISO SAE

Below 40°F (4°C) 60 20

40°F to 80°F

(4°C to 27°C)

100

30

80°F to 100°F

(27°C to 38°C)

150

40

Pump Capacities.

Refer to the following table for crankcase capacity

Item # Crankcase capacity

46851 48 oz

Engine start Engine run