TABLE OF CONTENTS

TABLE OF CONTENTS ............................................... . ................................................. . ................................................. . .................... 2

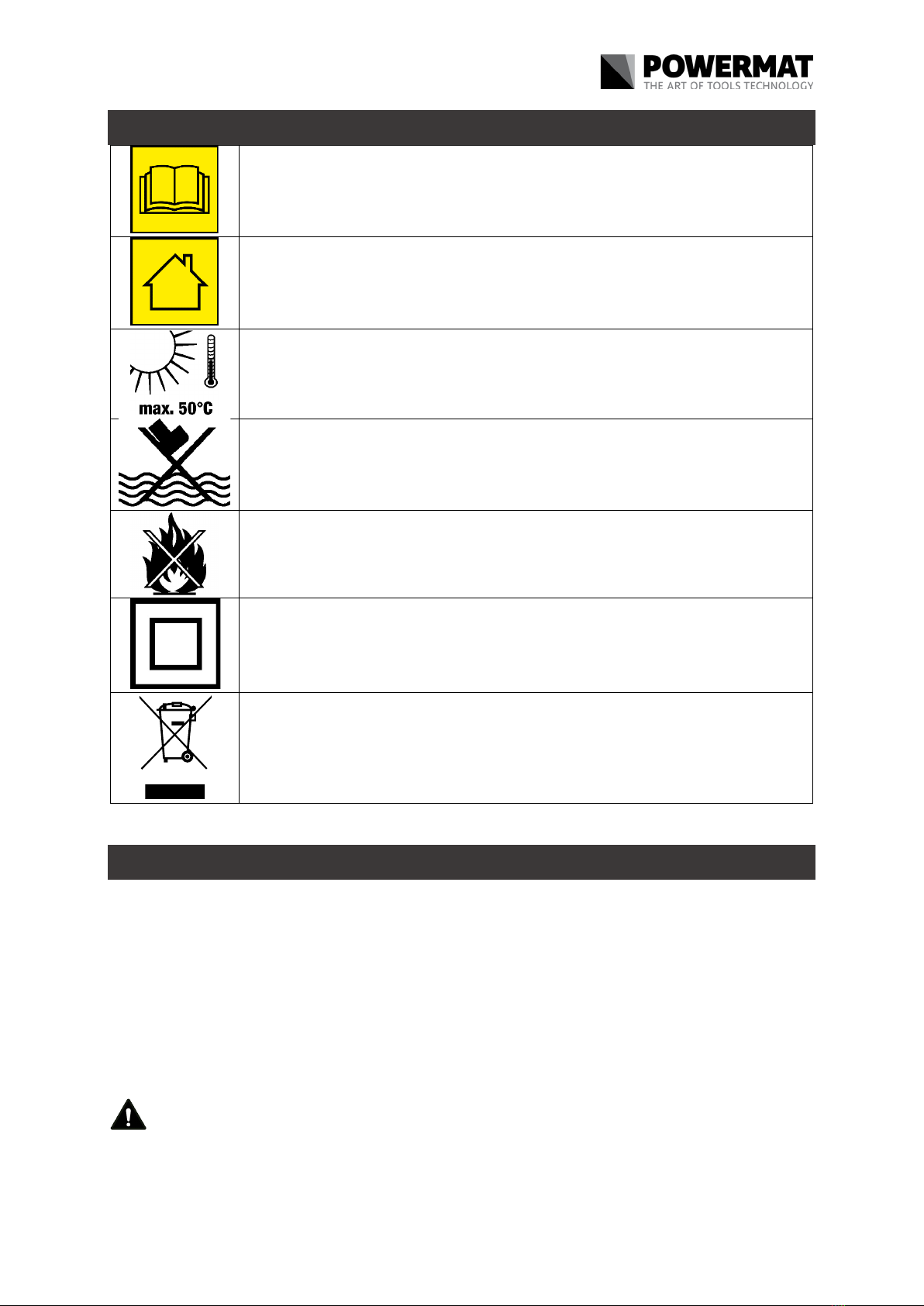

WARNING / INFORMATION SYMBOLS .............................................. .................................................. .................... 3

APPLICATION OF THE DEVICE .............................................. .. ................................................ .. .......................................... 3

TECHNICAL DATA ................................................ .................................................. .................................................. ......... 4

SECURITY ................................................. .................................................. .................................................. ......... 4

General safety rules ............................................... .................................................. .................................................. ................. 4

Concerning working with the sprayer ............................................. . ................................................. . ................................................. . .............. 5

About electrical safety ............................................... .................................................. .................................................. .. 6 For cordless

tools ............................................ .. ................................................ .. ............................................ 7

Concerning the position ............................................... . ................................................. . ................................................. . .............................. 7

Concerning personal security ............................................... .................................................. .................................................. ...... 7

For proper operation ............................................... .................................................. .................................................. ................. 8

Safety rules for contact with chemical plant protection products ......................................... ......................................... 8

Safety rules for the battery and the electrical system ......................................... .. ................................................ .. ......... 9

Protective clothing ................................................ .................................................. .................................................. ..................................... 10

Transporting the sprayer ............................................... . ................................................. . ................................................. . .......................... 10

Safety rules before starting and during work ........................................... .................................................. ................ 10

Safety rules for the maintenance and repair of the device ........................................ ... ............................................... ... ............. 11

DEVICE DESCRIPTION ................................................ .................................................. .................................................. ........ 12

PRELIMINARY STEPS ................................................ .................................................. .................................................. ..13

HOW TO USE THE DEVICE ............................................. ... ............................................... ... ............................................... ... 13

Battery charging ................................................ .................................................. .................................................. ......................... 13

Installing the battery ............................................... . ................................................. . ................................................. . .............................. 13

Removing the battery ............................................... . ................................................. . ................................................. . .......................... 14

Installation of accessories ............................................... . ................................................. . ................................................. . ................................ 14

Preparing the spray liquid, filling the liquid tank ......................................... .. ................................................ ... ........................ 15

Filling the liquid tank .............................................. . ................................................. . ................................................. . ........................................... 15

Recommended volumes of the working liquid ............................................ .. ................................................ .. ................................................ ... ................................... 15

Preparation of the working liquid ............................................. .. ................................................ .. ................................................ ... ........................................ 15

Identification of the chemicals used ............................................. . ................................................. . ................................................. . ............ 16

Operation of the cordless knapsack sprayer ............................................ .. ................................................ .. ............................... 16

Application of the sprayer .............................................. .. ................................................ .. ................................................ ... ........................................... 16

Outlet nozzle, fluid flow ............................................. .................................................. .................................................. ....................................... 16

WORKING WITH SPRAYER ............................................... . ................................................. . ............................................... 17

End of spraying, consumption of spray liquid in the tank ....................................... ... ............................................... ... .............................. 18

SPRAYER CARE AND MAINTENANCE .............................................. .................................................. ................... 19

General principles of operation and maintenance of the pressure sprayer ........................................ ... ............................................... ... ................ 19

Checking the spray liquid output ............................................. . ................................................. . ................................................. . ...... 19

Emptying and cleaning the spray liquid tank ........................................... . ................................................. . ...................................... 19

Storing the device ............................................... . ................................................. . ................................................. . ................... twenty

SERVICE ................................................. .................................................. .................................................. ....................... twenty

DISPOSAL OF USED DEVICES .............................................. . ................................................. . .................................. twenty

MANUFACTURER'S DATE ................................................ .................................................. .................................................. .... 21

DECLARATION OF CONFORMITY ............................................... . ................................................. . .............................................. 22

2