2

TABLE OF CONTENTS

TABLE OF CONTENTS ................................................ .................................................. ............................................ 2

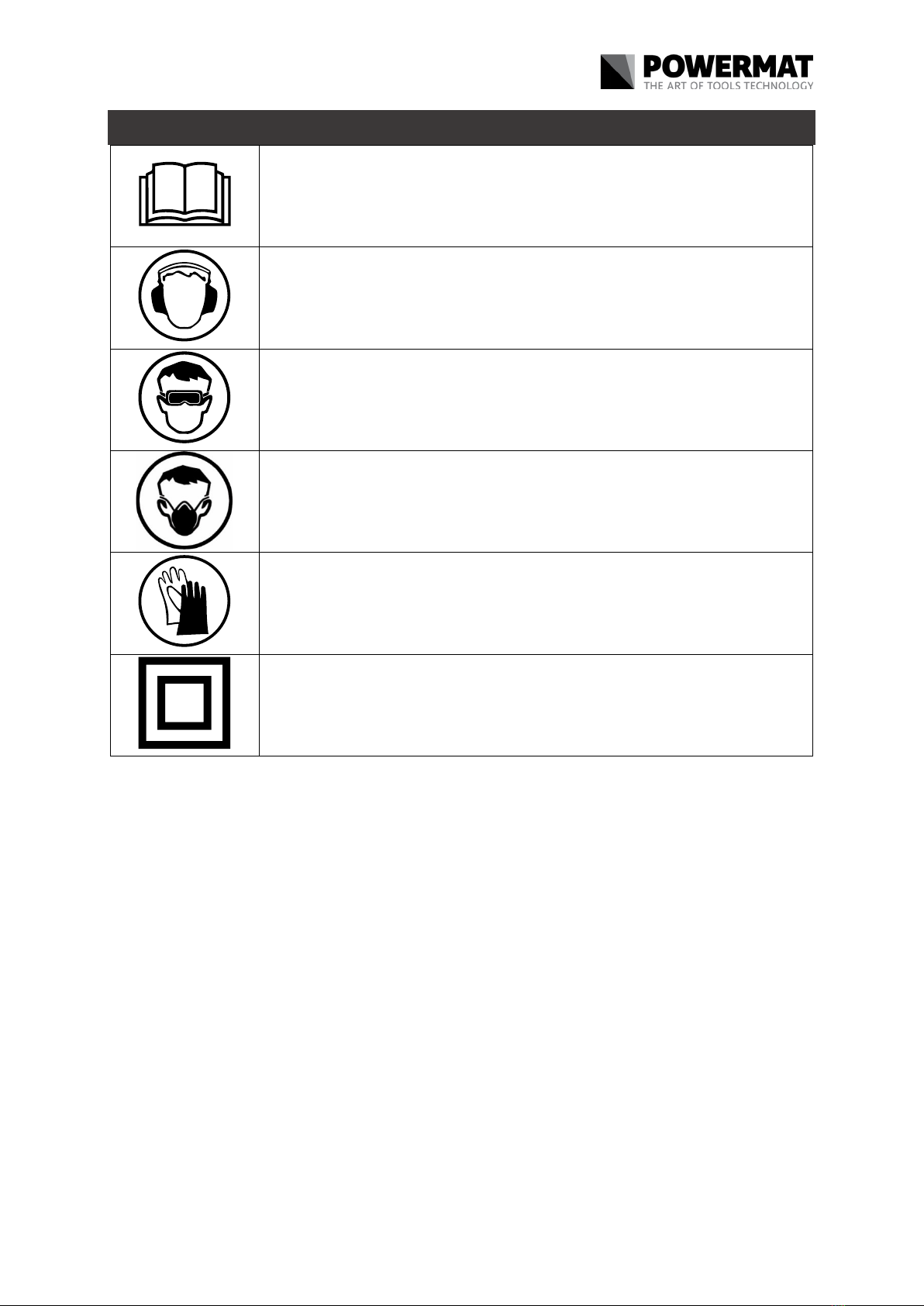

SYMBOLS WARNING / INFORMATION .............................................. ........................................... 4

PURPOSE OF THE DEVICE ................................................ .................................................. ............... 5

SAFETY RULES ................................................ .................................................. .................... 5

General safety ............................................... .................................................. ... 5

Protection against electric shock .............................................. ............................................ 5

Protection from causing a fire or explosion ............................................ .......................... 6

In order to minimize the risk of skin penetration ............................................ .................................. 7

In order to minimize the risk of injury ............................................. ............................................ 7

Risk of damage to equipment ............................................... .................................................. ............... 8

The risk associated with aluminum components ............................................. ...................................... 8

Risks associated with moving parts tools ............................................ ........................... 8

Risks associated with the inhalation of toxic liquids or gases .......................................... ....... 9

The rules require special attention .............................................. ................................................. 9

Safety guidelines Airless spray system .................................... 10

Safety ................................................ .................................................. ................. 10

DESCRIPTION OF THE DEVICE ................................................ .................................................. ............................... 11

OPERATING UNIT painting ............................................... .................................................. .. 12

Connecting the device ................................................ .................................................. ................... 12

Lock the gun to paint .............................................. ............................................... 13

Connecting the unit ................................................ .................................................. ...................... 14

The procedure for removing excess pressure .............................................. ............................................ 14

Cleaning and filling of the sprayer .............................................. ............................................ 15

Cleaning and filling spray hose ............................................. ........................................ 16

TROUBLESHOOTING ................................................ .................................................. ......... 19

Disconnecting the spray nozzle ............................................... .................................................. .......... 19

Filter cleaning spray gun .............................................. .......................................... 20

Cleaning the filter inlet ............................................... .................................................. ........... 21

MAINTENANCE AND REPAIR ............................................... .................................................. ................. 21

Important tips on cleaning .............................................. ........................................... 22

Cleaning the latex material .............................................. ............................................ 22

Cleaning the oil materials .............................................. ............................................... 25

Clean the suction set ............................................... .................................................. ........... 26

STORAGE ................................................. .................................................. ............................ 27

Short-term storage (up to 16 hours) ........................................... ............................... 27