TABLE OF CONTENTS

USER MANUAL................................................ .................................................. ............................ 1

WARNING / INFORMATION SYMBOLS .............................................. ........................................... 3

PURPOSE OF THE DEVICE ................................................ .................................................. ............... 3

MAIN FEATURES OF THE DEVICE ............................................... .................................................. ............... 3

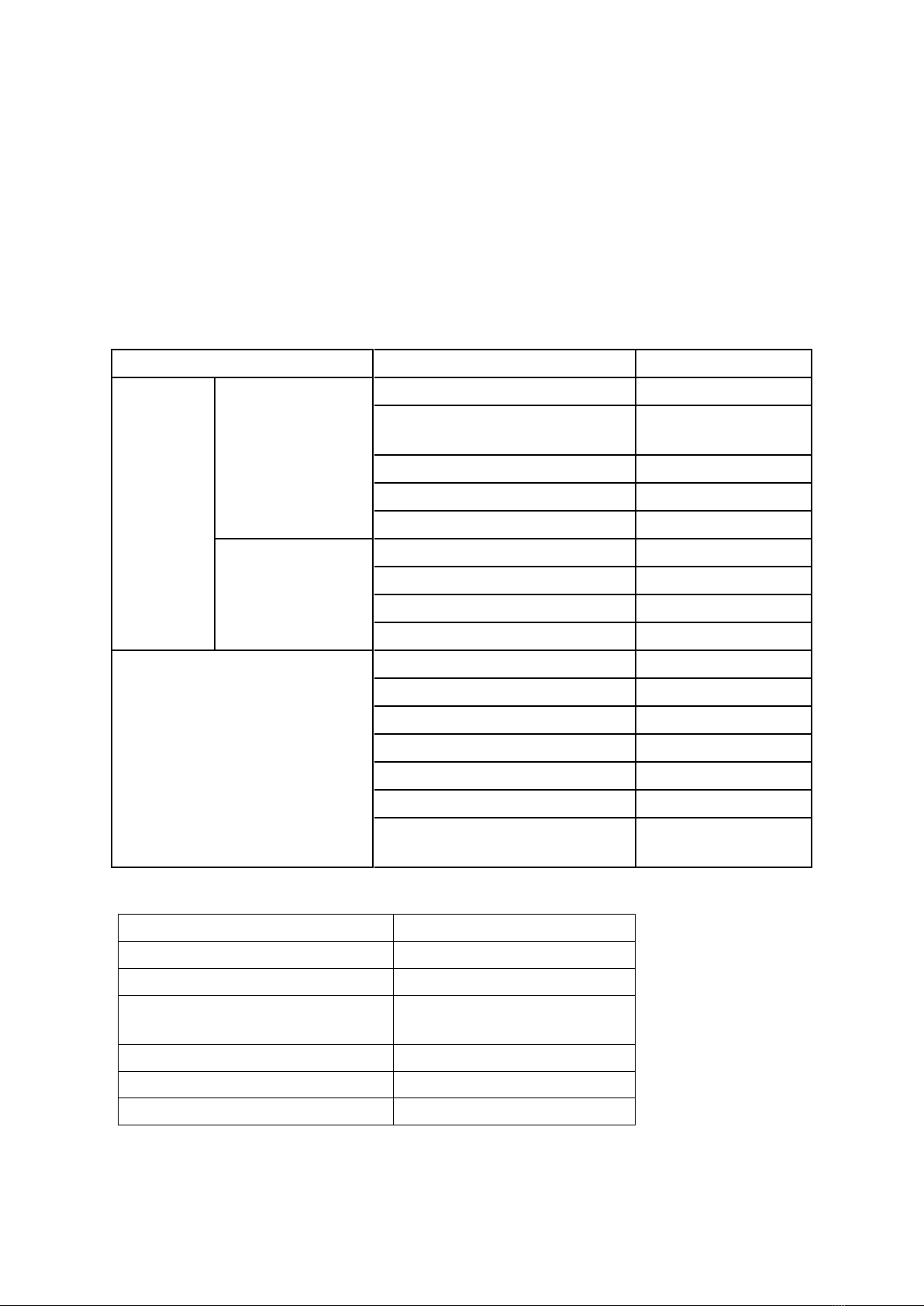

TECHNICAL DATA ................................................ .................................................. ................................ 4

ASSEMBLY ................................................. .................................................. ............................................... 4

Sprayer mode ................................................ .................................................. ............................. 4

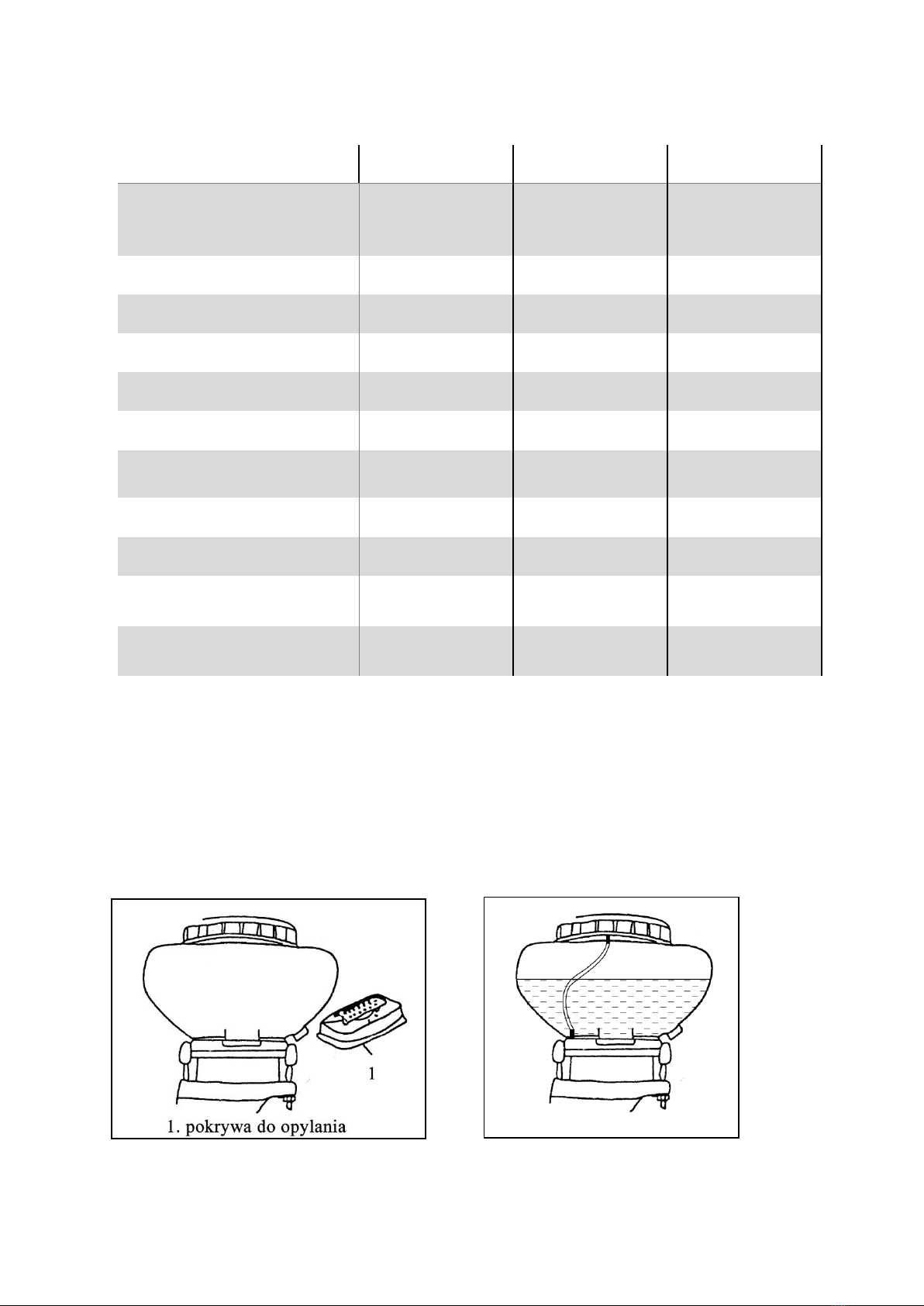

Dusting (spreading) mode ............................................. .................................................. ................. 5

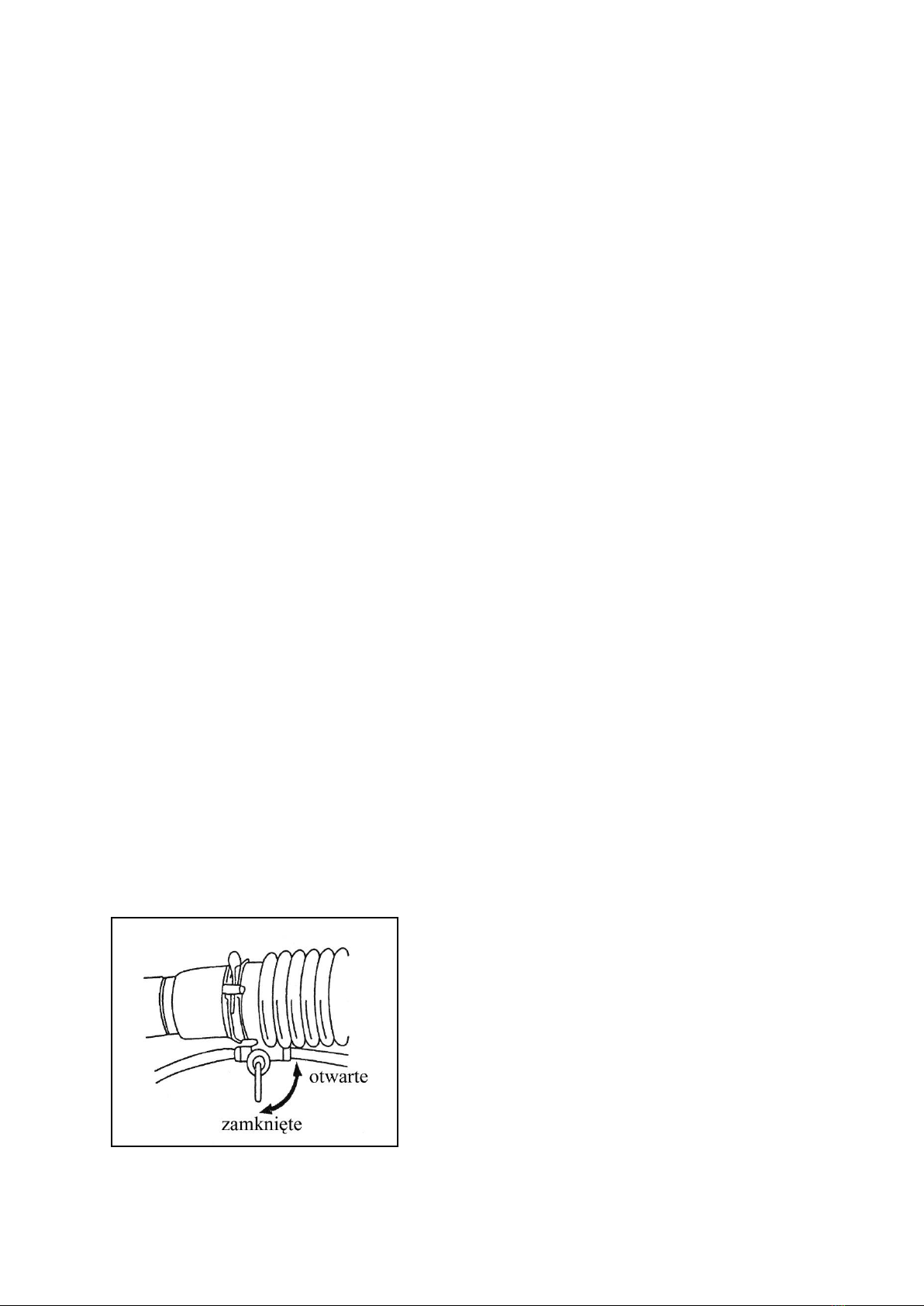

Antistatic installation ................................................ .................................................. ......... 6

USE ................................................. .................................................. ..................................... 6

Adding fuel ................................................ .................................................. .............................. 6

Adding chemicals ................................................ .................................................. ................... 6

Starting a cold engine ............................................... .................................................. ................... 7

Starting a warm engine ............................................... .................................................. ............ 8

Setting the rotation speed ............................................... .................................................. .......... 8

Stopping the engine ................................................ .................................................. ....................... 8

SPRAYING / SPRAYING (SPREADING) ............................................. ................................................ 8

SAFETY RULES ................................................ .................................................. ................... 9

SOLVING COMMON PROBLEMS ............................................... ........................................ 10

Maintenance and preparation for longer storage ............................................ ......................... 11

DISPOSAL OF USED DEVICES ............................................... .................................................. ....... 12

MANUFACTURER'S DATA ................................................ .................................................. ............................ 13

DECLARATION OF CONFORMITY................................................ .................................................. .................... 13

2