2 a brand of ICD, Inc.

• Page 2: Table of Contents for installation manual HCPMAN0001_R3 (2018-03-05)

• Page 3: Table of Contents (cont.)

• Page 4: Product Overview

• Page 5: Inspection & Environmental Conditions

• Page 6: Electrical Ratings for 450 & 600 amp Models

• Page 7: Electrical Ratings for 900 & 1200 amp Models

• Page 8: Equipment Installation

• Page 9: Mounting Orientation

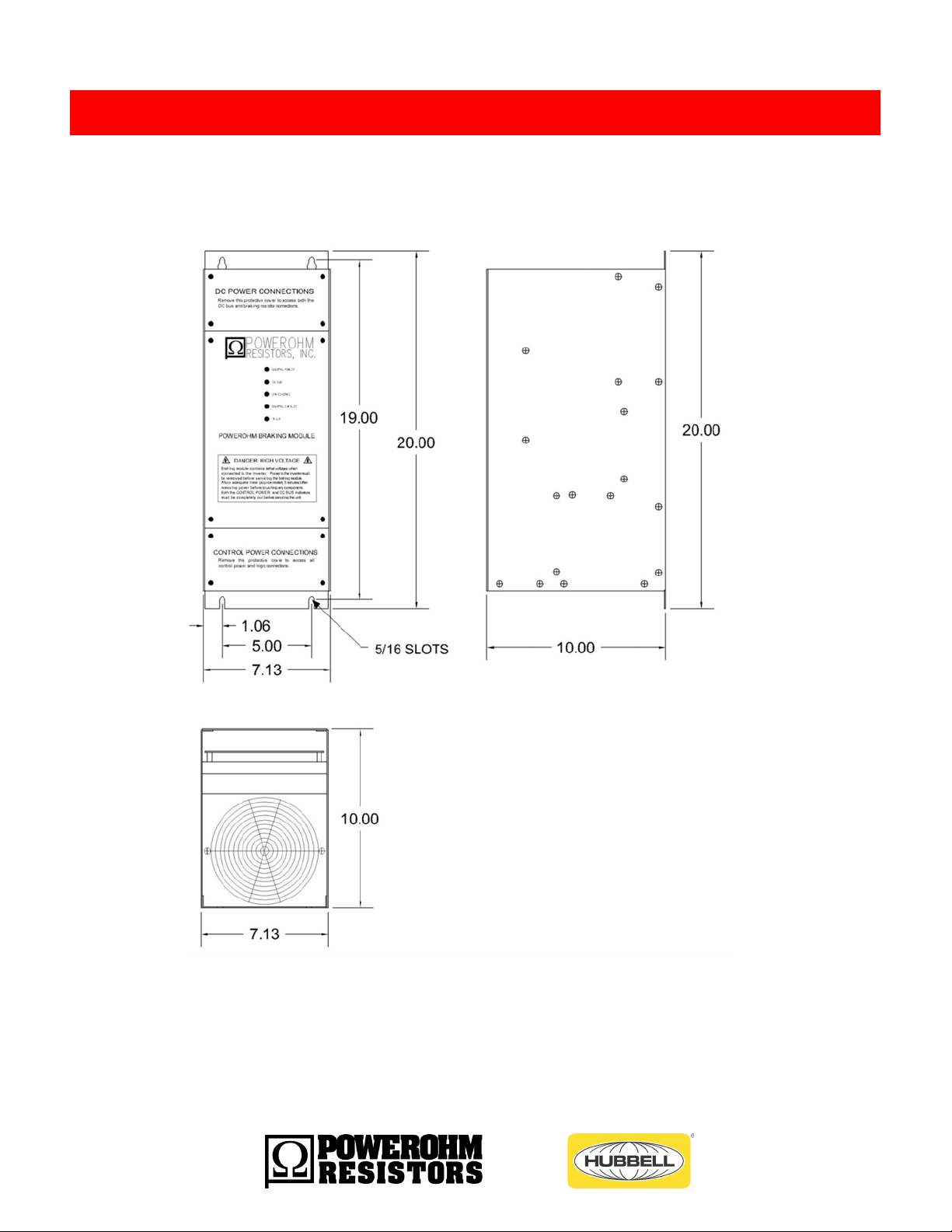

• Page 10: Dimensions and Weight for 450 & 600 amp Models

• Page 11: Dimensions and Weight for 900 & 1200 amp Models

• Page 12: Wiring Recommendations

• Page 13: Wire Sizing

• Page 14: Power Connections for 450 & 600 amp models

• Page 15: Power Connections for 900 & 1200 amp models

• Page 16: TB3 115vac Enable & Control Connection Specs

• Page 17: TB3 24vdc Enable & Control Connection Specs

• Page 18: TB2 I/O Input Command Connections Specs

• Page 19: TB2 I/O Input Commands Basic Schematic

• Page 20: TB2 I/O Input Commands Detailed Descriptions

• Page 21: TB1 I/O Output Status Signal Connection Specs

• Page 22: TB1 I/O Output Status Basic Schematic

• Page 23: TB1 I/O Output Status Detailed Descriptions

• Page 24: TB1 I/O Output Status Detailed Descriptions

• Page 25: Master / Slave Fiber Optic Connections

• Page 26: Module Set Up

• Page 27: System Integration - Drive DC Bus Connections

• Page 28: System Integration – Power Connections for single Module

• Page 29: System Integration – Power Connections for 2 Modules

• Page 30: System Integration – Power Connections for 3 or more Modules

• Page 31: System Integration – Control Connections for 2 Module

• Page 32: System Integration – Control Connections for 3 or more Modules