PowerPlus Energy Pty Ltd 12/05/2023 | V3.6 page 7 of 20

3.4 CHARGING AND DISCHARGING

The battery should be charged and discharged within

the operating temperature windows as outlined within

thespecicationsandasindicatedintheCharge

Discharge table below “Connected PCE Programming

Requirements”. All currents are maximum for each

battery, and should be taken into consideration when

multiple devices are charging the battery.

3.4.1. PRIMARY CHARGING SOURCE

APrimaryChargingSourceshouldbeidentiedinthe

system and programmed to charge the batteries as

outlined in the table below. A primary charging source,

is the charging device that will be used to charge the

batteryfor75%ofthetime(chargeenergy)orhigher.

3.4.2. SECONDARY CHARGING SOURCE

A Secondary Charging Source can also be used, the

preference is to also have these devices programmed

to the charging settings in the table “Connected PCE

Programming Requirements”. However if this is not

possible, they can be used as long at the output voltage

does not exceed the upper voltage of the Operational

Voltage Window of the battery, does not exceed the Max

Charge Current, and does not account for more than

25%ofthecharging(energy)ofthebattery.

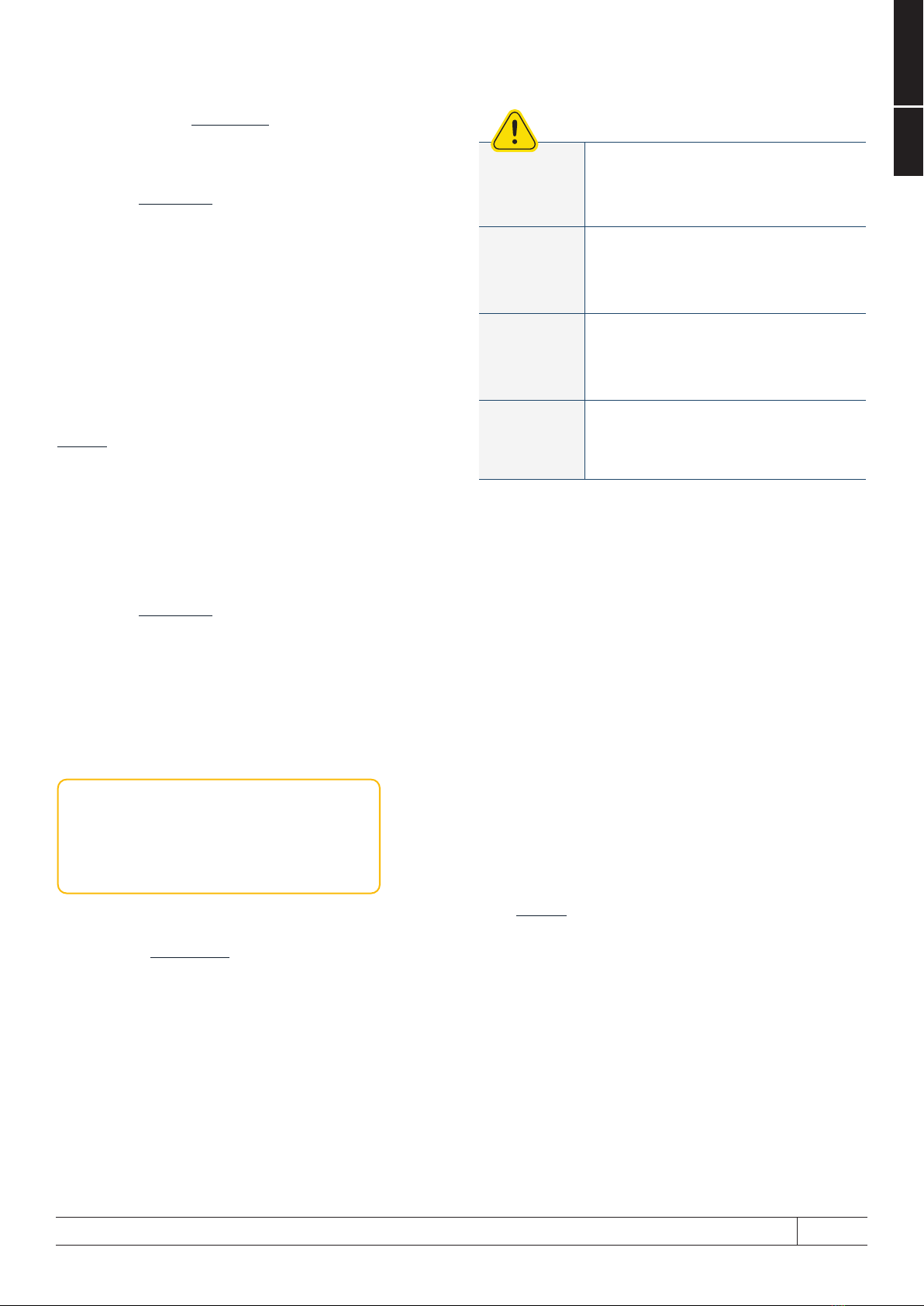

3.4.4. BATTERY CHARGING REQUIREMENTS PCE FOR P SERIES

Example

Primary Charging Source = Solar PV will be used to

perform 75% of charging and will be programmed as

per below table.

Secondary Charging Source = Wind Turbine will be

used to supply approximately 25% of the charging,

however can not have the voltage adjusted as per the

specicchargingvoltagesasspeciedinthetable

“Connected PCE Programming Requirements”, and

will not exceed the Operational Voltage Window or Max

Charge Current/Power of the battery.

3.4.3. CALIBRATION TO 100%

Calibrationto100%every7days(minimum)isrequired

to perform a cell balance maintenance charge. Cell

balancing allows the BMS to equalise the battery cells

to limit battery capacity slip and ensures battery will

accept the charge voltage correctly.

Calibration to 100% is achieved by:

Chargebatteriesatspecied“ContinuousCharge

Voltage”andnogreaterthanthespeciedMaximum

Charge Current.

Battery is considered full after battery is absorbing less

than 1% of maximum charge current after being held at

speciedchargevoltagefor30minutesminimum.

IfPowerPlusEnergyhasreleasedCustomCharge

Settings for your connected PCE, then these

instructions can be followed instead.

3. Product Information

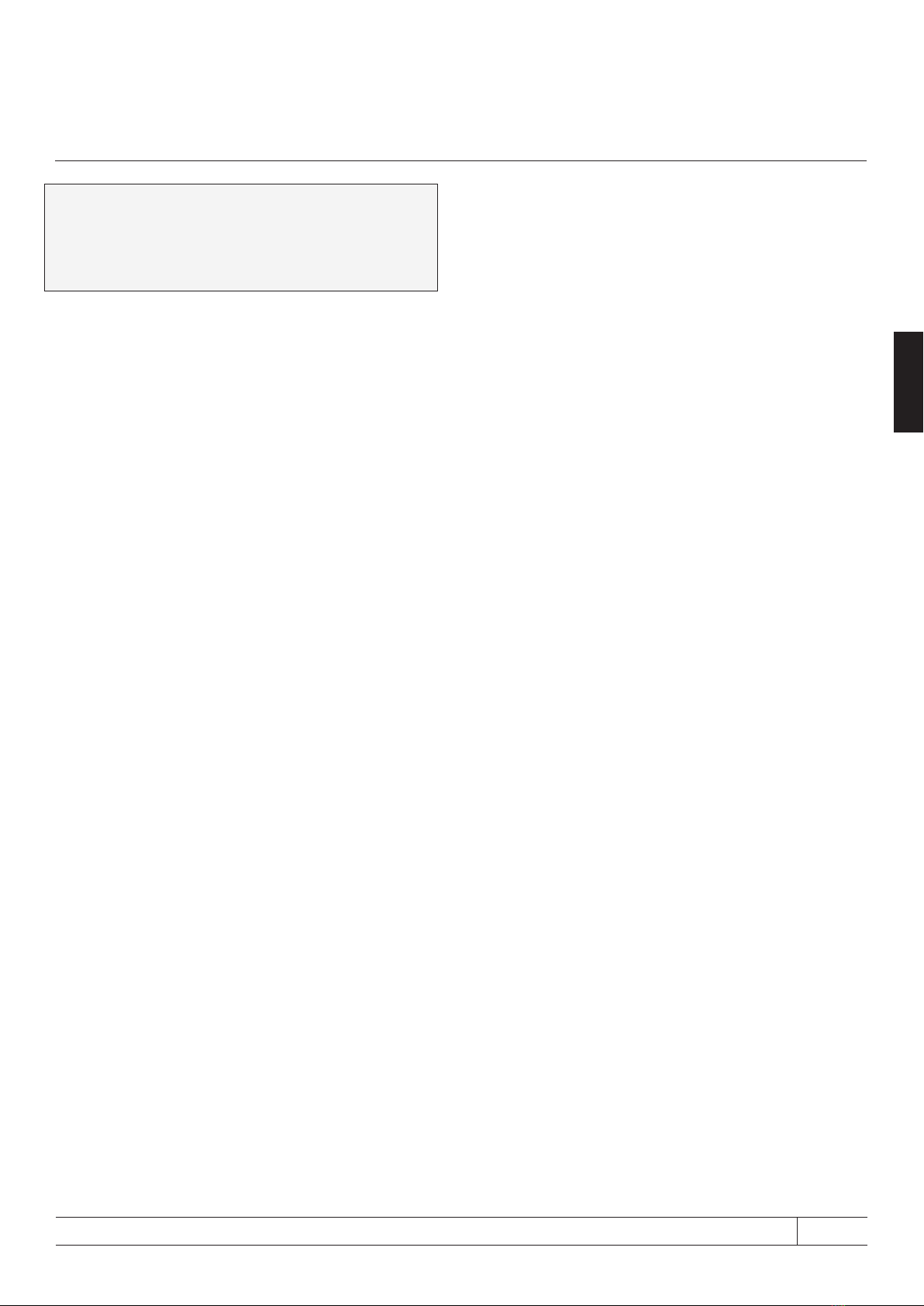

Connected PCE Programming Requirements

Shutdown DC Voltage @0.5C 48.0V

Shutdown Voltage Recommended 50.2V

Recovery / Restart Voltage 52V

Continuous Charge Voltage 57.6V

Continuous Charge Transition Battery is considered full after battery is absorbing less than 1% of maximum

chargecurrentafterbeingheldatspeciedchargevoltagefor30minutesminimum.

Float Voltage Cyclic (Short Term Float) (Example

Solar Application) 57.6V

Float Voltage Standby (Long Term Float) (Example

UPS Application) 54.4V to 56V

Charge Current 39A

Peukert Exponent 1.02

Shutdown SoC Recommended 20%

Calibration to 100% Every 7 days or more frequent where possible.

(Ensurescellbalancingisperformed&keepsexternalSoCcountermoreaccurate)