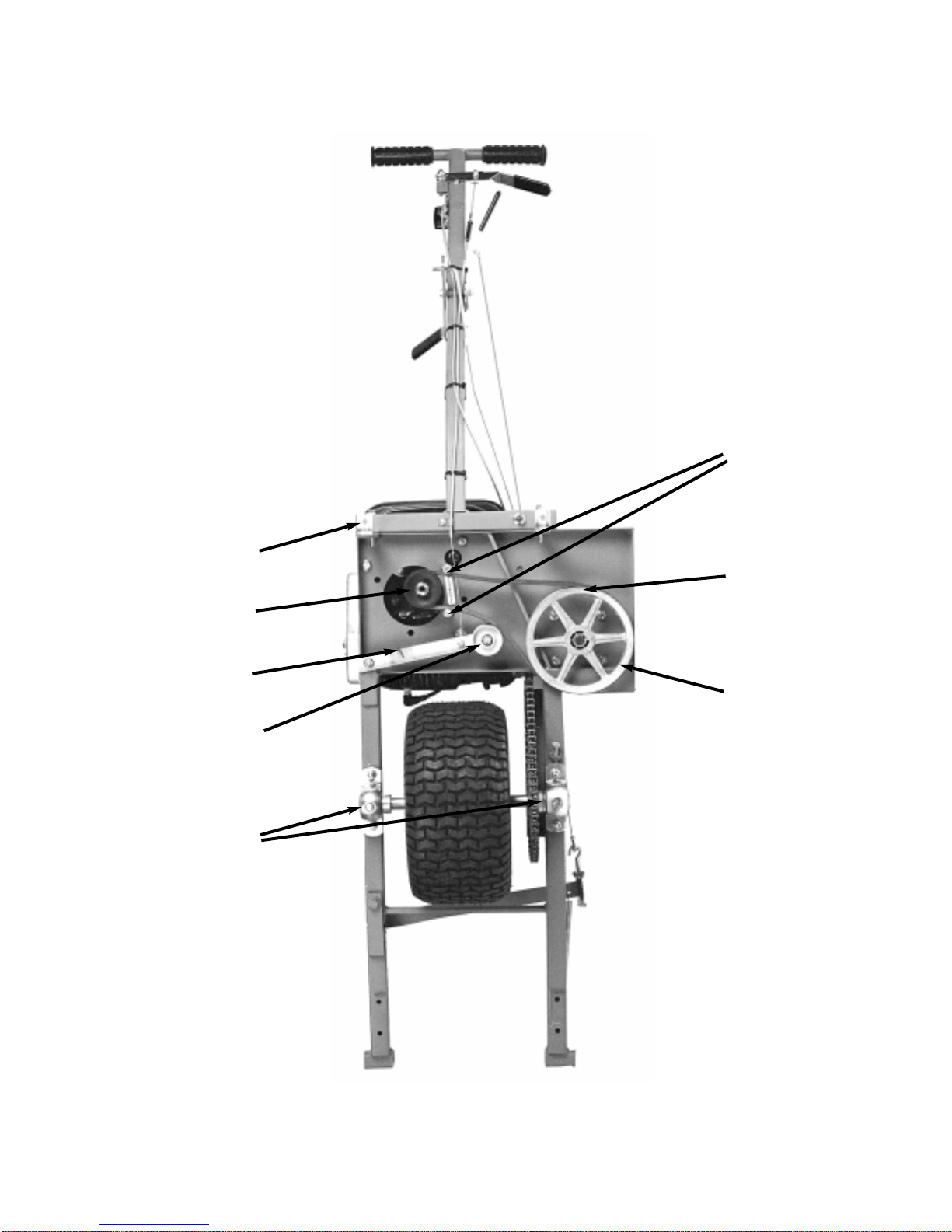

With the swing arm positioned parallel to the stationary arm, the adaptor set screws loose and

the adaptors fully retracted, move the machine up to the aircraft nose wheel so that the

Powertow tire and aircraft nose tire are in line. Slide in adaptors evenly on each side snug.

Tighten the stationary side adaptor. Next loosen the swing arm adaptor 1/16” of an inch

and tighten down. This will allow the lanyard cable to lock down without undo pressure.

Too tight and the adaptors will pop off or the z-swag will break.

IMPORTANT! - The swing arm and the stationary arm should always be parallel when the

lanyard lever is in the locked position. BEFORE MOVING THE AIRCRAFT, TRY OUT THE

POWERTOW UNDER POWER BY ITSELF TO GET USED TO THE CLUTCHING CONTROL.

Note: Without aircraft attached, unit may creep when clutch is released.

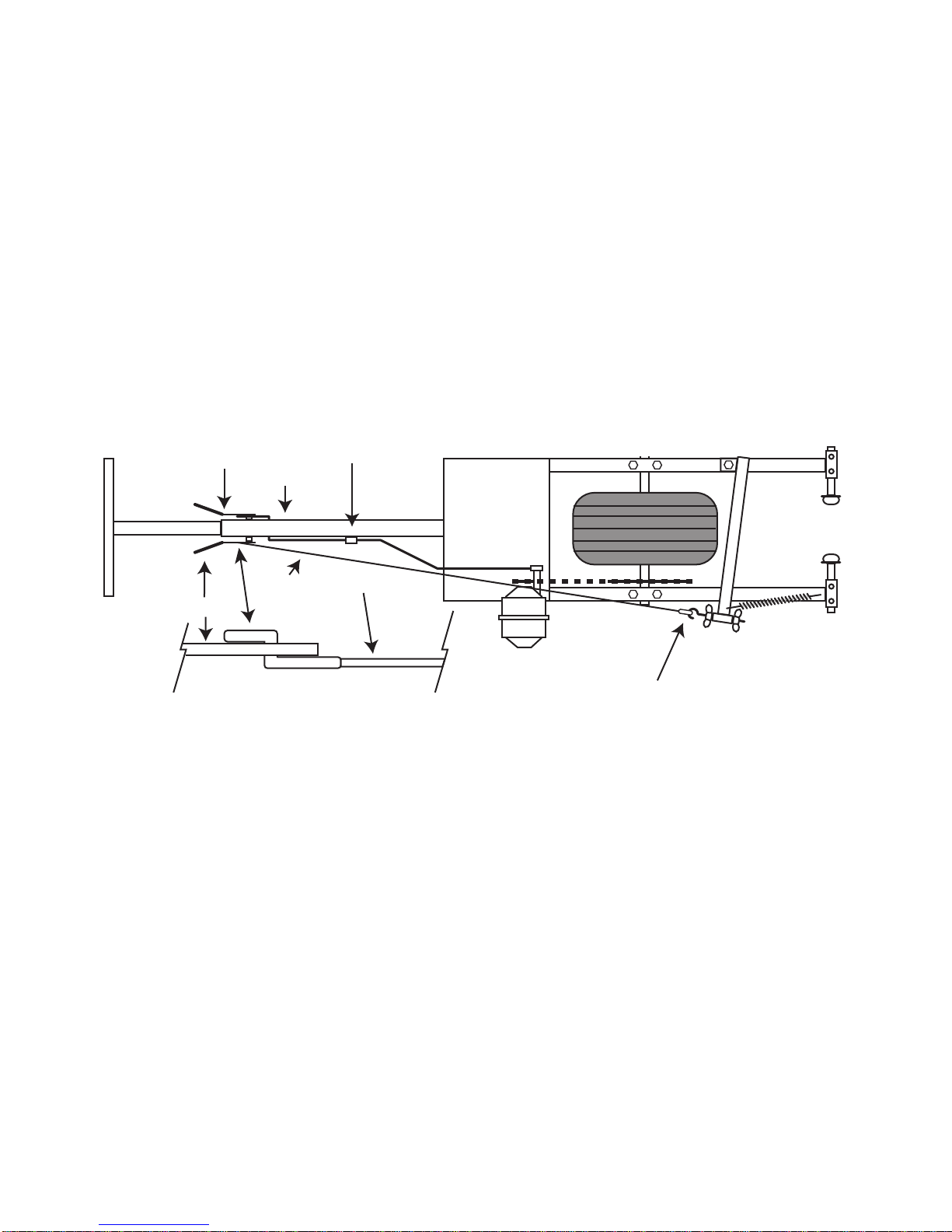

EZ HOOK-UP: Open the lanyard handle, move unit up to the aircraft at a slight angle from the

right side to engage the stationary adaptor. By using the stationary arm adaptor, as a pivot to

lift the wheel, you can swing the machine to your left far enough to engage the hookup, while

pulling the lanyard lever into the down and locked position. (It may be necessary to shift the

machine left and right and/or up and down to get the lanyard lever completely down and the

swing arm adaptor to fully seat.)

IF THE ADAPTORS SLIP OFF OR OUT OF POSITION - Check that the stationary arm and

swing arm are parallel and that both adaptor set screws are tight on each of the adaptors.

IF THE SWING ARM OPENS UNDER LOAD - check that the arms are parallel and that the

lanyard lever goes past center to the down lock position. Loosen cable at eyebolt slighty. Make

smaller turns.