POWERWINCH CAPSTAN POWERED LIFT ASSIST

7

OPERATING THE WINCH

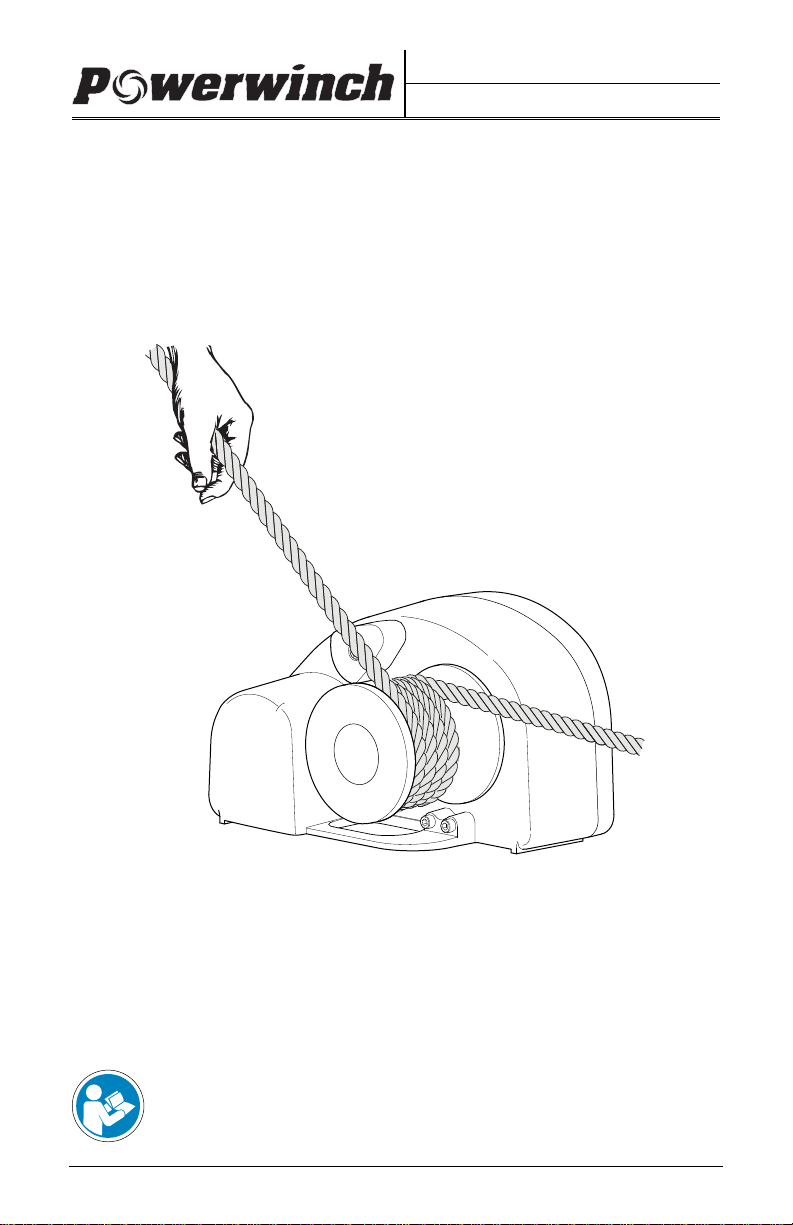

The Capstan can be usedto retrieve anchors, traps or pots; these are referred to

as the "load" in the directions below.

CAUTION NEVER use the winch to exclusively hold, support or

permanently secure the load. ALWAYS secure the rope to a deck cleat or

similar device.

NOTICE To prevent damage to the motor, do not operate the winch

continuously for periods over 20 minutes. Allow the motor to “rest” for

aminimum of 1 hour.

LOADING THE ROPE

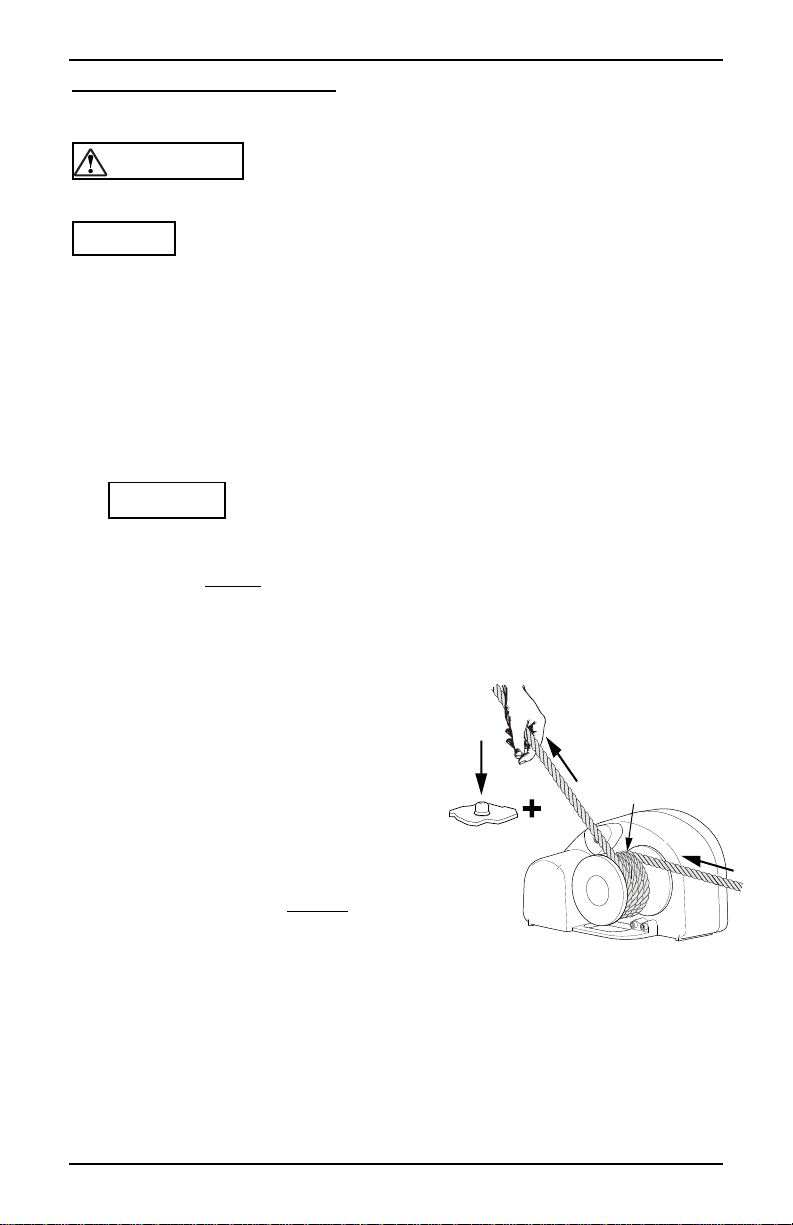

1. Thread the rope through the davit or bow roller and pull back to the winch.

2. Wrap the rope counterclockwise 4-5 wraps around the capstan.

LOWERING THE LOAD

1. Turn boat into wind and place boat motors in neutral.

2. After the boat has stopped all forward progress, release the rope from the

deck cleat. Allow the load to free fall to the sea bed.

NOTICE Never use the winch to lower the load or to brake the load

during free fall. This can result in serious damage to the gear train.

3. After the desired amount of rope has been released, tie the rope off to a

deck cleat. DO NOT use the winch to tie-off the anchor.

4. For anchors, place the boat's motors in neutral and allow the boat to drift

back and set the anchor in the sea bed.

RETRIEVING THE LOAD

1. Untie the rope from the deck cleat.

2. Align bow of boat with load.

3. Place the boat's motors in forward and

move boat slowly toward the anchor point.

4. Press the winch switch and pull the rope

hand over hand.

NOTE: The rope must be kept under

tension for the winch to work properly.

5. After the load is secured, tie the rope

off to a deck cleat. DO NOT use the

winch to tie-off the load.

MAINTENANCE

Following each boat outing, flush exterior of winch with fresh water. Use only

mild detergents to clean exterior. Use of solvents can cause damage to the

finishes and seals, as well as void product warranty.

Every 6 months inspect capstan for wear. Replace any worn components.

Check rope periodically for abrasion or deep cuts. Never splice an old rope with a new

rope. If replacement is necessary, use only Powerwinch recommended rope.

Check electrical connections every 6months for corrosion. Replace any

connection or wire which is damaged, corroded, frayed or worn.

pwcs002

Pull Rope Hand over

Hand While Pressing

the Foot Switch

Wrap Rope

4-5 Times

Counterclockwise

Foot Switch