OperatingInstructions

ModelsH500,H80O

and H880

vapor. Never operate or repair near a

flammable gasor vapor. Never store

flammable tiquids or Eases

in the

vi.inity of the hoist.

24.Warn

personnel

of anapproaching

load.

Make

sureallpersons

stay

clearof suspendedload.

25.

Keep

hands

clearofcablespool.

26.Donot lift more

thanthe rated

toao.

AWARNING Do not tift toads

over people or

teavea suspended toad unattended.

27.8e

certainloadiscenteredunder

hoist

to avoidanyswinging

of load.

28.Maintainfirm footing when

operatinghoist,

Donotallow

your

attention

to bediverted.

29.

Take

upslack

carefully,checkload

balance,lift afew inchesand

check

Ioadholding

action

before

contrnurng.

30.Keepbrake

surfaceandlining{ree

of grease.

31.Inspectregularly,

andkeep

accurate

maintenance

records.

Permitonly

qualified

personnel

to adjustor

repair

hoi5t.

32.Donot use

damagedor

malfunctioning

hoist

untilall

necessary

adjustments

or repairs

have

been

made.

AWARNING Make aertain

power supply is

disconnected berore attempting to

service, relocate, or perlotm any

rnaintenance-

lf power disconned point

is out-of-sighL tock it in the open

position and tag ta prevent unexpected

applicationof power.

33.Mako

certainloadis

removedfrom

hoistbefore

performing

anyservice.

34.Only

qualified

electrician

orservice

person

should

perform

any

electrical

troubleshooting

or maintenance.

35.UseonlyPowerwinchreplacement

parts

with thishoist.

Installation

AWARNING Hoist is not

suitablelor usein

outdoor tocations or areas containing

explosive dust, vapo's, or gases. Do not

use hoist in or around wet areas, lhe

instaltation area must provide sale

operating <onditions fot the operator,

in.luding sufficient room for the

operator and other pe/'sonnel to stand

ctear of the load at atl times.

1. Attach the hoistto supporting

structure usingthe brackets

and

bolts provided- Failure

to usethe

supplied anchoring hardware will

void the warranty.

2.

5.

Makesure

any

mounting

pointfor

the hoistis

structurally

strong

enoughfor manytimes

the hoist

rated

capacity.

lf supporting

the hoistinroof

trusses,

makesureto distributethe

load

overmorethanoneortwo

trusses

byextending

thesupport.

Makecertain

thehoistis

notfree

to

swingorturn in

the mountings.

Intended

for useon 115V,

single

phase,

60Hz

power

supply.Voltage

atthe hoistshould

bewithin plus

or

minus10%

of 115V.

Equipped

with

3-prong,

grounding-

type

plug

to minimize

shockhazards

Itmust

be

plugged

into

aproperly

installed

and

grounded

receptacle

to

maintain

this

protection.

A heawduty,

three

prong

extension

cordmust

beusedif required

to plug

in

thehoist.

Anertension

cordwhictr

is

toosmallwillrestrict

power

tothe

hoist

andreducelifting

capacity.

Pu5hbutton

station.brake

andlimit

switches

shouldbe

tested

bythe

7.

operatorbeforebeginning

a

job.lf

thesecontrolsdo notoperate

properly,

theyshouldberepaired

or

replaced

beforeoperationsare

started.

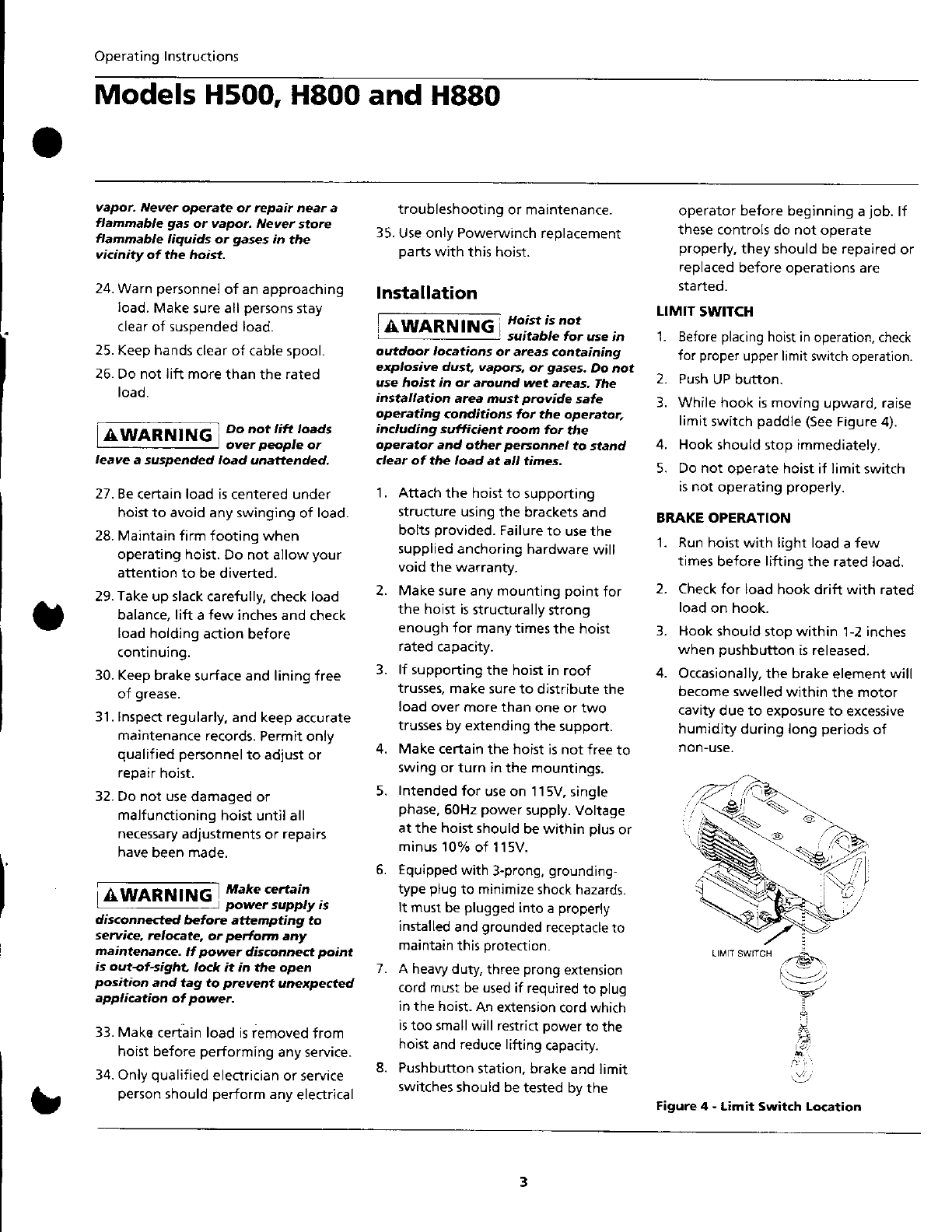

LIMIT SWITCH

Beiore

placing

hoistin

operation,che(k

forproper

upperlimit

switchoperation.

Push

UPbutton.

Whilehook ismoving

upward,

raise

limit

switch

paddle(see

Figure4).

4. Hook

shouldstopimmediately.

5. Donot operatehoistif limit

switch

isnotoperating

properly.

BRAKEOPERATION

1. Runhoist

with lightload

afew

times

beforeliftingthe rated

load.

2. Check

for loadhookdrift with rated

load

on hook.

3.

1.

2.

3.

3. Hook

shouldstopwithin l-2 inches

whenpushbutton

isreleased.

Occasionally,

the brakeelementwi

becomeswelled

withinthe motor

cavltydue to exposureto excessive

humidity

duringlongperiods

of

non-u5e.

8.

!

,-&\.

-v:

Figure 4 - Limit Switch Location