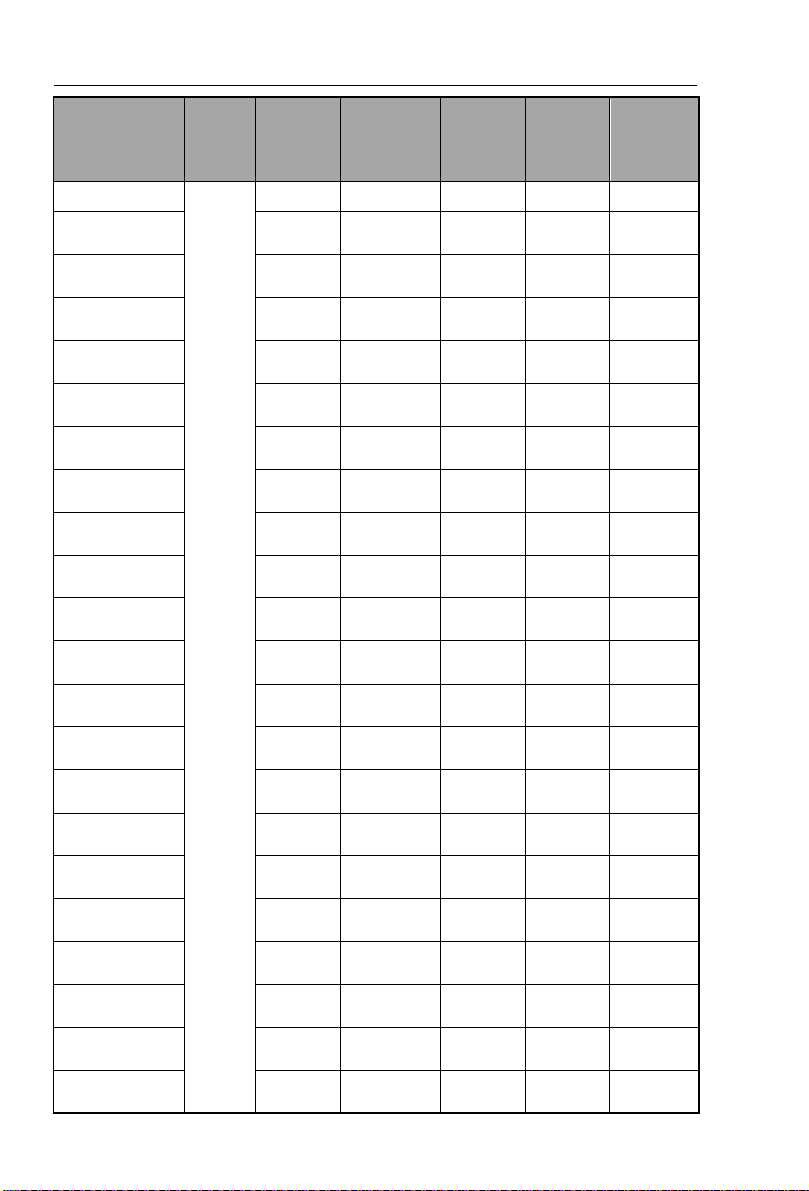

5-2-14. Extended parameter:FC.00-FC.02........................................................... 153

5-2-15. Wobbulate, fixed-length and counting:E0.00-E0.11 ................................. 154

5-2-16. Multi-stage command, simple PLC: E1.00-E1.51 .................................... 156

5-2-17. PID function: E2.00-E2.27...................................................................... 160

5-2-18. Virtual DI、Virtual DO:E3.00-E3.21 ...................................................... 165

5-2-19. Motor parameters: b0.00-b0.35............................................................... 170

5-2-20. Function code management:y0.00-y0.04 ................................................. 174

5-2-21. Fault query:y1.00-y1.30.......................................................................... 177

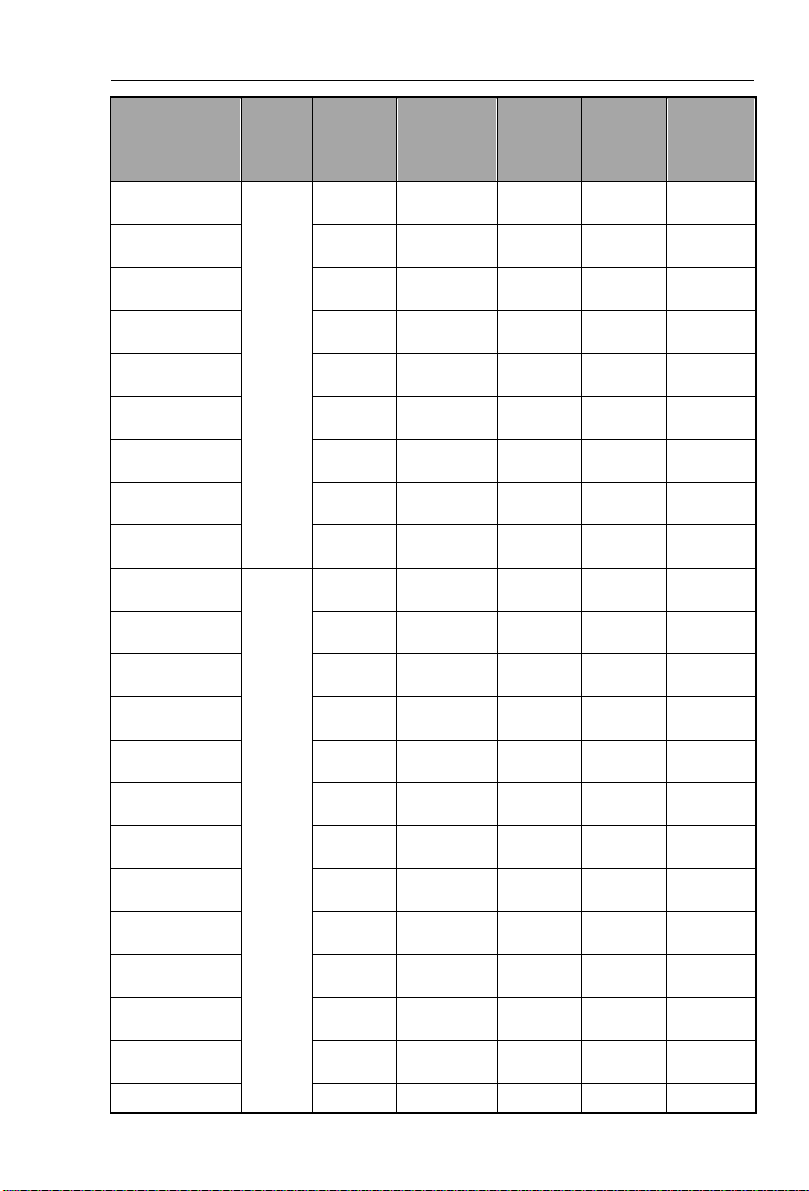

Chapter 6 EMC (Electromagnetic Compatibility) ................................................ 182

6-1. Definition.................................................................................................... 182

6-2. EMC standard............................................................................................. 182

6-3. EMC directive............................................................................................. 182

6-3-1. Harmonic effect........................................................................................ 182

6-3-2. Electromagnetic interference and installation precautions.......................... 182

6-3-3. Remedies for the interferences from the surrounding electromagnetic

equipments to the inverter................................................................................... 183

6-3-4. Remedies for the interferences from the inverter to the surrounding

electromagnetic equipments................................................................................ 183

6-3-5. Remedies for leakage current.................................................................... 183

6-3-6. Precautions on installing EMC input filter at the input end of power supply 184

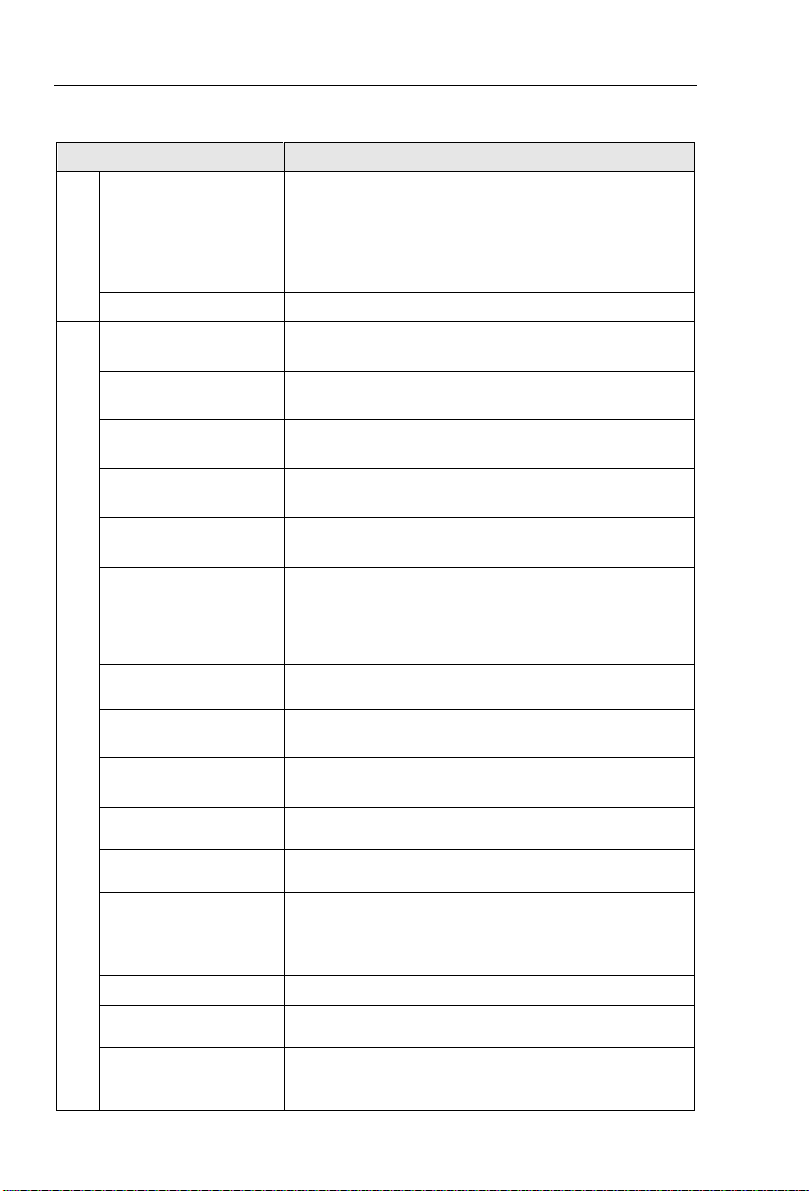

Chapter 7 Troubleshooting.................................................................................. 185

7.1 Fault alarm and countermeasures................................................................... 185

Chapter 8 Installation and spare circuit................................................................ 191

8-1. Operating environment................................................................................ 191

8-2. Installation direction and space.................................................................... 191

8-3. Wiring diagram ........................................................................................... 191

8-3-1. Wiring diagram(< 11kW).......................................................................... 192

8-3-2. Wiring diagram(11kW to 15kW)............................................................... 193

8-3-3. Wiring diagram(18.5kW to 355kW).......................................................... 194

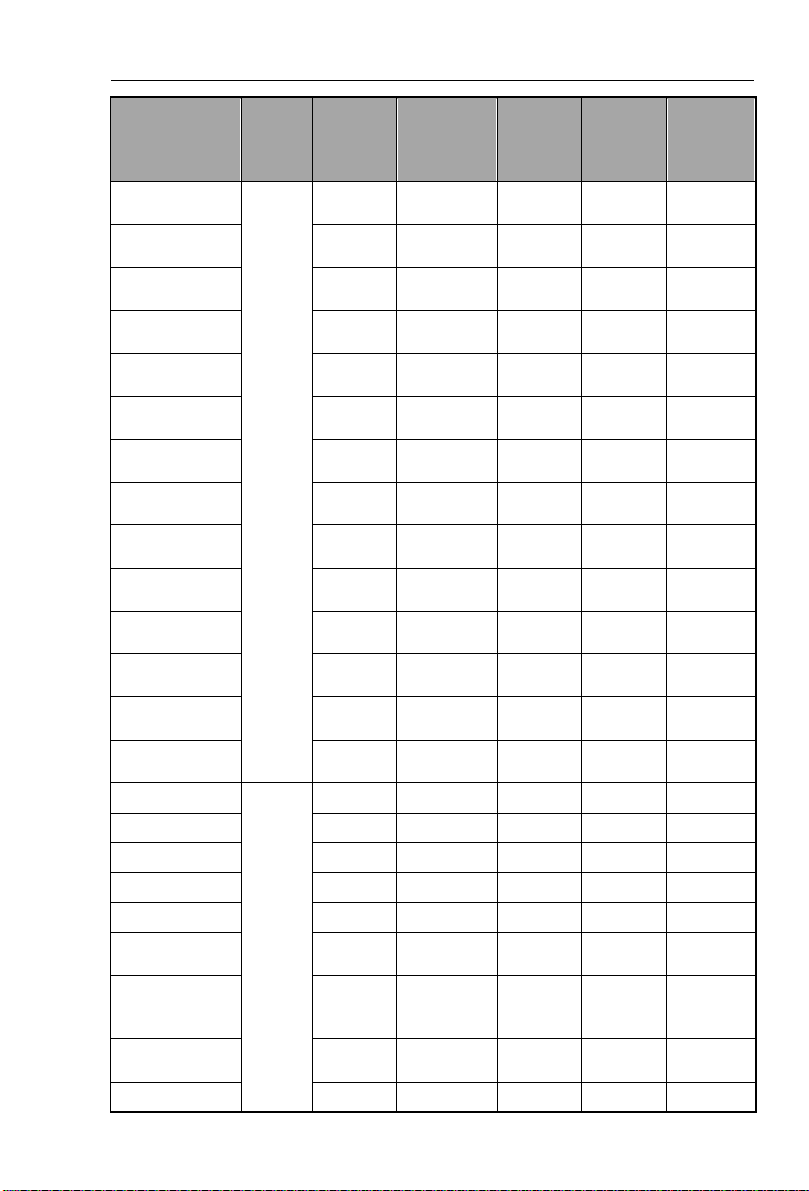

8-4. Main circuit terminal (G type)...................................................................... 195

8-4-1. PI9000 main circuit terminal..................................................................... 195

8-4-2. Function description of main circuit terminal............................................. 196

8-5. Control circuit terminals.............................................................................. 196

8-5-1. Description of control circuit terminals..................................................... 196

8-5-2. Arrangement of control circuit terminals................................................... 198