PR electronics 2289 User manual

Programmable displays with a wide se-

lection of inputs and outputs for display of temperature,

volume and weight, etc. Feature linearisation, scaling,

and difference measurement functions for programming

via PReset software.

Interfaces for analogue and digital

signals as well as HART® signals between sensors / I/P

converters / frequency signals and control systems in Ex

zone 0, 1 & 2 and for some modules in zone 20, 21 & 22.

Galvanic isolators for analogue and digital

signals as well as HART® signals. A wide product range

with both loop-powered and universal isolators featuring

linearisation, inversion, and scaling of output signals.

PC or front programmable modules with

universal options for input, output and supply. This range

offers a number of advanced features such as process

calibration, linearisation and auto-diagnosis.

A wide selection of transmitters for DIN

form B mounting and DIN rail modules with analogue

and digital bus communication ranging from application-

specific to universal transmitters.

Temperature

Isolation

Ex interfaces

Universal

Displays

DK

UK

FR

DE

Side 1

Page 35

Page 69

Seite 103

SIGNALS THE BEST

2289

Signal Calculator

No. 2289V101-IN (1015)

From ser. no. 980338001

34

SIGNAL CALCULATOR

Type 2289

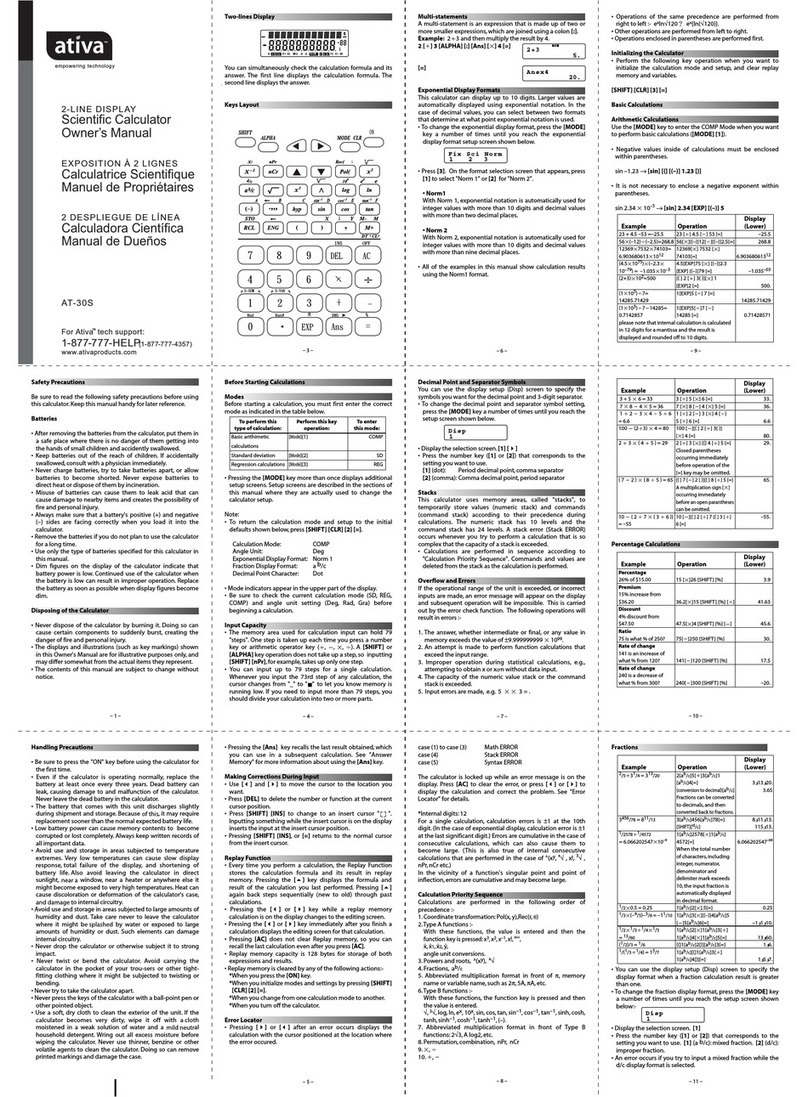

CONTENTS

Declaration of Conformity .................................................. 36

How to dismantle SYSTEM 2200....................................... 37

Application ......................................................................... 38

Technical characteristics .................................................... 38

Functions:

Analogue calculator ....................................................... 38

Sample-Hold.................................................................. 38

Peak-Hold...................................................................... 39

Delay.............................................................................. 39

PID controller ................................................................. 39

Manual / automatic controller........................................ 39

Signal limiter .................................................................. 39

Averaging transmitter .................................................... 39

Slope transmitter (dI/dt function)................................... 39

Analogue multiplexer ..................................................... 40

Inputs.................................................................................. 40

Digital input - 2289A .......................................................... 40

Output ................................................................................ 40

Electrical specifications...................................................... 41

Order .................................................................................. 43

Block diagrams .................................................................. 44

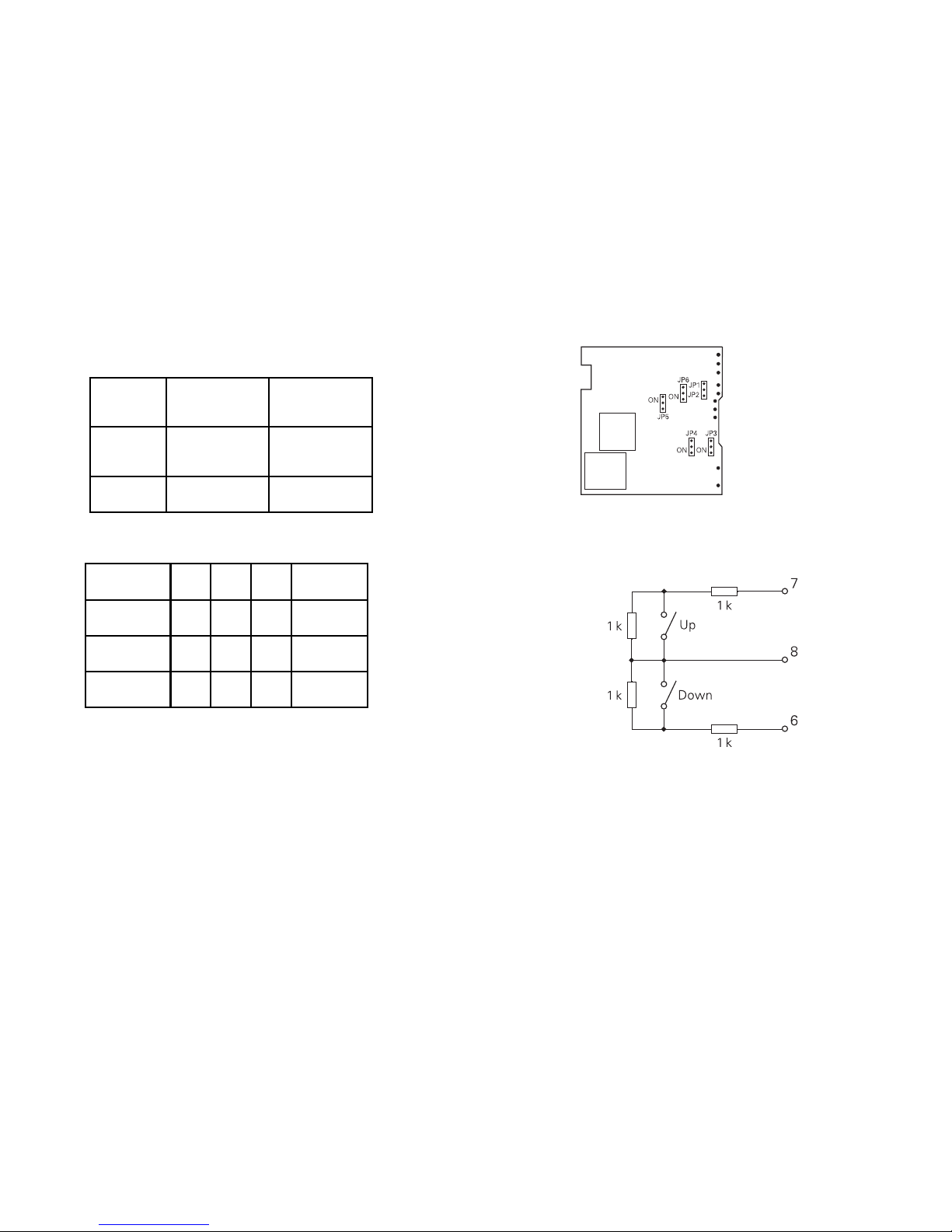

Hardware programming ..................................................... 46

Jumper positioning............................................................. 47

External up/down operation of manual controller ............. 47

Routing diagram................................................................. 48

Programming / operating the function keys ...................... 50

Function description (selection of application) .................. 59

Graphic illustration of the functions................................... 64

35

HOW TO DISMANTLE SYSTEM 2200

Picture 1:

The back panel of the module is

detached from the housing by way

of a screwdriver.

Picture 2:

After this, the back panel can be

pulled out together with the PCB,

but please notice the position of

the PCB as there is a number of

different positions in the house. Do

not pull the wires unnecessarily,

instead pull the PCB.

Switches and jumpers can now be

moved.

When assembling the back plate

and housing, please make sure no

wires are stuck.

37

DECLARATION OF CONFORMITY

As manufacturer

PR electronics A/S

Lerbakken 10

DK-8410 Rønde

hereby declares that the following product:

Type: 2289

Name: Signal calculator

is in conformity with the following directives and standards:

The EMC Directive 2004/108/EC and later amendments

EN 61326-1

For specification of the acceptable EMC performance level, refer to the

electrical specifications for the module.

Rønde, 5 June 2009 Kim Rasmussen

Manufacturer’s signature

36

PEAK-HOLD:

At a deactivated digital input the output value is the greatest input value

registered since the last reset. Activation of the digital input will set the output

value at the present input value (reset).

DELAY:

The delay function transfers the input value to the output according to an

exponential curve (R/C delay), where the time constant of the R/C delay can be

entered.

PID CONTROLLER:

Features the following regulation parameters: XP (proportional band), TI

(integrating time), and TD (differentiating time). The units are selected as XP %,

TI s, and TD s. By selecting TI and TD as 0, the function will be a pure proportional

controller. The regulation can be either direct or inverted. The setpoint can be

selected as an internal or external current / voltage signal.

MANUAL / AUTOMATIC CONTROLLER:

The digital input is used to change between the manual and automatic mode. In

the automatic mode the analogue output follows input A. When changing to the

manual mode the analogue output is fixed and can now be activated up or down

manually. The output holds the manual setting for an unlimited period.

SIGNAL LIMITER:

By the signal limiting function the output follows the input values linearly in the range

between the min. and max. settings. At input signals outside the min. and max.

settings, the output is fixed on either the min. or the max. value. The min. or the

max. value can be set externally by means of the other analogue input.

AVERAGING TRANSMITTER:

The averaging function calculates an accurate average value of the input values

over a set period. Once this period has expired the output will be updated by the

average value. This means that the ouput will typically make a jump at each update.

A stack function can be selected to increase the updates of the output and to

decrease any jumps while still keeping the set averaging period.

SLOPE TRANSMITTER (DI/DT FUNCTION):

The dI/dt function converts the slope of the input over a set period to an analogue

output signal. The min. and max. slope to be converted are entered in % of the

input span. The slope can be selected as either positive or negative. By means

of a pressure transmitter the dI/dt function is suitable for for instance leak

monitoring or flow measurement of substances with a high viscosity grade.

39

SIGNAL CALCULATOR 2289

• Two analogue inputs

• Multiple functions

• Front-programmable

• 3-digit LED display

• Version with a Pt100 input

• Analogue output

APPLICATION:

Operates as a PID controller with an analogue or a Pt100 input, a manual /

automatic controller, an analogue calculator with a scale function on both inputs,

a sample-hold transmitter, a peak-hold transmitter, a delay transmitter, a signal

limiter, averaging of noisy signals, monitoring of a signal’s slope, or an analogue

multiplexer. •The 2289 Signal Calculator will meet the demands of any process

engineer with an unexpected or special signal processing assignment at hand.

TECHNICAL CHARACTERISTICS:

The unit is built around a microprocessor core with an efficient program operation.

The basic calibration data and the present set-up are saved in an EEPROM

thereby avoiding the loss or change of data at power off. The user interface

consists of a 3-digit display and 3 front function keys. The input and output values,

function, and all parameter selections are entered by means of the user interface.

Both the input signals and the output signal can be inverted.

FUNCTIONS:

ANALOGUE CALCULATOR:

Contains the following calculation functions: addition, subtraction, maximum /

minimum selection, multiplication, division, raising to a power and root extraction.

At raising to a power and root extraction, any of the analogue inputs can be

selected. By means of the scale function the calculation functions can be

executed on differently scaled input signals.

SAMPLE-HOLD:

Activation of the digital input (hold) will set the output value to the present

input value and will hold this value for as long as the digital input is active. At a

deactivated digital input the output value will track the input value.

38

ELECTRICAL SPECIFICATIONS:

Specifications range:-

-20 to +60°C

Common specifications:

Supply voltage .......................................... 19.2...28.8 VDC

Internal consumption ................................ 2.4 W

Max. consumption .................................... 2.7 W

Signal / noise ratio ................................... Min. 60 dB

Signal dynamics, input.............................. 20 bit

Signal dynamics, output ........................... 16 bit

Proportional band (XP) ............................. 0.01...999%

Gain ........................................................... 0.1...10000

Integrating time (TI) ................................... 0...999 s

Differentiating time (TD)............................. 0...999 s

Response time ......................................... < 60 ms

Updating time............................................ 20 ms

Calibration temperature ............................ 20...28°C

Temperature coefficient............................. < ±0.01% of span/°C

Linearity error ............................................ < ±0.1% of span

Effect of supply voltage change ............... < ±0.002% of span/%V

Auxiliary voltages:

Reference voltage ..................................... 2.5 VDC ±0.5% / 15 mA

EMC immunity influence ........................... < ±0.5%

Relative air humidity.................................. < 95% RH (non-cond.)

Dimensions (HxWxD) (D is excl. pins)....... 80.5 x 35.5 x 84.5 mm

Protection degree...................................... IP50

Weight ....................................................... 130 g

Electrical specifications - INPUT:

Current input:

Measurement range .................................. 0...20 mA

Min. measurement range (span) ............... 4 mA

Max. offset ................................................ 50% of selec. max. value

Input resistance......................................... Nom. 50 Ω

41

ANALOGUE MULTIPLEXER:

At a deactivated digital input, input A x P1 is sent to the output. At an activated

digital input, input B x P2 is sent to the output. P1 and P2 are scaling factors for

the two inputs.

INPUTS:

ANALOGUE INPUTS - 2289A

The A and B inputs can be programmed according to your choice to receive

current signals in the range 0...20 mA (for instance 4...20 mA), or voltage signals

in the range 0...10 VDC.

PT100 INPUT - 2289B

Input A is a linearised Pt100 temperature input in the range -99...+850°C with a 3-

wire connection. The measurement range can be scaled via the front keys acc. to

your choice. As 2289A, input B is an analogue current / voltage input.

DIGITAL INPUT - 2289A

By way of JP6 the 2289 signal calculator can be programmed to NPN (pull up to

24 VDC), or PNP (pull down to 0 VDC). Min. pulse length is 50 ms.

OUTPUT:

Analogue standard current / voltage output of 0/4...20 mA / 0/2...10 VDC. The

output span can be set to special current / voltage signals acc. to your choice.

Max. load on the current output is 600 Ω. Min. load on the voltage output is 500

kΩ.

40

Voltage output via internal shunt:

Signal range .............................................. 0...10 VDC

Min. signal range (span) ............................ 250 mV

Max. offset ................................................ 50% of selec. max. value

Load (min.)................................................. 500 kΩ

Voltage limit............................................... 10.25 VDC

GOST R approval:

VNIIM, Cert. no........................................... See www.prelectronics.com

Observed authority requirements: Standard:

EMC 2004/108/EC .................................... EN 61326-1

Of span = Of the presently selected range

ORDER: 2289

43

Voltage input:

Measurement range .................................. 0...10 VDC

Min. measurement range (span) .............. 200 mV

Max. offset ................................................ 50% of selec. max. value

Input resistance ........................................ Nom. 10 MΩ

Digital input:

NPN........................................................... Pull up 24 VDC / 6.9 mA

PNP ........................................................... Pull down 0 VDC / 6.9 mA

Pulse length............................................... > 50 ms

Pt100 input 2289B:

Measurement range .................................. -99...+850°C

Min. measurement range (span) .............. 50°C

Max. offset ................................................ 50% of selec. max. value

Cable resistance per wire (max.)............... 25 Ω

Sensor current........................................... Nom. 1.25 mA

Response time .......................................... < 100 ms

Basic accuracy.......................................... < ±0.2°C

Temperature coefficient:

span < 100°C .......................................... < ±0.01°C/°Camb.

span > 100°C .......................................... < ±0.01% of span/°Camb.

Immunity influence:

span < 100°C .......................................... < ±1% of span

span > 100°C .......................................... < ±0.5% of span

Effect of sensor cable resistance.............. < 0.002 Ω/Ω

Electrical specifications - OUTPUT:

Current output:

Signal range .............................................. 0...20 mA

Min. signal range (span) ............................ 5 mA

Max. offset ................................................ 50% of selec. max. value

Load (max.)................................................ 20 mA / 600 Ω / 12 VDC

Load stability............................................. < ±0.01% of span/100 Ω

Current limit............................................... 20.5 mA

42

Type Input

2289 Current / voltage : A

Pt100 & current / voltage : B

BLOCK DIAGRAM -2289B:

45

BLOCK DIAGRAM -2289A:

44

4746

HARDWARE PROGRAMMING:

INPUT:

OUTPUT:

JUMPER POSITIONING:

EXTERNAL UP / DOWN OPERATION OF MANUAL CONTROLLER:

Channel A

0...20 mA

0...10 VDC

JP4 ON

JP4 OFF

MENU 2.3 = I

MENU 2.3 = U

Channel B

0...20 mA

0...10 VDC

JP3 ON

JP3 OFF

MENU 3.3 = I

MENU 3.3 = U

NPN

PNP

JP6 ON

JP6 OFF

Output JP1 JP2 JP5 MENU 4.3

0...10 mA

0...20 mA OFF OFF OFF

ON

1

2

0...500 mV

0...1000 mV ON OFF OFF

ON

3

4

0...5 V

0...10 V OFF ON OFF

ON

5

6

4948

0.0

5.0 5.1 5.2 5.3

3.0 3.1 3.2 3.3

4.3

1.0

2.0 2.1 2.2 2.3

4.0 4.1 4.2

5.4

4.4

5.1

5.0

A input

B input

Output

1.3

1.4

1.5

1.6

1.7

1.8

Menu 5.1 = 15

Function: Slope transmitter

1.1

1.2

1.3

1.4

1.5

1.0 Parameter line

1.0 Parameter line

Menu 5.1 = { 8 , 9 }

Function: Sample / hold - peak

1.1 - 1.3No function

1.4 Channel selection

Menu 5.1 = 10

Function: Time delay

1.1 Time constant

1.2 Channel selection

Integrating time

Differentiating time

Setpoint int. / external

Direct / inverted

Digital input function

Power UP

Menu 5.1 = { 5 , 6 }

Function: Multiplication / division

1.1 Scale factor

1.2 No function

1.3 Calculation offset

1.4 Divisor channel selection

1.5 Input A hold

Menu 5.1 = { 1 , 2 , 3 , 4 }

Function: +, -, Max., Min.

1.1 Input A scale factor

1.2 Input B scale factor

1.3 Calculation offset

1.4 Channel selection

1.5 Input A hold

1.6 Out of range

Menu 5.1 = 7

Function: Root / Power

1.1 Scale factor

1.2 Power of function

1.3 Calculation offset

1.4 Channel selection

1.5 Low cut off

Menu 5.1 = 12

Function: Man./auto controller

1.1 Step up/down in %

1.2 Int./external up/down

1.3 Digital input function

Menu 5.1 = 16

Function: Analogue multiplexer

1.1 Input A scale factor

1.2 Input B scale factor

Menu 5.1 = 13

Function: Signal limiter

1.1 Min. output %

1.2 Max. output %

1.3 Int./ext. Lo/ ext. Hi

1.4 Channel selection

Menu 5.1 = 14

Function: Averaging

1.1 Averaging time

1.2 Stack size ( 1...14 )

1.3 Channel selection

Time constant in s

0% slope in %

100% slope in %

Sampling in s*1000

Sampling in s

If no buttons are pressed for a period of 20 minutes,

the display returns to default 0.0.

Fast Setting

Fast Setting

Store and exit fast setting

040 = Enable change in all stages

- - - = Disable change

Routing diagram

Function

selection

Value 1...16

See function

description

Application Programming access

0...999

Input 0%

Input 0%

Output 0% Output 100%

Input 100%

Input 100%

Password code

Parameters

Input A

Input B

Press or for 2 s for an automatic counting

Decrement setpoint

Increment setpoint

Analogue

output

Input type

U = voltage

I = current

U = voltage

I = current

Input type

Output type

Frequency

50 Hz

60 Hz

Display

Pt 100: -99...850°C Pt 100: -99...850°C

Pt 100: °C

Pt 100: No function

0.0...20.0 mA

0.0...10.0 VDC

0.0...20.0 mA

0.0...10.0 VDC

0.0...20.0 mA

0.0...10.0 VDC

0.0...20.0 mA

0.0...10.0 VDC

0.0...20.0 mA

0.0...10.0 VDC

0.0...20.0 mA

0.0...10.0 VDC

001 = 0...10 mA

002 = 0...20 mA

003 = 0...500 mV

004 = 0...1000 mV

005 = 0...5 V

006 = 0...10 V

Overrange

ON

OFF

Memory

Programming

Programming

Press and hold , then press

Press and hold , then press

to store changes

to store changes

Change of parameter

Change of parameter

Next digit or point

Next digit or point

Go to entry menu / Leave

Go to entry menu / Leave

menu without changes

menu without changes

Main menus

Menu 5.1 = 11

Function: PID controller

1.1

1.2 Setpoint

Proportional band

3Fast setting short cut key

When the PID controller with an internal setpoint has been selected, a

fast setting is possible by way of the Fast Setting function. In this menu

the function keys have a special function as 3downcounts the setpoint

and 1upcounts the setpoint from the value it had when activated.

Activate 2to save the setpoint value displayed and to leave the Fast

Setting menu. The setpoint value is displayed in % of the input span.

1.0 PAr - Parameter menu - entry of parameters.

The parameter menu line differs according to the selection made in menu

5.1 - FUn. Please see the function description and applied expression

in menu 5.1 - FUn. At the calculation functions, the 0...100% input and

output spans are converted to values between 0 and 1. A scale factor of

1 means that the input signal is scaled to its full value. A scale factor of

0.5 means that the input signal is scaled to half its value.

1.0 PAr for Addition, Subtraction, Max. and Min. [Function no. 1, 2, 3, and 4]

1.1 P1 - Scale factor for input A.

A typical value is 0.5 for addition and 1.0 for subtraction, max. and

min. Valid selections are -99...999. [Factor]

1.2 P2 - Scale factor for input B.

A typical value is 0.5 for addition and 1.0 for subtraction, max. and

min. Valid selections are -99...999. [Factor]

51

PROGRAMMING / OPERATING

THE FUNCTION KEYS

DOCUMENTATION FOR ROUTING DIAGRAM

GENERAL:

The programming is menu-controlled. The main menus are numbered in

level 0 (X.0), and the submenus are numbered in level 1 (X.1 to X.5). Each

submenu has an accompanying entry menu. The menus are structured in

such a way that the menus most frequently used are closer to the default

menu 0.0. Please note that programming is only possible when submenu 5.4

PAS has the value 040.

Submenus and branches are selected by

the 3 function keys 3,1and 2as outlined

in the routing diagram.

Activating 2in the branches will display the

current value of the entry and parameter

selection menus.

In entry menus, the digit that can be

changed will flash.

Active digit position is shifted by the 3 key,

and the value is changed by the 1key.

When the decimal point flashes, its

position can be changed by the 1key.

In parameter selection menus you switch

between the parameters by the 1key.

Save by first activating 3and then 1simultaneously.

To return to the previous menu without changing the parameters, activate 2.

If a non-valid value is entered, the display will show Err for 2 s and then

return to the entry menu with the initial value.

0.0 Default - menu 5.3 displays the selection - dSP.

The display returns to default at power ON, or if no keys have been

activated for a period of 20 minutes.

50

1.5 HLd - Hold of signal on input A.

When the digital input is active, the input signal is held at the value it

had when activated.

Possible selections are EnA [Enable hold], or dSA [Disable hold].

1.0 PAr for root extraction and raising to a power. [Function no. 7]

1.1 P1 - Scale factor.

A typical value is 1.0.

Possible selections are -99...999. [Factor]

1.2 P2 - Exponent.

A value of 00.5 is the square root of the input signal, and 002 is the

input signal raised to the second power.

Valid selections are -99...999. [Exponent]

1.3 P3 -Calculation offset.

A typical value is 0.0.

Valid selections are -99...999. [Factor]

1.4 CH - Input.

Possible selections are A or B. [Input]

1.5 LCO - Cut off low values.

The values are entered in % of the input span. Input values smaller

than LCO are considered a 0% input signal.

A typical value is 0.5 for root extraction and 0.0 for power.

Valid selections are 0...100. [Per cent]

1.0 PAr for Hold and Peak. [Function no. 8 and 9]

1.1 P1 - No function.

1.2 P2 - No function.

1.3 P3 - No function.

1.4 CH - Input.

Possible selections are A or B. [Input]

1.0 PAr for Delay. [Function no. 10]

1.1 tAU - Time constant.

Valid selections are 0...999. [Seconds]

53

1.3 P3 - Calculation offset.

A typical value is 0.0.

Valid selections are -99...999. [Factor]

1.4 CH - Input for subtraction.

If A has been selected the result is A - B.

If B has been selected the result is B - A.

Possible selections are A or B. [Input]

1.5 HLd - Fixing of signal on input A.

When the digital input is active, the input signal is fixed on the value it

had when activated.

Max. and Min. functions are not available.

Possible selections are EnA [Enable hold], or dSA [Disable hold].

1.6 OOr - Input signal less than the selected 0% value.

When the selected input span of the A and B channels is for instance

4...20 mA, input signals smaller than the selected 0% value (4 mA)

will be considered negative signals. As the mathematical rules for

operational signs apply to the calculation functions some may consider

this calculation incorrect.

When ON has been selected there is no limit on the input signals.

When OFF has been selected the input signals’ influence on the

calculation functions is limited to 0...100% input span.

Max. and Min. functions are not available.

Possible selections are ON or OFF. [Allow negative signals]

1.0 PAr for Multiplication and Division. [Function no. 5 and 6]

1.1 P1 - Scale factor.

A typical value is 1.0.

Valid selections -99...999. [Factor]

1.2 P2 - No function.

1.3 P3 - Calculation offset.

A typical value is 0.0.

Valid selections are -99...999. [Factor]

1.4 CH - Selection of input at division.

If A has been selected the result is A/B.

If B has been selected the result is B/A.

Possible selections are A or B. [Input]

52

1.8 PUP - Integration value at power on.

When - rES - has been selected, the integration value is reset at power

on. When - HLd - has been selected, the integration value present

prior to power off is applied at power on.

Possible selections are rES or HLd. [Integration value]

1.0 PAr for Manual / Automatic controller / Signal simulator. [Function no. 12]

1.1 StP - Percentage value for step up and down.

Selection of the percentage value that the output must jump whenever

an up or down signal is detected.

Valid selections are 0...99.9. [Per cent]

1.2 IE - Internal or external up / down.

When - I - has been selected and the display is in default menu 0.0,

the output will jump by the value set in menu 1.1 each time the arrow

keys are activated.

When - E - has been selected, an external current / voltage signal can

be applied for the up / down function. To select down, a signal < 40%

of the input span must be connected. To select up, a signal > 60% of

the input span must be connected.

Both internal and external have a repeat function meaning that a

continued activation will result in an up / down function with an

increasing rate.

Possible selections are I - [Internal], or E - [External].

1.3 dIF - Selection of digital input function.

When - InP - has been selected, a deactivated digital input will result

in the autofunction where the input A value is transferred to the output.

An activated digital input will result in the manual function where the

output adopts the value of input A at power on. Now the output value

can be activated up or down manually.

When - OFF - has been selected, the function is compulsory auto.

When - ON - has been selected, the function is compulsory manual.

Possible selections are InP, OFF, or On. [Digital input]

1.0 PAr for Signal limiter. [Function no. 13]

1.1 IL - Minimum output value.

The minimum output value is entered in % of the output span.

Valid selections are 0...100. [Per cent].

1.2 IH - Maximum output value.

The maximum output value is entered in % of the output span.

Possible selections are 0...100. [Per cent]

55

1.2 CH - Input.

Possible selections are A or B. [Input]

1.0 PAr for PID controller. [Function no. 11]

1.1 SEt - Setpoint.

The setpoint value is entered in % of the input span.

Valid selections are 0...99.9. [Per cent]

1.2 hP - Proportional band.

The proportional band is entered in % of the input span.

Valid selections are 0.1...999. [Per cent]

1.3 tI - Integrating time.

The integrating time is entered in seconds.

Valid selections are 0...999. [Seconds]

1.4 td - Differentiating time.

The differentiating time is entered in seconds.

Valid selections are 0...999. [Seconds]

1.5 IE - Internal or external setpoint.

When internal has been selected, input B is disabled, and the setpoint

value is set in menu 1.1.

When external has been selected, input B is the setpoint. The signal

type and measurement range of input B are set in menu 3.0.

The selection made is overruled by the selection of ISP in menu 1.7.

Possible selections are I - [Internal], or E - [External].

1.6 dI - Direct / Inverted controlling method.

When direct has been selected, a process value > the setpoint will

result in an increasing output value. When inverted has been selected,

a process value > the setpoint will result in a decreasing output value.

Possible selections are dIr - [Direct], or InU - [Inverted].

1.7 dIF - Digital input function.

When - ISP - has been selected, a deactivated digital input will select

an internal setpoint, and an activated digital input will select an

external setpoint. The ISP selection overrules the internal setpoint (IE)

in menu 1.5.

When - HLd - has been selected, a deactivated digital input will result

in a normal PID control of the output, and an active digital input will

hold the output value and stop the integrator.

When - OFF - has been selected, the digital input has no function.

Possible selections are ISP, HLd or OFF. [Digital input]

54

A typical value is 5.0, but the degree should be adapted to the present

application.

Valid selections are -99...100. [Per cent]

1.4 dt3 - Period in seconds * 1000 between the readouts of the input

value.

The period between the readouts of the input is set both in this menu

and in menu 1.5. The total period is the sum of menus 1.4 and 1.5 with

the limit of 0.02...3600 seconds.

A typical value is 0, but the period should be adapted to the present

application.

Valid selections are 0...003. [Seconds * 1000]

1.5 dt0 - Period in seconds between readouts of the input value.

The period between readouts of the input is set both in this menu and

in menu 1.4. The total period is the sum of menus 1.4 and 1.5 with the

limit of 0.02...3600 seconds.

A typical value is 1.0, but the period should be adapted to the present

application.

Valid selections are 0.02...999. [Seconds]

1.0 PAr for analogue multiplexer. [Function no. 16]

The input that must be transferred to the output must be selected by

the digital input.

Input A is selected by deactivating the digital input.

Input B is selected by activating the digital input.

1.1 P1 - Scale factor for input A.

A typical value is 1.0.

Valid selections are -99...999. [Factor]

1.2 P2 - Scale factor for input B.

A typical value is 1.0.

Valid selections are -99...999. [Factor]

2.0 InA - Input A.

The input signal can be inverted by selecting the 0% value greater

than the 100% value.

2.1 IAL - Setting of 0% input signal.

Valid selections are current 0.0...20.0 [mA], or voltage 0.0...10.0 [VDC].

For modules with a Pt100 input, the valid 0% temperature is

-99...+850 [°C].

57

1.3 IE - Internal / external signal limiter.

When - I - has been selected, the other analogue input is disabled, and

the signal limiting follows the set IL and IH values.

When - EL - has been selected, the high limit will follow the set IH

value, while the low limit will follow the other analogue input.

When - EH - has been selected, the low limit will follow the set IL

value, while the high limit will follow the other analogue input.

Possible selections are I - [Internal], EL - [External low], or EH -

[External high].

1.4 CH - Input.

The input that the output must follow.

Possible selections are A or B. [Input].

1.0 PAr for averaging. [Function no. 14]

1.1 AtI - Averaging time.

The time in seconds that the input is averaged before it is sent to the

output.

Valid selections are 0.1...999. [Seconds]

1.2 StS - Stack size.

Number of memories. The time between the updates of the output is

AtI divided by StS.

Valid selections are 1...14. [Memories]

1.3 CH - Input.

The input that is averaged before it is sent to the output.

Possible selections are A or B. [Input]

1.0 PAr for slope transmitter (Input A). [Function no. 15]

1.1 tAU - Time constant for exponential averaging of the input.

Valid selections are 0.00...999. [Seconds]

1.2 dIL - Smallest slope for 0% output value.

The slope in % of the input span that must correspond to the 0%

output signal.

A typical value is 0.0.

Valid selections are -99...100. [Per cent]

1.3 dIH - Greatest slope for 100% output value.

The slope in per cent of the input span that must correspond to the

100% output signal.

56

003 = voltage output in the range 0...500 mV

004 = voltage output in the range 0...1 V (for instance 0.2...1 V)

005 = voltage output in the range 0...5 V

006 = voltage output in the range 0...10 V

4.4 Or - Selection of overrange.

When ON has been selected, the output can exceed the selected

output span by ±3%, however only within the range 0...20.5 mA /

0...10.25 VDC.

When OFF has been selected, the output is limited to the selected

output span.

Possible selections are ON or OFF. [Permit overrange]

5.0 APP - Selection of application.

5.1 FUn - Selection of function.

Possible selections are:

001 = Addition of 2 analogue signals (P1*A + P2*B + P3).

002 = Subtraction of 2 analogue signals (P1*A - P2*B + P3) or

(P2*B - P1*A+P3).

003 = Max. selection of 2 analogue signals Max. (P1*A, P2*B) + P3.

004 = Min. selection of 2 analogue signals Min. (P1*A, P2*B) + P3.

005 = Multiplication of 2 analogue signals (P1*A*B) + P3.

006 = Division of 2 analogue signals (P1*A/B) + P3 or (P1*B/A) + P3.

007 = Root extraction / Raising to a power (P1(A or B)P2) + P3.

A and B are the input signal spans for the A and B inputs respectively.

P1 and P2 are the scale factors multiplied on the A and B inputs

respectively. When the scale factors are 1, the input signal is scaled

to its full value. A scale factor of 0.5 will scale the input signal to half

its value. At the multiplication, division, root extraction and power

functions the scale factor must be set as P1. At the root extraction and

raising to a power P2 is the exponent. An exponent of 0.5 will result

in a square root function; an exponent of 2 will raise the input to the

second power.

P3 is a calculation offset set to values between 0 and 1 (0...100%)

and added to the present signal range of the output. If for instance the

output is set to a signal range of 10...20 mA, a P3 of 0.5 will result in

an extra offset of 50% of the output span. This means that the signal

range starts at 15 mA and starts to limit at 20 mA. At most calculations,

the calculation offset must be set to 0, but at complex calculations it

can be used for moving the range of the output signal range.

59

2.2 IAH - Setting of 100% input signal.

Valid selections are current 0.0...20.0 [mA], or voltage 0.0...10.0 [VDC].

For modules with a Pt100 input, the valid 100% temperature is

-99...+850 [°C].

2.3 UI - Selection of current / voltage input.

To select the current / voltage input the jumper on the PCB must be

moved.

For modules with a Pt100 input, this menu has no function.

Possible selections are I - [Current], or U - [Voltage].

3.0 Inb - Input B.

The input signal can be inverted by selecting the 0% value greater

than the 100% value.

3.1 IbL - Setting of 0% input signal.

Valid selections are current 0.0...20.0 [mA], or voltage 0.0...10.0 [VDC].

3.2 IbH - Setting of 100% input signal.

Valid selections are current 0.0...20.0 [mA], or voltage 0.0...10.0 [VDC].

3.3 UI - Selection of current / voltage input.

To select the current / voltage input the jumper on the PCB must be

moved.

Possible selections are I - [Current], or U - [Voltage].

4.0 OUt - Output.

The output signal can be inverted by selecting the 0% value greater

than the 100% value.

4.1 OL - Setting of 0% output signal.

Valid selections are current 0.0...20.0 [mA], or voltage 0.0...10.0 [VDC].

4.2 OH - Setting of 100% output signal.

Valid selections are current 0.0...20.0 [mA], or voltage 0.0...10.0 [VDC].

4.3 UI - Selection of current or voltage output.

The basic calibration data in the module differ according to the

selected output signal range meaning that the current output is current-

calibrated, and the voltage output is voltage-calibrated by the internally

mounted resistors.

To change between the output voltage in the range 0...1 and 0...10

VDC, the jumper on the PCB must be moved.

Possible selections are:

001 = current output in the range 0...10 mA

002 = current output in the range 0...20 mA (for instance 4...20 mA)

58

obtained. Therefore it is important that the the proportional band Xp,

the integrating time Ti, and the differentiating time Td are adjusted

according to the present application. Before setting the parameter,

the method of regulation direct / inverted must be determined. Direct

controlling results in an increasing output when the process value is >

the setpoint. Inverted controlling results in a decreasing output when

the process value is > the setpoint. Less experienced users may use

the following rule-of-thumb for determining the process parameters:

1. Set Xp at max., Ti and Td at 0 (only proportional controlling).

2. Reduce Xp until the process starts oscillating.

3. Double Xp.

4. Set Ti at max.

5. Reduce Ti until the process starts reoscillating.

6. Double Ti.

7. If the controller is too slow reaching its setpoint, the differential

controller can be activated. The differential function increases the

control signal proportionally to the rise time of the process signal.

Therefore the setting varies according to the process.

012 = Manual / Automatic controller:

The digital input is used to switch between the manual and automatic

mode. A deactivated digital input results in the auto function, where

the value of input A is transferred to the output. An activated digital

input results in the manual function, where the output adopts the value

of input A when activated. Now the output can be activated up or

down manually. The output holds the manual setting for an unlimited

period. The setting is saved at power failure.

013 = Signal limiter:

The output follows the value of the selected analogue input (A or B)

linearly in the range between the min. and max. settings. At input

signals smaller than the min. or greater than the max. settings, the

output is held on the min. or max. value respectively. The min. or max.

value can be set externally via the other analogue input.

014 = Averaging function:

The averaging function reads the input value of the selected A or B

channel every 20 ms and adds up the measurements in a memory.

When the averaging time has expired, the average value is calculated

by dividing the memory value by the number of measurements made,

and the output is then updated by this value. The averaging function

61

When calculating scale factors the input and output signal spans

always have values between 0 and 1. When adding 2 identically scaled

input signals of for instance 4...20 mA, the output would be 8...40 mA

at the same scaling. But as the output follows standard current signals

of 0/4...20 mA, the scaling on the output is double of the scaling on

the inputs. This means that each input must be scaled by only half

the scale of the output. The figures can be calulated according to the

following expression (P1*A + P2*B + P3) = 1, and with this in mind it

will be (0.5*1+0.5*1 + 0) = 1.

When adding 2 differently scaled input signals, the scale factors can

be calculated as follows:

Signal A is 4...20 mA corresponding to a flow of 0...100 m3 / h

Signal B is 4...20 mA corresponding to a flow of 0...150 m3 / h

The output signal of 4...20 mA must correspond to a flow of 0...250 m3 / h

Signal A must be scaled by 100/250 corresponding to a scale factor

P1 of 0.4.

Signal B must be scaled by 150/250 corresponding to a scale factor

P2 of 0.6.

008 = Sample-Hold:

When the digital input is deactivated, the analogue output follows the

selected analogue input (A or B). When the digital input is activated,

the output value is fixed at the value it had when activated until the

digital input is deactivated. The hold value is saved at power failure.

009 = Peak-Hold:

When the digital input is deactivated, the greatest value (the peak

value) of the selected analogue input (A or B) since the latest reset is

held. An activated digital input will reset the peak value to the value

that the input had when activated. By inverting the input and output

signals, the smallest input value is held. The peak value is saved at

power failure.

010 = Time delay:

The output follows the values of the selected input (A or B) averaged

according to an exponential function.

011 = PID controller:

In a correctly tuned PID controller, the constant error will be eliminated.

This means that at a correctly tuned Xp, Ti, and Td, a regulation

accuracy close to what the process value can be measured to can be

60

6362

has 2 parameter settings, AtI - averaging time, and StS - number

of memories. The averaging time is the time that is averaged. The

number of memories to be selected is (1...14). The time between the

updates of the output is determined by the average time divided by

number of memories (AtI/StS). If AtI/StS is smaller than 20 ms, the

output will be updated every 20 ms.

Example:

With an average time of 10 s and 1 memory, the period between the

updates of the output will be (10/1) = 10 s. The output will typically

make a jump at the update.

If the number of memories is for instance 10, the period between the

updates of the output will be (10/10) = 1 s. Each memory (1…10) will

hold the average value for 1 s. The output is updated every second

by the average value of the 10 memories. This means that the jumps

on the output will be smaller. The 10 memories will be replaced

continously according to the FIFO method (first in, first out).

015 = Slope transmitter (dI / dt function):

The slope transmitter converts the slope (dI) of input A according to a

set period (dt) to an analogue output signal. Each time the set period

(dt) has expired, the input value is read. The latest readout is compared

to the previous, and the difference between these two values is the

slope of the input signal, which is converted to an analogue output

signal. The output is updated each time a period (dt) has expired. The

slope can be selected as either positive or negative. The input signal

can be averaged according to an exponential function so that it can be

applied to noisy signals.

Example:

Minimum slope (dIL) = 0%.

Maximum slope (dIH) = -1%.

Period = 5 seconds.

Analogue output = 4...20 mA.

Result:

Has the input value not been changed within 5 seconds, the output

will be 4 mA. Has the input value decreased by 0.5% after 5 seconds,

the output will be 12 mA. Has the input value decreased by 1% after 5

seconds, the output will be 20 mA.

016 = Analogue multiplexer:

Expression: (P1*A) and (P2*B).

The input (A or B) to be transferred to the output is selected by the

digital input. Input A has been selected when the digital input is

deactivated, and input B has been selected when the digital input

is activated. P1 and P2 are scale factors multiplied on input A or B

respectively. When the scale factor is 1, the input value is scaled to

its full value. A scale factor of 0.5 will scale the input signal to half its

value.

5.2 FrQ - Frequency.

Common mode frequency suppression.

Possible selections are 50 or 60. [Hz]

5.3 dSP - Default display.

The selected span is displayed in per cent. For modules with a Pt100

input, also °C can be displayed.

Possible selections are A or B [Input], OUt [Output], or °C

[Temperature].

5.4 PAS - Password.

When the password is 040, changes can be made in all menu points.

When the password is <> 040, programming is blocked in all menu

points but open to a reading of settings.

Valid selections are 0...999. [Password]

6564

6766

Table of contents