iv EDDYSENSOR Operating Manual

General information

Due to the nature of eddycurrent testing, strong

electro-magnetic fields could affect the test results.

Areas of use This equipment is intended for use exclusively in collecting

and processing eddycurrent test data in areas where there

is no danger of explosion.

Electro-magnetic

compatibility

This equipment was tested for electro-magnetic compatibil-

ity according to EN 55011 Group 1, Class A and EN 50082-

2.

Operative restrictions Using this equipment in a residential area can lead to electro-

magnetic interference and therefore requires special authori-

zation from the national regulatory agency for post and tel-

ecommunications (BAPT).

Installation site

requirements

Installation instructions

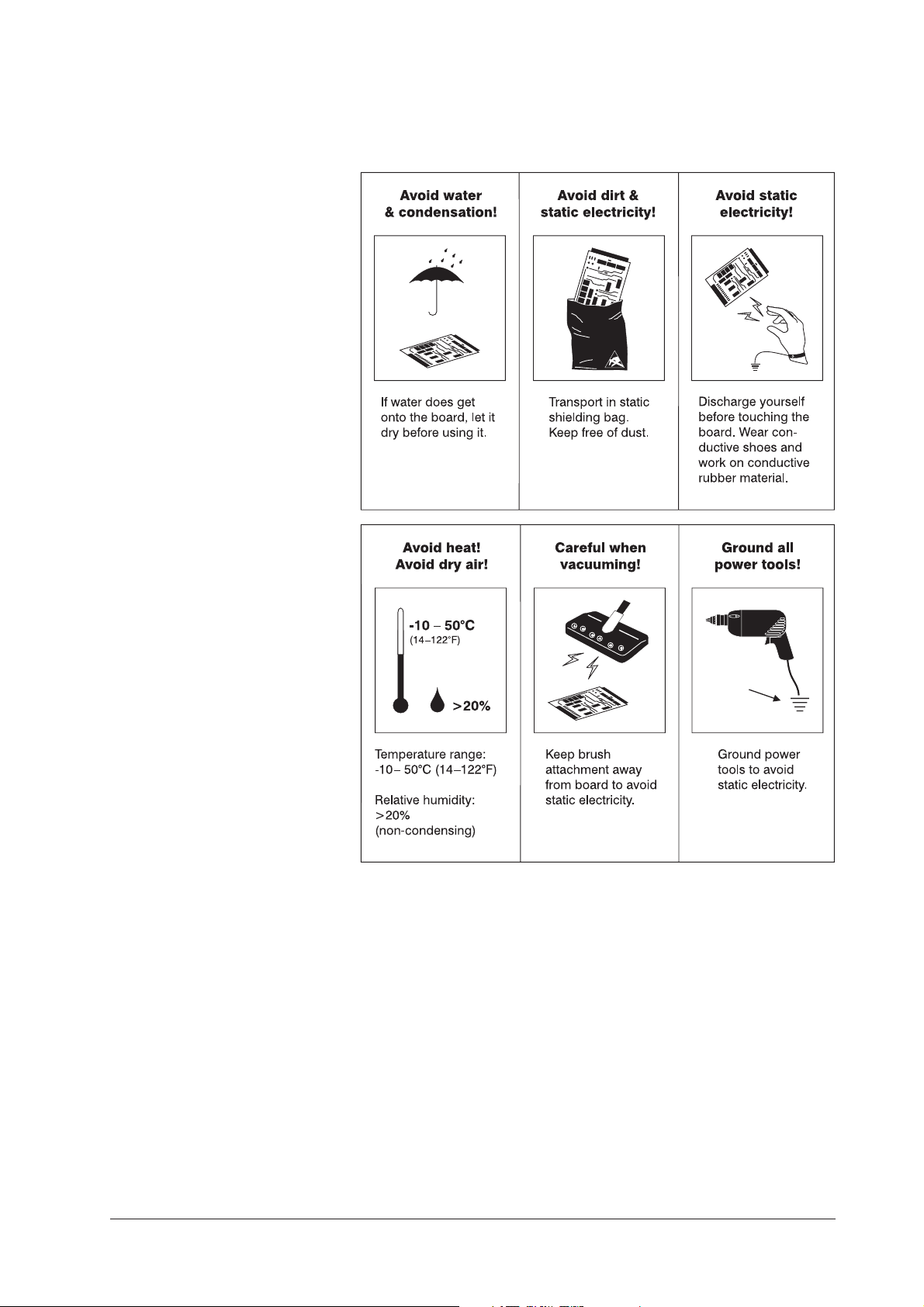

•Temperature range: see "Technical Data"

•Flat, level installation surface

•Equipment must be far enough away from the wall to open

the rear door easily and access the interior

(For actual dimensions, see "Technical Data" at the back of

the operating manual.)

Technical data

The technical data relevant to this equipment is listed at the

back of the Operating Manual.