Practical Automation ITK 38 SERIES User manual

ITK 38

Printer Series

User’s Manual

PRACTICAL AUTOMATION INC.

ITK 38 User’s Manual Version V1.03 Date: (7/2/09) File: UMITK103.pdf 1 of 79

TABLE OF CONTENTS

1.0 HOW TO CONTACT US................................................................................................................................................... 7

1.1 LIMITED PRODUCT WARRANTY ........................................................................................................................................ 7

1.1.1 Warranty Terms........................................................................................................................................................... 7

1.1.2 Warranty Procedure.................................................................................................................................................... 7

1.2 FCC NOTIFICATION........................................................................................................................................................... 8

1.3 REGULATORY COMPLIANCE.............................................................................................................................................. 8

2.0 ITK 38 OVERVIEW........................................................................................................................................................... 9

2.1 INTRODUCTION.................................................................................................................................................................. 9

2.2 PRODUCT DESCRIPTION..................................................................................................................................................... 9

2.3 ITK 38 MODEL NUMBER SYSTEM................................................................................................................................... 10

2.3.1 ITK 38 Power Supply Model Number........................................................................................................................ 10

2.3.2 ITK 38 Printer Model Number Example.................................................................................................................... 11

2.3.3 ITK 38 Separate Component Model Numbers........................................................................................................... 11

PREPARATION FOR USE............................................................................................................................................................ 12

2.4 UNPACKING AND INSPECTION ......................................................................................................................................... 12

2.5 INSTALLATION LOCATION............................................................................................................................................... 12

2.6 POWER CONNECTION ...................................................................................................................................................... 12

2.7 DATA I/O INTERFACE CONNECTION................................................................................................................................12

2.7.1 Parallel Interface....................................................................................................................................................... 12

2.7.2 USB Interface............................................................................................................................................................. 12

2.8 PRINTER DRIVER INSTALLATION..................................................................................................................................... 12

2.8.1 Discussion of Printer Drivers.................................................................................................................................... 12

2.8.1.1 Discussion of Driver Names: ........................................................................................................................... 12

2.8.1.2 Which Driver to Load?..................................................................................................................................... 13

2.8.1.3 Loading The Printer Driver:............................................................................................................................. 13

2.8.1.4 Printer’s Status Information: ............................................................................................................................ 13

2.8.1.5 Host Controlled Printer Firmware Update: ...................................................................................................... 13

2.8.1.6 Printer Utility DLL:.......................................................................................................................................... 13

2.8.2 Selecting and Configuring the Driver........................................................................................................................ 13

2.9 PAPER SUPPLY................................................................................................................................................................. 14

2.10 PAPER LOADING.............................................................................................................................................................. 14

2.11 TEST PRINT ..................................................................................................................................................................... 14

2.12 OPERATION FROM THE INTERFACE.................................................................................................................................. 14

3.0 OPERATOR CONTROLS AND INDICATORS........................................................................................................... 15

3.1 SWITCH AND DISPLAY..................................................................................................................................................... 15

3.2 PANEL LEDS INDICATORS............................................................................................................................................... 15

3.2.1 Power / Paper............................................................................................................................................................ 15

3.2.2 Ready......................................................................................................................................................................... 15

3.2.3 Attn. / Error ............................................................................................................................................................... 15

3.3 PANEL SWITCHES ............................................................................................................................................................ 15

3.3.1 Forcing Reset Initialization ....................................................................................................................................... 15

3.4 REAR I/O PANEL ............................................................................................................................................................. 16

4.0 PANEL SWITCH OPERATIONS................................................................................................................................... 17

4.1 SWITCH MODES............................................................................................................................................................... 17

4.2 OFFLINE OPERATIONS ..................................................................................................................................................... 17

4.3 OFFLINE SWITCH OPERATIONS TABLE ............................................................................................................................ 17

4.4 OFFLINE SWITCH OPERATIONS........................................................................................................................................ 17

4.5 POWER-ON OPERATIONS................................................................................................................................................. 17

4.6 POWER-ON OPERATIONS TABLE ..................................................................................................................................... 17

4.7 PRINTER SYSTEM INFORMATION AND REPORTS .............................................................................................................. 17

4.7.1 System Status Report.................................................................................................................................................. 18

4.7.1.1 System Report – for Registration Marked Paper.............................................................................................. 18

4.7.1.2 System Report – for Continuous Paper............................................................................................................ 19

4.8 SYSTEM INFORMATION HELP REPORT............................................................................................................................. 20

4.9 DIAGNOSTIC MENU ......................................................................................................................................................... 21

4.10 CHANGE TOF CONFIGURATIONS..................................................................................................................................... 21

4.11 EEPROM CHANGE MENU .............................................................................................................................................. 21

4.12 RE-PROGRAM FLASH MEMORY....................................................................................................................................... 21

4.13 HEX DUMP DIAGNOSTIC MODE....................................................................................................................................... 21

ITK 38 User’s Manual Version V1.03 Date: (7/2/09) File: UMITK103.pdf 2 of 79

4.14 PRINTHEAD CLEANING DIAGNOSTIC MODE .................................................................................................................... 21

5.0 PAPER HANDLING OPTIONS & ACTIONS .............................................................................................................. 22

5.1 PAPER DELIVERY OUTPUT OPTIONS................................................................................................................................22

5.1.1 Disposing Transport-Presenter ................................................................................................................................. 22

5.1.1.1 Perforated Paper Stock..................................................................................................................................... 22

5.1.1.2 Loop Storage Chamber..................................................................................................................................... 22

5.1.1.3 Dispose Storage Chamber................................................................................................................................22

5.1.1.4 Host Monitoring of Dispose Documents.......................................................................................................... 23

5.1.1.5 Document Not Taken Status............................................................................................................................. 23

5.1.1.6 Transport-Presenter Control Parameters and Operating Mode Selection......................................................... 23

5.1.1.6.1 Transport-Presenter Control Parameters for a Document Not Taken.......................................................... 23

5.1.1.6.1.1 Host Controlled - Document Not Taken Reactions.............................................................................. 23

5.1.1.6.1.2 Printer Assisted – Document Not Taken Reactions............................................................................. 24

5.1.1.6.1.3 Purge Options – Document Not Taken ................................................................................................ 25

5.1.1.6.2 Transport-Presenter Control Parameters for a Blocked Output Jam............................................................ 25

5.1.1.7 Printer & Host Reactions – Document Not Taken or Blocked Output............................................................. 26

5.1.1.7.1 Document Not Taken .................................................................................................................................. 26

5.1.1.7.2 Blocked Output............................................................................................................................................ 26

5.1.2 Cutter with Jam Resistant Output Chamber Option.................................................................................................. 26

5.1.3 Cutter Only Output Option ........................................................................................................................................ 26

5.1.4 Tearbar With Jam Resistant Output Chamber Option............................................................................................... 26

5.1.5 Minimum Form Length Adjustment ........................................................................................................................... 27

5.2 PAPER INPUT DELIVERY OPTIONS ................................................................................................................................... 28

5.2.1 Formula for Calculating Paper Roll Capacity .......................................................................................................... 28

5.2.1.1 Paper Roll I.D................................................................................................................................................... 28

5.2.2 Internal 6"/8" (152mm/203mm) Diameter Paper Roll Holder ................................................................................. 28

5.2.3 External 10" Diameter Paper Roll Holder ................................................................................................................ 28

5.2.3.1 External 10"” Diameter Paper Roll Holder Drawing ....................................................................................... 28

5.2.3.2 Externally Located Paper Design Considerations............................................................................................ 29

5.2.3.2.1 External Roll Holder Paper Path Recommendations Drawing.................................................................... 29

5.2.4 Low Paper Monitoring............................................................................................................................................... 29

5.2.4.1 Low Paper Host Status Information................................................................................................................. 29

5.2.4.2 Printer Reactions to the Low Paper Conditions................................................................................................ 30

5.2.4.3 Low Paper Cable Detection.............................................................................................................................. 30

6.0 PAPER INFORMATION................................................................................................................................................. 31

6.1 PAPER SPECIFICATIONS ................................................................................................................................................... 31

6.1.1 Paper Width............................................................................................................................................................... 31

6.1.2 Roll Size..................................................................................................................................................................... 31

6.1.3 Recommended Papers................................................................................................................................................ 31

6.1.4 Other Thermal Papers............................................................................................................................................... 31

6.1.5 Print Activation Energy ............................................................................................................................................. 31

6.1.6 Roll Paper Curl Considerations ................................................................................................................................31

6.1.7 Paper Form Type....................................................................................................................................................... 31

6.1.7.1 Paper Supply .................................................................................................................................................... 31

6.1.7.2 Continuous Forms............................................................................................................................................ 31

6.1.7.3 Registration Mark Forms ................................................................................................................................. 31

6.1.8 Paper Pre-printing Information................................................................................................................................. 32

6.1.8.1 Pre-printed Paper: Bottom Side Restrictions.................................................................................................... 32

6.1.8.2 Pre-Printed Paper: Top Side............................................................................................................................. 32

6.1.8.3 Fan Fold / Perforated Paper.............................................................................................................................. 32

6.1.8.4 Cutting Perforated Paper.................................................................................................................................. 32

6.1.8.5 Registration Mark Location: Bottom Side ....................................................................................................... 33

6.2 PAPER FORM TYPE RECOGNITION ................................................................................................................................... 33

6.2.1 Printer Recognition of Paper Form Type.................................................................................................................. 33

6.2.2 Top and Bottom Margins........................................................................................................................................... 33

6.2.3 Host PC Recognition of Paper Form Type and Size.................................................................................................. 33

6.3 PAPER FORM SIZE DETERMINATION................................................................................................................................33

6.3.1 Document Length....................................................................................................................................................... 33

6.3.2 Registration Mark Document Size Measurement....................................................................................................... 34

6.3.3 Printer Determination of Form Size .......................................................................................................................... 34

ITK 38 User’s Manual Version V1.03 Date: (7/2/09) File: UMITK103.pdf 3 of 79

6.3.3.1 Continuous Forms............................................................................................................................................ 34

6.3.3.2 Registration Marked Forms.............................................................................................................................. 34

6.3.3.2.1 Autosize Measurement of Form Length...................................................................................................... 34

6.3.3.2.2 Stored Form Length..................................................................................................................................... 34

6.3.3.2.2.1 Default Form Size................................................................................................................................34

6.3.3.2.2.2 Entering a Fixed Form Size Into EEPROM Memory........................................................................... 34

6.3.3.2.2.3 Autosize Measurement and Save to EEPROM.................................................................................... 34

6.3.3.2.2.4 Manual Size Data Entry....................................................................................................................... 34

6.3.3.2.2.5 Document Re-Sizing............................................................................................................................ 34

6.3.3.2.2.6 Reporting Document Length................................................................................................................ 35

6.3.4 Host Determination of Form Size – Registration Marked Forms.............................................................................. 35

7.0 PRINTER PROGRAMABLE CONFIGURATION SETTINGS.................................................................................. 36

7.1 OVERVIEW ...................................................................................................................................................................... 36

7.1.1 I/O PCB Configuration resistors and configuration straps....................................................................................... 36

7.1.2 Printer EEPROM Parameter Storage........................................................................................................................ 36

7.1.3 Paper Output Delivery Option Detection .................................................................................................................. 36

7.1.4 Special Customization................................................................................................................................................ 36

8.0 DATA AND AUXILIARY INTERFACES ..................................................................................................................... 37

8.1 IEEE-1284 PARALLEL DATA INTERFACE........................................................................................................................ 37

8.1.1 Parallel Interface Cable ............................................................................................................................................ 37

8.1.2 Parallel Interface (IEEE-1284) Cable Schematic...................................................................................................... 37

8.1.3 Parallel Interface Pin-out Table................................................................................................................................37

8.1.4 Parallel Port Signaling.............................................................................................................................................. 37

8.2 USB DATA INTERFACE ................................................................................................................................................... 37

8.2.1 USB Data Interface Cable......................................................................................................................................... 37

8.3 DATA INTERFACE CABLE QUALITY................................................................................................................................. 37

8.4 AUXILIARY I/O CONNECTOR........................................................................................................................................... 37

8.4.1 Auxiliary I/O Pin-out................................................................................................................................................. 37

9.0 ERROR CODES................................................................................................................................................................ 38

9.1 ANNUNCIATIONS ............................................................................................................................................................. 38

9.2 SEQUENCE LENGTH......................................................................................................................................................... 38

9.3 WEIGHTED POSITIONS..................................................................................................................................................... 38

9.4 COUNTED ........................................................................................................................................................................ 38

9.5 EXAMPLE ........................................................................................................................................................................ 38

9.6 ERROR CODE TABLE ....................................................................................................................................................... 39

9.7 ERROR CODE TABLE NOTES............................................................................................................................................ 39

9.8 ERROR CODE TABLE INFORMATION ................................................................................................................................39

9.9 ERROR CODE COMPUTATION .......................................................................................................................................... 39

10.0 EEPROM PRINTER PARAMETER STORAGE MEMORY ..................................................................................... 40

10.1 EEPROM OVERVIEW...................................................................................................................................................... 40

10.2 EEPROM CHANGE MENU OPERATION ........................................................................................................................... 40

10.3 ACTIVE AND IN-ACTIVE MENU LINE ............................................................................................................................... 40

10.4 EEPROM MENU #1 PRINTOUT ....................................................................................................................................... 40

10.5 EEPROM MENU #1 PARAMETERS.................................................................................................................................. 41

10.5.1 Print Intensity........................................................................................................................................................ 41

10.5.2 Print Energy Table................................................................................................................................................ 41

10.5.3 IPS Clamp............................................................................................................................................................. 41

10.5.4 Power Supply ........................................................................................................................................................ 41

10.5.5 Interface Control................................................................................................................................................... 41

10.5.6 Beeper Control...................................................................................................................................................... 41

10.5.7 Low Paper Actions................................................................................................................................................ 41

10.5.8 Purge Spooler on Error ........................................................................................................................................ 42

10.5.9 Configuration Misc. .............................................................................................................................................. 42

10.6 EEPROM MENU #2 PRINTOUT ....................................................................................................................................... 42

10.7 EEPROM MENU #2 PARAMETERS.................................................................................................................................. 42

10.7.1 Paper Backup........................................................................................................................................................ 42

10.7.2 Change Stored Size: Form Size 10’s, 1’s, 0.1’s, 0.01’s......................................................................................... 42

10.7.3 Stored Size............................................................................................................................................................. 42

10.7.4 Form Control........................................................................................................................................................ 42

10.7.5 End of Document Length....................................................................................................................................... 43

ITK 38 User’s Manual Version V1.03 Date: (7/2/09) File: UMITK103.pdf 4 of 79

10.7.6 Autosize................................................................................................................................................................. 43

10.7.7 Minimum Form Length ......................................................................................................................................... 43

10.7.8 Status Pointer........................................................................................................................................................ 43

10.7.9 Blocked Output Jam Error Control....................................................................................................................... 44

10.7.10 Document Not Taken Control ............................................................................................................................... 44

10.8 EEPROM MENU #3 PRINTOUT ....................................................................................................................................... 44

10.9 EEPROM MENU #3 PARAMETERS.................................................................................................................................. 44

10.9.1 Parallel Interface.................................................................................................................................................. 44

10.9.2 Low Paper Cable Detection.................................................................................................................................. 45

10.10 EEPROM FACTORY DEFAULTS ...................................................................................................................................... 45

11.0 PRINTER STATUS INFORMATION............................................................................................................................ 46

11.1 ITK 38 PRINTER STATUS OVERVIEW............................................................................................................................... 46

11.1.1 Operator Status..................................................................................................................................................... 46

11.1.2 Parallel Interface - Compatibility Mode Status.................................................................................................... 46

11.1.3 Parallel IEEE 1284 Interface Standard................................................................................................................ 46

11.1.4 Parallel Interface IEEE-1284 Reverse Channel Status......................................................................................... 46

11.1.4.1 Requesting Status Data..................................................................................................................................... 46

11.1.4.2 Reverse Channel Status Data Types................................................................................................................. 46

11.1.4.3 Reverse Channel - Detailed Status - Application Program Reading Protocol.................................................. 47

11.1.4.4 Reverse Channel Speed.................................................................................................................................... 47

11.2 SELECTION OF DETAILED STATUS INFORMATION............................................................................................................ 47

11.2.1 Status Data Request.............................................................................................................................................. 47

11.2.2 Status Group Selection Commands....................................................................................................................... 48

11.2.3 Status Information Data Organization.................................................................................................................. 48

11.2.3.1 IEEE 1284 ID String Format (Plug & Play ID String Reverse Channel Status).............................................. 48

11.2.3.2 Detailed Status Format (Normal Reverse Channel Status)............................................................................... 48

11.2.3.2.1 Status Field Format.................................................................................................................................... 49

11.2.3.2.2 Status Field Notes...................................................................................................................................... 49

11.2.3.2.3 Status Field Descriptions ........................................................................................................................... 49

11.2.3.2.4 Short Status Group..................................................................................................................................... 50

11.2.3.2.4.1 Short Status Group – Bit Status Format............................................................................................. 50

11.2.3.2.5 Normal Status Group................................................................................................................................. 50

11.2.3.2.6 Extended Status Group .............................................................................................................................. 50

11.2.3.2.7 Complete Status Group.............................................................................................................................. 51

11.2.3.2.8 Addressed Status Group............................................................................................................................. 51

11.2.3.2.9 Bit Flag Data – Status Field 00.................................................................................................................. 51

11.2.3.2.10 Error Code – Status Field 01.................................................................................................................... 51

11.2.3.2.11 Document Count – Status Field 02.......................................................................................................... 51

11.2.3.2.12 Printhead Temperature – Status Field 03................................................................................................. 51

11.2.3.2.13 Form Length – Status Field 04................................................................................................................. 52

11.2.3.2.13.1 Reporting Document Length............................................................................................................ 52

11.2.3.2.14 Firmware Version – Status Field 05......................................................................................................... 52

11.2.3.2.15 Plug & Play ID String – Status Field 08.................................................................................................. 52

11.2.3.2.16 Product Electronic Serial Number – Status Field 09................................................................................ 52

11.2.3.2.17 Capabilities – Status Field 11................................................................................................................... 52

11.2.3.2.18 Flash Ready Acknowledge Status – Status Field 15................................................................................ 52

11.2.4 Field 01 Error Code List....................................................................................................................................... 53

12.0 OPERATOR RE-PROGRAMMING OF FLASH MEMORY PROCEDURE ........................................................... 55

12.1 GENERAL......................................................................................................................................................................... 55

12.2 REQUIREMENTS............................................................................................................................................................... 55

12.3 ENTERING THE FLASH LOAD MODE ................................................................................................................................55

12.4 FLASH LOADING PROCESS............................................................................................................................................... 55

12.5 WARNING........................................................................................................................................................................ 55

12.6 FLASH LOADING COMPLETION........................................................................................................................................ 55

12.7 FLASH LOADING TIME..................................................................................................................................................... 56

12.8 FIRMWARE DATA FILES .................................................................................................................................................. 56

13.0 HOST RE-PROGRAMMING OF FLASH MEMORY PROCEDURE....................................................................... 57

13.1 OVERVIEW ...................................................................................................................................................................... 57

13.2 FLASH MEMORY REPROGRAMMING MODE ENTRY ......................................................................................................... 57

13.2.1 Manual Entry........................................................................................................................................................ 57

ITK 38 User’s Manual Version V1.03 Date: (7/2/09) File: UMITK103.pdf 5 of 79

13.2.2 Command Entry .................................................................................................................................................... 57

13.3 FLASH READ ONLY MEMORY ORGANIZATION................................................................................................................ 57

13.4 FIRMWARE BINARY DATA FILES..................................................................................................................................... 57

13.5 FLASH MEMORY REPROGRAMMING ACTIONS................................................................................................................. 58

13.6 COMMAND DRIVEN PROCESS FOR REPROGRAMMING THE FLASH MEMORY:.................................................................. 58

13.6.1 Command Driven Process Details:....................................................................................................................... 60

14.0 APPLICATIONS PROGRAMMER INFORMATION................................................................................................. 62

14.1 PRINTER UTILITY DLL.................................................................................................................................................... 62

14.2 DOCUMENT PAGE LENGTHS ............................................................................................................................................ 62

14.3 STATUS STRING SELECTION ............................................................................................................................................ 62

14.4 STATUS AND SPOOLER MANAGEMENT............................................................................................................................ 62

14.5 DOCUMENT RE-PRESENT (EJECT)AND DISPOSE COMMANDS.......................................................................................... 62

15.0 MAINTENANCE.............................................................................................................................................................. 63

15.1 PRINTER ASSEMBLY-MAINTENANCE POINTS ................................................................................................................. 63

15.2 PAPER REGISTRATION MARK SENSOR............................................................................................................................. 63

15.3 PRINTHEAD ALIGNMENT &PRESSURE CAM.................................................................................................................... 63

15.4 PRINTHEAD CLEANING.................................................................................................................................................... 63

15.4.1 Printhead Cleaning Diagnostic Mode................................................................................................................... 64

15.4.2 Printhead Cleaning Sheets.................................................................................................................................... 64

15.5 DOCUMENTATION PRESENTER /JAM SENSORS................................................................................................................ 64

15.6 SENSOR ACCESS AND ALIGNMENT ADJUSTMENTS .......................................................................................................... 64

15.7 DOCUMENT JAM –REQUIRING REMOVAL OF THE HEAD ................................................................................................. 65

16.0 DIAGNOSTIC................................................................................................................................................................... 66

16.1 GENERAL......................................................................................................................................................................... 66

16.2 OFF-LINE SWITCH OPERATIONS ...................................................................................................................................... 66

16.3 POWER ON SWITCH......................................................................................................................................................... 66

16.4 DIAGNOSTICS .................................................................................................................................................................. 66

16.4.1 Special Functions.................................................................................................................................................. 66

16.4.2 Burn-in and Cut Tests........................................................................................................................................... 66

16.5 HEX DUMP MODE ........................................................................................................................................................... 66

16.5.1 Data Rate Measurement Test................................................................................................................................66

16.6 PRINTHEAD CLEANING MODE ......................................................................................................................................... 66

17.0 POWER INFORMATION............................................................................................................................................... 67

17.1 D.C. POWER INPUT.......................................................................................................................................................... 67

17.2 POWER MANAGEMENT.................................................................................................................................................... 67

17.3 POWER SUPPLY REQUIREMENTS ..................................................................................................................................... 67

17.3.1 Power Supply Additional Requirements................................................................................................................ 67

18.0 APPENDIX........................................................................................................................................................................ 68

18.1 PRINTER SPECIFICATIONS................................................................................................................................................ 68

18.2............................................................................................................................................................................................... 68

18.3 ITK 38 PRINTER DIMENSIONAL DRAWINGS –CUTTER WITH DISPOSING TRANSPORT-PRESENTER ................................. 70

18.4 ITK 38 PRINTER DIMENSIONAL DRAWINGS –OPTIONAL OUTPUT EXTENSION ............................................................... 70

18.5 ITK 38 PRINTER DIMENSIONAL DRAWINGS –CUTTER WITH OUTPUT PROTECTION CHAMBER....................................... 71

18.6 ITK 38 PRINTER DIMENSIONAL DRAWINGS –CUTTER ONLY OUTPUT............................................................................ 71

18.7 ITK 38 PRINTER DIMENSIONAL DRAWINGS –TEARBAR WITH OUTPUT PROTECTION CHAMBER .................................... 72

18.8 ITK 38 PRINTER DIMENSIONAL DRAWINGS –FANFOLD PAPER TRAY MODEL #ATX-FFPHLP ................................. 72

18.9 ITK 38 PRINTER DIMENSIONAL DRAWINGS –LARGE (10" DIAMETER)PAPER ROLL HOLDER ........................................ 73

18.10 ITK 38 PRINTER DIMENSIONAL DRAWINGS –STANDARD (6"/8" DIAMETER)PAPER ROLL HOLDER............................... 73

18.11 ITK 38 PRINTER DIMENSIONAL DRAWINGS –60 WATT POWER SUPPLY......................................................................... 74

18.12 ITK 38 PRINTER DIMENSIONAL DRAWINGS –130 WATT POWER SUPPLY....................................................................... 75

18.13 CONNECTOR PIN-OUT –8PIN POWER CONNECTOR......................................................................................................... 75

18.14 CONNECTOR PIN-OUT –8PIN AUXILIARY CONNECTOR .................................................................................................. 75

18.15 CONNECTOR PIN-OUT 26 PIN PARALLEL CONNECTOR.................................................................................................... 76

18.16 IEEE-1284 PARALLEL A-B CABLE SCHEMATIC.............................................................................................................. 77

18.17 TEST DOCUMENT (SMALL).............................................................................................................................................. 78

18.18 TEST DOCUMENT (LARGE)............................................................................................................................................. 79

ITK 38 User’s Manual Version V1.03 Date: (7/2/09) File: UMITK103.pdf 6 of 79

1.0 HOW TO CONTACT US

PRACTICAL AUTOMATION INC.

The Alinabal Group of Companies

45 Woodmont Road

P.O. Box 3028

Milford, CT 06460

VOICE: (203) 882-5640

FAX: (203) 882-5648

INTERNET: http://www.practicalautomation.com

1.1 Limited Product Warranty

1.1.1 Warranty Terms

Practical Automation, Inc. warrants each new ITK 38 series printer to be free from defects in materials and workmanship to the

original purchaser. Our responsibility is limited to repair or replacement of the printer and/or accessory or part thereof at our

option for a period of one year from the date of shipment. This warranty does not cover the repair or replacement of the printhead

if it was damaged, or used in excess of its specified wear life. Also, only Practical Automation approved paper can be used to

maintain the warranty.

This limited warranty does not extend to any defect, malfunction or failure caused by or resulting from improper service, packing,

maintenance or repair, abuse, neglect, accident, or any other cause beyond the control of Practical Automation, Inc. or to any

product whose serial number has been removed, altered, replaced or rendered illegible.

Except and to extent provided herein, Practical Automation, Inc. makes no warranty, either express or implied, including any

warranty of merchantability or fitness for a particular purpose.

Practical Automation, Inc. shall not be liable to the purchaser or to any other person or firm for any specified or consequential

damages of any kind, which result from the use or misuse by any person or loss of profits or product resulting from any defect or

malfunction or failure of this product.

No person, agent, distributor, service facility or company is authorized to change, modify or amend the terms of this limited

warranty in any manner or fashion whatsoever.

1.1.2 Warranty Procedure

If you cannot resolve your equipment problem, notify Practical Automation, giving the model and serial number of your

equipment. Describe your problem in detail.

Upon receipt of this information, Practical Automation will send you service information if the trouble is easily corrected. If the

trouble requires factory service, we will so advise and provide written return authorization. Loaner printers can usually (subject to

availability) be shipped within 24 hours during the workweek by Practical Automation. Customers are required to pay all shipping

charges.

Refer also to the Warranty Terms and Packaging and Shipping instructions before returning any equipment.

ITK 38 User’s Manual Version V1.03 Date: (7/2/09) File: UMITK103.pdf 7 of 79

1.2 FCC Notification

FOR USERS IN THE UNITED STATES

Warning:

Changes or modifications to this unit not approved by the party responsible for compliance could void the user's authority to

operate the equipment.

Note:

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the FCC

rules. These limits are designated to provide reasonable protection against harmful interference when the equipment is operated in

a commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used

in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment

in a residential area is likely to cause harmful interference in which case the user will be required to correct the interference at his

own expense.

Shielded cables must be used with this unit to insure compliance with the Class A FCC limits.

FOR USERS IN CANADA

--------------------------------------------------------------------------------------------------------------------------------------------------

This Class [A] digital apparatus meets all requirements of the Canadian Interference-Causing Equipment Regulations.

--------------------------------------------------------------------------------------------------------------------------------------------------

Cet appareil numerique de la classe [A] respecte toutes les exigences du Reglement sur le material brouilleur du Canada.

--------------------------------------------------------------------------------------------------------------------------------------------------

1.3 Regulatory Compliance

CE Mark: Compliant

Safety: UL 60950, 3rd Edition/CSA C22.2 No. 60950-00

IEC/CENELEC STDS EN 60950: (2000)

EMI/EMC: FCC Class A

EN 55024: 1998 and EN 55022 : 1998 Class A

CB Test Certificate: Compliant IEC 60950 1st Edition (2002)

ITK 38 User’s Manual Version V1.03 Date: (7/2/09) File: UMITK103.pdf 8 of 79

2.0 ITK 38 OVERVIEW

2.1 Introduction

This instruction manual provides information the ITK 38 printer and its associated support options. It provides installation,

operational, programming, systems applications notes and maintenance information.

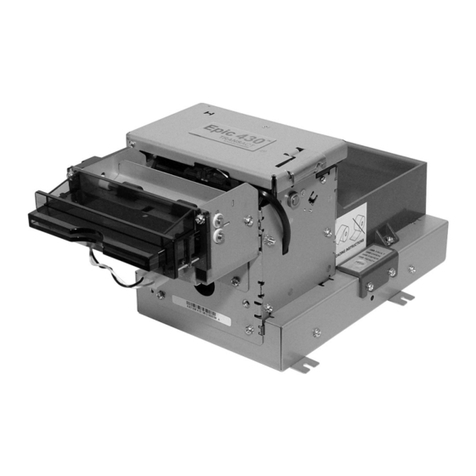

2.2 Product Description

The ITK 38 printer uses direct thermal imaging to print on wide format (6.5” to 8.5”) paper. It can print on rolls or fan-folded

paper (with registration marks for form position sensing). Designed for use in applications where fast, wide format printing is

required, the ITK 38 has features and options structured to support unattended operation in a kiosk or similar environment. These

features include output isolation devices providing a range of function from simple jam protection to complete document isolation

during the print cycle, as well as disposing an untaken document. Document separation is by integrated cutter or tearbar. Paper

supply can be from a mechanism mounted roll holder for 6” or 8” diameter paper roll or an externally mounted, large capacity, 10”

diameter roll holder, or fan folded registration marked flat paper. Each paper holder can be outfitted with a low paper sensor.

The ITK 38 is connected to the host computer system using an IEEE-1284 Parallel or USB Serial Interface.

The ITK 38 printer makes its extensive status information, accessible over the interface. This printer status provides the OEM

host system with information such as: low paper, out of paper, document taken, error conditions, a unique 64 bit electronic serial

number, etc.

The power for ITK 38 printer is supplied by an external +24V desktop power supply module. The standard power supply is 60 watts.

It is completely adequate for most applications, however, for printing applications that require large dark areas that need to

be printed at the highest print speed (2 IPS) then a 130 watt supply can be purchased as an optional choice. This single +24V

operation makes for easier integration into an OEM system power distribution scheme. The printer has a built in intelligent power

management system which budgets the printer’s operation to a modest 60W average power allocation, or alternately, if selected,

to 130 watts. For OEM customers who plan to provide their own +24 power supply refer to section 17.0 for the required

power supply characteristics. If a user supplied alternate power supply is used it must meet these specifications.

The ITK 38 operates under the WindowsTM operating system utilizing a Practical Automation supplied WYSIWYG driver.

Combined with a raster organized printer controller this flexible driver produces simple, direct, printed output, at 300 DPI

resolution, from any WindowsTM application or language.

The printer with its control electronics are integrated into a self-contained printer module. To this printer module a paper supply

module can be attached or made external. The power supply is a separate module that is connected to the printer through

a 6’ DC power cable with a circular DIN connector. This modular packaging is flexible making it easy to mount into any

OEM system.

ITK 38 User’s Manual Version V1.03 Date: (7/2/09) File: UMITK103.pdf 9 of 79

2.3 ITK 38 Model Number System

___ ITK 38 - ____ ____ __ __ ____ - ____

| | | | | |

p BN PO FC PI I CN

Note: The standard models are shown shaded.

p Prefix blank = Standard ITK 38 Printer (Note: this entry is normally blank)

s = Special Configuration Prefix (Refer to the CN information below)

BN Base Number: ITK 38

PO Paper Output Options: D= Cutter with Disposing Transport-Presenter (18.3)

C= Cutter with Output Protection Chamber (18.5)

K = Cutter Only Output (without Output Protection Chamber) (18.6)

T= Tearbar with Output Protection Chamber (18.7)

FC Forms Control: blank = Continuous roll stock paper (6.1.7.2)

R= Registration marked paper (6.1.7.3 & 6.1.8.5)

PI Paper Input Options: _ _ ## Paper Holder/Guide

0 0 = A rear paper guide (ITK 38 RPG), for an external paper supply, is included

(5.2.3.2.1) with this printer, however, no paper roll holder is supplied. An

external paper holder must be selected from the Separate Component model

numbers information shown below (2.3.3)

8 L = Attached paper roll holder for 6/8” (152/203 mm) diameter paper rolls (18.10)

with low paper sensor & 18” (457 mm) interconnect cable (AC8-18)

8 0 = Attached paper roll holder for 6/8” (152/203 mm) diameter paper rolls

without low paper sensor.

I Interface: Parallel = IEEE 1284 Parallel Data Interface (3.4, 18.15 & 18.16)

USB = USB 2.0 Full Speed Interface ( 8.2)

Note: This suffix is stamped into the Interface Module’s face plate and

becomes part of the product’s model number label.

CN Customization Number: blank = This entry is normally blank

### = For special ordered configurations the “s” prefix will be used (sITK38) along

with this three digit configuration number.

2.3.1 ITK 38 Power Supply Model Number

PS60-14 __

| |

MN LC

Note: Standard models are shown shaded.

MN Power Supply Model Number PS60-14 = Standard 60 Watt External Power Supply (18.11)

PS130-14 = Optional 130 Watt External Power Supply (18.12)

LC Line Cord Option (Blank) = supplied with a US approved line cord

E = no line cord supplied for Export applications

ITK 38 User’s Manual Version V1.03 Date: (7/2/09) File: UMITK103.pdf 10 of 79

2.3.2 ITK 38 Printer Model Number Example

ITK38 – D 8L – Parallel with PS60–14

The above two model numbers, together, specify a complete ITK 38 printer

configured with the following options:

- no special customization - - - - - - - - (prefix blank)

- ITK 38 Series 300 DPI, 8.5” (216mm) paper width printer - - - ITK38

-

- a cutter with disposing/non-disposing transport-presenter is the paper output option - - D

- the forms control jumper is set to except continuous form paper - - - (blank)

- the input paper option is an attached 6”/8” diameter roll holder w/low paper sensor and cable 8L

- no customer specific configuration modifications - - - - - (blank)

-

- a parallel data interface - - - - - - - Parallel

with

- a 60 watt external desktop power supply with a line cord for the North American market- PS60-14

2.3.3 ITK 38 Separate Component Model Numbers

Model Number Description

Power Supply

PS60-14 Universal Input 90-264 VAC @ 47-63 Hz; 24VDC @ 60W, w/US 115V line cord. (18.11)

PS60-14E Universal Input 90-264 VAC @ 47-63 Hz; 24VDC @ 60W, w/o line cord (18.11)

(Safety Label Working Voltage 100-240VAC @47-63Hz, 1.6A max.)

PS130-14 Auto-Ranging Input 85-264 VAC @ 47-63 Hz; 24VDC @ 130W, w/US 115V line cord. (18.12)

PS130-14E Auto-Ranging Input 85-264 VAC @ 47-63 Hz, 24VDC @ 130W, w/o line cord (18.12)

(Safety Label Working Voltage 100-120VAC and 200-240VAC @ 47-63Hz, 3.2A max.)

Interface Cables

ATX-PC36 Parallel Interface Data Cable: IEEE-1284 A-B Interface Cable, 6 feet (1.8m) long.

CUSB-206 USB 2.0 A-B Cable, 6 feet (1.8m) long.

Detached Paper Roll Holders for external mounting

ITK38-8RHLP For a 6"/8" (152/203 mm) dia. roll w/low paper sensor & 18" (457 mm) cable (AC8-18) (18.10)

ITK38-8RH For a 6"/8 (152/203 mm) dia. roll (18.10)

External Roll & Fan-Fold Paper Holders and Options

ATX-10RH Large 10" (254mm) dia. capacity paper roll holder (5.2.3.1 &18.9)

ATX-10RHLP Large 10" (254mm) dia. capacity paper roll holder w/low paper sensor & ATX-AC8 (5.2.3.1 &18.9)

ATX-FFPHLP Fan-fold Paper Holder with low paper sensor includes ATX-AC8 (18.8)

ATX-AC8 Auxiliary low paper cable, shielded, 6' (1.8 m) long, 8 conductors, w/MINIDIN-8 connector).

AC8-18 Auxiliary low paper cable, shielded, 18" (457 mm) long, 8 conductors, w/MINIDIN-8 connector).

ITK 38 RPG Rear Paper Guide that attaches to the ITK 38 printer, when using an external paper supply. (5.2.3.2.1)

ITK 38 TP-PG1 Transport-Presenter add-on output paper guide extension. (5.1.1) & (18.4)

ITK 38 User’s Manual Version V1.03 Date: (7/2/09) File: UMITK103.pdf 11 of 79

PREPARATION FOR USE

2.4 Unpacking and Inspection

-a- Inspect the shipping container for signs of damage. If any damage is noted, contact freight carrier and file a claim with them.

-b- Carefully unpack the printer system.

-c- Inspect the printer system carefully.

-d- Check the received items to the packing list. If any discrepancies are noted, contact our Customer Service Department.

-e- Save the packing material for reuse in shipment of the printer system.

2.5 Installation Location

The ITK 38 printer system is designed for OEM applications. It is the responsibility of the OEM system designer to insure that the

printer is applied in a manner to insure operation with-in specifications. The printer’s application environment should be clean and

ventilated appropriately.

2.6 Power Connection

Refer to section 3.4 for a drawing of the printer’s rear panel and to section 18.11 or 18.12 for a drawing of the power supply.

-a- Insure that the power switch, on the rear panel of the printer, is in the OFF position.

-b- Connect the power supply’s DC output cable to the power input connector on the rear panel of the printer.

-c- Connect the AC line cord to the IEC connector on the power supply.

-d- Connect the AC line cord to the wall power outlet.

2.7 Data I/O Interface Connection

The ITK 38 can have a Parallel or USB Interface.

2.7.1 Parallel Interface

The ITK 38 printer requires an IEEE-1284 A-B Parallel Cable for connection to a WindowsTM Computer. Only use an IEEE 1284

compliant cable. A compliant cable will be marked “IEEE 1284”, typically stamped on the cable’s outer cover or molded into one

of the connector housings. This cable can be purchased “off-the-shelf” or from Practical Automation. Refer to section (2.3.3) for

the cable’s ordering information.

-a- Connect the 36 pin connector end of the cable to the parallel input connector on the rear of the printer. Refer to

section 3.4 for a drawing of the printer’s rear panel.

-b- Connect the 25 pin connector end of the cable to the parallel output port of the computer.

2.7.2 USB Interface

The ITK 38 printer requires a USB 2.0 A-B Full Speed compliant cable. This cable can be purchased “off-the-shelf’ or from

Practical Automation. Refer to section (2.3.3) for the cable’s ordering information.

-a- Connect the 4 pin B cable connector to the USB connector on the rear of the printer. Refer to section 3.4 for a drawing

of the printer’s rear panel.

-b- Connect the 4 pin USB A connector to the computer’s USB port.

2.8 Printer Driver Installation

Printer Drivers are available for all WindowsTM operating systems (WindowsTM 95/98/ME, WindowsTM NT 4.0, WindowsTM

2000/XP). These drivers can also be downloaded from the Practical Automation WEB site:.http://www.practicalautomation.com

2.8.1 Discussion of Printer Drivers

The ITK 38 has two types of printer drivers available. These are version V1.xx or V2.xx drivers. The printer driver’s major

version number differentiates it as noted below:

Version V1.xx driver is a unidirectional printer driver.

Version V2.xx driver is a bi-directional printer driver. When a V2.xx driver is loaded

it also installs a Language Monitor DLL which is used to support bi-directional communications.

Both V1.xx and V2.xx drivers are identical in rendering printable information.

2.8.1.1 Discussion of Driver Names:

The printer driver’s name is composed of up to three parts.

The first part is our abbreviated manufacturer’s name: “PA”.

The second part is the printer’s model identification: “ITK38”.

The third part is the driver’s version number: “Vx.xx”.

ITK 38 User’s Manual Version V1.03 Date: (7/2/09) File: UMITK103.pdf 12 of 79

For all new printer drivers released this third part will no longer be part of the driver’s name. The driver naming technique of “PA

ITK 38 V1.04” will be changed to simply “PA ITK 38” leaving off the version information. The driver’s version information will

be determined by its file name, or on floppy label, or when it is installed, by viewing the Properties tab of the

ITK38_VERSION.DLL which is part of the driver’s file set. Refer to the documentation included with the printer driver for more

information on viewing the version information .

2.8.1.2 Which Driver to Load?

Load V2.xx driver:

if: the printer’s status information WILL be acquired, by the application program, using

the Language Monitor acquisition technique for bi-directional communications with the

printer.

Load V1.xx driver:

if: the printer’s status information WILL NOT be acquired by the application program.

or: the printer’s status information WILL be acquired, by the application program, using

an alternate, non-Language Monitor, technique to achieve bi-directional

communications with the printer.

Note: The V2.xx driver is the recommended driver to use when getting printer status, however,

many currently installed printer deployments are using this communications technique. The

V1.xx is only provided for legacy support for those applications.

2.8.1.3 Loading The Printer Driver:

Please refer to the documentation included with the printer driver for instruction on driver loading.

2.8.1.4 Printer’s Status Information:

The printer’s status information refers to the printer’s operating data, which can be delivered to the controlling application

program over the reverse channel of the printer’s data interface.

2.8.1.5 Host Controlled Printer Firmware Update:

Any ITK 38 printer can have its printer firmware updated in the field. This update process can be a manually evoked or

host controlled.

2.8.1.6 Printer Utility DLL:

A Printer Utility DLL (PADLL.DLL) is available from Practical Automation. This Printer Utility DLL provides

programmers with a toolbox to facilitate many of the esoteric tasks associated with reading the printer’s status information, host

controlled printer firmware updates, as well as other printer related programming tasks. The Printer Utility DLL supports both the

version V1.xx or V2.xx Printer Drivers.

For customers who desire to implement this functionality Programming/Technical Support is available. These processes

are, however, sufficiently complex so that this level of technical support is only available to qualified OEM customers. To access

this level of technical support, please contact your Practical Automation Sales Representative and explain your project’s printer

deployment plans.

2.8.2 Selecting and Configuring the Driver

Configure your application to use the ITK 38 printer driver by setting it as the default printer. Select paper size and margins as

required. See the information supplied with the printer driver for more information on these selections. The printer driver is now

matched to your application and ready use. If you are not using a WindowsTM based application, refer to the appropriate OEM

system User’s Manual for operation of the ITK 38 printer under their driver and application software.

ITK 38 User’s Manual Version V1.03 Date: (7/2/09) File: UMITK103.pdf 13 of 79

2.9 Paper Supply

The paper supply for the ITK 38 can be from several sources depending on the selected options for the printer. These are:

-1- an on mechanism mounted (detachable) paper roll holder

-2- an externally mounted paper roll holder

-3- a fan fold tray holder for registration marked paper.

For all paper supplies the thermally active side of the paper needs to be facing upward. For a roll supply the paper curl will be up

when entering the printer’s paper entry path. For an external paper supply, the holder must be set up to provide a smooth, well

aligned, path to enter into the printer’s paper entry guides.

2.10 Paper Loading

Apply power to the printer by turning on its rear mounted power switch. The printer will complete its initialization process and

then beep indicating that it is ready to have paper loaded. For auto-loading, the printhead pressure lever, located on top of the

printer mechanism, must be closed (downward position). Insure that the paper has a clean straight leading edge. Feed the paper

into the printer’s rear paper guide until it is detected by the printer’s paper sensor, which will then trigger the paper loading

operation.

2.11 Test Print

Once the paper has been loaded a test document should be printed to insure that everything is operating properly. Pressing the

SELECT/F0 switch will place the printer in the OFFLINE mode, the READY LED will go out. Then, by pressing the TEST/F1

switch a test page will be printed refer to 18.17 and 18.18. Refer to section 4.1 for detailed information on these switch operations.

2.12 Operation From the Interface

The printer is ready for operation. Refer to the appropriate OEM system manual for operation of the printer, through data interface,

by the application software or create a simple document in Word Pad and print it.

ITK 38 User’s Manual Version V1.03 Date: (7/2/09) File: UMITK103.pdf 14 of 79

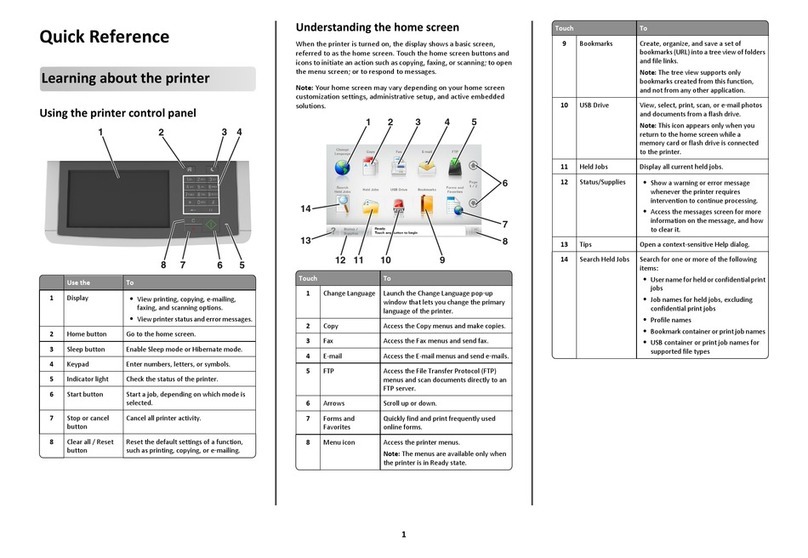

3.0 OPERATOR CONTROLS AND INDICATORS

3.1 Switch and Display

The switch and display panel provides the operator with an interface to the printer. The display LEDs and Beeper are used to

output relevant printer operational status and warnings. The switches provide a means to control the various printed output menus

and test functions.

3.2 Panel LEDs Indicators

3.2.1 Power / Paper

This LED indicator provides the following printer status information:

-1- Sanity indication/Normal display = very short OFF blink approx. every 14 sec.

-2- Presence of DC power = ON or Flashing when power is on.

-3- Status of the paper supply = rapid ON/OFF 50% duty cycle flashing when out of paper.

-4- Status of low paper = slow ON/OFF 50% duty cycle flashing when paper is low.

-5- Diagnostic testing modes = 10% ON and 90% OFF when in diagnostic mode

3.2.2 Ready

This LED indicator provides the following printer status information:

-1- System readiness for operation = ON system is ready to accept data ; OFF not ready.

-2- Data flow = During the receipt of data the LED will blink following the state of the Busy signal.

-3- Reverse channel status = While not printing, during an IEEE-1284 or USB reverse channel status event, this

LED will blink following the Printer’s Busy signal flow.

3.2.3 Attn. / Error

This LED indicator, in combination with the beeper, is a general purpose information display for the operator. It provides the

following printer status information:

-1- Switch press annunciation = short flash/beep for each switch pressed

-2- System warnings = an attention flash/beep to alert the operator to load paper, etc.

-3- System error codes = a repeating sequential series of coded flash/beep signals.

-4- Normal display = OFF

3.3 Panel Switches

There are four momentary push button switches on the user panel. These are used for a variety of manual interactions with the

printer. Some of these are: printing a test document, entering data into the printer parameter memory (EEPROM), and selecting

miscellaneous diagnostic operations. The switches are labeled:

SELECT/F0 On/Off line Select / Function 0 (F0)

TEST/F1 Test print / Function 1 (F1)

RESET Pressing & holding F1 & F2 for 5 sec.

FEED/F2 Line feed / Function 2 (F2)

FORM FEED/F3 Form feed / Function 3 (F3)

3.3.1 Forcing Reset Initialization

The ITK 38 has a power switch. Cycling this switch will cause a printer reset initialization sequence. Also, by pressing two of the

Front Panel switches (F1 & F2) together for 5 seconds. The printer will respond with a short flash/beep signal, to indicate that the

initialization process will start, followed by a two second delay, to permit making the next switch selection, if appropriate.

Switch Operation/Function Notes

F1 and F2 Force a Printer Reset. Switches held for 5 seconds.

ITK 38 User’s Manual Version V1.03 Date: (7/2/09) File: UMITK103.pdf 15 of 79

3.4 Rear I/O Panel

Located on this rear printer panel are: the power switch, power input connector, auxiliary I/O cable connector and the parallel or

USB data interface connector. The power switch in combination with holding one or more of the switch and display panel switches

provides entry into special set-up menus or diagnostic programs.

ITK 38 User’s Manual Version V1.03 Date: (7/2/09) File: UMITK103.pdf 16 of 79

4.0 PANEL SWITCH OPERATIONS

4.1 Switch Modes

The switch and display panel switches are used for two modes of operation. These are: offline and power-on operations.

4.2 Offline Operations

When the printer is operating normally, pressing the [SELECT/F0] switch manually takes the printer to an offline state. NOTE: As

a reminder to the operator the A/E LED and beeper will produce a single flash/beep approximately every 14 seconds. When the

system is offline the switches operate in accordance with the Offline

Switch Operations Table shown below.

4.3 Offline Switch Operations Table

Switch Operation/Function Notes

SELECT / F0 Offline / Online toggle Offline enables functions below.

TEST / F1 Prints a test document Alternately prints 1 of 2 test documents (18.17 & 18.18).

LINE FEED / F2 Advances the paper approximately 0.1" Simple paper movement testing.

FORM FEED / F3 Advances the paper one form length. Length depends on printer setup.

F0 and F1 Causes the cutter to actuate. The switches must be released together.

4.4 Offline Switch Operations

These above noted functions provide the operator with a simple means of operating the printer to verify basic operation.

4.5 Power-On Operations

These functions provide an additional level of diagnostic support tools. These functions are provided for service or technical

support personnel.

4.6 Power-On Operations Table

For this mode, one or more switches are held while applying power to the printer. The switch is held until a flash/beep

(A/E LED/ beeper) occurs. The list of power-on operations are detailed below. Refer to section 4.8 for System Information

Help Report which outlines each menu listed below.

Switch Operation/Function Notes

SELECT / F0 Print system status report If held longer, prints help menus (4.8)

TEST / F1 Enter diagnostics menu entry Factory and service modes (4.9)

LINE FEED / F2 Change the TOF (Hold 5 Sec) Wait for confirming beep sequence (4.10)

FORM FEED / F3 Enter EEPROM change menu Requires special sequence using [F3 switch] (4.11)

F0 and F1 Re-program Flash Memory Wait for long beep (4.12 ; 11.0)

F0 and F2 Printhead cleaning Printer becomes a switch driven paper mover(4.14)

F2 and F3 Hex Dump Diagnostic Mode Printer becomes a interface diagnostic tool (4.13)

4.7 Printer System Information and Reports

Printer system status information is available through a number of printed reports. These are the system status report, system

help report, EEPROM interactive parameter change menu, and diagnostic support menus.