2016-04-11

Printed in Canada

TABLE DES MATIÈRES

IDENTIFICATION .................................................................................................................. 4

Product number and type................................................................................................ 4

Manufacturer name and adress ....................................................................................... 4

DECLARATION OF CONFORMITY .......................................................................... 4

SPECIFICATION .................................................................................................................... 4

General fonction.............................................................................................................. 4

Dimensions and weight................................................................................................... 4

Electrical and pneumatic specification ........................................................................... 4

SET UP BEFORE USING THE MACHINE................................................................................. 4

Security precaution before using the machine................................................................ 4

SET-UP TO PRINT............................................................................................................. 5

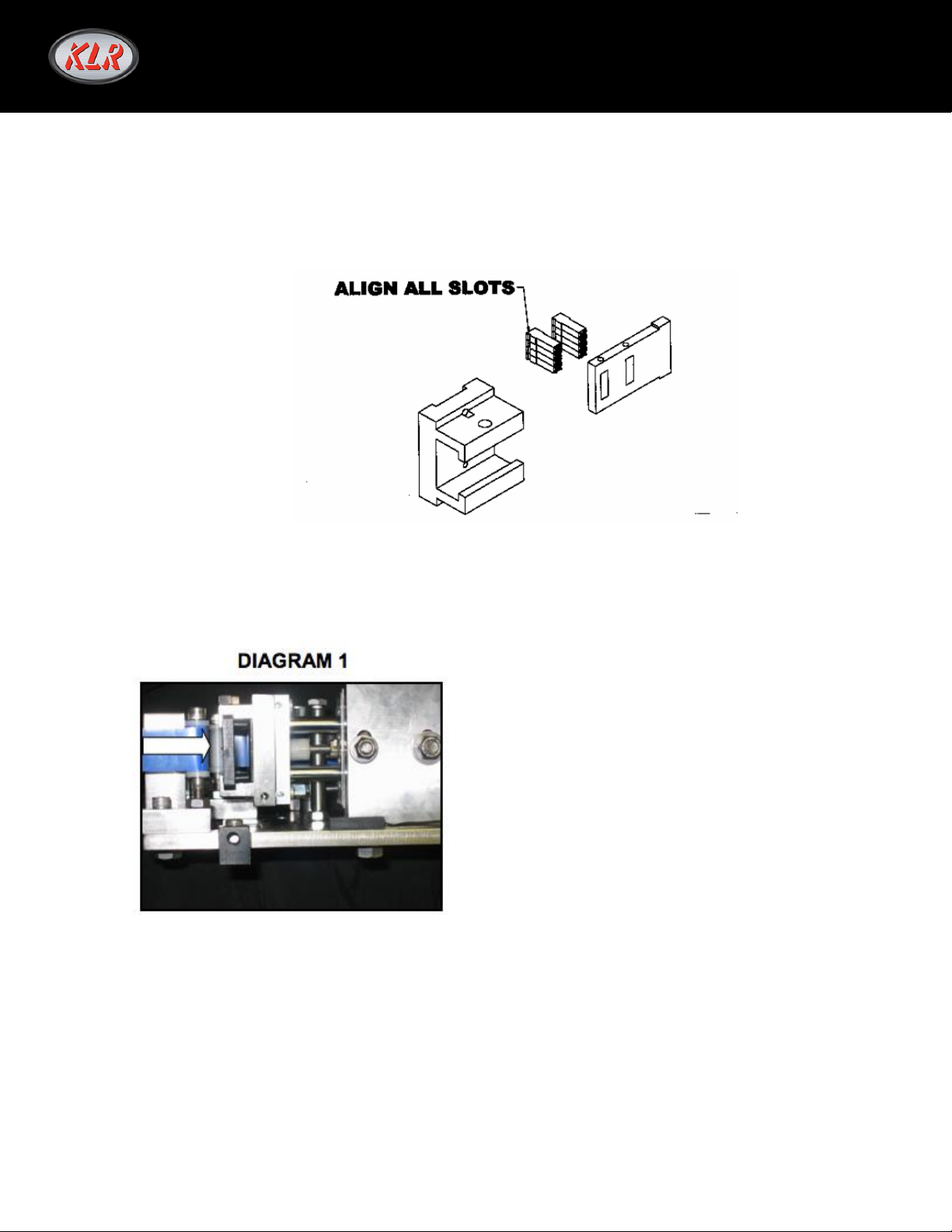

1.1 Type Installation:....................................................................................................... 5

1.2 Printing Tape Threading:........................................................................................... 5

1.3 Tape Feed Length:..................................................................................................... 7

1.4 ................................................................................................................................... 7

1.4.1 ................................................................................................................................ 7

1.4.2 ................................................................................................................................ 7

Mechanical setting.......................................................................................................... 8

2.1 Printing Tape Supply Roll Brake: ............................................................................... 8

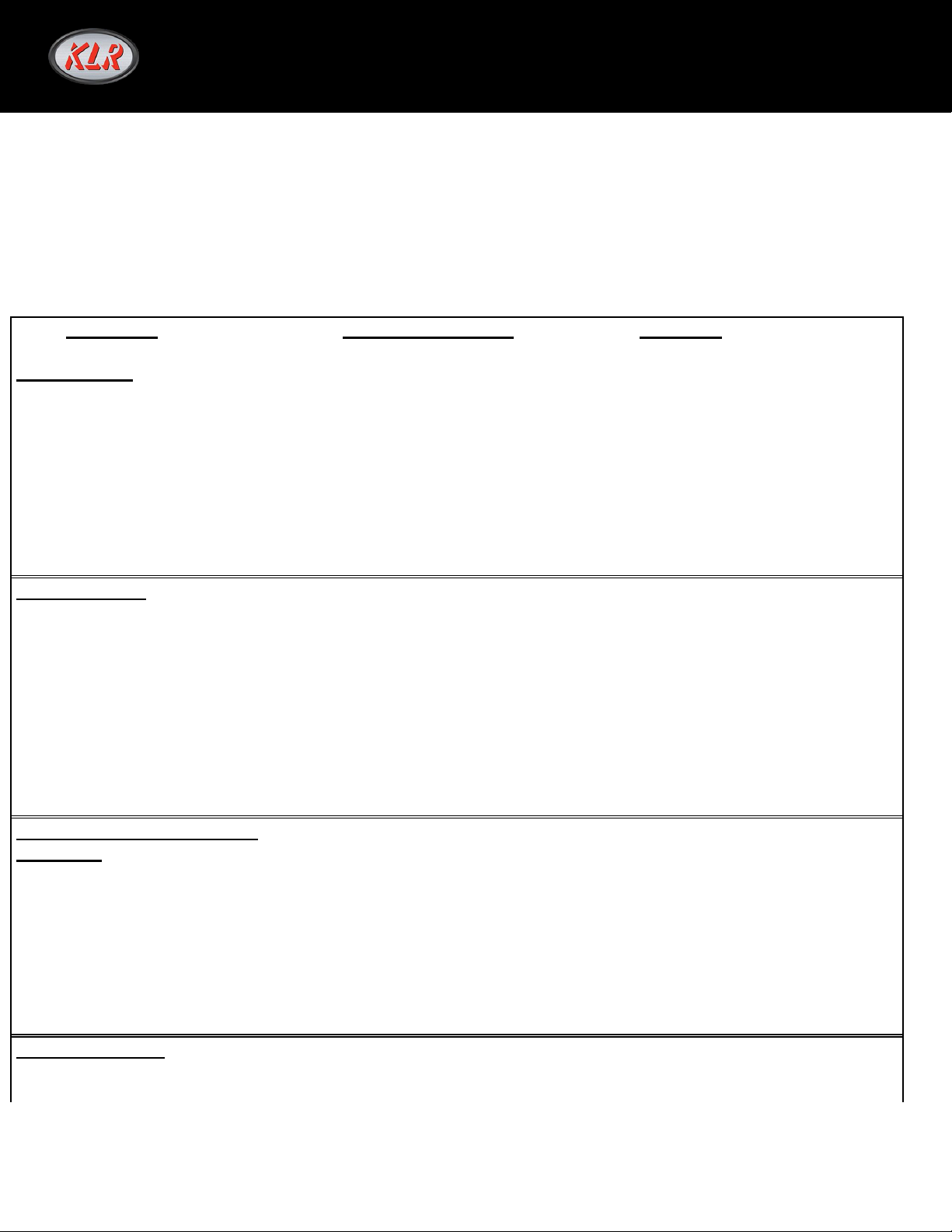

2.2 Anvil Adjustment:...................................................................................................... 8

2.3 Automatic Compensator drive the tape: .................................................................. 9

2.4 Cylinder adjustment :................................................................................................ 9

2.5 Type Face to worktable Distance.............................................................................. 9

Fonctions/situations exceptionnelles ............................................................................ 10

MAINTENANCE AND CLEANING ........................................................................................ 11

Operator maintenance................................................................................................... 11

Cleaning Tape Guide Rollers:....................................................................................... 11

System Lubrication:...................................................................................................... 11

Air filter Regulator:....................................................................................................... 11

Mechanical maintenance............................................................................................... 11