Pramac Powermate WX 2200 User manual

Owner’s Manual

WX 2200

WX 3200

WX 5000

WX 6200 / WX 6200 ES

WX 6250 / WX 6250 ES

WX7000

Thank you for selecting a Powermate generator.

This manual contains important operational information for your selected generator. For

best results, please read all safety messages and warnings carefully before starting and

operating your generator.

All information in this publication is based on the latest product information available at the

time of printing. The contents in this manual may be different from the actual parts due to

revision and other changes.

Our company reserves the right to make changes at any time without notice and without

incurring any obligation. No part of this publication may be reproduced without our

company’s written permission.

This manual should be considered a permanent part of the generator and should remain

with the generator if it is resold.

SAFETY MESSAGES

Your safety and the safety of others are very important. We have provided important safety

messages in this manual and on the generator. Please read these messages carefully.

A safety message alerts you to potential hazards that could hurt you or others. Each safety

message is preceded by a safety alert symbol and one of three words: DANGER,

WARNING, or CAUTION. These mean:

You WILL be KILLED or SERIOUSLY HURT if you don’t follow instructions.

You CAN be KILLED or SERIOUSLY HURT if you don’t follow instructions.

You CAN be HURT if you don’t follow instructions.

Your generatoror other property could be damaged if you don’t follow

instructions.

PR INDUSTRIAL s.r.l.

Loc. Il Piano

CAP 53031, Casole D’Elsa (SI)

ITALIA

CONTENTS

SAFETY NOTICE. .................................................................................................................................................. 4

COMPONENT IDENTIFICATION .......................................................................................................................... 5

CONTROL . ............................................................................................................................................................. 7

GENERATOR OPERATION .................................................................................................................................. 8

PRE-OPERATION CHEK. ..................................................................................................................................... 9

STARTING THE ENGINE.....................................................................................................................................11

STOPPING THE ENGINE .....................................................................................................................................11

MAINTENANCE . ...................................................................................................................................................12

STORAGE . ............................................................................................................................................................15

TROUBLESHOOTING. .........................................................................................................................................16

WHEEL KIT .........................................................................................................................................................17

CE DELARATION . ................................................................................................................................................18

SERIAL NUMBER PLATES .................................................................................................................................19

SAFETY NOTICE

1. SAFETY STANDARD

Read and understand this owner’s manual before starting and operating your generator.

You can help prevent accidents by being familiar with your generator’s controls, and by

observing safe operating procedures.

Don’t operate indoors. Don’t operate in the wet condition

Don’t directly connect to the household

power supply Don’t smoke when refuelling

Don’t overflow the fuel when refuelling. Stop the engine before refuelling

4

5

Please keep it 1m minimum

away from the inflammable materials

2. SPECIAL REQUIREMENTS

•Electrical equipment including lines and plug connections should be free from

exposure.

•The circuit breakers should be matched with the generator equipment. If the circuit

breakers require replacement, they must be replaced with a circuit breaker having

identical ratings and performance characteristics

COMPONENT IDENTIFICATION

1CHOKE LEVER

2AIR CLEANER

3FUEL VALVE

4RECOIL-STARTER GRIP

5BATTERY (ES)

6 MUFFLER

7FUEL TANK CAP

8FUEL TANK

9CARBURETOR

10 GENERATOR SWITCH

11 CIRCUIT BREAKER

12 SOCKET CIRCUIT BREAKER

13 SOCKET

15 HOUR METER – VOLT METER

–FREQUENCY METER

16 GROUND TERMINAL

14 CEE SOCKET

1

2

3

4

5

6

7

8

9

WX5000

11

14

10

13

15

16

14

10

13 WX6200

12

11

15

16

WX2200 - WX3200

11

15

10

13

16

WX6250

11

14

10

13

15

16

WX2200 - WX3200

UK

11

15

10

13

16

WX3200 UK IND

11 15

10

14

16

WX6200 ES - WX7000

12

11

15

10

13 14

16

WX6250 ES

11

1510

13 14

16

CONTROL

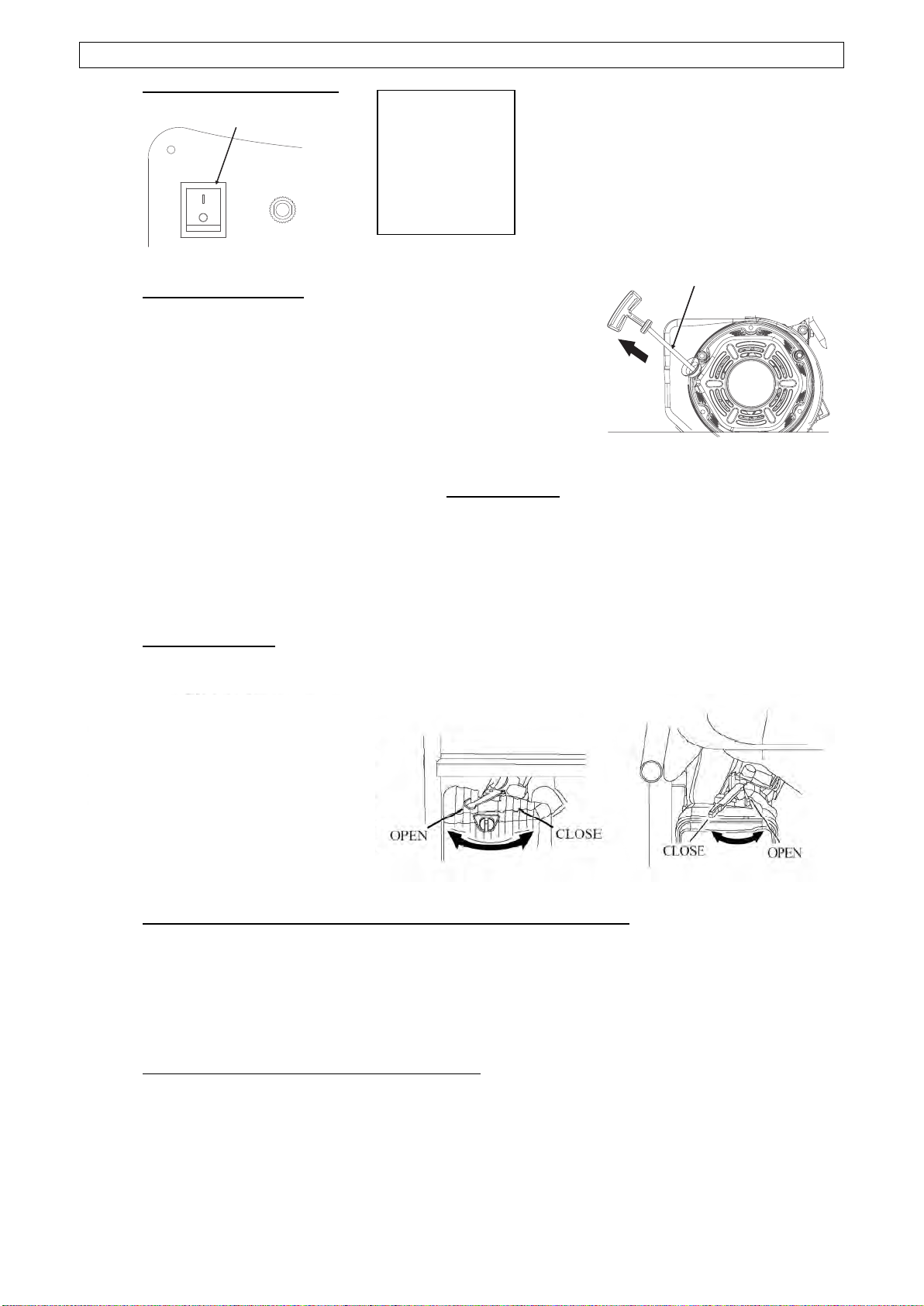

1. GENERATOR SWITCH

2. RECOIL STARTER

To start the engine, pull the starter grip lightly until resistance

is felt, then pull briskly.

Do not allow the starter to snap back against the engine.

Return it gently to prevent damage to the starter.

3. FUEL VALVE

The fuel valve controls fuel flowing from the fuel tank

to carburetor. Be sure to return the lever to “OFF”

after stopping the engine.

4. CHOKE LEVER

The choke lever is used to provide an enriched fuel mixture when starting a cold engine.

Slowly put the choke lever to “OPEN” position after the engine is heated.

5. AC CIRCUIT BREAKER / OVERCURRENT PROTECTOR

The overload current will automatically switch off circuit breaker to avoid short circuit of the

load or overload. If the indicator of AC Overcurrent Protector is raised, the Over-current

Protector is now in the “OFF” position. Press the button of AC Over-current Protector to

the “ON” position again a few minute later. If the circuit breaker is switched OFF

automatically, switch the circuit breaker ON again.

6. OIL ALERT SYSTEM

The oil alert system is specially designed to prevent engine damage caused by an

insufficient amount of oil in the crankcase. When the oil level in the crankcase falls down

below a safe limit, the oil alert system will automatically shut down the engine (though the

generator switch still remain in the ON position), so that the engine can’t be damaged

resulting from the insufficient amount of the oil.

STARTER GRIP

GENERATOR SWITCH

ON

OFF

7

GENERATOR OPERATION

Generator operation environment:·

Temperature:-15℃~40℃·

Humidity: 95% lower.·

Height above sea level: 1000 m lower (If the area is 1000 m over, the power should be

lowered in operation).

1. CONNECTION TO THE HOUSEHOLD POWER SUPPLY

When connecting the generator to the household power supply, connection must be

made by a qualified electrician. After connecting, carefully check electric

connections for their safety and reliability.

Unsafe connections will result in generator damage and risk of fire.

2. AC CURRENT

Before starting the generator, make sure that total

load appliance power (Total resistance, capacitive

and inductive) does not exceed rated power of the

generator

Overload operation will greatly shorten

generator service life.

If the generator set is connected to multi- loads or

electric appliances, please first connect to current

maximum, in turn, current second, and final,

current minimum.

8

In general, capacitive and inductive load, especially, motor-driven devices have a big

starting current when starting.

3. HIGH ALTITUDE OPERATION

At high altitude, the standard carburetor air-fuel mixture will be excessively rich. Output

power will decrease, and fuel consumption will increase. Engine performance can be

improved by installing a smaller diameter main fuel jet in the carburetor and readjusting the

pilot screw. If you always operate the engine at altitudes above sea level 1000 meters,

have our company authorized dealer perform this carburetor modification. If not, lower load

power in operating generator.

Even equipped with suitable carburetor, engine horsepower will decrease approximately

3.5% for each 300 meter increase in altitude. The effect of altitude on horsepower will be

lowered greater than this if no carburetor modification is made.

If a carburetor for high altitude is equipped with engine suitable to a lower altitude,

the lean air fuel mixture will cause the engine output power lowering, over-heat and

seriously damage.

PRE-OPERATION CHEK

1. ENGINE OIL

Engine oil is a major factor affecting engine performance and service life. Non-

detergent and 2-stroke engine oils will damage the engine and are not

recommended. Check the oil level before each use with the generator on a level

surface with the engine stopped.

Recommended oil

4-stroke gasoline oil

API service Classification's SF

or SAE10W-30 of equivalent SG class.

Method of check oil level:

Remove the oil filler cap and wipe the dipstick clean.

Check the oil level by inserting the dipstick into the filler neck without screwing it in.

If the level is low, add the recommended oil to the upper mark on the dipstick.

After adding, don’t forget to reinsert and screw down the oil dipstick.

9

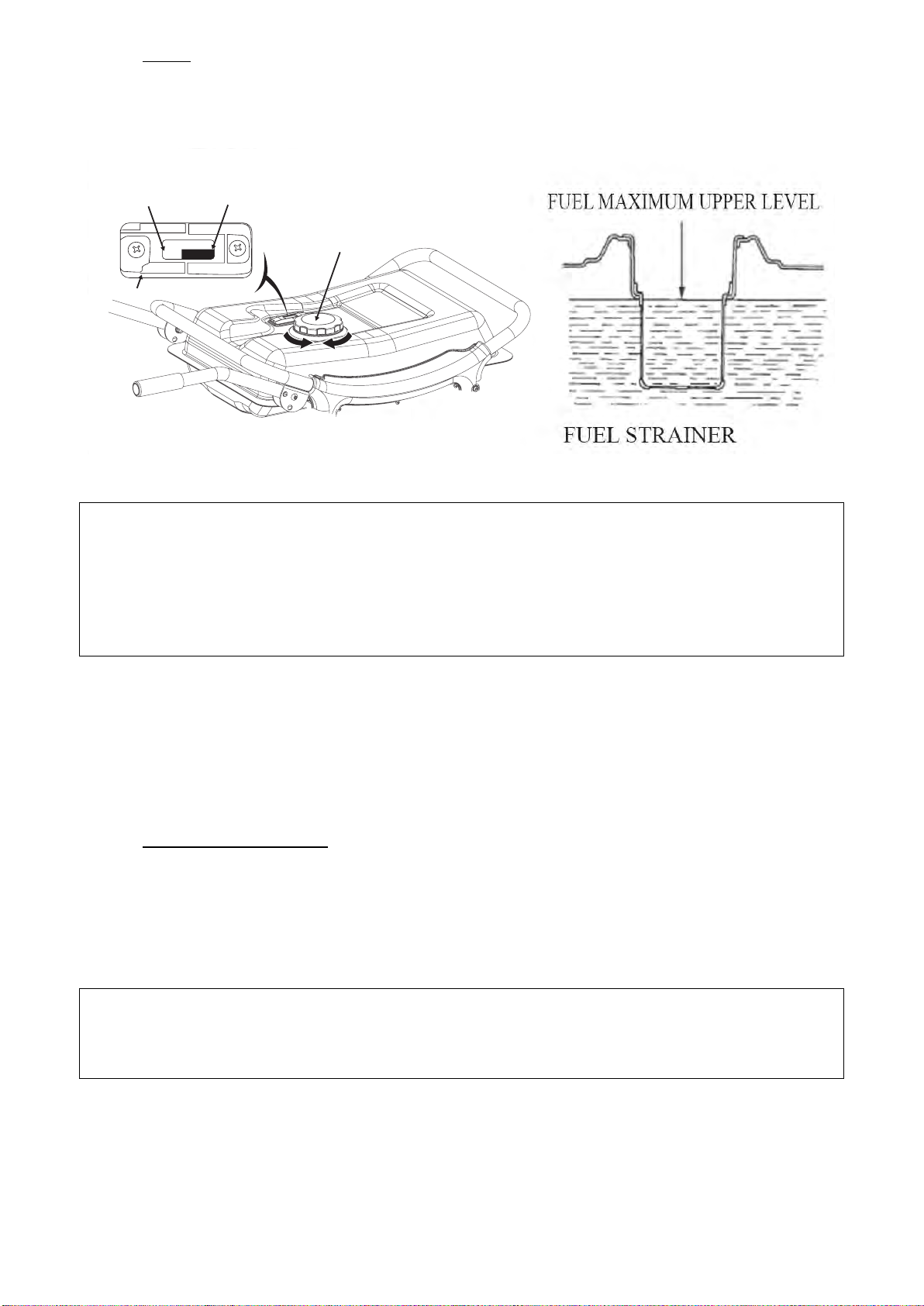

2. FUEL

1. Check the fuel level gauge,

2. Refill the tank if the fuel level is low. Do not fill above the shoulder of the fuel strainer.

3. Reinstall and screw down the fuel tank cap after refuelling.

• Refuel in a well-ventilated area with the engine stopped. Do not smoke or allow

flames or sparks in the area where the engine is refuelled or where gasoline is

stored.

• Do not overfill the fuel tank.

• Avoid repeated or prolonged contact with skin or breathing of vapour.

• Keep out of reach of children.

• Don’t use the oil and gasoline mixture or gasoline contained impurity.

Use gasoline with octane rating ≥90 .

We recommend unleaded gasoline because it produces fewer engine and spark plug

deposits and extends exhaust system life.

Never use stale or contaminated gasoline or oil/gasoline mixture. Avoid getting dirt or

water in the fuel tank.

3. BATTERY (WX6200ES, WX6250ES, WX7000)

Don’t connect the battery positive and negative poles in reverse. Reversed

connection can seriously damage the generator set and battery.

• If operated improperly, the battery may be explosive and potentially hurt others

nearby. Keep the fire and inflammable materials far away from battery.

• The battery will release the explosive gas, please keep the fire far away from

battery. Keep the air ventilating when battery is charging and using.

FUEL TANK CAP

EMPTY

FULL

FUEL LEVEL GAUGE

10

STARTING THE ENGINE

1. RECOIL STARTER

1. Remove all the loads out of the output.

2. Turn the fuel valve to the “ON” position.

3. Turn the AC circuit breaker to the “OFF” position.

4. Turn the choke lever to the “CLOSE” position.

Don’t close the choke when starting the engine in warm state

5. Turn the generator switch to the “ON” position.

6. Pull the starter grip until compression is felt, then pull briskly.

7. Turn the choke lever to the “OPEN” position after the engine is warm.

8. Don’t use electric apparatus before setting circuit breaker to the “ON” position.

2. ELECTRIC STARTING (WX6200ES, WX6250ES, WX7000)

1. Remove all the loads out of the output.

2. Turn the fuel valve to the “ON” position.

3. Turn the choke lever to the “CLOSE” position.

Don’t close the choke when starting the engine in warm state.

4. Turning the generator switch to electric starting position.

5. After starting engine, immediately release generator switch and generator switch can

automatically return to open position.

6. Turn the choke lever to “OPEN” position after the engine is warm.

Turn the generator switch to electric starting position for more than 5 seconds can

damage the starting motor. If failing to start, release the switch and wait 10 seconds

before operating it again.

If the speed of the starting motor drops fast after a period of time, it means that the

battery should be recharged.

STOPPING THE ENGINE

1. Turn the AC circuit breaker to the OFF position.

2. Turn the generator switch to the OFF position.

3. Turn the fuel valve to the OFF position.

To stop the engine in an emergency, turn the generator switch to the OFF position.

11

MAINTENANCE

Good maintenance is essential for safe, economical, and trouble-free operation. It will also

help reduce air pollution.

Exhaust gas contains poisonous carbon monoxide. Shut off the engine before

performing any maintenance. If the engine must be run, make sure the area is well

ventilated.

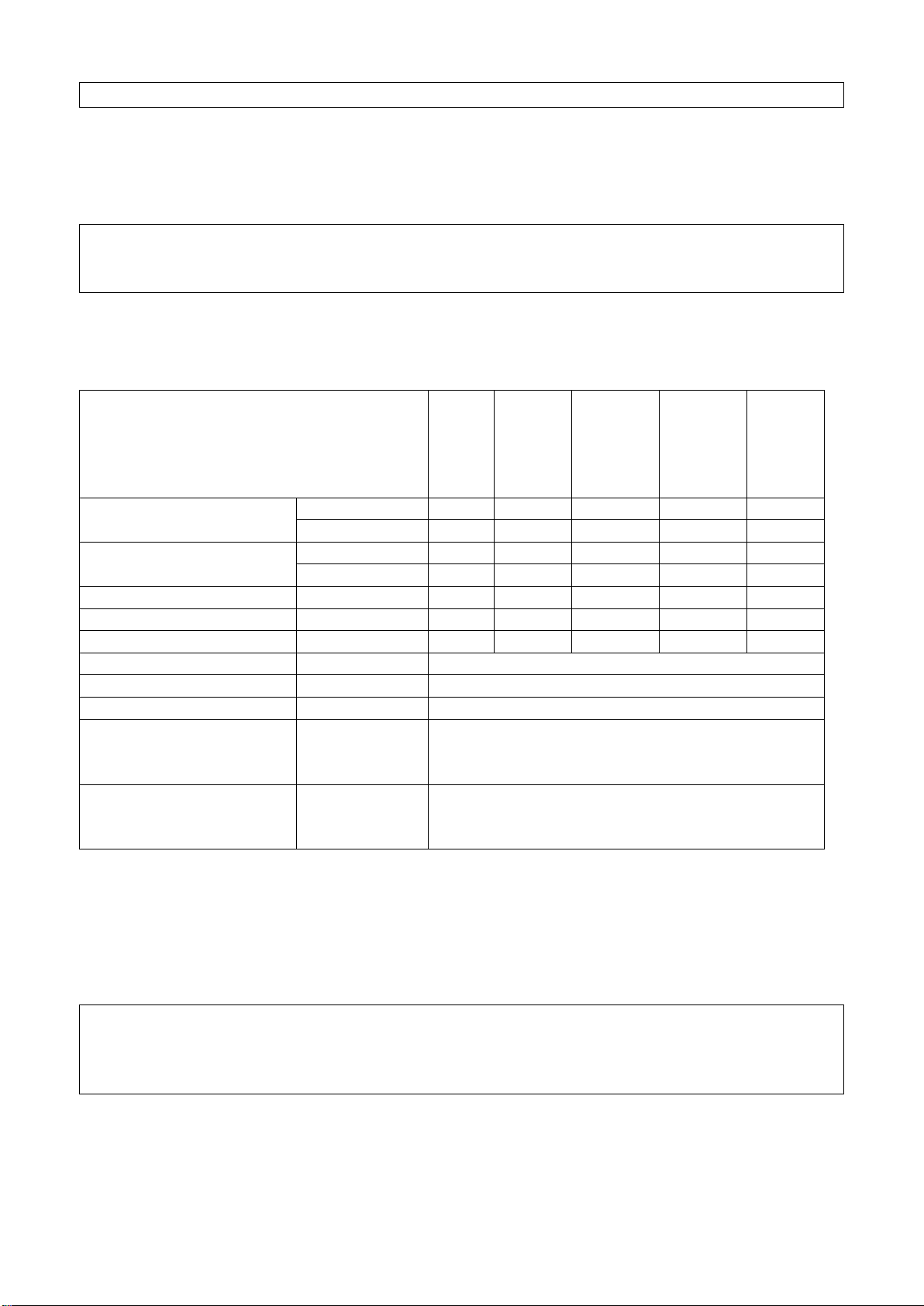

Periodic maintenance and adjustment is necessary to keep the generator in good

operating condition. Perform the service and inspection at the intervals shown in the

Maintenance schedule below:

1. Service more frequently when used in dusty areas.

2. These items should be serviced by an authorized generator dealer.

3. When used more often, only servicing according to above correct intervals can

insure the generator set long-term use.

Improper maintenance, or failure to correct a problem before operation, can cause a

malfunction in which you can be seriously hurt or killed.

Always follow the inspection and maintenance recommendations and schedules in

this owner’s manual.

REGULAR SERVICE PERIOD Each

Use

First

Month

or 20

Hrs.(3)

Every

3

Months

or 50

Hrs. (3)

Every

6

Months

or 100

Hrs. (3)

Every

Year

or 300

Hrs.

(3)

Engine oil Check Level ○

Change ○ ○

Air cleaner Check ○

Clean ○ (1)

Sediment Cup Clean ○

Spark plug Clean ○ renew

Valve clearance Check-Adjust ○ (2)

Cylinder Cover Clean Every 300 Hours (2)

Fuel tank and strainer Clean Every 2 Years (2)

Fuel line Replace Every 2 Years (2)

WX2200–WX3200

Cylinder head and the

head of piston

Clean carbon Every 125 hours (2)

WX6200–WX7000

Cylinder head and the

head of piston

Clean carbon Every 250 hours (2)

12

1. ENGINE OIL CHANGE

Drain the oil while the engine is warm to assure complete and rapid draining.

1. Remove the oil dipstick and drain plug to drain the oil.

2.Reinstall the drain plug, then tighten the plug securely.

3. Refill oil and check the oil level.

Oil capacity: WX2200-WX3200: 0.6L;

WX5000-WX6200-WX6250-WX7000: 1L

Refer to the oil security card.

Dispose of the oil according to the local requirements

2. AIR CLEANER SERVICE

A dirty air cleaner will restrict air flow to the carburetor. To prevent carburetor malfunction,

service the air cleaner regularly. Service more frequently when operating the generator in

extremely dusty areas.

Using gasoline or flammable solvent to clean the filter element can cause a fire or

explosion. Use only soapy water or non flammable solvent.

Never run the generator without the air cleaner. If not, rapid engine wear will result.

1. Open the air cleaner clip and open the air cover. Check the air cleaner element for

any damage and clean.

2. If the air cleaner element is dirty, please clean the air cleaner element: Wash the

air cleaner element in a solution of household detergent and warm water, then rinse

thoroughly or wash in non flammable or high flash point solvent: Pour a few drops

of engine oil, on the oil filter element then squeeze out.

13

3. Reinstall the air cleaner element and the cover.

3. FUEL SEDIMENT CUP CLEANING

1. Turn the fuel valve to the OFF position. Remove the

sediment cup, o-ring and strainer according to the

arrow direction.

2. Clean the sediment cup, and o-ring, and strainer in

non flammable or high flash point solvent.

3. Reinstall o-ring, and strainer and screw down the

sediment cup.

4. Turn the fuel valve ON and check for leaks.

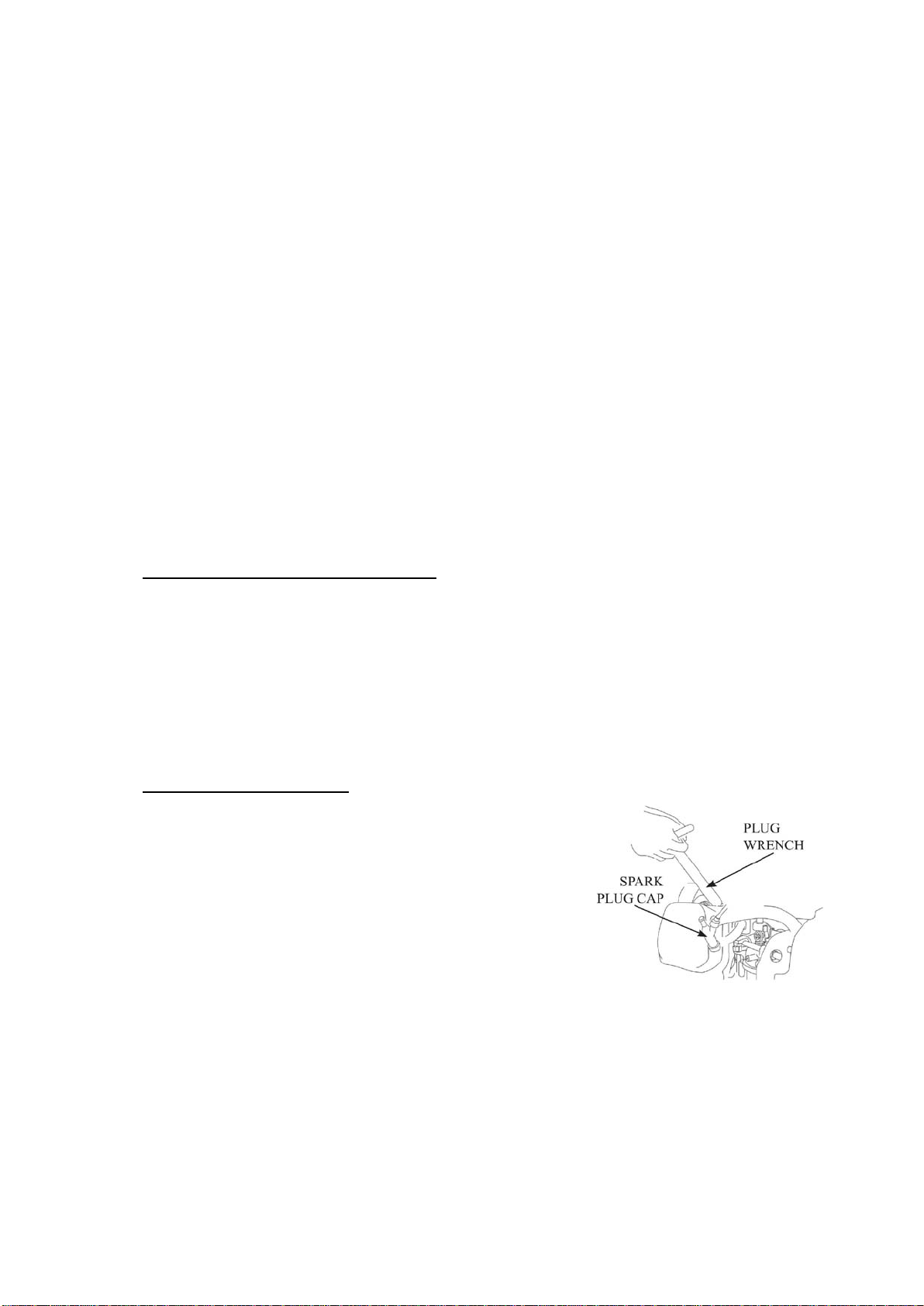

4. SPARK PLUG SERVICE

1. Recommended spark plugs: F7RTC or other

equivalents

2. Remove the spark plug cap.

3. Use the plug wrench to remove the spark plug.

4. Visually inspect the spark plug if the insulator is

cracked. If cracked, replace with new the spark plug.

5. Measure the plug gap with a feeler gauge. Correct as

necessary by carefully bending the side electrode. The

gap should be: 0.70-0.80 mm.

6. Check the spark plug washer for damage.

7. Reinstall the spark plug, tighten it with plug wrench and impact the washer. Reinstall

the spark plug accurately.

Please use the spark plug with suitable heat range.

14

STORAGE

Do not touch a hot engine or exhaust system to avoid burns or fires. Let the engine

cool before storing the generator.

If storing the unit for an extended period, be sure the storage area is free of excessive

humidity and dust.

1. Drain the fuel in the fuel tank out, clean strainer, o-ring and sediment cup, then

reinstall. Drain fuel out of the carburettor by loosening the drain screw, then

reinstall and screw down the carburetor screw.

Gasoline is extremely flammable and is explosive under certain conditions. Drain

fuel in a well ventilated area with the engine stopped. Do not smoke or allow flames

or sparks in the area during this procedure.

2. Screw the oil dipstick off and screw the drain bolt off the crankcase to completely

drain the oil out. Then screw down the drain bolt and fill fresh oil to upper mark,

finally reinstall the oil dipstick.

3. Remove the spark plug, and pour about a tablespoon of clean engine oil into the

cylinder. Crank the engine several revolutions to distribute the oil, then reinstall the

spark plug.

4. Slowly pull the starter grip until resistance is felt. Leave the intake and exhaust

valves in the closed position.

5. Place the generator in the clean area.

15

TROUBLESHOOTING

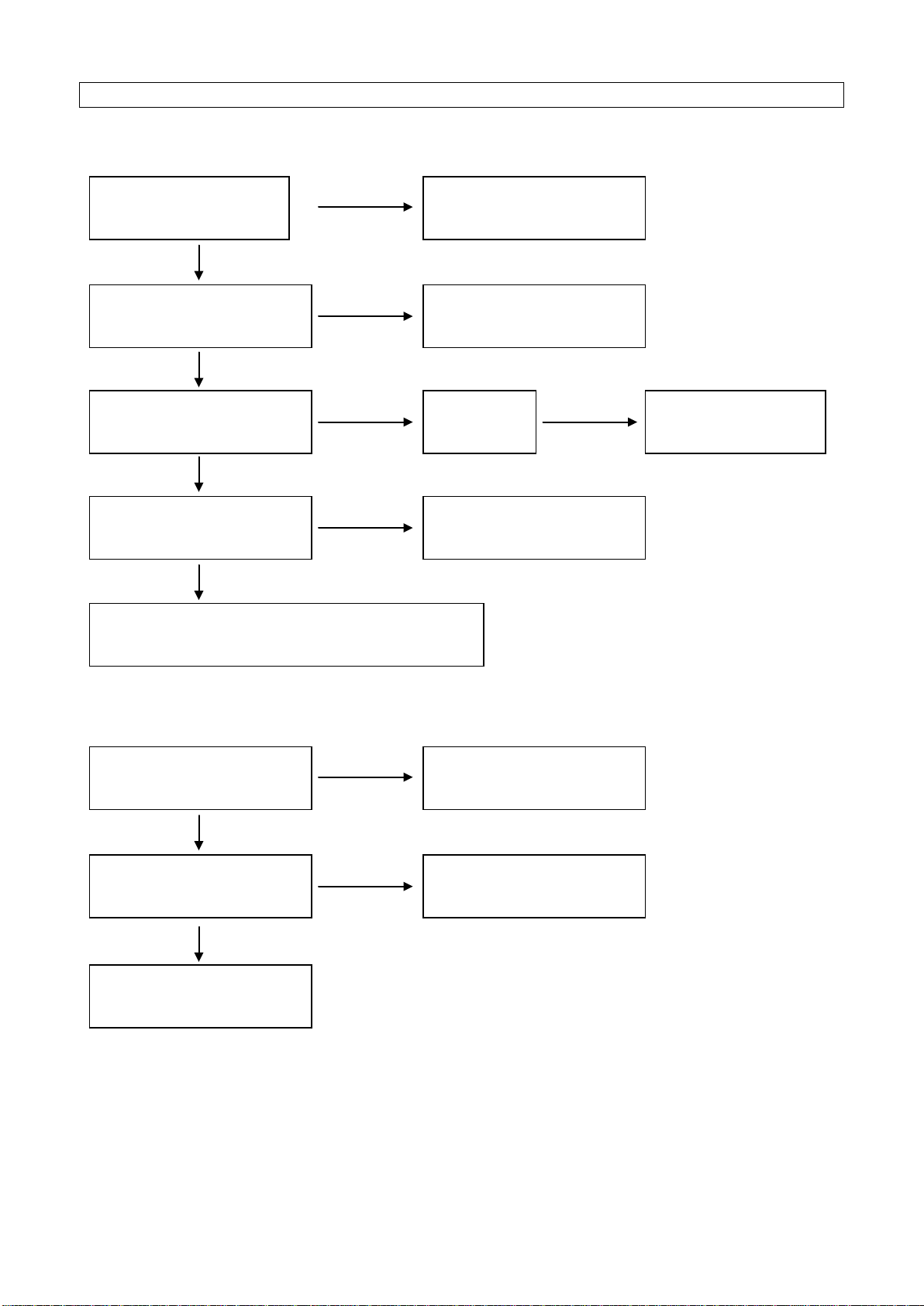

ENGINE UNABLE TO START:

NO POWER SUPPLY:

Is there fuel in the tank?

Refill the fuel tank.

Is there enough oil in the

engine?

Add the recommended oil.

Is there a spark from the

spark plug?

Replace the

spark plug

Take the generator to

an authorized dealer.

Is the fuel reaching the

carburetor?

Check and clean the fuel

sediment cup.

If the engine still does not start, take the

generator to an authorized generator dealer.

NO

NO

NO

NO

Still NO

spark

YES

YES

YES

YES

Is the AC circuit breaker

ON?

Turn the AC circuit

breaker ON.

Check the electrical

appliance or equipment for

any defects.

Take the generator to an

authorized dealer.

NO

NO

YES

Replace the electrical

appliance or equipment.

YES

16

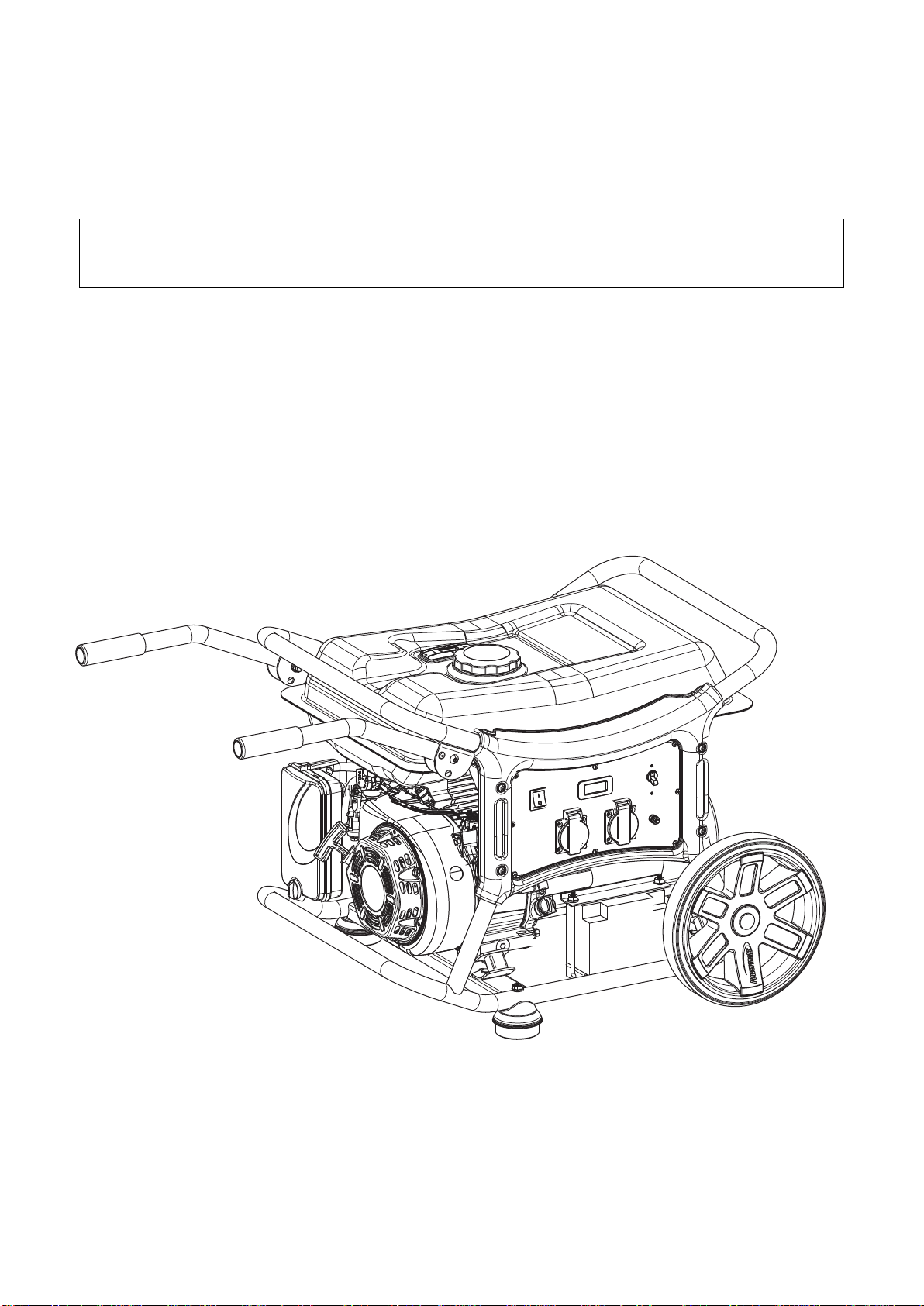

WHEEL KIT

1. Install the two wheels on the wheel axle with gaskets and pins.

2. Install the wheel on the bottom plate of the generator frame with bolts and nuts.

3. Fix the handle on the frame.

17

CE DECLARATION

SERIAL NUMBER PLATES

Manuale Uso e Manutenzione

WX2200

WX3200

WX5000

WX6200 / WX6200 ES

WX6250 / WX6250 ES

WX7000

Grazie per aver scelto un gruppo elettrogeno della nostra Azienda.

Questo manuale contiene le informazioni per l’uso e la manutenzione del generatore.

Leggere attentamente le istruzioni prima di usare il generatore.

Un uso corretto e sicuro, vi aiuterà ad ottenere i migliori risultati.

La Casa Costruttrice si riserva il diritto di effettuare modifiche ai propri prodotti in qualsiasi

momento, senza preavviso e senza incorrere in alcuna sanzione. Questo manuale nè

parte di esso potrà essere riprodotta senza autorizzazione scritta da parte della Casa

Costruttrice.

Tutte le informazioni qui riportate sono basate sui dati disponibili al momento della stampa;

il contenuto di questo manuale potrebbe essere diverso dalle parti reali dovuto a revisioni

o altre migliorie.

Il presente manuale deve essere considerato parte integrante del generatore e dovrà

essere incluso all’atto di vendita.

INDICAZIONI DI SICUREZZA

La Vostra sicurezza e la sicurezza degli altri è molto importante.

Nel manuale del generatore troverete importanti indicazioni per la sicurezza. Leggere

questi messaggi attentamente.

I messaggi sulla sicurezza Vi allerteranno sui potenziali rischi in cui potrete incorrere Voi o

altre persone. Ogni messaggio di sicurezza è preceduto dal simbolo di pericolo e una delle

seguenti parole: PERICOLO, ATTENZIONE o AVVERTENZA.

Il mancato rispetto delle istruzioni PROVOCHERÀ la MORTE o GRAVI

LESIONI PERSONALI

Il mancato rispetto delle istruzioni POTREBBE provocare la MORTE o

GRAVI LESIONI PERSONALI

Il mancato rispetto delle istruzioni POTREBBE provocare LESIONI

PERSONALI.

Il mancato rispetto delle istruzioni potrebbe provocare danni al generatore o

ad altre proprietà

PR INDUSTRIAL s.r.l.

Loc. Il Piano

CAP 53031, Casole D’Elsa (SI)

ITALIA

This manual suits for next models

7

Table of contents

Languages:

Other Pramac Portable Generator manuals

Pramac

Pramac P2200i User manual

Pramac

Pramac E3100 User manual

Pramac

Pramac E3750 User manual

Pramac

Pramac P Series User manual

Pramac

Pramac S5500 User manual

Pramac

Pramac E5000 User manual

Pramac

Pramac E3750 User manual

Pramac

Pramac S3100 User manual

Pramac

Pramac Powermate PMi1000 User manual

Pramac

Pramac ES5500X 5.5 KW Owner's manual

Pramac

Pramac P7500i User manual

Pramac

Pramac S2800 User manual

Pramac

Pramac GA20000 User manual

Pramac

Pramac PMi 2000 User manual

Pramac

Pramac S6000 User manual

Pramac

Pramac Pmi3000 User manual

Pramac

Pramac S3100 User manual

Pramac

Pramac LP3200 User manual

Pramac

Pramac TG 12/3 User manual

Pramac

Pramac WX6200ES User manual