Preeflow eco-PEN450 Guide

Table of contents

Popular Dispenser manuals by other brands

Gilson

Gilson dispensman user guide

Tork

Tork Performance Maxi W2 Service and parts manual

Silver King

Silver King Majestic SK6MAJ Technical manual and replacement parts list

Follett

Follett CVU155N Series Installation, operation and service manual

U-Line

U-Line H-1131 installation instructions

Witeg

Witeg LABMAX airless operating manual

APW Wyott

APW Wyott CCW MK VII, RCCW MK VII, LCCW MK VII, RLCCW MK... Installation and operating instructions

Bartscher

Bartscher 500379 manual

Dolphin

Dolphin DP1900MB quick start guide

Eldom

Eldom DO10 user manual

Bennett

Bennett BlueFueler Series installation manual

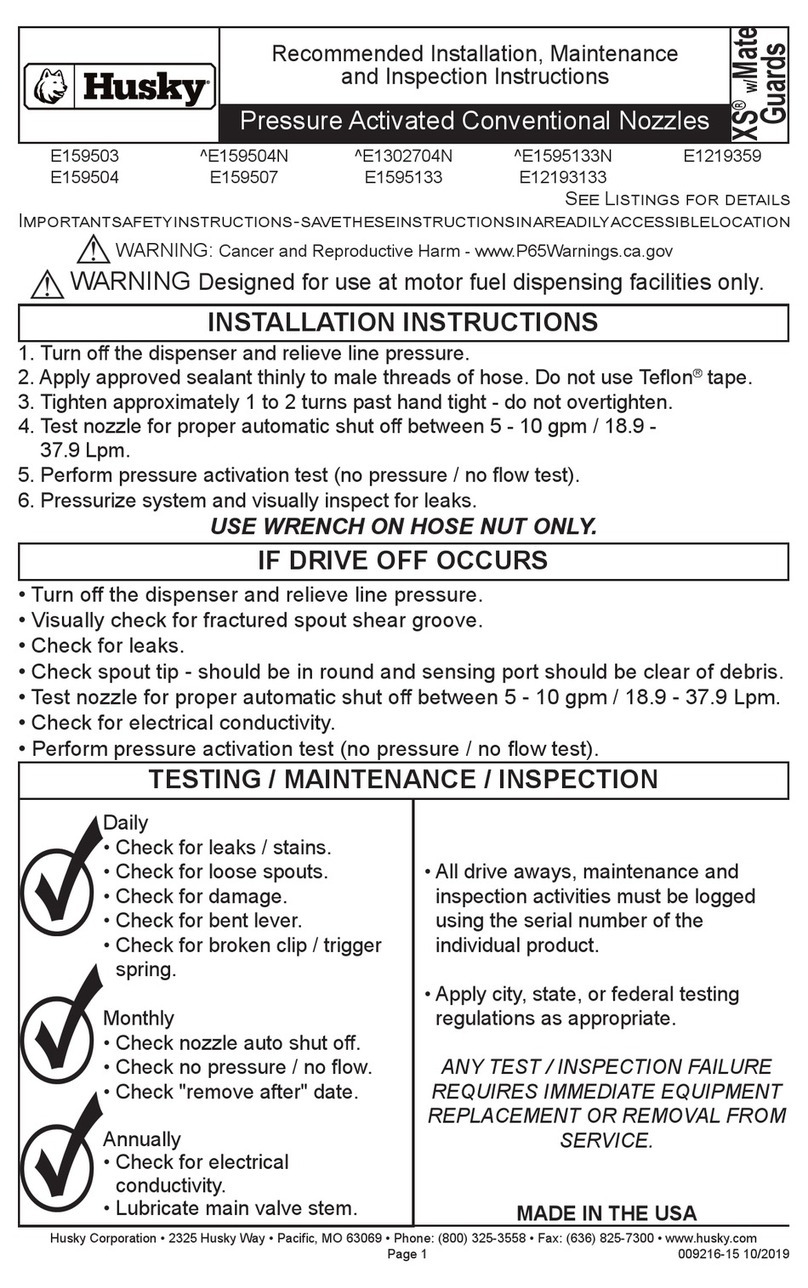

Husky

Husky XS E159503 Recommended Installation, Maintenance and Inspection Instructions

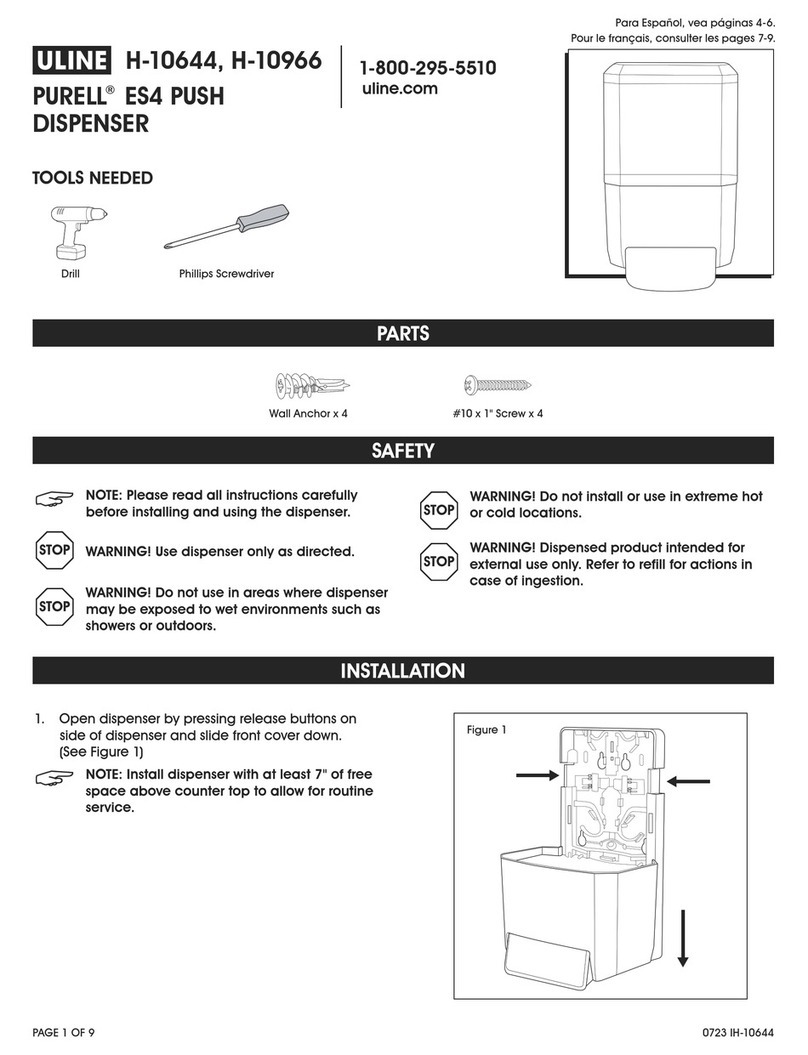

U-Line

U-Line PURELL H-10644 quick start guide

Franke

Franke STRATOS STRX627 Installation and operating instructions

Fast Mover

Fast Mover FMT4200 instruction manual

Hilti

Hilti HDM 330 operating instructions

Global Industrial

Global Industrial 244248 user manual

Franke

Franke RODAN RODX625H Installation and operating instructions