Preferred JC-22D2 Installation instructions

SDI-JC-22D2 rev. 11-1-21 page 1 of 22

Preferred Utilities Mfg Corp

Preferred Instruments div.

31-35 South Street, Danbury CT 06810

203-743-6741 www.preferred-mfg.com

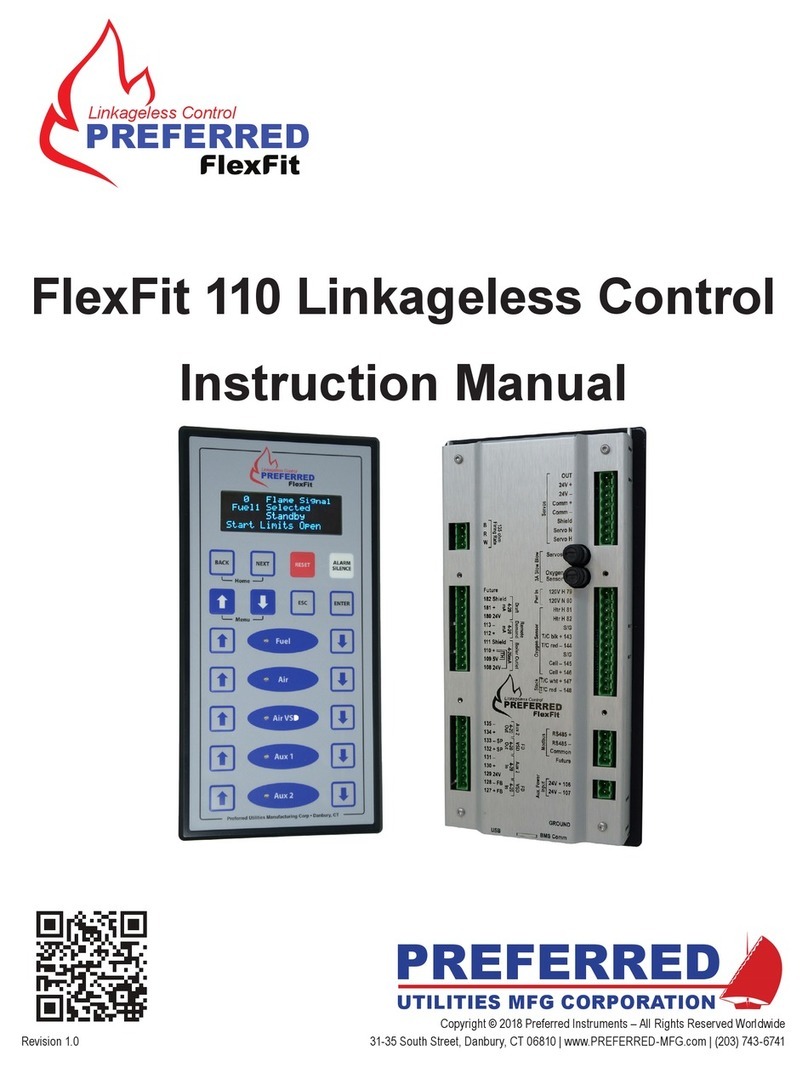

JC-22D2 Sequence Draft Controller

NYC DEP Accepted

Installation & Operation Instructions

The JC-22D2 controller maintains the flue gas at a constant positive or

negative Draft by modulating the outlet damper on a boiler or furnace.

A separate 4-20mA Draft transmitter is required to modulate the damper.

The JC-22D2 interfaces to the burner flame safeguard to automatically

sequence the outlet damper Open for: Purge, Light-Off, and Post-Purge.

The sequence closes the damper after the burner shutdown to minimize

heat loss up the stack.

A separate time delayed Draft Cutout switch wired into the flame safeguard

Lockout Limits is required by Code for Safety.

The JC-22XMTR-xxCO includes a separate Draft xmtr and a separate time

delayed Draft Cutout switch in a single enclosure to reduce installation effort.

Features

Automatic Draft Control for increased boiler efficiency and reliability.

Precision Outlet Draft Control for low NOx induced FGR burners.

Firing Rate Feedforward option is included and assures stable draft during

load changes. Separate curves for up to two fuels.

Floating Draft Control mode is the easiest to tune. Floating Control can be

used with any type of actuator or an ID Fan VSD.

PID Draft Control mode is for those who prefer this type of tuning.

Automatic Damper Sequencing for purge, lightoff, post-purge burner

shutdown, and standby. Simple Flame Safeguard interface.

Damper Adjustable Start Position option is included for installations with

excessively high draft during lightoff.

High Draft Alarm with time stamped alarm and event history.

Modbus Communication with RS-485 and Ethernet capability.

Live Data Tuning Screen for more convenient tuning.

Table of Contents:

SAFETY .............................................................................. 2

Operation ............................................................................ 3

Alarms ............................................................................ 3

History ............................................................................ 3

Standard Sequence ............................................................ 4

Control Types, Control Options, and Actuators .................. 5

Control Types: Floating vs. PID ..................................... 5

Command Types: Triac vs. mA ...................................... 5

Firing Rate Feedforward ................................................ 5

Adjustable Start Position Option .................................... 5

Configuration Compatibility Chart .................................. 5

Installation ........................................................................... 6

JC-22D2 Indicator Mounting: ......................................... 6

JC-22XMTR-xxCO Mounting ......................................... 6

Damper Actuator Linkage: ............................................. 6

Wiring Requirements ..................................................... 7

BEFORE installing the wiring: ........................................ 7

Terminal Layout and Wiring Diagrams ........................... 8

Wiring Diagrams Sheet 1 of 3 ...................................... 8

Parameters / Menu Map ................................................... 12

Screen Settings ........................................................... 13

Draft Control Setpoint .................................................. 13

Tuning ......................................................................... 13

Control Options ........................................................... 14

Sequencing ................................................................. 14

Adjustable Start Menu ................................................. 15

Draft Xmtr. ................................................................... 15

Bargraph Setup ........................................................... 15

Commissioning ................................................................. 16

Triac Servo Calibration ................................................ 16

Triac Deadband Test ................................................... 16

Firing Rate Signal Calibration ...................................... 16

Controller Tuning Screens ............................................... 17

Tuning Screen Loop .................................................... 17

Firing Rate Feedforward Curve Screen ....................... 17

Live Tuning Data Screen ............................................. 17

I/O Examine - Troubleshooting ........................................ 18

Modbus ............................................................................ 19

Parts List .......................................................................... 20

Specifications ................................................................... 20

Full Size Cutout Template ................................................ 21

SDI-JC-22D2 rev. 11-1-21 page 2 of 22

SAFETY

DANGER

Electric Shock Hazard

Multiple power sources may be present.

Disconnect all electric power sources, local and remote, before servicing

WARNING

This product is intended for use in Commercial and Industrial installations,

it is NOT intended for Residential use.

This product is intended to be used by Trained Operators.

Installation, start-up, and troubleshooting is intended to be done by

Experienced Technicians familiar with Industrial Safety Codes

and all Safety Codes specific to burners and boilers.

WARNING

This product is NOT a Primary Safety Interlock rated device.

The Relay Outputs should only be used as an

additional auxiliary Operating limit and should not replace or bypass

any Primary Safety Interlock devices required by Safety Codes.

A High Draft Cutout switch and Open Damper position switch are required

to be installed and wired into the flame safeguard system.

Failure to do so can result in equipment damage, injury, or death.

If the Adjustable Starting Draft Option is used,

an additional Outlet Damper Low Fire Start position proving switch

will be required and wired into the flame safeguard low fire circuit.

Incorrect wiring connections to burner/boiler Flame Safeguard controls

can cause Equipment Damage, Injury, or Death

SDI-JC-22D2 rev. 11-1-21 page 3 of 22

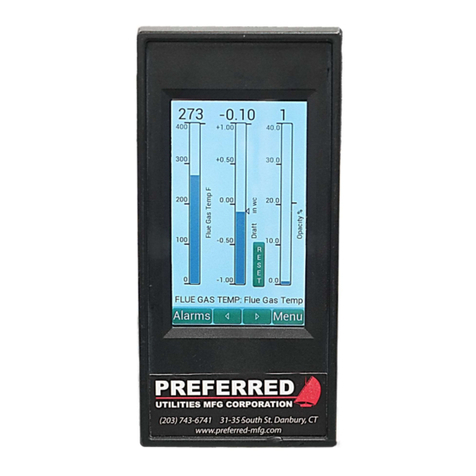

Operation

Home Screen

The current boiler outlet draft pressure is displayed at the top in the selected engineering units:

“wc, cm wc, mm wc, or kPa. The Bargraph height varies in proportion to the measured draft.

The line on the right side of the bargraph is the high draft pressure alarm setpoint.

The triangle on the right is the draft control Setpoint.

The Auto/Manual button allows for manual control of the draft damper when the boiler is in

standby or released to modulate.

Press either the left or right arrow to display the large font alternate home screen.

Alarms

The lower left button on all screens indicates one of these three words:

Silence or Alarms or History

When a new Alarm occurs, Silence and the bargraph blink, and the Alarm Relay energizes.

Touch Silence to stop the blinking and to de-energize the Alarm Relay.

Alarms is displayed after silencing (if an Alarm is still active).

History is displayed when there are no active Alarms.

Active Alarms Screen

From any other screen, touch the Alarms button to display the Active Alarms Screen.

If there are no active Alarms, Alarms will not be displayed on the Home or Menu screens.

All active Alarms are displayed on this screen: High Draft Pressure Alarm, Configuration Errors,

Hardware Faults, etc….

The draft pressure and time/date shown occurred when the Alarm time delay expired and the

Alarm triggered.

When the Alarms screen is displayed, History and Home are displayed.

Touch History to display the History screen.

Touch Home return to the Home screen.

History

Touch History to display the History screen.

The History screen displays the Time/Date of the most recent 50 Alarms and Events.

Events include: when an Alarm Clears, a Shutdown Reset, JC-22D2 power-up, etc..

Touch the Up or Down arrow to advance to the next page of History. Touch Date to enter a

time/date and then to jump to the nearest History records.

The Hide Events and Show Events removes or displays Events.

The History memory is retained when powered down. The History can be extracted via the USB

port using the free JC_Edit Windows App.

Menu Screens

To set clock, Alarm Setpoints, and other initial Setup…..See pages 12-15

SDI-JC-22D2 rev. 11-1-21 page 4 of 22

Standard Sequence

Sequence

Steps

Burner Flame Safeguard Sequence

(Typical)

JC-22D2 Draft Controller

Sequence

1. Shutdown Operating Limits, Fan and Fuel Valve

inputs = OFF

Fan Delay relay output = OFF

2. Fan Start

Delay

“Call for Heat “ Operating Limits make and

energize JC-22D2 term. 15.

Burner fan starts after JC-22D2 Fan Delay

relay energizes.

The JC-22D2 commands the outlet damper to start opening and

also starts the 15 sec. (adjustable.) When the timer expires, the

Fan Delay relay closes, which completes the Burner Limits input

which starts the Burner fan. By then the outlet damper should be

open enough to prevent pressurizing the furnace with the burner

fan running.

3. Purge When both burner and outlet damper

actuators limit switches make, the Purge

starts. When Purge is complete the burner

actuator returns to low fire for Ignition.

The outlet damper continues to fully open position. The outlet

damper remains wide open.

4. Release To

Modulate

Delay

Burner main flame trial period The outlet damper remains wide open. The 15-sec. (adjustable)

release to modulate timer holds the outlet damper wide open during

the flame safeguard main flame trial period and longer if desired.

5. Modulate Burner Modulates Outlet damper modulates when the JC-22D2 is in Auto.

In Manual the operator sets the damper position.

6. Post Purge No Call for Heat

(Operating Limits and Fuel Valve inputs =

OFF, Fan remains on for post-purge)

The JC-22D2 commands the outlet damper to wide open for post

purge.

7. Damper

Close Delay

Burner completes post-purge and stops

the Fan

(Operating Limits, Fan and Fuel Valve

inputs = OFF)

Cooldown Delay timer (0 seconds, field adjustable) starts. This

timer is typically only used with refractory lined furnaces that need

an extended cooldown period. It keeps the outlet damper open for

a time delay after the Fan stops. When this timer expires, if the JC-

22D2 is in AUTO, the outlet damper moves to the fully closed.

Fan Delay Relay Output

Terminals 9-10

Operating Limit Input

Terminal 15

Fan Starter Input

Terminal 8

Fuel Valve Input

Terminal 13

Outlet Damper

12 5 6 73 1

Shutdown

Fan Start

Delay

Purge

and

Ignition

Modulation

Delay

Modulate

Post-Purge

Damper Close

Delay

Shutdown

4

open

closed

on

off

on

off

on

off

on

off

Fan Start Delay

Cooldown

Delay

Draft Modulation Delay

SDI-JC-22D2 rev. 11-1-21 page 5 of 22

Control Types, Control Options, and Actuators

The JC-22D2 allows field selection of: control types, output/actuator type etc…. The field wiring and the required auxiliary

equipment changes based on the selections made. Please read the following descriptions.

Control Types: Floating vs. PID

Floating control has (2) tuning adjustments: Deadband (DB) and Proportional Band (PB). PB slows down the actuator/VSD

rate of change (speed) as the Draft approaches the Setpoint, which makes overshoot and oscillation less likely. This makes

it easier to tune and provides very good control.

PID control has (3) tuning adjustments: Deadband (DB), Proportional Band (PB), and Integral (I) (also called “Reset”).

Instrument Technicians are typically more familiar with this type of controller tuning and can tune for tight Draft control.

However, burner technicians who are less familiar with PID tuning can improperly tune the controller and inadvertently

cause overshoot and Draft control oscillation.

Command Types: Triac vs. mA

Triac output is used with a 3 wire AC reversible actuator with Open, Close, Neutral terminals. The JC-22D2 internal solid

state Triacs energize the Open or Close outputs. Some Triac actuators have a position feedback potentiometer, such as:

models R-AL-2A, SM-xx, UM-xxx, some do not: models: PL-2A-xxx. Triac actuators without a position feedback pot

can not be used with some features, see the compatibility chart below.

4-20 mA or 0-20 mA output can be used with actuators that have with built-in “positioners” (electric or pneumatic) that move

the actuator to a position proportional to the mA command. mA outputs can also command an ID Fan VSD.

External resistors (available separately) can be used to convert the mA signal into a wide variety of DC voltage signals:

1-5V, 2-10V, 0-5V, 0-10V. The Adjustable Starting Position option can not be used with a mA Command actuator or VSD.

Firing Rate Feedforward

During a burner firing rate change, Feedforward control starts to move the damper (or VSD) before the change in burner air

flow causes the draft to deviate from the Setpoint. This is very beneficial for low NOx burners that require tight FGR and air

flow control in order to prevent combustion issues. The JC-22D2 has a Feedforward Proportional Band tuning adjustment

and has 2 “firing rates versus damper position” Feedforward curves for dual fuel burners. See the compatibility chart below.

A burner Firing Rate signal is required: 4-20mA, 0-5V, 0-10V, or Potentiometer. The Model SPS (Shaft Position Sensor)

includes linkage for jackshaft style burners

Adjustable Start Position Option

Installations with extremely tall stacks, or with an oversized ID fan, can create an excessively negative draft if the

Draft Damper wide open during light-off. This can cause nuisance pilot flame failures. The default JC-22D2 sequence

positions the damper wide open for Purge, Ignition, and Main Flame Trial.

The Adj. Start Position option positions the damper wide open for Purge and then moves to a partially closed position after

Purge completes. When the damper reaches this position, if the measured draft not sufficiently negative, the damper will jog

open until the Draft is more negative that the User set Adj. Start Draft Setpoint. When the Draft is acceptable, the

JC-22D2 Adj Start Relay Output energizes.

NOTE: This Option should NOT be used unless absolutely required by the site conditions. This Option requires a second

damper proving switch to be used as a Burner Flame Safeguard Ignition Interlock, see page 11 wiring diagram.

Configuration Compatibility Chart

Actuator Compatible Control Type and Options

Command Type Triac Feedback

Control Type Feedforward Adj. Start Position

Triac No Floating No No

Triac Yes PID or Floating Yes* Yes**

4-20 or 0-20 mA

damper or VSD N/A PID or Floating Yes* No

*The controller must have a firing rate input to use the Feed-forward option.

**The controller must have either a firing rate input or a purge/low fire DIN indication from the

FSG to use the Adjustable Start option.

SDI-JC-22D2 rev. 11-1-21 page 6 of 22

Installation

JC-22D2 Indicator Mounting:

The JC-22D2 Indicator is designed for flush mounting in an enclosure

located rated NEMA 12 or better.

The JC-22D2 should not be subjected to excessive vibration.

Continuous operation is guaranteed over the 32-131 F (0-55C) ambient

operating range.

JC-22XMTR-xxCO Mounting

The JC-22XMTR-xxCO is the standard xmtr for use with the

JC-22D2. Other 4-20 mA xmtrs may be used with the JC-22D2.

Mount the transmitter in a location that is free from excessive

vibration and that will remain at a stable temperature. To prevent

incorrect pressure measurements, the pressure tap in the duct

should be flush with the inside wall of the duct and should be

perpendicular to the primary flow pattern.

Burner flue gas contains a significant amount of water vapor, which

condenses inside the impulse tubing. If the condensed water

collects and remains in the impulse tubing, a false higher pressure

will be applied to the transmitter, which will cause improper draft

control system operation and/or nuisance burner trips.

Mounting the JC-22XMTR close to the pressure tap minimizes

condensate drainage problems.

See the SDI-JC-22XMTR-xxCO instruction manual for additional important installation details.

Damper Actuator Linkage:

The linkage arrangement between the servo actuator and the damper is

important. The wrong arrangement can make it very difficult to control the

draft at reduced firing rates.

Single blade and Parallel blade dampers have a very non-linear flow vs.

rotation characteristic. Rotating from fully closed toward open, the flow

increases very rapidly as the damper opens. The flow changes much less

near the fully open end of the rotation.

The linkage for single and parallel blade dampers should be arranged in a

'Slow Opening' configuration in order to linearize the draft control loop. Near

the Closed position, the servo rotation opens the damper very slowly.

Opposed blade dampers have a more linear flow vs. rotation characteristic.

The linkage for a properly sized opposed blade damper should be between

Linear. Oversized opposed blade dampers may require a Slow Opening

linkage arrangement.

Furnace

or

Flue Gas Duct

UP

12"

minimum

Pitch Down

2" per foot

(minimum)

for drainage.

Pressure Tap with

Clean-out Plug (1-1/4" pipe typ.)

JC-22XMTR

Must be located

ABOVE the flue gas

tapping for proper

condensate draining

Impulse Line

See text for size

Single

Blade

Parallel

Blade

Damper Style: Linkage Setup:

Damper

Servo

Slow Opening:

O

C

C

O

Opposed

Blade Damper

Servo

Linear:

O

C

C

O

Panel Cutout

3.61 x 7.65

3.88

8.00

Touch

Screen

8.74

Plug-in Terminals

1.00

4.88

Plug-in Terminals

SDI-JC-22D2 rev. 11-1-21 page 7 of 22

Wiring Requirements

DANGER

Electric Shock Hazard

Multiple power sources may be present.

Disconnect all electric power sources, local and remote, before servicing

WARNING

This product is intended for use in Commercial and Industrial installations,

it is NOT intended for Residential use.

This product is intended to be used by Trained Operators.

Installation, start-up, and troubleshooting is intended to be done by

Experienced Technicians familiar with Industrial Safety Codes

and all Safety Codes specific to burners and boilers.

This product is NOT a Primary Safety Interlock rated device.

The Relay Outputs should only be used as an

additional auxiliary Operating limit and should not replace or bypass

any Primary Safety Interlock devices required by Safety Codes.

A High Draft Cutout switch and Open Damper position switch are required

to be installed and wired into the flame safeguard system.

Failure to do so can result in equipment damage, injury, or death.

If the Adjustable Starting Draft Option is used,

an additional Outlet Damper Low Fire Start position proving switch

will be required and wired into the flame safeguard low fire circuit.

Incorrect wiring connections to burner/boiler Flame Safeguard controls

can cause Equipment Damage, Injury, or Death

BEFORE installing the wiring:

Consult with the burner control system designer to determine which wiring options on the following pages

should be installed. The JC-22D2 has field selectable options for: Control Type, Actuator type,

Feedforward, Sequence, etc..

All wiring must comply with all local and national electrical codes. Tighten all terminals to 4.4 in-lb. Wire must be stranded

copper, 12-24 ga., 150V / 75 C insulation minimum.

AC and DC wiring must be separated and must not be run in the same conduit to prevent electrical noise coupling.

Use shielded cables where shown, connect shields only where shown, insulate all other shields to prevent accidental

grounding.

Ignition transformer and motor VFD wiring are particularly noisy and should be kept away from all AC and DC wiring.

Relay contacts are rated: 10 A resistive, 9 FLA / ½ Hp / 120 Vac

If the 4-20 mA output will not be used, jumper terminal 42 to 43 to prevent the OUTPUT FAILURE error message.

RS485 is electrically Isolated from all other DC and AC wiring.

All DC '-', terminals are connected together internally.

Terminals 1-20 are Line Voltage AC. Terminals 31-60 are low voltage DC.

An external Line Voltage supply switch or circuit breaker, marked as the disconnect for this instrument, suitably located and

easily reached, and complying with IEC 60947-1 and -3 must be provided.

Fuse: 3.15 amp Slo-Blo, 250 V, 5x20mm (Littlefuse 02393.15HXP, Belfuse 5TT 3.15-R, Preferred Utilities 16740-3.15S)

2 amp Slo-Blo, 250 V, 5x20mm (Littlefuse 0239002.HXP, Belfuse 5TT 2-R, Preferred Utilities 16740-2S)

Caution: To reduce the risk of fire, only replace fuses with the same type.

SDI-JC-22D2 rev. 11-1-21 page 8 of 22

Terminal Layout and Wiring Diagrams

Wiring Diagrams Sheet 1 of 3

L1

L1

N

N

4

3

2

1

8

7

6

5

50

48

46

44

42

40

38

36

34

32

49

47

45

43

41

39

37

35

33

31

Main

Board

USB

Ethernet

3.15A

Slo Blo

N

19

18

17

16

15

14

9

13

12

11

10

60

59

58

57

56

55

54

53

52

51

Future

Rmt I/O

Aux

Board

USB

2A

Slo Blo

20

Low Voltage DC terminals

31

+24 Vdc

32

2.5Vref

33

DC -

34

AIN 1

35

+24 Vdc

JC-22XMTR term 1, 4-20mA "+"

36

AIN 2

JC-22XMTR term 2, 4-20mA "-"

37

+24 Vdc

38

AIN 3

39

DC -

40

AOUT 1

41

DC -

42

AOUT 2

Damper (or VSD) 4-20mA Command

43

DC -

Damper (or VSD) 4-20mA Command

44

DC DIN 1

Remote Alarm Silence

45

RS485 A+

46

DC DIN 2

Burner at Purge Position

47

RS485 B-

48

DOUT 1

49

RS485 Com

50

DOUT 2

51

+24 Vdc

52

2.5Vref

Actuator Feedback Pot Closed

53

AIN 3

Actuator Feedback Pot Wiper

54

DC -

Actuator Feedback Pot Open

55

+24 Vdc

Burner Firing Rate, Vdc or mA

56

AIN 4

Burner Firing Rate, Vdc or mA

57

DC -

Burner Firing Rate, Vdc or mA

58

future

59

future

60

future

Line Voltage AC terminals

N

N

N

N

L1

L1

L1

L1

1

ROUT 1 NO

Common Alarm

2

ROUT 1 C

Common Alarm

3

ROUT 1 NC

4

ROUT 2 NO

5

ROUT 2 C

6

ROUT 2 NC

7

AC DIN 1

Burner at Purge Position

8

AC DIN 2

Fan Starter Energized

9

ROUT 3 NO

Fan Start Delay Contacts

10

ROUT 3 C

Fan Start Delay Contacts

11

ROUT 4 NO

Adj Start at Position

12

ROUT 4 C

Adj Start at Position

13

AC DIN 3

Fuel Valve Energized

14

AC DIN 4

Fuel 2 Select

15

AC DIN 5

Operating Limits Made

16 Close Triac Damper Actuator x Vac CLOSE Cmnd.

17 Open Triac Damper Actuator x Vac Open Cmnd.

18 Triac Power

Input

Actuator 24-120Vac Power Input

19 Actuator Neutral

20 Fused 120 Vac

Output

N

N

SDI-JC-22D2 rev. 11-1-21 page 9 of 22

Typical JC-22D2 Interfacing to a Burner Flame Safeguard

L1

L2

G

3

P

JC-22D2

Draft

Controller

35

36

39

+24 V

+

-

4

L2

G

L1

L2

G

L1

N

Draft Sensor and

High Pressure Switch

Model: JC-22XMTR-xPCO

15

9

10

6 13

Operating Limit

Fan Start

Delay

Contacts

Non-Recycling / Lockout Limits

3

7 P

Draft / Pressure

Connection

T1-1 R

T1

5 sec

Off Delay

blk

wht

red

red

4-20 mA

" WC Xmtr

+

-

1

2

Low Voltage DC

Do not run in Conduits with AC

H

N

G

120 Vac

60 Hz

26 VA

Fireye

E100/E110

Honeywell

RM7800L

Existing Burner Flame Safeguard:

WARNING:

* Some Flame Safeguard Wiring is Omitted for Clarity.

* Consult Burner Manual for Complete Wiring Diagram.

* An Experienced Burner Technician must adapt this TYPICAL

wiring diagram to each specific burner wiring diagram.

Fireye

YB110

Safety Interloc k (required by Co de)

Burner

Flame

Safeguard

120 Vac

60 Hz

99 7 13

8

M

D

8

Low Fire Proving Switches

Purge Proving Switches

Fan

Fan

Fuel Valve

Fuel Valves

Draft Purge Interlock (required by Code)

Fireye

E100/E110

Honeywell

RM7800L

Fireye

YB110

D

M

8

18

5

19

RM7800 / YB110

E100 / E110

For Draft Damper Actuator

and ID Fan VSD wiring

See sheet 2

For Additional Options

See sheet 3

Fan

Operating Limits

Legend:

Existing AC Wire (Do NOT change this wiring)

Remove Existing AC Wire

New AC Wire

New Shielded Low Voltage DC Cable

Do Not Run in Conduits with AC Wires

SDI-JC-22D2 rev. 11-1-21 page 10 of 22

Wiring Diagrams Sheet 2 of 3

Damper Actuator (or ID Fan VSD) Wiring

Damper Actuator or ID Fan VSD

42

43

-

+

Draft Purge Interl ock (required by Co de)For an Actuator:

Draft Purge Interl ock (required by Co de)

Input:

4-20mA, 0-20mA,

1-5V, 2-10V ,

0-5V, 0-10V

+

-

Command: 4-20mA or 0-20mA

Feedback: None

Command/Output Input Resistor

4-20 mA 4-20 mA none

4-20 mA 1-5 V 250 ohms

4-20 mA 2-10V 500 ohms

0-20mA 0-20mA none

0-20mA 0-5V 250 ohms

0-20mA 0-10V 500 ohms

JC-22D2

Resistors not included, order Separately

Actuator Compatiblity

YES: Floating Control, PID, Feedforward

NO: Adj. Start.

54

53

52

+2.5 V

+

-

CW

CCW

16

17

OPEN

CLOSE

18

20

To Reverse

Rotation

Swap Wires

on Terminals:

16 & 17

52 & 54

fused 120 Vac output

Triac Power Input

3

14

CW

CCWEXT

RET

510

69

5

711

EXT

RET

OPEN

CLOSE

0.15 – 2.29 Vdc

2

3

Low Voltage DC

Do not run in Conduits with AC

131

142

EXT

RET 7

Draft Purge Interlock (required by Code)

Bias Resistors are required for some feedback pot styles.

Not needed for SM-xx actuators. See Instructions.

Resistors not included, order Separately

SM-15, SM-37

R-AL-2, R-AL-2A

Actuator

Terminals:

6

EXT

RET

Command: Triac

Feedback: Pot

Potentiometer Spec:

500 - 10,000 ohms

JC-22D2

Actuator Compatiblity

YES: Floating Control, PID,

Feedforward, Adj. Start.

16

17

OPEN

CLOSE

18

N

20

fused 120 Vac output

Triac Power Input

24Vac Damper Actuator

120 V 24 V

Draft Purge Interlock (required by Code)

Damper Open

Switch

Command: Triac

Feedback: None

To Reverse

Rotation

Swap Wires

on 16 & 17

JC-22D2

Actuator Compatiblity

YES: Floating Control

NO: PID, Feedforward, Adj. Start.

SM-15, SM-37

PL-2, PL-2A

Actuator

Terminals:

120 Vac Damper Actuator

16

17

OPEN

CLOSE

18

19

20

Damper Open Switch

To Reverse

Rotation

Swap Wires

on 16 & 17

fused 120 Vac Output

Triac Power Input

5

3

14

138

146

CW

CCWEXT

RET

EXT

RET 7

3

2

JC-22D2

Draft Purge Interl ock (required by Code)

Command: Triac

Feedback: None

Actuator Compatiblity

YES: Floating Control.

NO: PID, Feedforward, Adj. Start.

Made from

90-100% Open.

Made from

90-100% Open.

Damper Open Switch

Made from

90-100% Open.

Damper Open Switch

Purge Air Flow Switch

For an ID Fan VSD:

N

19

Note

Terminal 20 is connected to the

internal Triac surge suppressors

Note

Terminal 20 is connected to the

internal Triac surge suppressors

Note

Terminal 20 is connected to the

internal Triac surge suppressors

19

N

SDI-JC-22D2 rev. 11-1-21 page 11 of 22

Wiring Diagrams Sheet 3 of 3

Feedforward, Adj. Start, Miscellaneous Wiring

Burner Firing Rate Signal Types

(choose one), required for the Feedforward Option

52

56

57

+

Low Fire

High Fire

Potentiometer Signal

0.15 – 2.29 Vdc

Low Voltage DC

Do not run in Conduits with AC.

Connect Shields only where shown.

Potentiometer Spec:

500 - 10,000 ohms

linkage to burner

Model SPS or equal

+2.5 VHi Fire

-Low Fire

JC-22D2

56

57

+

4-20mA Signal

+

-

-

Firing Rate

4-20 mA Output

from

Burner Controls

(Order Separately) 100k

56

57

+

0-5V or 0-10V Signal

(or any 2V min. span)

+

-

-

Firing Rate

Voltage Output

from

Burner Controls

Miscellaneous Optional Wiring

41

L1

2

1

44

N

ROUT 1 C

ROUT 1 NO

Alarm

Horn

24 Vdc Remote

Alarm Silence

Pushbutton

DC DIN 1

-

RS485

Isolated

A +

B -

Isolated

Common

45

47

49

ORG

BLU

WHT

ORG

BLU

WHT

Belden 3106A

or equal

JC-22D2

JC-22D2

Adjustable Starting Draft Sequence Option Wiring

7

AC DIN 1

Low Fire

Proving Switches

Purge

Proving Switches

Draft Purge Interlock

(required by Code)

Fireye

E100/E110

Honeywell

RM7800L

Fireye

YB110

Made from

90% to 100% Open.

Draft Damper

Position Switches

Draft Adjustable Start Interlock

(required by Code)

JC-22D2

12

11

Adj. Start

Relay Made from the

Adj. Start position

up to 100% Open.

SM-x and UM-x servos

include (2) aux. switches

All wiring on Sheet 1 is also required

All wiring on Sheet 2 for Command: Triac / Feedback: Pot is also required

A signal indicating when the burner is at the Purge Position is required.

There are 3 options, choose one: Burner Firing Rate Signal (above), AC DIN 1, or DC DIN 2.

46

33

DC DIN 2

-

Compatible with RM7800L or YB110 (NOT allowed for E100/E110)

24 Vdc Purge position limit switch

M

D

8

D

M

8

18

5

19

120 Vac Purge position signal

L1

14

120 Vac

Fuel 2 FF Curve Select

Fuel 2

Feedforward Curve

Select

SDI-JC-22D2 rev. 11-1-21 page 12 of 22

Parameters / Menu Map

From the Home screen, touch Menu to display the Main Menu.

Tuning Live Data

Draft

Draft Setpoint

Proportional Term

Feedforward Term

Output

Control Options

Control Type

Command Type

Triac Feedback Type

Firing Rate Signal Type

FR Feedforward Option

Sequencing Menu

Utilities

Set Clock

Calibrate Touch

Clean Screen

Screen Settings

Firmware Version

Startup History

Pasword

Enter

Change

Logout

Screen Settings

Brightness

Touch Buzzer

Alarm Buzzer

Main Menu

Utilities

Password

Draft Control Setpoint

Tuning

Alarm

Configure/Setup

I/O Examine

Alarm

Low Draft Alarm Setpoint

Alarm Delay Seconds

Configure/Setup

Control Options

Inputs / Outputs

RS485

Ethernet

Calibrate Firing Rate

Start Auto Calibration

FR Volts/mA at 100%

FR Volts/mA at 0%

Sequencing

Fan Start Delay

Draft Modulate Delay

Cooldown Delay

Adj. Start Position Option

Adjustable Start Menu

Adj Draft Ignition Position

Purging Input

Firing Rate % at Purge

Fuel 1 Draft Ign. Position

Fuel 2 Draft Ign. Position

Ignition Draft Setpoint

Bargraph Setup

Bargraph Top Draft

Bargraph Bottom Draft

BG Tick Decimal Digits

Draft Xmtr Setup

Draft Xmtr Units

Xmtr 20mA = ? Draft

Xmtr 4mA = ? Draft

Draft Decimal Digits

Draft Xmtr Name

Bargraph Setup

Triac Servo Calibration

Auto Calibration

Volts at 100% (Open)

Volts at 0% (Closed)

Triac Servo Stroke Sec.

Tuning Screens Loop

Inputs / Outputs

Draft Xmtr

Triac Servo Cal.

Triac Deadband Test

Firing Rate Signal Cal.

Triac

Deadband Test

Tuning

Draft Proportional Band

Draft Deadband

Xmtr Smoothing Filter

More Tuning

Feedforward Prop. Band

PID Minutes/Repeat

Output Rate Limiter

Auto Max Output

Auto Min Output

Feedforward Curv e

Curve Data Entry Screen

Control Options Factory Defaults are:

Control = Floating, Command = Triac, Feedback = None

Parameters that are grayed out are ignored.

Changing Control Options enables those parameters.

Some Combinations of Options are Not Allowed,

Always do the Config. Error Check after changing Options

Only displayed when

Feedforward Option is

Enabled

SDI-JC-22D2 rev. 11-1-21 page 13 of 22

Parameters

Screen Settings

Parameter

Default

Max.

Min.

Go

to: Menu > Utilities > Screen Settings

1 Disable Enable Disable

Touch Buzzer Enable

Activates faceplate Tone when a

screen item is touched

2

Disable

Enable

Disable

Alarm Buzzer Enable

Activates faceplate Tone when a

n Alarm is triggered.

Draft Control Setpoint

Parameter

Default

Max.

Min.

Go to: Menu > Draft Control Setpoint

40 -0.10 +200.00

-200.00

Draft

Control Setpoint

See: Draft Xmtr Setup for the Units

Tuning

Parameter

Default Max. Min. Go to: Menu > Tuning

41 0.25 25.00

0.025

Draft Proportional Band

Expressed in the same units/scaling of the Draft Xmtr (see Draft Xmtr Setup menu)

Smaller values cause more aggressive control action.

Larger

values cause less aggressive

control

action.

42 0.030 1.500

0.003

Draft Deadband

Expressed in the same units/scaling of the Draft Xmtr (see Draft Xmtr Setup menu)

If the draft pressure is with +/- Draft Deadband of the setpoint, the damper stops.

Smaller Deadband increases damper movement and allows for tighter control.

Setting the deadband too low can cause draft damper oscillation/hunting

Larger

values decrease damper movement but limit control pre

cision.

43 2.0 5.0 0.5

Xmtr Smoothing Filter (seconds)

Smooths out normal combustion pressure pulsations.

Smaller values reduce smoothing (Too small can cause damper hunting).

Larger

values ca

us

e more smoothing. (Too large can ca

us

e overshoot

oscillations

).

44 125 1000

75 Feedforward Prop. Band

Determines how the Damper/VSD responds to a change in the Burner Firing Rate.

Smaller proportional band will cause more aggressive Feedforward action.

L

arger

proportional band will cause less aggressive

Feedforward

action.

45 0.50 4.00 0.12 PID Minutes/Repeat

Proportional Band responds instantly to a Draft disturbance. After that, PID “Repeats”

ramps the damper back to the Draft Setpoint.

Smaller minutes/repeat will cause faster ramping (Too small causes oscillation).

Larger minutes/repeat will cause slower ramping.

46 30 75 25 Output Rate Limiter Sec./100%

Only affects Floating control mode. Prevents the damper from moving too fast.

Smaller Sec/100% allows damper to move faster.

Larger Sec/100% limits the damper speed.

This

value

should

always

be set to longer than the actuator

0

-

100%

stroke time.

47 100.0 100.0

0.0 Auto Max Output

When Released to Modulate AND in AUTO, this is the maximum damper opening.

This prevents “Reset Windup”. Otherwise, the Damper can stroke the full 0-100%.

Auto Max

Output

m

ust be

greater than

:

(Auto Min

Output

+ 25

)

48 0.0 100.0

0.0

Auto Min Output

When Released to Modulate AND in AUTO, this is the minimum damper opening.

This prevents “Reset Windup”. Otherwise, the Damper can stroke the full 0-100%.

Auto Min

Output

must be Less than

:

(Auto Max

Output

-

25)

SDI-JC-22D2 rev. 11-1-21 page 14 of 22

Draft Alarm

Parameter

Default

Max.

Min.

Go

to: Menu >

Alarm

52 2.00 250.0 -250.0

Alarm

Setpoint

Draft Alarm will only activate when the boiler is released to modulate.

Alarm activates when Draft is more positive than this Setpoint for longer than the Alarm

Delay. Example: Draft =

-

0.10”, Alarm SP =

-

0.20”,

Alarm activates after Delay.

53 8 60 1

Alarm

Delay (se

conds)

Draft Alarm time delay, see Alarm Setpoint description.

Control Options

Parameter

Default

Max.

Min.

Go

to: Menu > Configure / Setup >

Control Options

55 Floating PID Floating

Control Type

Options: PID

or

Floating

See pg 5

Compatibility

chart

56 Triac 4-20mA Triac Actuator or VSD Command Type

Options: Triac / 4-20mA / 0-20mA

With an external resistor, 0-20mA can drive 0-5V or 0-10V devices.

See pg 5

Compatibility

ch

art

57 None Pot. None Triac Feedback Type

Options: None / Potentiometer

See pg 5

Compatibility

chart

58

Disable

0

-

10V

Disable

Firing Rate Signal Type

Options: Disabled / 4-20mA / Potentiometer / 0-5V / 0-10V

Firing rate signal input is required for

the Feedforward control option.

59

Disable

Enable

Disable

F

iring Rate

Feedforward Option

Options: Disable / Enable

See pg 5

Compatibility

chart

Sequencing

Parameter

Default

Max.

Min.

Go

to: Menu > Configure / Setup >

Sequencing

65 15 60 1 Fan Start Delay Seconds

When the Operating Limits input makes: the draft damper starts to drive fully open and

the timer starts timing. The JC-22D2 Fan Start Delay Relay energizes at the end of the

delay and energizes the FSG Operating Limits input.

This delay allows the Draft damper to get enough open to prevent pressurizing the

boiler when the burner FD fan starts. This delay prevents a nuisance Draft Cutout

Lockout during startup.

6

6

15

60

0

D

raft Modulate Delay Seconds

This sets the delay after the fuel valves are opened before the draft damper can begin

to start modulating.

If the adjustable start position option is being used, the modulate delay must be set for at

least as long as the MTFI.

67 0 900 0 Cooldown Delay Seconds

This keeps the damper wide open for the selected seconds after a burner shutdown.

Note: T

he cooldown delay will only activate if the burner had been released to modulate

for at least 60 seconds.

68

Disable

Enable

Disable

Adjustable Start Position Option

Options: Disable / Enable

The JC-22D2 must have either a firing rate input or FSG purge position input to use the

adjustable start position option. See additional Code required Interlock, see page 11.

The Adj. Start parameters are in the next Menu screen.

SDI-JC-22D2 rev. 11-1-21 page 15 of 22

Adjustable Start Menu

Parameter

Default

Max.

Min.

Go

to: Menu > Configure / Setup > Sequencing > Adjustable Start Menu

70 AIN 5 AIN 5

AC_DIN1

Burner Purging Input

Options: AC_DIN 1 / DC_DIN 2 / AIN 5

This signal indicates when the burner is at the Purge position

. See

page 5 des

cription.

71 90 95 50 Firing Rate % at Purge

If AIN 5 is selected as the Burner Purging Position input and the signal is greater than

this parameter, the Adj. Start sequence detects that the burner is Purging.

See page

5

description.

72 35 50 10 Fuel 1 Draft Ign. Position

When the JC-22D2 Fuel 2 input is de-energized,

the draft damper will go to this position

before checking adjustable start draft.

See page

5

description.

73 35 50 10 Fuel 2 Draft Ign. Position

When the JC-22D2 Fuel 2 input is energized, the draft damper will go to this position

before checking adjustable start draft.

See page

5

description.

74 -0.25 -0.1 -8.0 Ignition Draft Setpoint

Once the damper has reached the adjustable start position, If required, the damper will

will slowly jog

open D

raft

is more negative than

this setpoint.

See page

5

description.

Draft Xmtr.

Bargraph Setup

Parameter

Default

Max.

Min.

Go

to: Menu > Configure / Setup > Inputs / Outputs >

Draft Xmtr > Bargraph Setup

87

1.00

250.0

-

250.0

Draft at Bargraph Top

This sets the scale at the top of the bargraph.

88 -1.00 250.0

-250.0

Draft at Bargraph Bottom

This sets the scale at the bottom of the bargraph.

89

2

3

1

BG Tick Decimal

Digits

The number of decimal digits displayed at the bargraph 0%, 25%, 50, 75%,

and 100% marks.

Parameter

Default

Max.

Min.

Go to: Menu > Configure / Setup > Inputs / Outputs > Draft Xmtr

80 In. wc

kPa In. wc Draft Xmtr Units

Options: in. wc / cm wc / mm wc / kPa

This is the Units text used on various screens.

Changing the Units does NOT change, or re-calculate, or any other parameter’s

numeric value

…such as the Control setpoint, Alarm setpoint, etc…

8

1

-

1.0

250.0

250.0

Xmtr 20 mA = ?? Draft

Draft transmitter 20 mA calibration value.

Fail Safe design for a xmtr or field wiring fault, typically means the xmtr 20 mA

calibration

should

correspond to the

more

negative

value

.

82 1.0 250.0

-250.0 Xmtr 4 mA = ?? Draft

Draft transmitter 4 mA calibration value.

Fail Safe design for a xmtr or field wiring fault, typically means the xmtr 4 mA

calibration should correspond to the

more positive value

.

8

3

2

3

1

Draft Decimal Digits

The number of digits

displayed on the screen to the right of the decimal point.

84 Draft Econ

Outlet

Draft Draft Xmtr Name

Options: Draft / Furnace / Outlet / Econ Outlet

SDI-JC-22D2 rev. 11-1-21 page 16 of 22

Commissioning

Triac Servo Calibration

Menu > Configure/Setup > Inputs/Outputs >Triac Servo Cal.

A Triac servo with a feedback pot must be stroked and the

0% and 100% feedback voltages must be stored before the

draft controller is run in automatic.

Initially this screen is in Manual and the damper servo can

be opened/closed in order to check rotation, and to set the

travel limit switches. Verify that there is no linkage or

damper binding, and that the servo stops before the

damper hits a hard stop at both ends of travel. Verify that

the Pot voltages at full Open and Closed are in the ranges

shown on the screen (if needed, correct the Pot wiring).

After the Manual checks are completed, press Manual to

change to Auto mode. To prevent injury: Verify that no

one is near the servo or damper .

Press Start to initiate the automated Calibration cycle. The Start button then changes to Stop. Press Stop at any time to stop

servo movement (which also aborts the cycle). The automated calibration cycle is:

Close output energizes. The closed limit switch stops the servo, Pot voltage settles, 0% Pot Vdc is stored.

Open output energizes. The open limit switch stops the servo, Pot voltage settles, 100% Pot Vdc is stored.

Close output energizes. The seconds to move 100% -> 0% is measured and stored.

Mode changes to Manual

Triac Deadband Test

Menu > Configure / Setup > Inputs / Outputs >Triac Deadband Test

Place the Servo Command in Manual. During the following observe how close the servo

comes to the command, and whether the servo hunts before finally stopping.

Set the command to 30%, then 20%, then 10%, then 20%, then 30%, etc…

Reduce the deadband and repeat until:

Deadband is at the minimum value or the servo hunts

If the servo hunts, increase the deadband gradually until the hunting stops, then test again.

Firing Rate Signal Calibration

Menu > Configure / Setup > Inputs / Outputs > Firing Rate Signal Cal

The Firing Rate input can NOT be calibrated when:

The burner is firing AND ( Feedfoward is Enabled OR Adj. Start Position is Enabled )

Firing Rate CAN be calibrated when firing IF (Feedfoward and Adj. Start are both disabled).

To calibrate the firing rate input:

Use the burner firing rate controls to position the burner at Low Fire.

When the signal settles, press “Save 0% Signal”.

Use the burner firing rate controls to position the burner at High Fire.

When the signal settles, press “Save 100% Signal”.

Use the burner firing rate controls to gradually move the burner from 100% to 0%.

If the JC-22D2 displayed “% Firing Rate” does not approximately track the burner,

trouble shoot the wiring and/or the firing rate sensor.

SDI-JC-22D2 rev. 11-1-21 page 17 of 22

Controller Tuning Screens

Tuning Screen Loop

The tuning screens are in a loop to

allow you to change a value and then

to quickly get to the “Live Data”

screen to watch how the controller

responds. Use the right/left arrows in

the title bar to move through the loop.

The “More Tuning” and/or “Feedforward” screens are skipped over if the related options are Disabled.

See the descriptions for each of the tuning parameters, and how it affects the tuning, on page 13.

Firing Rate Feedforward Curve Screen

With a Tech level password, Feedfoward Curve data can be manually entered/edited at any

time (burner firing, or not firing), just touch one of the feedforward values. When Released to

Modulate, the Store button method or the manual method can be used to enter curve data.

Store Button method (Tech Password required and Draft is Released to Modulate)

When the Manual/Auto button is in Auto, the controller moves the damper until the Draft

is within the Setpoint Deadband. In Manual the User enters the “% Damper” value.

Put the Burner controller in Manual and position the burner at any firing rate within

+/- 2% of any Curve Firing Rate, and keep the burner fixed at that firing rate.

** is displayed when within +/-2%. --- is displayed when NOT within +/-2%

When the Draft is near the Draft Setpoint, change the Auto/Manual button to Manual to

hold the draft damper at a fixed position

Press Store to save that damper position in the curve

Repeat

Live Tuning Data Screen

This screen allows you to watch how the Proportional, Integral (aka “Reset”) and feedforward

settings affect the Draft control. See the descriptions for each of the tuning parameters, and

how it affects the tuning on page 13.

After making a tuning value change these two methods should both be used to test the draft

controll tuning:

Leave the Draft in Auto and make the burner firing rate change (at a realistic ramp rate).

Put the draft in Manual, open the damper 5-15% for 10-15 sec, and then put the Draft in

back in Auto.

If control is sluggish control (slow return to Setpoint without overshoot), gradually decrease

the Proportional Band.

If control is overly aggressive control (Draft overshoots the setpoint and cycles excessicely

before settling), gradually increase the Proportional Band.

If the burner firing rate is not changing, and the damper is hunting, gradually increase the

Deadband.

If the burner firing rate is not changing and the draft Damper is in Manual (not moving), and the draft xmtr signal is jumping

excessively, increase the filter sconds gradually. If the draft signal is not jumping much at all, the Filter Seconds must be

decreased because excessive Filter seconds will cause the controller to overshoot.

Tuning Live Data

Draft

Draft Setpoint

Proportional Term

Feedforward Term

Output

Tuning Screens Loop

Tuning

Draft Proportional Band

Draft Deadband

Xmtr Smoothing Filter

More Tuning

Feedforward Prop. Band

PID Minutes/Repeat

Output Rate Limiter

Auto Max Output

Auto Min Output

Feedforward Curve

Curve Data Entry Screen

Main

Menu

SDI-JC-22D2 rev. 11-1-21 page 18 of 22

I/O Examine - Troubleshooting

The I/O Examine screen shows the current values for all JC-22D2 inputs and outputs and is very usefull for detecting wiring and

sequencing problems.

Verify that JC-22D2 “N” is connected to Flame Safeguard “N”

Check the Alarms screen to verify that there are no Configuration Errors.

Correct Errors (see Compatability Chart on page 5)

The damper will not open/close when: JC-22D2 is in Manual and I/O screen shows: Start Limits=Off, Fan=Off, Fuel Valve=Off

For Triac actuators:

To test, change to Floating Control and “No Feedback”.

Check the 2A fuse

Check the actuator (or VSD) wiring, page 10.

Damper doesn’t Open for Purge when burner Operating Limits Make

Use I/O screen to verify: Start Limits = ON.

If Off, check wiring, see page 9. Verify that JC-22D2 “N” is connected to Flame Safeguard “N”

Burner won’t start

Use I/O screen to verify: Start Limits = ON and that the Fan Start Relay = ON after the Fan Start Delay timer expires.

Then check wiring, see page 9. Verify that JC-22D2 “N” is connected to Flame Safeguard “N”

The damper opens for Purge, stays wide open and will not modulate when the burner is firing

Check the I/O screen to verify: Fuel valve = ON

If I/O shows fuel valve is OFF:

Check the wiring.

Verify that the JC-22D2 120 Vac Neutral is wired to the Flame Safeguard Neutral.

If Fuel valve input = ON, with the JC-22D2 in Manual, can the Damper be Closed and Opened?

If NO:

Check the Close Triac wiring to the actuator, page 10.

If YES:

Is the Draft Setpoint more Negative than the Draft?

If YES, the damper should stay wide open, there is no problem.

Examples of “More Negative”: SP = -0.2”, Draft = -0.1” and SP = +0.15, Draft = +0.2”

Damper closes before burner Post Purge is completed

Check the I/O screen to verify: Fan Run Command = ON during Post Purge

SDI-JC-22D2 rev. 11-1-21 page 19 of 22

Modbus

RS485 Baud: 4800, 9600, 19200, 38400, 57600

RS485 Parity: Odd, Even, None

Ethernet: 10/100 Mb/s

Protocol: RTU

Address: 1-247

Register Formats: 16 bit Signed Integer and 32 bit Floating Point

Modbus Commands: 01 Read Coils, 03 Read Registers, 05 Write Single Coil, 06 Write Single Register,

16 Write Multiple Registers (2 registers max)

Max Poll Size: 120 coils or registers (except Code 16)

Coil

0 =

1 =

Description

98

WO

Alarm Silence

Remote Alarm Silence

99

RO

No Alarm

Alarm

Common Alarm

120

RO

No Alarm

Alarm

High Draft Alarm

121

R

O

Auto

Manual

Auto/Manual

1

22

RO

Fan OFF

Fan ON

Fan Energized Input

123

RO

De

-

Energized

Energized

Fuel Valve Energized Input

124

RO

Limits OFF

Limits ON

Start Limits Input

125

RO

De

-

Energized

Energized

Burner Start Delay Relay

Register

Type

Description

40

200

RO

F

LOAT

Filtered Draft PV

40202

R

O

F

LOAT

Draft Control Setpoint

40204

R

O

F

LOAT

Actuator Position Command

SDI-JC-22D2 rev. 11-1-21 page 20 of 22

Parts List

Part Number Description

JC-22D2 Draft Controller

16740-2S FUSE, 2 A, SLO-BLO, 250 V, 5x20mm

16740-3.15S 3.15 amp Slo-Blo, 250 V,5x20mm fuse

90437-KIT JC-xxD2 Panel Mounting Clip (2)

90434 JC-xxD2 Panel Mounting Gasket

92791 8 pt Terminal Block, line voltage, 5.08mm

92794 5 pt Terminal Block, line voltage, 5.08mm

92795 10 pt Terminal Block, low voltage, 3.81mm

92799 2 pt Terminal Block, line voltage, 5.08mm

92800 10 pt Terminal Block, line voltage, 5.08mm

JC-22XMTR-HPCO +1” to -1” 4-20mA Draft Transmitter with 4 sec High Pressure Cutout (Positive Setpoint)

JC-22XMTR-LDCO +1” to -1” 4-20mA Draft Transmitter with 4 sec Low Draft Cutout (Negative Setpoint)

JC-22-HDPCO-8 +0.05” to +9”, Draft Cutout Switch, 8 Second Delay

JC-22-HDPCO-8 -0.05” to -9”, Draft Cutout Switch, 8 Second Delay

190388-xx 10’’ thru 48” dia, E-Link Draft Damper assy with Triac actuator and JC-22XMTR-HPCO.

107362-D2-1 JC-xxD2 Single Unit, Wall Mount Enclosure, 12h x10w x 8d

107362-D2-2 JC-xxD2 Dual Unit, Wall Mount Enclosure, 14h x12w x 8d

107362-D2-3 JC-xxD2 Three Unit, Wall Mount Enclosure, 14h x16w x 8d

190751-D2 JC-xxD2 or TG-EL-D4B Adapter Plate, Panel Cutout: 7.5” X 7.6”

190753-D2 JC-xxD2 or TG-EL-D4B Adapter Plate, Panel Cutout: 8.00” X 10.75”

Specifications

Mechanical:

Enclosure: Nema 12 Faceplate, Indoor Locations

Bezel: 3 7/8 w x 8 h x 1 d

Rear Case: 3 1/2 w x 7 9/16 h x 4 7/8 d

Panel Cutout: 3.61 w x 7.65 h

Weight: 2 lbs

Ambient: 32-131 F (0-55 C)

Altitude: 6560 feet (2000 meters)

Electrical:

Input Power: 120Vac +/-15%, 50/60 Hz, 26 VA

Output Power: 24 Vdc, 300mA max combined load

Terminals: 31,35,37,40,42

Analog Inputs

(3) 16 bit, 5 samples/sec, 50/60Hz filter: -90db

Draft: 4-20 mA

Feedback Pot: 0.15 - 2.29 Vdc

Burner Firing Rate: 4-20mA, 0-2.3V, 0-5V, 0-10V

field selected

Analog Output

(1) 16 bit, 4-20mA, max 650 ohm load

Servo/VSD Command

AC Discrete Inputs

(5) 120 Vac, 13 mA typ/ch., opto-isolated

Oper. Limits, Fan Running, Fuel Valve, Fuel 2 Select,

Burner at Purge

DC Discrete Inputs

(2) Sinking, 33k / 24V internal pull-up

Remote Alarm Silence, Burner at Purge

Relay Outputs

(2) SPDT, (2) SPST, 120Vac,10 A

Alarm, Fan Start Delay, At Adj. Start

Triac Outputs

(2) 24-120 Vac, 2A fuse, opto-isolated

Actuator Open, Close

Commmunications

USB: non-isolated, JC_D2Edit config & Firmware Flashing

RS485: Isolated, 4.8 - 57.6 kbaud, Modbus RTU

Ethernet: 10/100 Mb/s, Modbus/TCP

Table of contents

Other Preferred Controllers manuals

Popular Controllers manuals by other brands

Reo Elektronik

Reo Elektronik REOTRON MDW 700 operating instructions

Nacon

Nacon MG-X quick start guide

Ruijie Networks

Ruijie Networks RG-WS6008 Series Hardware installation and reference guide

VWR

VWR Powerpette Plus instruction manual

Intel

Intel G35 Express Chipset Design guidelines

BBH

BBH SMX Series installation manual