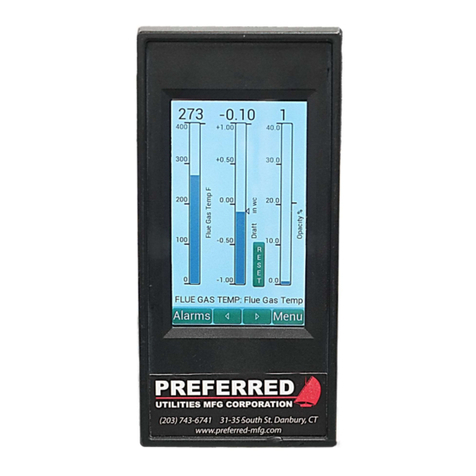

Preferred FlexFit 110 User manual

FlexFit 110 Linkageless Control

Copyright © 2018 Preferred Instruments – All Rights Reserved Worldwide

The information contained herein is provided in good faith but is subject to change without notice. It is supplied with no warranty

whatsoever and does not represent a commitment on the part of Preferred Instruments. Companies, names, and data used

as examples herein are ctitious unless otherwise stated. No part of this document may be reproduced or transmitted in any

form or by any means, electronic or mechanical, without the express written permission of Preferred Instruments.

The Preferred Instruments logo is a registered trademark ® of Preferred Instruments.

FlexFit, FlexFit Edit, and the FlexFit logo are trademarks ™ of Preferred Instruments.

All other trademarks are acknowledged as the property of their respective owners.

WARNING

If improperly installed or irresponsibly used, the equipment covered in this

manual can cause extreme property damage, severe injury, or death. It

is the responsibility of the owner and user to ensure that the equipment

described herein is installed, commissioned, and used in compliance with the

requirements of all national and local legislation, whichever may prevail.

The FlexFit is used to control potentially dangerous boiler, burner, and com-

bustion processes. Only qualied instrument engineers or senior technicians

that have read this entire manual and are familiar with all aspects of the

processes being controlled should attempt to install and commission this

controller. Only qualied operators that are familiar with all aspects of the

processes being controlled should attempt use this equipment. Failure to

do so can result in extreme equipment damage, severe injury, or death.

Revision Changes Author

1.0 Initial Release BKB

Specications iii

FlexFit – Linkageless Control – Revision 1.0 PREFERRED

UTILITIES MFG CORPORATION

FlexFit 110 Linkageless Control

FlexFit Specications ....................................................................................... vi

Safety Cautions and Warnings ........................................................................vii

Section 1 – Description 1-1

Overview ........................................................................................................1-2

Features .........................................................................................................1-2

Safety Relay ..........................................................................................1-2

Field Selectable Flex Sequence Option ................................................1-3

Servo Checks ........................................................................................1-3

Automatic Fuel SSOV Leak Test ...........................................................1-3

Lockout and Alarm History ....................................................................1-3

MAF and PAF Safe Start Checks ..........................................................1-3

High Flue Gas Temperature Shutdown .................................................1-3

Fuel Selection and Flexibility .................................................................1-3

FD VSD to VSD Bypass Changeover ...................................................1-3

Pilot Test Hold .......................................................................................1-3

Flame Scanner/Relay ............................................................................1-3

Fuel/Air Position "Pacing Logic" ............................................................1-3

Tandem Oil/Gas Valve Servo ................................................................1-4

Oxygen Trim ..........................................................................................1-4

Firing Rate Setpoint and Control ...........................................................1-4

Call for Heat ...........................................................................................1-4

Domestic Hot Water Override ...............................................................1-4

Warm Standby Option ...........................................................................1-4

Cold Start WarmUp Cycle Option .........................................................1-4

Integrated Draft Control .........................................................................1-5

RS485 Modulating Lead/Lag Interface .................................................1-5

Burner Management System .........................................................................1-5

Description of BMS Sates .....................................................................1-8

Boot ...............................................................................................1-8

Standby .........................................................................................1-8

Safe Start Checks .........................................................................1-8

Prestart .........................................................................................1-8

Purge ............................................................................................1-8

Pilot Trial for Ignition (PTFI) ..........................................................1-8

Main Trial for Ignition (MTFI) ........................................................1-8

Release to Modulate .....................................................................1-8

Assured Low Fire Cutout (ALFCO) Option ...................................1-8

Post Purge ....................................................................................1-8

Gas Valve Leak Test Option (Flex Sequence Option Only) .........1-9

Lockout .........................................................................................1-9

Interlock Groups ....................................................................................1-9

Call for Heat ..................................................................................1-9

Recycling Limits ............................................................................1-9

Fuel Select ....................................................................................1-9

Non-Recycling Limits ....................................................................1-9

Purging .........................................................................................1-9

Ignition ..........................................................................................1-9

False Flame ..................................................................................1-9

Flame Failure ................................................................................1-9

Fuel Valve Proof of Closure Switches (POCS) .............................1-9

Fan Speed ....................................................................................1-9

Combustion Control System ..........................................................................1-9

Parallel Positioning ..................................................................... 1-10

Section 2 – Installation 2-11

Electrical Noise Suppression ....................................................................... 2-12

General Wiring Requirements ............................................................. 2-12

Ignition Transformer Wiring / Mounting ............................................... 2-12

VSD Wiring .......................................................................................... 2-12

Oxygen Analyzer Wiring ...................................................................... 2-12

Flame Scanner Wiring ......................................................................... 2-12

Installation Warnings and Notes .................................................................. 2-13

Flex Sequence Option ......................................................................... 2-13

Burner Management System (Flame Safeguard) Installation ..................... 2-14

Combustion Control Installation ................................................................... 2-18

Variable Speed Drive Installation .................................................................2-20

Servo Installation .........................................................................................2-21

Servo Description and Operation ........................................................2-21

Servo Control Board ...................................................................2-22

Travel Limit Switches ..................................................................2-23

Servo Mechanical Installation .............................................................2-24

Servo Wiring ........................................................................................2-24

QD1 Quick Disconnect Cables ...........................................................2-26

Flame Scanner/Relay ...................................................................................2-27

Flame Status .......................................................................................2-27

Flame Relay ........................................................................................2-28

Self-Checking ......................................................................................2-28

Flame Scanner Specications ............................................................2-28

Flame Scanner Installation ..................................................................2-28

Flame Scanner Wiring .........................................................................2-29

ZP Oxygen Sensor System Overview .........................................................2-30

Detector ...............................................................................................2-30

Measuring Principle .............................................................................2-30

Probe ...................................................................................................2-32

ZP Oxygen Sensor Installation ...........................................................2-32

Oxygen Probe Mounting Location ..............................................2-33

Mounting Oxygen Probe Nipple and Flange ..............................2-33

Check Oxygen Detector Flange Temperature ............................2-33

Rotating the Probe to Lower Detector Flange Temperature ......2-34

Oxygen Calibration Gas Tubing .................................................2-34

Oxygen Sensor Wiring ........................................................................2-35

Operation .............................................................................................2-36

Boiler Startup and Shutdown: .....................................................2-36

Insertion into a Hot Stack or Duct: .............................................2-36

Powering Down and Removing a ZP Oxygen Sensor: ..............2-36

Maintenance ........................................................................................2-36

Cleaning the Detector and Probe ...............................................2-36

ZP Oxygen Sensor Calibration ............................................................2-37

Section 3 – Operation &

Commissioning 3-39

Initial Steps .................................................................................................. 3-40

Operating the FlexFit ................................................................................... 3-40

Button Functions ................................................................................ 3-40

LCD Screen Indicators ........................................................................3-41

Alarm and Event Log ...........................................................................3-41

Menu Tree ................................................................................................... 3-42

Main Menu Functions .................................................................................. 3-45

Entering and Navigating the Main Menu ............................................ 3-45

Lockout Data ...................................................................................... 3-45

Passwords .......................................................................................... 3-45

Password Levels ........................................................................ 3-46

Obtaining a Temporary Password ............................................. 3-46

Utilities ................................................................................................ 3-46

Date/Time and S/N .................................................................... 3-46

I/O Data Display ......................................................................... 3-46

Cycle Statistics .......................................................................... 3-46

Oxygen Cell Status .................................................................... 3-46

Oxygen Calibration .................................................................... 3-46

Software Versions ..................................................................... 3-46

Conguring Parameters ...............................................................................3-47

FlexFit Edit ...........................................................................................3-47

Servo Setup .................................................................................................3-47

Servo Setup Step 1 – Congure the Servos' Travel Limit Switches .. 3-48

Servo Setup Step 2 – Congure the Servos' Addresses ................... 3-48

Servo Setup Step 3 – Congure the Servos' Functions and Feedback

Data ................................................................................... 3-48

Servo Setup Step 4 – Congure the Servos' Zero and Direction of Travel

........................................................................................... 3-49

iv Specications

FlexFit – Linkageless Control – Revision 1.0 PREFERRED

UTILITIES MFG CORPORATION

Servo Setup Step 5 – Congure the Servos' Span by Seeking Limits

........................................................................................... 3-49

Servo Setup Troubleshooting ............................................................. 3-49

Commission Mode ...................................................................................... 3-50

Curve Points ................................................................................................ 3-50

Starting the Burner ...................................................................................... 3-50

Verifying Positions and Curve Points .......................................................... 3-50

Flame Scanner Tests ...................................................................................3-51

Pilot Test Hold .....................................................................................3-51

Pilot Flame Test (Non-DSI Burners) ....................................................3-51

Main Flame Test ................................................................................. 3-52

Pilot Turndown Test (Non-DSI Burners) ............................................. 3-52

Tuning the Burner ........................................................................................ 3-52

Fuel/Air Ratio Curves ......................................................................... 3-52

Entering Additional Curve Points ....................................................... 3-53

Low Fire, High Fire, Avoid Setpoint .................................................... 3-53

Verifying Curves .......................................................................................... 3-54

Tuning .......................................................................................................... 3-55

The Proportional Function .................................................................. 3-55

The Integral Function ......................................................................... 3-55

The Derivative Function ..................................................................... 3-55

Recommended Procedure for Tuning a PID Loop ............................. 3-55

General Steps for Tuning the FlexFit PID Loop ......................... 3-55

Documentation ............................................................................................ 3-56

Section 4 – Parameters 4-57

Introduction ................................................................................................. 4-60

Flame Safety ............................................................................................... 4-60

Flame Safety > Basic ......................................................................... 4-60

Flame Safety > Advanced ...................................................................4-61

Flame Safety > Flex Sequences ........................................................ 4-62

Gas Valve Leak Test Option ............................................................... 4-64

Timing Calculations ................................................................... 4-64

Fuel-Air ........................................................................................................ 4-66

Fuel-Air > FD VSD .............................................................................. 4-66

Fuel-Air > Aux 2 .................................................................................. 4-66

Fuel-Air > O2 Analyzer ....................................................................... 4-67

Fuel-Air > O2 Trim .............................................................................. 4-68

Fuel-Air > FGR ................................................................................... 4-69

Firing Rate ....................................................................................................4-70

Firing Rate > Basic ..............................................................................4-70

Firing Rate > Tuning ............................................................................4-71

Firing Rate > 24 Hour Recycle ............................................................4-72

Firing Rate > Local/Remote Mode ......................................................4-72

Call for Heat (Option) ..................................................................4-72

Firing Rate > LFH-DHW-Warm Standby .............................................4-75

Firing Rate > Cold Start Warmup ........................................................4-75

Firing Rate > Advanced .......................................................................4-76

Draft Control .................................................................................................4-77

Draft Control > Basic ...........................................................................4-78

Draft Control > Tuning .........................................................................4-79

Draft Control > Options .......................................................................4-81

Button Sets ...................................................................................................4-81

Modbus ........................................................................................................ 4-82

Serial Number ............................................................................................. 4-82

Section 5 – Troubleshooting 5-83

General Troubleshooting Tips ..................................................................... 5-84

Lockout Data ............................................................................................... 5-86

I/O Data Display .......................................................................................... 5-86

Electrical Noise ........................................................................................... 5-86

"... Not at Position" Lockouts ....................................................................... 5-87

"... Not at Position" Lockout Exceptions ............................................. 5-87

Possible Reasons for a "... Not at Position" Lockout .......................... 5-87

ZP Oxygen Analyzer Troubleshooting ........................................................ 5-88

ZP Wet Measurement Vs. Dry Measurement .................................... 5-88

Normal Operating Values ................................................................... 5-88

Slow Response Time ......................................................................... 5-89

Reading is Lower than Expected ....................................................... 5-89

Reading is Higher than Expected ...................................................... 5-89

Cell Can't Reach Operating Temperature .......................................... 5-89

Low Calibration Gas Flow Rate .......................................................... 5-90

Detector Leak Test ............................................................................. 5-90

LCD Messages .............................................................................................5-91

Normal Operating Messages ..............................................................5-91

Curve Commissioning Error Messages ............................................. 5-93

Oxygen Cell Status and Messages .................................................... 5-94

Trip Messages .................................................................................... 5-96

General Alarm, Error & Warning Messages .....................................5-102

Common Problems & Solutions .................................................................5-104

Section A – Appendix A-105

Abbreviations Used in This Manual .......................................................... A-106

Terms and Denitions ................................................................................A-107

Parts List ................................................................................................... A-109

Parameter Documentation Sheet

Boiler Operating Data Sheet

Specications v

FlexFit – Linkageless Control – Revision 1.0 PREFERRED

UTILITIES MFG CORPORATION

Figure 1 – 1 FlexFit 110 Safety Relay ......................................................1-2

Figure 1 – 2 FlexFit BMS States ..............................................................1-5

Figure 1 – 3 FlexFit 110 Timing Diagram .................................................1-6

Figure 1 – 4 FlexFit 110 Flex Sequence Timing Diagram ........................1-7

Figure 1 – 5 FlexFit Parallel Positioning Example ................................. 1-10

Figure 2 – 1 FF-110 BMS Internal Block Diagram ................................. 2-15

Figure 2 – 2 FF-110 BMS Standard Wiring Diagram (Typical) (Default) 2-16

Figure 2 – 3 FF-110 BMS Flex Sequence Wiring Diagram (Typical) (Field

Selectable) ......................................................................... 2-17

Figure 2 – 4 LCD Cutout Dimensions .................................................... 2-18

Figure 2 – 5 FlexFit-CC Rear View ........................................................ 2-18

Figure 2 – 6 FF-CC Wiring Diagram (Typical) ....................................... 2-19

Figure 2 – 7 FF-110 VSD Wiring (Typical) ..............................................2-20

Figure 2 – 8 FF-110 VSD with Bypass Wiring (Typical) .........................2-21

Figure 2 – 9 Servo Control Board ..........................................................2-22

Figure 2 – 10 Servo Travel Limit Switches ...............................................2-23

Figure 2 – 11 Servo Forbidden Zone .......................................................2-24

Figure 2 – 12 QD1 to FlexFit Wiring .........................................................2-26

Figure 2 – 13 QD1 Junction Box Connections (Example) .......................2-26

Figure 2 – 14 QD1 Daisy-chain Connections (Example) .........................2-27

Figure 2 – 15 QD1 Mixed Junction Box & Daisy-chain Connections

(Example) ...........................................................................2-27

Figure 2 – 16 FlexFit Flame Scanner (Model BMU-UVSC) .....................2-27

Figure 2 – 17 Typical Scanner Mounting .................................................2-29

Figure 2 – 18 Typical Flame Scanner Wiring ...........................................2-29

Figure 2 – 19 ZP Oxygen Sensor with FlexFit CC ...................................2-30

Figure 2 – 20 ZP Detector ........................................................................2-30

Figure 2 – 21 Detector Measuring Principle ............................................2-31

Figure 2 – 22 Nernst Equation .................................................................2-31

Figure 2 – 23 Oxygen Sensor Gas Flow ..................................................2-32

Figure 2 – 24 ZP Oxygen Probe Mounting Location ...............................2-33

Figure 2 – 25 Temperature Sensitive Labels ...........................................2-33

Figure 2 – 26 Rotating the Oxygen Probe ...............................................2-34

Figure 2 – 27 Calibration Gas Tubing ......................................................2-34

Figure 2 – 28 Wiring the ZP Oxygen Sensor to the FlexFit CC ...............2-35

Figure 3 – 1 Menu Tree ......................................................................... 3-42

Figure 3 – 2 Menu Tree 2 ...................................................................... 3-43

Figure 3 – 3 Menu Tree 3 ...................................................................... 3-44

Figure 3 – 4 Menu Tree 4 ...................................................................... 3-45

Figure 3 – 5 Avoid Gap Setpoint ........................................................... 3-54

Figure 4 – 1 Typical Gas Train with No Vent Valve ............................... 4-64

Figure 4 – 2 Valve Train Volume Calculation ........................................ 4-65

Figure 4 – 3 Test Time Calculation ....................................................... 4-65

Figure 4 – 4 Gas Leak Test Timing Calculation Example ..................... 4-65

Figure 4 – 5 Call for Heat Logic .............................................................4-73

Figure 4 – 6 Floating Draft Control ........................................................4-77

Figure 4 – 7 Draft Feed Forward Curves .............................................. 4-80

Figure 5 – 1 Calibration Port Check Valve ............................................ 5-90

Figure 5 – 2 Detector Leak Test .............................................................5-91

Table A FlexFit 110 Flame Safeguard Terminal Ratings .....................vii

Table B Combinations for Fuel & Ignition Terminals ...........................vii

Table C Explanation of Each Combination .........................................vii

Table 2 – 1 ZP Sensor Maintenance Periodicity ..................................2-36

Table 4 – 1 Total Pipe Area ................................................................. 4-64

Table 4 – 2 Gas Leak Test Timing Calculation Example Data ............ 4-65

Table 5 – 1 Lockout Messages ............................................................ 5-86

Table 5 – 2 Approximate Wet Vs. Dry Correction Factors .................. 5-88

Table 5 – 3 Cell mV Vs. % Oxygen ...................................................... 5-89

Table 5 – 4 Troubleshooting Chart .....................................................5-104

Table A – 1 Abbreviations ...................................................................A-107

Table A – 2 Denitions ....................................................................... A-108

Table A – 3 Parts List ..........................................................................A-110

vi Specications – FlexFit Specications

FlexFit – Linkageless Control – Revision 1.0 PREFERRED

UTILITIES MFG CORPORATION

Mechanical Specifications

Flame Safeguard Size...............................................................................................7.2" Length; 5.7" Width"; 3.995" Height

Combustion Control Size ..........................................................................................9.880" Height; 5.054 Width; 1.6" Deep

Panel Cutout..............................................................................................................9.375" Height; 4.5" Width; See "Figure 2 – 4

LCD Cutout Dimensions" on page 2-18.

Enclosure Type..........................................................................................................Flush Panel Mounted

Electrical

Flame Safeguard Terminals ......................................................................................See Table A

Input Power ...............................................................................................................120 VAC (+10%/-15%) 60 Hz

Power Dissipation......................................................................................................12 W

Maximum Connected Load .......................................................................................2000 VA

Fusing........................................................................................................................15A Max, Fast Blo

Environmental

Operating Temperature .............................................................................................0 to 140 °F (-18 to 60 °C)

Storage Temperature ................................................................................................-20 to 150 °F (-28 to 65 °C)

Humidity Limits..........................................................................................................15 to 95% (non-condensing)

Front Panel ................................................................................................................NEMA 13, IP65

Certification

Testing Authority........................................................................................................UL 60730-1, UL 60730-2-5, CSA E60730-1,

CSA C22.2 No. 60730-2-5: UL le MH45788

Electrical Ratings

• Maximum connected load must not exceed 2000 VA

• Volt-Amp (VA) ratings apply to transformers and similar devices whose inrush current is approximately the same as their

running current.

• VA Pilot Duty ratings apply to relays, solenoid valves, lamps, etc. whose inrush current does not exceed 10 times the

operating current.

• Full Load Amps (FLA) and Locked Rotor Amps (LRA), aka inrush, ratings are intended for motors. VA and VA Pilot Duty

loads may be added provided the total load does not exceed the FLA rating.

Terminal # Description Rating

GGround

L2 Line Voltage Common

ALockout Alarm 120 VAC, 125 VA

L1 Line Voltage Supply 120 VAC, 60 Hz

M Burner Motor (Fan) 120 VAC, 9.8 FLA, 59 LRA (inrush)

13 Burner Controller & Limits Input 120 VAC, 5 mA

PLockout/Running Interlock Input 120 VAC, 5 mA

5Pilot Valve/Ignition 120 VAC, See Table

7 Main Fuel Valve 120 VAC, See Table

WIgnition 120 VAC, See Table

X Firing Rate High Fire 120 VAC, 125 VA Pilot Duty

10 Firing Rate Common 120 VAC, 125 VA Pilot Duty

12 Firing Rate Low Fire 120 VAC, 125 VA Pilot Duty

11 Firing Rate Modulate 120 VAC, 125 VA Pilot Duty

16 Valve Proving Pressure Switch Input 120 VAC, 5 mA

17 Call For Heat Input 120 VAC, 5 mA

D Low Fire Switch Input 120 VAC, 5 mA

8 High Fire Switch Input 120 VAC, 5 mA

3Preignition Interlock Input 120 VAC, 5 mA

6 Pilot Valve/Downstream Fuel Valve 120 VAC, See Table

S1 Unused

XAAF Burner

Management System

LISTED

Specications – Safety Cautions and Warnings vii

FlexFit – Linkageless Control – Revision 1.0 PREFERRED

UTILITIES MFG CORPORATION

Terminal # Description Rating

S2 Unused

24 Fuel 1 Select Input 120 VAC, 5 mA

25 Fuel 2 Select Input 120 VAC, 5 mA

26 FD Fan Mode Input (0V = VSD; 120V = Fixed Speed) 120 VAC, 5 mA

27 LFH or DHW CFH Input 120 VAC, 5 mA

28 Remote Reset Input 120 VAC, 5 mA

Fl+ Flame Intensity Input +4-20 mA

Fl- -

FR Flame Signal Input 120 VAC, 5 mA

Table A FlexFit 110 Flame Safeguard Terminal Ratings

Table B

Combination # Ignition (TW)

Pilot Valve/Igni-

tion (T5)

Pilot/Downstream

Fuel Valve (T6)

Main Fuel Valve

(T7)

1No Load CNo Load E

2No Load BNo Load E

3No Load No Load B E

4 A E No Load E

5 A No Load E E

6 A D No Load E

7 A No Load D E

8 A D No Load D

9 A No Load D D

10 ANo Load No Load E

11 A D E E

Combinations for Fuel & Ignition Terminals

Table C

A B C D E

4.5A Ignition @ 120

VAC

50 VA Pilot Duty plus

4.5A Ignition @ 120

VAC

180 VA Ignition plus

motor valves with 660

VA inrush, 360 VA

open, 250 VA hold

2A Pilot Duty @ 120

VAC

65 VA Pilot Duty plus

motor valves with 3850

VA inrush, 700 VA

open, 250 VA hold

Explanation of Each Combination

Safety Cautions and Warnings

Throughout this manual, numerous cautions are warnings are called out with a symbol. These warning could be either in

the main text or in a side note. Before attempting to install, commission, or operate this equipment, the technician or user is obligated

to read all sections of this manual and to adhere to the precautions and warnings herein to ensure the safety of all personnel and to

maintain the integrity of the operating equipment and systems to which this equipment is applied. If the reader has any doubt about

any of the requirements, it is his/her obligation to consult the supplier.

The manufacturer of this equipment accepts no liability for any consequences resulting from the inappropriate, negligent, or

incorrect installation, commissioning, or adjustment of operating parameters of this equipment.

WARNING

The equipment covered in this manual can cause extreme property damage, severe injury, or death. It is the

responsibility of the owner or user to ensure that the equipment described herein is installed and commis-

sioned in compliance with the requirements of all national and local legislation, whichever may prevail.

WARNING

The installation and

commissioning of this

product must be carried

out by suitably trained

personnel who are expe-

rienced with the intended

functions of this product

and the operation of the

equipment and systems

to which it is applied.

Description 1-1

FlexFit – Linkageless Control – Revision 1.0 PREFERRED

UTILITIES MFG CORPORATION

DD

EE

SS

CC

RR

II

PP

TT

II

OO

NN

Section 1 – Description

Overview ........................................................................................................1-2

Features .........................................................................................................1-2

Safety Relay ..........................................................................................1-2

Field Selectable Flex Sequence Option ................................................1-3

Servo Checks ........................................................................................1-3

Automatic Fuel SSOV Leak Test ...........................................................1-3

Lockout and Alarm History ....................................................................1-3

MAF and PAF Safe Start Checks ..........................................................1-3

High Flue Gas Temperature Shutdown .................................................1-3

Fuel Selection and Flexibility .................................................................1-3

FD VSD to VSD Bypass Changeover ...................................................1-3

Pilot Test Hold .......................................................................................1-3

Flame Scanner/Relay ............................................................................1-3

Fuel/Air Position "Pacing Logic" ............................................................1-3

Tandem Oil/Gas Valve Servo ................................................................1-4

Oxygen Trim ..........................................................................................1-4

Firing Rate Setpoint and Control ...........................................................1-4

Call for Heat ...........................................................................................1-4

Domestic Hot Water Override ...............................................................1-4

Warm Standby Option ...........................................................................1-4

Cold Start WarmUp Cycle Option .........................................................1-4

Integrated Draft Control .........................................................................1-5

RS485 Modulating Lead/Lag Interface .................................................1-5

Burner Management System .........................................................................1-5

Description of BMS Sates .....................................................................1-8

Boot ...............................................................................................1-8

Standby .........................................................................................1-8

Safe Start Checks .........................................................................1-8

Prestart .........................................................................................1-8

Purge ............................................................................................1-8

Pilot Trial for Ignition (PTFI) ..........................................................1-8

Main Trial for Ignition (MTFI) ........................................................1-8

Release to Modulate .....................................................................1-8

Assured Low Fire Cutout (ALFCO) Option ...................................1-8

Post Purge ....................................................................................1-8

Gas Valve Leak Test Option (Flex Sequence Option Only) .........1-9

Lockout .........................................................................................1-9

Interlock Groups ....................................................................................1-9

Call for Heat ..................................................................................1-9

Recycling Limits ............................................................................1-9

Fuel Select ....................................................................................1-9

Non-Recycling Limits ....................................................................1-9

Purging .........................................................................................1-9

Ignition ..........................................................................................1-9

False Flame ..................................................................................1-9

Flame Failure ................................................................................1-9

Fuel Valve Proof of Closure Switches (POCS) .............................1-9

Fan Speed ....................................................................................1-9

Combustion Control System ..........................................................................1-9

Parallel Positioning ..................................................................... 1-10

1-2 Description – Overview

FlexFit – Linkageless Control – Revision 1.0 PREFERRED

UTILITIES MFG CORPORATION

DD

EE

SS

CC

RR

II

PP

TT

II

OO

NN

Overview

Preferred Instruments' FlexFit 110 is a ame safeguard and linkageless, parallel positioning combustion control system. It is the

next innovative leap to offer the benets of parallel positioning without the high cost or effort of previous parallel positioning upgrades.

Draft control and Oxygen trim options are provided for additional combustion efciency and consistent fuel/air ratios.

The FlexFit replaces existing ame safeguard systems, or it can be used in a new installation. It is designed for any single burner,

one or two fuels, retube or watertube, steam or hot water boiler. It is offered with a complete package of eld devices, or it can be

used with compatible existing equipment. Commissioning is done using the FlexFit's LCD display.

The FlexFit 110 is UL/CSA 60730-1, 2-5 recognized, having both fuel/air ratio control and ame safeguard capabilities. Along with

all other requirements, NFPA 85 compliance is met by having total separation of the fuel/air ratio control and ame safeguard hardware.

The Burner Management System (BMS) (FlexFit-BMS) governs the step-by-step starting sequence for the red equipment.

At the release to modulate state, control is turned over to the combustion control system until the operator elects to shut down the

system, there is no longer a call for heat, or an abnormality results in a BMS-directed shutdown of the equipment. The BMS also

provides ame supervision, system status indication, system and self-diagnostics, and troubleshooting features.

The Combustion Control System (CCS) (FlexFit-CC) is responsible for burner fuel/air ratio control. During the startup and

shutdown sequences, fuel, air, FGR, draft, O2 trim, or other auxiliary control elements are directed to specic positions by the BMS.

In the modulate state, their positions are governed by the CCS. The FlexFit uses a parallel positioning control system.

The FlexFit-CC provides three analog inputs for various uses (boiler outlet, draft, remote setpoint, 135-ohm ring rate), oxygen

sensor inputs with optional stack temperature, and two analog outputs with paired feedback analog inputs, typically used for VSD

control. Modbus RS485 communication is provided for SCADA, building automation, etc. Additionally, the FlexFit can accommodate

up to seven control servos depending on application requirements. Examples of typical servo applications include the following:

• Fuel 1 servo

• Fuel 2 servo

• Tandem fuel valves (single servo for linked fuel valves)

• Combustion air FD damper servo

• FGR damper servo

• Atomizing steam control servo

• Outlet damper servo for draft control

Typical 4-20 outputs and inputs include the following:

• FD VSD

• FGR VSD

Features

Safety Relay

The safety relay (K1) provides 120 VAC to all ignition source and fuel valve relays. When the safety relay is deenergized, the

120 VAC is removed from the safety power bus. Each safety bus relay output contact is individually monitored, and the safety relay

coil deenergizes if any safety bus relay malfunctions.

Figure 1 – 1 FlexFit 11

3 P

Running/Lockout

Interlocks

Safety Relay

K1

W 765

Ignition and Fuel Valve

Control Circuit

Ignition Xfmr

Pilot (10 sec TFI)

Pilot (15 sec TFI) (or V2)

Main Fuel Valves (or V1)

0Safety Relay

XAAF Burner

Management System

LISTED

NFPA

R

Description – Features 1-3

FlexFit – Linkageless Control – Revision 1.0 PREFERRED

UTILITIES MFG CORPORATION

DD

EE

SS

CC

RR

II

PP

TT

II

OO

NN

Field Selectable Flex Sequence Option

The ex sequence is an optional set of parameters that gives the commissioning engineer more exibility and options related

to burner ignition and gas valve leak testing. When the "Flex Sequence Option" is enabled, the various pilot ame and main ame

timings and whether direct spark ignition is used are set by the subsequent parameters. If the "Flex Sequence Option" is disabled,

the default timing sequence will be used. For more information, see "Flame Safety > Flex Sequences" on page 4-62. The "Flex

Sequence Option" must also be enabled if gas valve leak testing is to be used.

Servo Checks

Servos are stroke tested from minimum to maximum position during every burner startup. A detailed message will be displayed

to facilitate servo troubleshooting. Parameter "P2.5.6 FGR Servo Check Mode" on page 4-70 allows the setup engineer to choose

the desired action of the FGR damper servo during the servo test – "Closed Then Open" or "Open Then Closed".

Automatic Fuel SSOV Leak Test

Safety shutoff valve leak testing can be performed automatically. See "Gas Valve Leak Test Option" on page 4-64 for more

information.

Lockout and Alarm History

The LCD display has a large historical memory that stores the most recent 10 lockouts with a snapshot of boiler/burner variables

at the time of each lockout.

MAF and PAF Safe Start Checks

Unless the FD Fan is in running manually (in hand), the non-recycling and purge interlock inputs must be deenergized at the start

of a cycle, indicating that these switches are operable and not bypassed. There is a nuisance delay timer of 60 seconds before a lockout.

High Flue Gas Temperature Shutdown

The FlexFit can monitor ue gas temperature, and if it exceeds a user-dened setpoint (see parameter "P1.2.5 Lockout SP, Flue

Temp" on page 4-62), the FlexFit initiates a trip. This serves as additional protection against ring a "dry" boiler.

Fuel Selection and Flexibility

The desired fuel is selectable via eld contact inputs. The burner will light-off only if a single fuel is requested. If the requested

fuel is changed when not in standby or lockout, the burner will lockout.

Any two of light oil, heavy oil, natural gas, waste gas, propane, and/or renewable fuel ring are supported by the FlexFit. Fuel

ring exibility offers the opportunity to save fuel cost by ring the fuel that is most economical. The FlexFit will use the appropriate

combustion curve for the selected fuel.

FD VSD to VSD Bypass Changeover

There are two separate combustion curves for forced draft fan operation – Variable Speed Drive (FD VSD) and xed speed

(VSD bypass or xed-speed fan). The operator shuts down the burner, selects FD VSD or VSD bypass via the VSD controller, and

restarts the burner. The FlexFit will use the appropriate combustion curve for the selected mode of operation. Two sets of fuel/air

ratio curves can be stored for each fuel. If using only a xed-speed fan, then only one set of curves is necessary.

Pilot Test Hold

Pilot test hold can be turned on before the pilot ame has been proven so a pilot turndown test can be performed. See section

"Pilot Test Hold" on page 3-51 for more information.

Flame Scanner/Relay

The FlexFit can be congured for multiple styles of scanner/relays, including UV, UV self-checking, and IR. The scanner/relay

must be a listed device and have a dry contact 120 VAC ame-on/ame-off output. The FlexFit provides a power supply and the

analog inputs for the ame intensity relay display. Preferred Instruments ame scanners are intended for monitoring all gas, oil, and

waste gas red burners. All essential circuits are supervised. Two LEDs indicate scanner status.

Fuel/Air Position "Pacing Logic"

The key to efcient boiler operation is accurate, repeatable positioning of the fuel and air servos and VSDs. When the ring

rate is changing, the FlexFit moves all servos and VSDs simultaneously. However, because different servos can move at different

rates, the FlexFit ensures all servos and VSDs move at the same rate. Twice per second, the FlexFit measures the current position

of each servo and VSD, calculates a new target position/speed for each servo and VSD, based on the curves, and moves all outputs

simultaneously. This feedback measurement compensates for output position or speed deviations. When the fuel valve is not changing,

all outputs (servos and VSDs) will settle at each output's curve value.

1-4 Description – Features

FlexFit – Linkageless Control – Revision 1.0 PREFERRED

UTILITIES MFG CORPORATION

DD

EE

SS

CC

RR

II

PP

TT

II

OO

NN

E.g. due to fuel valve and air damper non-linearity, a 10-degree air damper change might correlate to a 5-degree fuel valve

change. In this example, the fuel servo must run at one-half the speed of the air servo to remain "on the curve" during a load change.

Additional information on the pacing logic is provided in section "Servo Description and Operation" on page 2-21.

Tandem Oil/Gas Valve Servo

This option allows a single servo to drive both the oil (fuel 1) and gas (fuel 2) control valves. The FlexFit maintains separate

curves for Standby, Purge, and Ignition positions and separate fuel/air ratio curves for fuel 1 and fuel 2. This allows the user to leverage

existing linkage or direct mount to a dual gas/oil valve.

Oxygen Trim

Oxygen measurement is used to continuously adjust (trim) the fuel/air ratio. Oxygen trim saves fuel by ne-tuning the burner to

operate safely and reliably at reduced excess air levels throughout the burner ring range. It also allows the controller to compensate

for external environmental changes that affect burner operation (i.e. ambient temperature, fuel heating value, viscosity, etc.). Low ue

gas oxygen will cause an alarm and can be elected to shut down the burner after an adjustable time delay.

Firing Rate Setpoint and Control

The FlexFit can operate in automatic mode where the ring rate is determined by an operator-selected setpoint; the FlexFit

will automatically use PID control to maintain that setpoint. The ring rate PID compares the pressure or temperature setpoint to the

measured pressure or temperature and adjusts the ring rate demand accordingly. The ring rate PID is active if the ring rate mode

is in local/automatic, remote 4-20mA SP, or remote Modbus SP.

The FlexFit can also operate in the manual mode where ring rate is determined by an operator-selected value, a local 135-ohm or

P7810 demand, a remote 4-20mA FR, or a remote Modbus FR. The remote ring rate modulation method is determined by parameter

"P3.4.6 Remote Modulation" on page 4-74.

Call for Heat

The Call For Heat (CFH) start and stop command is determined either by local setpoint deviation or a remote input (e.g. a lead-lag

controller). When setpoint deviation is selected, the FlexFit will generate a CFH when the boiler outlet is a user-dened temperature

(or pressure) below the setpoint. Alternatively, the CFH is removed when the boiler outlet is a user-dened value above the setpoint.

For more information on CFH, see section "Call for Heat (Option)" on page 4-72.

Domestic Hot Water Override

The Domestic Hot Water (DHW) override feature forces the exit water temperature setpoint to be greater than or equal to the

DHW setpoint. Some boilers are used primarily for building space heating, but they also provide heat for DHW tanks. When outdoor

weather is warm, there may be no space heating load and the boilers will shutdown. DHW override ensures hot water will still be

available by providing a call for heat when the DHW setpoint is greater than the current ring rate setpoint.

Warm Standby Option

When this option is selected, the warm standby logic starts and stops the boilers using a boiler shell temperature (or pressure)

switch.

Some boiler installations, such as those for manufacturing plants, research facilities, or medical facilities cannot tolerate a

sustained low header pressure (or temperature). Larger boilers require a long, slow warm-up cycle. Therefore, some facilities require

that one or more boilers be kept on warm standby.

Warm standby boilers are periodically red at low re until their boiler outlet is almost as high as the operating pressure or

temperature; then the boilers are shut down. When the outlet drops to a lower threshold, the cycle repeats. If a boiler is kept warm,

it can rapidly be brought up to modulate as needed.

Cold Start WarmUp Cycle Option

Because of the stress created by thermal expansion, some boilers require a slow warmup if the boiler is cold. Parameter "P3.6.1

Cold Start Warmup Option" on page 4-76 steps the ring rate up in stages in response to the boiler outlet temperature (or pressure).

An override timer can cause the ring rate to increase to the next ring rate step, even if the boiler outlet has not yet reached the

step setpoint. Consult the boiler manufacturer for the proper ring rate and setpoint step sizes and the proper override time for your

specic boiler.

An in-progress warmup cycle can be canceled by placing the ring rate in manual. This cycle occurs only once per boiler start-up.

The cold start warmup cycle ends automatically and the PID logic begins modulating the burner if the boiler outlet condition

exceeds a eld selectable value or becomes equal to the ring rate setpoint.

A low re hold option is also available. To minimize thermal stresses, some boilers require that the burner hold at low re (0%)

after lighting off. The FlexFit will release the burner to modulate when the boiler shell temperature (or pressure) increases to setpoint

Description – Burner Management System 1-5

FlexFit – Linkageless Control – Revision 1.0 PREFERRED

UTILITIES MFG CORPORATION

DD

EE

SS

CC

RR

II

PP

TT

II

OO

NN

or parameter "P3.5.3 Low Fire Hold, Override Seconds" on page 4-75 times out. This cycle occurs only once per boiler start-up. The

cold start warm-up cycle option overrides the burner light-off low re hold.

Integrated Draft Control

The FlexFit can perform proportional oating draft control with a servo-actuated damper. By utilizing oating control, the FlexFit

will maintain draft at a setpoint as determined during boiler commissioning. If the draft error (measured draft minus setpoint) is inside

the deadband (see "P4.2.2 Deadband, Draft" on page 4-79), the draft damper output doesn't change. If the draft error is outside the

deadband, the draft damper position is adjusted proportionally to the draft error until draft has returned to within the deadband. For

more information, see section "Servo Setup" on page 3-47.

RS485 Modulating Lead/Lag Interface

This option allows communication via a Modbus network to an optional Chief Dispatcher modulating lead/lag controller or to a

building automation system, thereby eliminating the need for individual ring rate and CFH signal wiring.

Burner Management System

The Burner Management System (BMS) logic provides automatic burner sequencing, ame supervision, system status infor-

mation, system and self-diagnostics, and troubleshooting information.

Once power is applied, after booting, the BMS sequence is divided into 11 separate states. Two of these 11 states are optional

operations: Assured Low Fire Cutout (ALFCO) and Gas Valve Leak Test. The 11 states are shown in "Figure 1 – 2 FlexFit BMS States"

in standard sequential order. Typical timing diagrams follow.

Figure 1 – 2

Standby (or Off)

Safe Start Checks

Prestart

Pre-Purge Gas Leak

Test (Option)

Purge

PTFI (Pilot Trial

for Ignition)

MTFI (Main Trial

for Ignition)

Release to Modulate

(single fuel)

ALFCO (Assured Low

Fire Cutoff) (Option)

Post Purge

Post Purge Gas Leak

Test (Option)

(if limits made)

Lockout (with Post

Purge, if required)

L

o

c

k

o

u

t

C

F

H

o

r

R

e

c

y

c

l

i

n

g

L

i

m

i

t

s

O

p

e

n

R

e

c

y

c

l

i

n

g

L

i

m

i

t

s

R

e

c

y

c

l

i

n

g

L

i

m

i

t

s

O

p

e

n

C

F

H

o

r

R

e

c

y

c

l

i

n

g

L

i

m

i

t

s

O

p

e

n

O

p

e

n

L

o

c

k

o

u

t

R

E

S

E

T

L

o

c

k

o

u

t

C

F

H

o

r

R

e

c

y

c

l

i

n

g

L

i

m

i

t

s

O

p

e

n

C

F

H

o

r

R

e

c

y

c

l

i

n

g

L

i

m

i

t

s

O

p

e

n

C

F

H

o

r

R

e

c

y

c

l

i

n

g

L

i

m

i

t

s

O

p

e

n

C

F

H

o

r

R

e

c

y

c

l

i

n

g

L

i

m

i

t

s

O

p

e

n

L

o

c

k

o

u

t

Lockout

Boot

CFH Open or time

for 24 Hr Recycle

P

o

s

t

P

u

r

g

e

R

e

q

u

i

r

e

d

N

o

L

o

c

k

o

u

t

FlexFit BMS States

1-6 Description – Burner Management System

FlexFit – Linkageless Control – Revision 1.0 PREFERRED

UTILITIES MFG CORPORATION

DD

EE

SS

CC

RR

II

PP

TT

II

OO

NN

Figure 1 – 3

Call For Heat

Servo Check Purge Position

Min.

Max. High Fire

Low Fire

Purge Hz Ignition Hz Low Fire Hz

Ignition

10 Sec Pilot

Main Fuel Valve(s)

(SSOVs)

Running (Lockout)

Interlocks

15 Sec Pilot

FD Fan

Preignition Interlock

(Proof of Closure)

High Fire Switch

Low Fire Switch

Standby

Safe Start

Checks Prestart Purge

Pilot

Trial For

Ignition

Main

Trial For

Ignition Modulate Post Purge Standby

Flame Signal

Moving

to Purge

Moving to

Ignition

High Fire (Purge)

Low Fire (Ignition)

Modulate

Servos

Start Limits

ALFCO

(Option)

VSD

Note 1

Note 2

Note 4

M

W

5

7

6

P

3

8

D

FR

X

12

11

Out

(with FB)

13

Note 5

Note 3

Note 6

Note 6

Standby Position Ignition Position

Standby Position

Out

(with FB)

Note 7

Out

Out

Out

Out

Out

In

In

In

In

In

Out

Out

Out

In

FlexFit 110 Timing Diagram

TIMING DIAGRAM NOTES:

1. If using call for heat, safe start checks will begin once both the start limits (13) input and the call for heat are made.

If not using call for heat, safe start checks will begin once the start limits (13) input is made.

2. Must be low during safe start checks if parameter "P1.1.4 MAF/Run Interlocks Safe Start Test" on page 4-61 is enabled.

3. The FD fan will start after the time delay set by parameter "P1.2.3 FD Fan Start Delay" on page 4-61.

4. Must be low during safe start checks if parameter "P1.1.5 PAF Switch Installed" on page 4-61 is set to Yes.

5. During the purge cycle, the high re switch (purge interlock) can be open for no more than 30 seconds (cumulative). The

purge timer does not run while open.

6. If direct spark ignition (DSI) is being used, the main fuel valves will open during PTFI and the MTFI state will be skipped.

7. If no main fuel valve(s) (SSOVs) have proof of closure, jumper 120 VAC to (7) and set parameters "P1.2.10 Fuel 1 Proof of

Closure Installed" and "P1.2.11 Fuel 2 Proof of Closure Installed" to No.

Description – Burner Management System 1-7

FlexFit – Linkageless Control – Revision 1.0 PREFERRED

UTILITIES MFG CORPORATION

DD

EE

SS

CC

RR

II

PP

TT

II

OO

NN

Figure 1 – 4

Call For Heat

Servo Check Purge Position

Min.

Max. High Fire

Low Fire

Purge Hz Ignition Hz Low Fire Hz

Ignition

10 Sec Pilot

V1 Fuel Valve

(Upstream SSOV)

Running (Lockout)

Interlocks

V2 Fuel Valve

(Downstream SSOV)

FD Fan

Preignition Interlock

(Proof of Closure)

High Fire Switch

Low Fire Switch

Standby

Safe Start

Checks Prestart Purge PTFI MTFI Modulate Post Purge Standby

Flame Signal

Moving

to Purge

Moving to

Ignition

High Fire (Purge)

Low Fire (Ignition)

Modulate

Servos

Start Limits

ALFCO

(Option)

VSD

Note 1

Note 2

Note 4

M

W

5

7

6

P

3

8

D

FR

X

12

11

Out

(with FB)

13

Note 5

Note 3

Note 7

Note 7

Standby Position Ignition Position

Out

(with FB)

Note 6

Note 8

Optional

Post Purge

Leak Test

(Note 9)

Optional

PrePurge

Leak Test

(Note 9)

Note 7

Note 10

Note 10

Out

Out

Out

Out

Out

In

In

In

In

In

Out

Out

Out

In

Valve Proving

Pressure Switch

16 In Note 11

Standby Position

FlexFit 110 Flex Sequence Timing Diagram

FLEX SEQUENCE TIMING DIAGRAM NOTES:

1. If using call for heat, safe start checks will begin once both the start limits (13) input and the call for heat are made.

If not using call for heat, safe start checks will begin once the start limits (13) input is made.

2. Must be low during safe start checks if parameter "P1.1.4 MAF/Run Interlocks Safe Start Test" on page 4-61 is enabled.

3. The FD fan will start after the time delay set by parameter "P1.2.3 FD Fan Start Delay" on page 4-61.

4. Must be low during safe start checks if parameter "P1.1.5 PAF Switch Installed" on page 4-61 is set to Yes.

5. During the purge cycle, the high re switch (purge interlock) can be open for no more than 30 seconds (cumulative). The

purge timer does not run while open.

6. Parameter "P1.3.2 PTFI Ign Xfmr Sec" on page 4-63 sets the PTFI seconds.

7. If direct spark ignition (DSI) is being used, the main fuel valves will open during PTFI and the MTFI state will be skipped.

8. If no main fuel valve(s) (SSOVs) have proof of closure, jumper 120 VAC to (7) and set parameters "P1.2.10 Fuel 1 Proof of

Closure Installed" and "P1.2.11 Fuel 2 Proof of Closure Installed" to No.

9. If leak testing is disabled or not required for the selected fuel, this state is skipped.

The optional gas leak test procedure requires both start and running interlocks to be made; therefore, the call for heat option

must be used to allow post purge leak testing to occur.

For more information on the optional gas leak test and for timing calculations, see section "Gas Valve Leak Test Option" on

page 4-64, and parameters "P1.3.9 Fuel1 Leak Test Option" and "P1.3.11 Fuel2 Leak Test Option".

10. If leak test is disabled, (7) energizes all main fuel SSOVs and (6) remains deenergized (is not used). See section "Burner

Management System (Flame Safeguard) Installation" on page 2-14, for typical wiring diagrams.

11. 120 V (made) = high pressure; 0 V (open) = low pressure.

1-8 Description – Burner Management System

FlexFit – Linkageless Control – Revision 1.0 PREFERRED

UTILITIES MFG CORPORATION

DD

EE

SS

CC

RR

II

PP

TT

II

OO

NN

Description of BMS Sates

Boot

When power is initially applied to the FlexFit, it will perform initial self-checks on itself and boot into either the standby state or

the lockout state, depending on its state prior to losing power.

Standby

During the standby state, the BMS will command all fuel/air devices to their standby positions and ensure fuel bus power and

safety relays are deenergized. During the standby state, a technician or engineer can change restricted and non-restricted parameters,

and the current fuel selection may be changed.

Standby is the state from which the BMS starts an operating sequence following a call for heat with the operating limits (L1-13)

input energized

Safe Start Checks

During safe start checks, the fuel/air ratio curve data are veried, parameter values are checked for conicts, and minimum/

maximum limits are checked. If all fans are off, the non-recycling limits (3-P) and high re switch (purge interlock) (L1-8) switches

are veried to be open.

The BMS initiates a lockout if the fuel valve Proof of Closure Switches (POCS) (if installed) are detected as open or if a false

ame is detected. If no lockout or other error has occurred, the start sequence is continued.

Prestart

During prestart, all combustion servo calibration data, parameters, and feedback potentiometer alignments are checked by

forcing the servos rst to their fully closed and then to their fully open positions. The servo for the unselected fuel is not checked.

When the above items have been proven, the combustion servos are sent to the purge position. The start sequence is now on

hold until non-recycling limits are made. Then, the BMS will test the safety relay by deenergizing the K1 coil and ensuring there is

no power detected on the safety bus.

Purge

Once the purge interlock is satised, the purge timer is started. During the purge cycle, the purge interlock can open intermittently

but for no more than 30 seconds (cumulative). The purge timer stops counting when a purge interlock is open. If the purge interlocks

are open for more than 30 seconds, the FlexFit will lockout. After the purge time is complete, the FlexFit will drive the servos to their

ignition positions.

Pilot Trial for Ignition (PTFI)

After the servos are proven in their ignition positions, the ignition transformer and pilot valve outputs are energized. A pilot ame

must be proven present before the PTFI times out (10 seconds), or a lockout will result (does not apply to direct spark ignition mode).

The pilot test hold function (see "Pilot Test Hold" on page 3-51) can be turned on before the ame has been proven so a pilot

turndown test can be performed, and the servos can be positioned to allow air or fuel adjustments for proper light-off.

Main Trial for Ignition (MTFI)

When the pilot ame is proven, the FlexFit energizes the main fuel valve. The pilot valve and ignition transformer deenergize

10 seconds after the main fuel valve is energized. From this point forward, the main ame must be proven continuously, or a lockout

will occur.

Release to Modulate

The FlexFit releases control of the combustion servos (fuel/air ratio control) to the FlexFit-CC. The fuel remains at the ignition

position while all other air and FGR devices must move to their corresponding curve positions within 20 seconds, or a lockout will

occur. Servo pacing is now enabled. Any servos that are not being used are commanded to the standby position. Based on the

process variable (steam PSI or water temperature) to setpoint comparison, a ring rate demand signal is generated that positions

the appropriate servos to their proper positions.

Assured Low Fire Cutout (ALFCO) Option

When the FlexFit detects that there is no longer a call for heat and parameter "P1.2.6 Assured Low Fire Cutoff" on page 4-62 is

enabled, all combustion servos are commanded to the low re position before the SSOVs are deenergized. If the ALFCO is disabled,

the SSOVs close immediately when there is no longer a call for heat.

Post Purge

After the fuel valves have deenergized, the fans continue to operate until the post purge time has elapsed. All combustion

devices remain in their last position. All fans and auxiliary outputs are deenergized.

Note

The descriptions of each

state to follow assumes

default parameter values

are set; the descrip-

tions can change

depending on how the

FlexFit is congured.

Note

From this point, restricted

parameters may not be

changed until the BMS has

returned to the standby

or lockout state. The

programming of non-re-

stricted parameters is

not allowed during safe

start check and prestart.

Note

In the commission mode,

the FlexFit holds at the

light-off position so the

technician can adjust

the fuel and air servos.

Note

A lockout closes

the SSOVs immedi-

ately, regardless of

ALFCO setting.

Description – Combustion Control System 1-9

FlexFit – Linkageless Control – Revision 1.0 PREFERRED

UTILITIES MFG CORPORATION

DD

EE

SS

CC

RR

II

PP

TT

II

OO

NN

Gas Valve Leak Test Option (Flex Sequence Option Only)

If enabled, when possible, the leak test is performed after the completion of post purge. If the recycling or non-recycling trips

open during the leak test, the leak test is postponed and done during the next start-up, after prestart and before purge. Optionally, the

leak test can be performed both after post purge and pre-purge. See "Gas Valve Leak Test Option" on page 4-64 for more information.

Lockout

The FlexFit reverts to the lockout state whenever an unsafe or undesirable condition has been detected. The operator must

reset the FlexFit before a burner restart can be attempted. Refer to the "Section 5 – Troubleshooting" for an overview of the lockout

messages and their meanings.

Interlock Groups

Call for Heat

Call for heat means a burner start request has been made by a local source, a remote source (T17 or Modbus), or a setpoint

deviation.

Recycling Limits

Should the recycle limit circuit open at any time during a normal sequence, the FlexFit will conduct a shutdown and revert to

the standby state. The burner will automatically restart when the recycle limit closes.

Fuel Select

Changing the fuel selection should only occur when the burner is in standby or lockout (recycle limits are not made). If there

is a problem with the selected fuel (selected fuel changes during operation, both fuels are selected, or neither fuel is selected), the

burner will lockout.

Non-Recycling Limits

Should the non-recycle limit circuit open from the end of prestart to the start of post purge, a lockout will result.

Purging

Purging indicates that the purge/high re limits are made. Should the purge limit circuit open for longer than 30 seconds (cumu-

lative) during purge, the FlexFit will lockout.

Ignition

Ignition indicates that the low re start interlock is made and, if necessary, the draft damper is open. The FlexFit will not attempt

to light a ame until the ignition interlock is made.

False Flame

If a ame is detected during the standby, safe start, prestart, or purge states a lockout will result. A false ame is ignored for

120 seconds after the fuel valves close and for the rst 30 seconds during prestart.

Flame Failure

A lockout occurs if no ame is detected during PTFI, MTFI, release to modulate, or ALFCO.

Fuel Valve Proof of Closure Switches (POCS)

The POCS indicate to the BMS that the fuel valves are closed. If they are shut during MTFI, release to modulate, or ALFCO or

open at other times, a lockout will occur. If allowed by code, POCS can be disabled for smaller burners.

Fan Speed

If the operator changes the xed fan speed versus variable fan speed input T26 in any of the FlexFit states (except standby or

lockout), the burner will lockout.

Combustion Control System

The primary objective of a combustion control system (CCS) is to ensure that the fuel/air ratio of the burner is maintained at

the commissioned levels. This is accomplished by maintaining all servos, VSDs, control valves, and air dampers at predetermined

positions based on curves set up during commissioning – a control type called parallel positioning.

The secondary objective of a CCS is to modulate the ring rate to provide a continuous supply of steam or hot water at the

desired pressure or temperature. Based on PID control action or a remote ring rate demand signal, the FlexFit-CC can modulate

the burner to maintain the process variable at a predetermined setpoint.

Other FlexFit options available, that can be used to enhance the performance of the CCS, are as follows:

1-10 Description – Combustion Control System

FlexFit – Linkageless Control – Revision 1.0 PREFERRED

UTILITIES MFG CORPORATION

DD

EE

SS

CC

RR

II

PP

TT

II

OO

NN

• Oxygen Trim – compares the oxygen levels in the ue gas to a value determined during commissioning and will implement

control actions to correct the error

• Draft Control – maintains a constant furnace or boiler outlet draft pressure (positive or negative) as the boiler ring rate

modulates from low to high re and as outdoor weather conditions change the draft effect

Parallel Positioning

In this system, both the fuel valve(s) and the air damper each have their own servo(s). Each servo is equipped with a position

feedback potentiometer. Unlike a jackshaft position system where every device is mechanically linked, the individual servos can be

electronically characterized for greater fuel/air ratio control accuracy.

The parallel positioning system is also safer as the FlexFit continually monitors the demand to the servo versus the feedback

potentiometer and will trip the burner should discrepancies be detected.

With a parallel positioning system, the adaptation of ue gas oxygen trim becomes an easier task. Instead of the added cost

of a link trim servo, the compensation for oxygen trim is performed by manipulation of the demand signal to the air damper servo.

Other advantages of parallel positioning over jackshaft positioning are that a Variable Speed Drive (VSD) can be used to save

energy and provide another means of oxygen trim.

Parallel positioning is especially suitable for larger boilers as all the control devices no longer must be in close proximity to a

common jackshaft. Fans, VSDs, and dampers can now be located distributed throughout the boiler room.

Figure 1 – 5

FlexFit Parallel Positioning (Hot Water Boiler)

Hot Water Boiler

S

S

S

Oil

Gas

VFD

S

PT

AE

TE

Servos

TE

4-20mA

Plant Master

Demand

Hot Water Supply

Hot Water Return

Water

Temp.

Flue

Temp.

Draft

Oxygen

FlexFit Parallel Positioning Example

Installation 2-11

FlexFit – Linkageless Control – Revision 1.0 PREFERRED

UTILITIES MFG CORPORATION

II

NN

SS

TT

AA

LL

LL

AA

TT

II

OO

NN

Section 2 – Installation

Electrical Noise Suppression ....................................................................... 2-12