Contents

Technical Information for the User ............................................................................................................... 2

1.0 General................................................................................................................................................... 3

2.0 Construction ........................................................................................................................................... 3

3.0 Functions................................................................................................................................................ 4

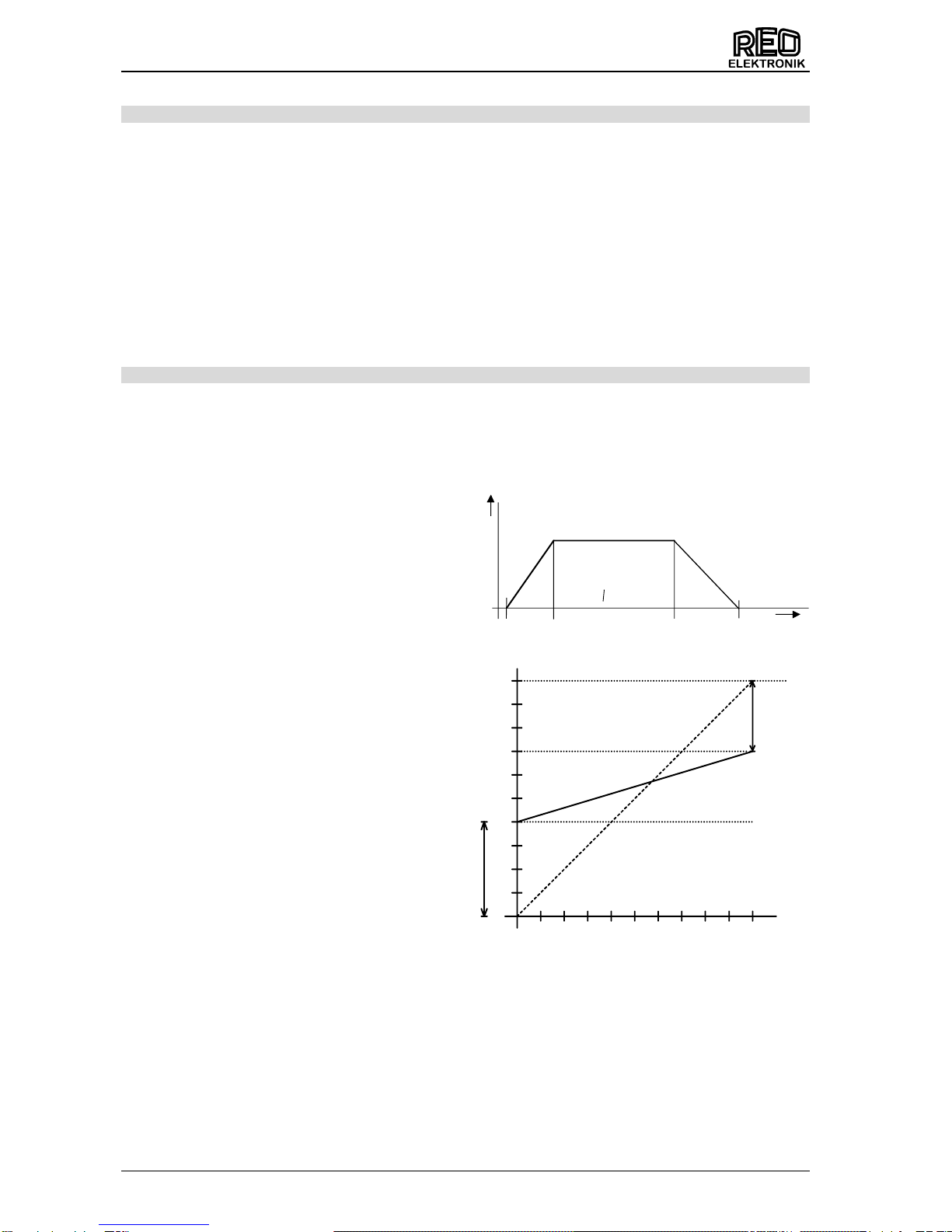

3.1 Modes ................................................................................................................................................. 4

3.2 Regulation mode................................................................................................................................. 5

3.3 Set point.............................................................................................................................................. 5

3.4 Feedback ............................................................................................................................................ 6

3.5 Control functions................................................................................................................................. 6

4.0 Technical Data........................................................................................................................................ 7

4.1 Limited the output voltage by using line input from 230V or 240V..................................................... 7

5.0 Declaration of Conformity....................................................................................................................... 7

6.0 Ordering codes....................................................................................................................................... 8

7.0 Operation................................................................................................................................................ 9

7.1 Adjustment.......................................................................................................................................... 9

7.2 Adjustment Procedure ........................................................................................................................ 9

7.3 Indications on display........................................................................................................................ 10

7.4 Error Messages................................................................................................................................. 10

8.0 Settings................................................................................................................................................. 11

9.0 Setting up instructions.......................................................................................................................... 12

9.1 Internal set point ............................................................................................................................... 12

9.2 Unit configuration.............................................................................................................................. 12

9.2.1 Service menu................................................................................................................................. 13

9.2.2 Display effective values measured inside unit............................................................................... 13

9.3 Setting Up Procedures...................................................................................................................... 14

9.4 Select Interface................................................................................................................................. 14

9.5 Save current settings........................................................................................................................ 15

9.6 Restore parameter settings .............................................................................................................. 15

9.7 Software version............................................................................................................................... 15

9.8 Hide parameter menus ..................................................................................................................... 15

10.0 Connection diagram ........................................................................................................................... 16

10.1 Connection details .......................................................................................................................... 17

11.0 Dimensions......................................................................................................................................... 18

12.0 Putting into service............................................................................................................................. 22

12.1 Preliminaries................................................................................................................................... 22

12.2 Measurements and Settings........................................................................................................... 22

12.3 Putting into service without a proper load....................................................................................... 22

13.0 Installation of Thyristor Control Units ................................................................................................. 23

13.1 Fuses .............................................................................................................................................. 23

13.2 Incoming breaker............................................................................................................................ 23

13.3 Output Breaker................................................................................................................................ 23

13.4 Installation and climatic Conditions................................................................................................. 23

13.5 Signal cables................................................................................................................................... 23

14.0 Interference prevention....................................................................................................................... 24

14.1 Earthing........................................................................................................................................... 24

14.2 Control cables................................................................................................................................. 24

14.3 Interference protection of other external components and equipment........................................... 24

15.0 Engineering notes............................................................................................................................... 25