Pressure Systems 9022 User manual

NetScanner™ System

Visit us on the web:

www.PressureSystems.com

Intelligent Pressure Scanner

User’s Manual

(Models 9016, 9021, 9022)

13th Edition

September 2007

Pressure Systems, Inc. NetScanner™ System (9016, 9021, & 9022) User’s Manual

www.PressureSystems.com

- i -

©This User’s Manual is a copyright product of Pressure Systems, Inc. , 2007.

Permission is hereby granted to make copies and distribute verbatim copies of this

manual, provided the copyright notice and this permission notice are preserved on all

copies.

Pressure Systems, Inc. NetScanner™ System (9016, 9021, & 9022) User’s Manual

www.PressureSystems.com

- ii -

REVISION REVISION HISTORY PRINT

DATE

1 Original - 2nd Edition 4/94

2 3rd Edition (add Model 902x and 9016) 11/97

3 4th Edition 3/98

4 5th Edition 9/99

5 6th Edition 03/00

6 7th Edition (delete Optomux references and add

multi-point calibration procedures) (add infor-

mation about the 9021R- ruggedized version)

02/01

7 8th Edition (officially change name from 9021R

to 9022, a new ruggedized version of the 9021) 03/02

8 9th Edition (added new commands and updates

to Chapter 3, Chapter 4, and Chapter 5 to ac-

commodate the 9022)

07/02

9 10th Edition (new Chapter 7 - deletes all refer-

ences to NETSTART as the startup software,

and replaces it with a brief description of NUSS 01/02

10 11th Edition adds information regarding using

the 9022 with third-party transducers that do not

have temperature compensation. Changes wir-

ing diagram.

06/03

11 12th Edition deletes references to the Repair

Department for RMAs. 04/04

12 Includes Application Note concerning mixing

transducers with and without temperature sensor

attached to Model 9022 and adds references for

high frequency in Model 9022.

01/05

13 Added new commands for Model 9022 & Model

9016 09/07

Pressure Systems, Inc. NetScanner™ System (9016, 9021, & 9022) User’s Manual

www.PressureSystems.com

- iii -

Preface

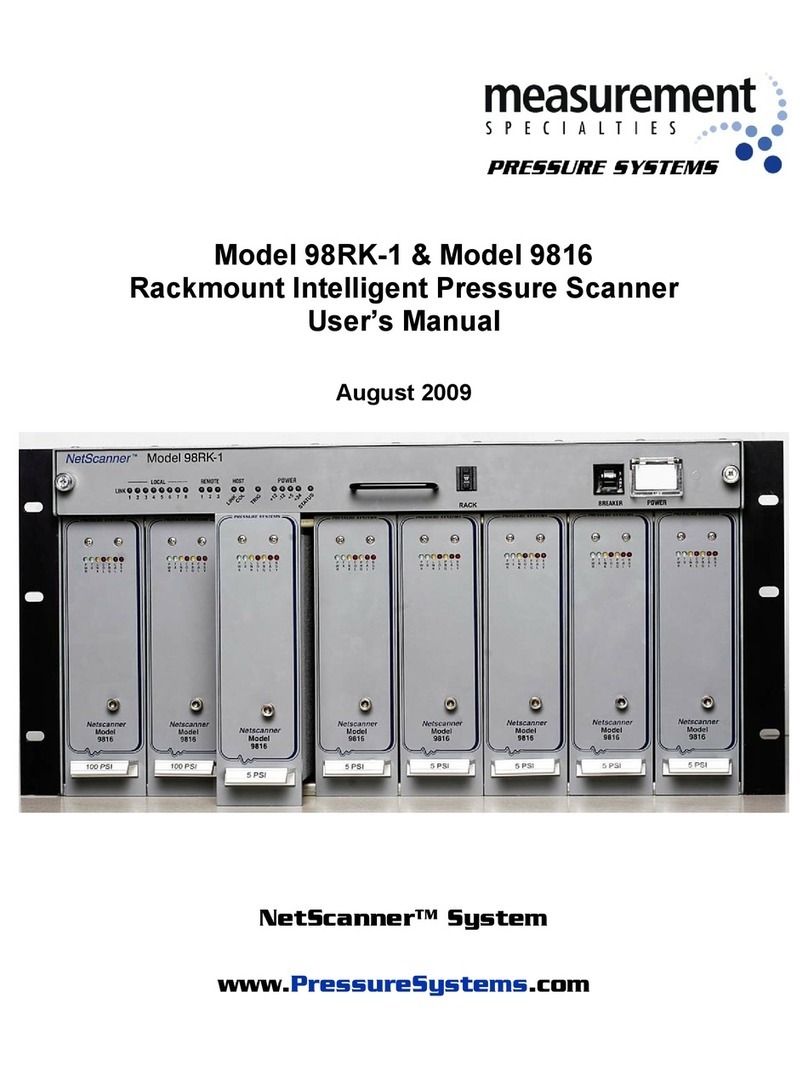

ThismanualdescribestheNetScannerSystemIntelligentPressureScannermodules(Models

9016, 9021, and 9022). It does not cover the 98RK Scanner Interface Rack, model 9816

IntelligentPressureScanner,normodels903x(PressureStandards/Controllers)andthe9116

IntelligentPressureScanner.These productsare coveredintheirindividual User’sManuals.

This manual is divided into seven (7) chapters and several appendices, each covering a

specific topic. They are summarized below:

Chapter 1: General Information describes Models 9016, 9021, and 9022

Intelligent Pressure Scanners and their

various options.

Chapter2: InstallationandSetUp describesthe unpacking and inspection of

amodule, and its connection to power,

pressure,andacommunicationsnetwork.

Chapter 3: Programming & Operation provides the information needed to

program a module from a host computer

and to get meaningful data from it.

Chapter 4: Calibration describesmethods of calibrating a

module.

Chapter 5: Service describes general safety precautions and

maintenance procedures.

Chapter 6: Troubleshooting describes module troubleshooting

techniques.

Chapter 7: Start-up Software brieflydescribes NUSS software.

Appendix A: All Commands — Quick Reference

Appendix B: Response Error Codes

Appendix C: Cable Diagrams

Appendix D: Module Mounting Dimensions

Appendix E: NetScanner System Range Codes

Appendix F: NetScanner™System/9000 Series Products

Appendix G: Binary Bit Map

Pressure Systems, Inc. NetScanner™ System (9016, 9021, & 9022) User’s Manual

www.PressureSystems.com

- iv -

Our Company

PressureSystemsIncorporated,(PSI)develops,manufactures,andserviceslevelandpressure

measuring instruments where the highest level of traceable accuracy is required for

aerospace, industrial, municipal, and environmental applications. Our products have

becometheworldstandardforelectronic levelandpressuremeasurementand scanning. We

are committed to the highest quality design, manufacture, and support of level and pressure

instrumentation that is in the best interest of our customers. PSI is an ISO9001:2000

certified company.

Our Warranty

Pressure Systems, Inc., warrants NetScanner™System products to be free of defects in

material and workmanship under normal use and service for one (1) year.

Technical Support

Monday through Friday, during normal working hours, (7:30 am through 5:30 pm,

Eastern time) knowledgeable personnel are available for assistance and troubleshooting.

Contact the Applications Support Group or the Customer Services Department at

Pressure Systems (757-865-1243 or toll free 1-800-328-3665) if your scanner is not

operating properly or if you have questions concerning any of our products. E-mail

assistance is available by contacting Applications@PressureSystems.com.

Merchandise Return Procedures

If your scanner needs to be returned to Pressure Systems, obtain a Returned Merchandise

Authorization (RMA) from the Customer Service Department.

Be prepared to supply the following information when requesting the RMA:

!Part number

!Serial number

!Complete description of problems/symptoms

!Bill To and Ship To address

!Purchase order number (not required by PSI warranty repairs)

!Customer contact and telephone number

The above information, including the RMA number must be on the customer’s shipping

documents that accompany the equipment to be repaired. PSI also requests that the

outside of the shipping container be labeled with the RMA number to assist in tracking

the repairs. All equipment should be sent to the following address:

Pressure Systems, Inc. NetScanner™ System (9016, 9021, & 9022) User’s Manual

www.PressureSystems.com

- v -

ATTN: PSI REPAIR DEPARTMENT (7-digit RMA number)

Pressure Systems, Inc.

34 Research Drive

Hampton, Virginia 23666

PSI will return warranty items prepaid via UPS GROUND. If the customer desires

another method of return shipment, PSI will prepayand add the shipping charges to the

repair bill.

Incoming freight charges are the customer’s responsibility. The customer is also

responsible for paying shipping charges to and from PSI for any equipment not under

warranty.

All products covered under the PSI warranty policy will be repaired at no charge. An

analysis fee will be charged to quote the cost of repairing any item not under warranty. If,

for anyreason, the customer decides not to have the item repaired, the analysis fee will

still be charged. If the quote is approved by the customer, the analysis fee will be waived.

The quote for repair will be based on the PSI flat rate for repair, calibration, and board

replacement. When these prices do not apply, the quote will be based on an hourly labor

rate plus parts. All replaced parts are warranted for 90 days from the date of shipment.

The 90-day warranty is strictly limited to parts replaced during the repair.

Website and E-Mail

Visit our website at www.PressureSystems.com to look at our new product releases,

application notes, product certifications, and specifications. E-mail your questions and

Our Firmware

This manual was prepared for various versions of module firmware as were released at the

time of this manual publication. Addenda will be distributed as deemed necessary by PSI.

Anyquestions regardingfirmware upgrades maybe addressedto theApplications Support

Group.Firmware revisions, manual addenda, and utility software may also be obtained

from the PSI web page at www.PressureSystems.com.

Our Publication Disclaimer

This document is thoroughly edited and is believed to be thoroughly reliable. Pressure

Systems, Inc., assumes no liability for inaccuracies. All computer programs supplied with

your products are written and tested on available systems at the factory. PSI assumes no

responsibility for other computers, languages, or operating systems. PSI reserves the right

to change the specifications without notice.

Pressure Systems, Inc. NetScanner™ System (9016, 9021, & 9022) User’s Manual

www.PressureSystems.com

- vi -

Table of Contents

Chapter 1 — General Information ....................................... 1-1

1.1 Introduction ....................................................1-1

1.2 Description of Instruments .........................................1-3

1.3 Options ........................................................1-4

1.3.1 Pressure Ranges ........................................... 1-4

1.3.2 Manifolds and Pressure Connections ........................... 1-4

1.3.3 Communications Interfaces ..................................1-5

Chapter 2 — Installation and Set Up ..................................... 2-1

2.1 Unpacking and Inspection .........................................2-1

2.2 Safety Considerations ............................................2-1

2.3 Preparation for Use ..............................................2-1

2.3.1 Environment ..............................................2-1

2.3.2 Power ...................................................2-2

2.3.3 Mounting and Module Dimensions ............................2-2

2.3.4 Network Communications Hookup ............................2-3

2.3.4.1 Ethernet Host Port Hookup ............................2-3

2.3.5 Diagnostic Port Hookup ..................................... 2-6

2.3.6 Pressure Connections .......................................2-6

2.3.6.1 RUN Mode Inputs ................................... 2-7

2.3.6.2 CAL Mode Inputs ...................................2-8

2.3.6.3 Purge Mode Inputs ...................................2-8

2.3.6.4 Leak Mode Inputs ...................................2-8

2.3.6.5 Supply Air .........................................2-9

2.3.7 9021 and 9022 Transducer Installation .........................2-9

2.3.7.1 Installation of 9400, 9401, and 9402 Transducers ..........2-10

2.3.7.2 Installation of All Other Transducers .................... 2-11

2.3.8 Case Grounding ..........................................2-11

2.3.9 Trigger Input Signal .......................................2-12

2.3.10 Power Up Checks and Self-Diagnosis .........................2-12

Chapter 3 — Programming and Operation ...............................3-1

3.1 Commands and Responses ......................................... 3-1

3.1.1 Introduction ..............................................3-1

3.1.1.1 TCP/UDP/IP Protocols ............................... 3-1

Pressure Systems, Inc. NetScanner™ System (9016, 9021, & 9022) User’s Manual

www.PressureSystems.com

- vii -

Table of Contents (Cont.)

3.1.2 Commands ...............................................3-2

3.1.2.1 General Command Format ............................. 3-2

3.1.2.2 Command Field .....................................3-3

3.1.2.3 Position Field .......................................3-3

3.1.2.4 Datum Fields .......................................3-4

3.1.2.5 Format Field ........................................ 3-4

3.1.3 Responses ................................................3-4

3.1.3.1 Interpreting Offset Values (Re-zero Calibration Adjustment) .. 3-5

3.1.3.2 Interpreting Gain Values (Span Calibration Adjustment) .....3-6

3.1.3.3 Interpreting Engineering Unit Output ....................3-6

3.1.4 Functional Command Overview ..............................3-6

3.1.4.1 Startup Initialization ............................3-6

3.1.4.2 Module Data Acquisition .............................. 3-7

3.1.4.3 Calibration Adjustment of Offset/Gain

Correction Coefficients .........................3-8

3.1.4.4 Delivery of Data to Host ..............................3-9

3.1.4.5 Network Query and Control Functions ...................3-9

3.1.4.6 Other Functions ....................................3-10

3.2 Detailed Command Description Reference ...........................3-10

APower Up Clear ..........................................3-12

BReset ...................................................3-13

CConfigure/Control Multi-Point Calibration .....................3-14

VRead Transducer Voltages ..................................3-22

ZCalculate and Set Gains .................................... 3-24

aRead Transducer A/D Counts ...............................3-26

bRead High-Speed Data .....................................3-28

cDefine/Control Autonomous Host Streams .....................3-29

hCalculate and Set Offsets ...................................3-45

mRead Temperature Counts ..................................3-47

nRead Temperature Voltages ................................. 3-49

qRead Module Status .......................................3-51

rRead High-Precision Data ..................................3-54

tRead Transducer Temperature ...............................3-56

uRead Internal Coefficients .................................. 3-58

vDownload Internal Coefficients ..............................3-62

wSet Operating Options .....................................3-65

psi9000 Network Query .....................................3-69

psireboot Re-boot Module ....................................3-71

psiarp Change Module’s IP Address Resolution and Re-boot ......3-72

Pressure Systems, Inc. NetScanner™ System (9016, 9021, & 9022) User’s Manual

www.PressureSystems.com

- viii -

Table of Contents (Cont.)

3.3 Obsolete Commands ............................................3-73

Chapter 4 — Calibration ...............................................4-1

4.1 Introduction ....................................................4-1

4.2 Re-zero Calibration ..............................................4-3

4.2.1 Re-zero Calibration Valve Control ............................4-3

4.2.2 Re-zero Calibration Summary ................................4-4

4.3 Span Calibration .................................................4-4

4.3.1 Span Calibration Valve Control ............................... 4-5

4.3.2 Span Calibration Summary ..................................4-6

4.4 Integrated Multi-Point Calibration Adjustment ......................... 4-7

4.4.1 Calibration Valve Control ...................................4-8

4.4.2 Multi-Point Calibration Summary .............................4-8

4.5 9021/9022 Analog Calibration ..................................... 4-10

4.5.1 Setup ..................................................4-11

4.5.2 Calibration Procedures ..................................... 4-11

4.6 Coefficient Storage .............................................4-13

4.7 Non-VolatileParameter Storage for “non-Digitally Compensated”Pressure Sensors

(9021/9022 Only) ............................................... 4-14

4.8 Line Pressure Precautions ........................................4-18

Chapter 5 — Service ..................................................5-1

5.1 Maintenance ....................................................5-1

5.1.1 Common Maintenance ......................................5-3

5.1.2 Module Disassembly .......................................5-3

5.1.3 Electronic Circuit Board Replacement ......................... 5-4

5.1.3.1 PC-206 Amplifier/Multiplexer Board ....................5-4

5.1.3.2 PC-242 Amplifier/Multiplexer Board ....................5-5

5.1.3.3 PC-280 Ethernet Microprocessor /A/D Board ..............5-6

5.1.3.4 PC-315, PC-316, and PC-317 Boards ....................5-7

5.1.4 Replacement of Transducers .................................5-8

5.1.5 Calibration Valve Solenoid Replacement ......................5-10

Pressure Systems, Inc. NetScanner™ System (9016, 9021, & 9022) User’s Manual

www.PressureSystems.com

- ix -

Table of Contents (Cont.)

5.1.6 Replacement of O-Rings ...................................5-10

5.1.6.1 DH200 Pressure Transducer O-Ring Replacement .........5-11

5.1.6.2 Tubing Plate O-Ring Replacement .....................5-12

5.1.6.3 Adapter Plate O-Ring Replacement ..................... 5-13

5.1.6.4 Calibration Manifold Piston O-Ring Replacement .........5-14

5.1.6.5 Solenoid Valve O-Ring Replacement ...................5-15

5.2 9022 Excitation Trim ............................................ 5-16

5.3 9022 Procedure for Changing the Excitation Jumper Setting (JB1) ........5-17

5.4 Upgrading Module Firmware ...................................... 5-17

5.2.1 Upgrading Firmware Via Host TCP/IP Port ....................5-18

Chapter 6 — Troubleshooting Guide .....................................6-1

6.1 Ethernet Module Troubleshooting ...................................6-1

6.1.1 Checking Module Power-up Sequence .........................6-1

6.1.2 Checking Module TCP/IP Communications .....................6-2

6.1.2.1 Module IP Address Assignment ........................ 6-2

6.1.2.2 Host IP Address Assignment for Windows 95/98/NT ........ 6-4

6.1.2.3 Verifying Host TCP/IP Communications ................. 6-4

6.2 Zero and Gain Calibration Troubleshooting ...........................6-6

6.3 User Software ...................................................6-7

Chapter 7 — Start-up Software .........................................7-1

7.1 Introduction ....................................................7-1

Appendices

Appendix A: All Commands — Quick Reference

Appendix B: NetScanner System Response Error Codes

Appendix C: Cable Diagrams

Appendix D: Mounting Diagrams

Appendix E: NetScanner™System Range Codes

Appendix F: NetScanner™System/9000 Series Products

Appendix G: Binary Bit Map

Pressure Systems, Inc. NetScanner™ System (9016, 9021, & 9022) User’s Manual

www.PressureSystems.com

- x -

List of Figures

Figure 1.1 NetScanner System Pneumatic Intelligent Pressure Scanners ........1-2

Figure 2.1 9016, 9021, 9022 Power Pin Assignments ......................2-2

Figure 2.3 Ethernet Host Port Connector Pins ............................2-3

Figure 2.3 Ethernet Network Topology .................................. 2-5

Figure 2.4 9021 Transducer Wiring ...................................2-10

Figure 2.4a 9022 Transducer Wiring ...................................2-10

Figure 2.5 9022 Jumper Set for 10 VDC Excitation .......................2-11

Figure 4.1 Calibration Manifold RUN Position ...........................4-2

Figure 4.2 Calibration Manifold CAL Position ............................4-2

Figure 4.3 Calibration Manifold PURGE Position .........................4-2

Figure 4.4 Calibration Manifold LEAK CHARGE Position .................4-2

Figure 4.5 9021 and 9022 Voltage Input Connections .....................4-11

Figure 5.1 Exploded View of 9016 and 9022 .............................5-1

Figure 5.1a 9016 Top Plate ............................................5-2

Figure 5.2b 9021 Top Plate ............................................5-2

Figure 5.2c 9022 Top Plate ............................................5-2

Figure 5.2 9016 Scanner Out of Housing ................................5-4

Figure 5.2a 9022 Scanner Out of Housing ................................5-4

Figure 5.3 PC-203 Board .............................................5-6

Figure 5.3a 9022 PCBs Outside the Housing ..............................5-7

Figure 5.3b 9022 PCBs Apart ..........................................5-7

Figure 5.4 Top View of DH200 ....................................... 5-9

Figure 5.5 Solenoid in Module .......................................5-10

Figure 5.6 DH200 Transducer O-Ring Replacement ......................5-11

Figure 5.7 Solenoid Valve O-Ring Replacement .........................5-15

Figure 5.8 PC-317 Board (Trim Potentiometer and Jumper) ................5-16

Figure 5.9 Update Firmware Screen ...................................5-18

List of Tables

Table 2.1 Diagnostic Port Wiring .....................................2-6

Table 3.1 Error Codes ..............................................3-5

Table 3.2 Intelligent Pressure Scanner Commands ....................... 3-10

Table 5.1 Component Cross Reference .................................5-2

Pressure Systems, Inc. NetScanner™ System (9016, 9021, & 9022) User’s Manual

www.PressureSystems.com

1 - 1

Chapter 1

General Information

1.1 Introduction

This User’s Manual will:

!Explain the electrical and pneumatic pressure connections for the NetScanner™

System Models 9016, 9021, and 9022 Intelligent Pressure Scanners.

!Instruct you on how to program each module with computer software.

!Instruct you on using the PSI start-up software to manipulate and acquire data from

each module.

Model 9016 is a pneumatic Intelligent Pressure Scanner, with integral pressure transducers and a

pneumatic calibration manifold.

Models 9021 and 9022 are all-media Intelligent Pressure Scanners which may be fitted with up to

twelve(12)externalall-media transducers(9400,9401,9402,orthirdparty). Becauseoftheexternal

natureofthesetransducers,andthevarietyofpneumaticorhydraulicmediasupported,the9021/9022

do not contain an integral calibration manifold.

Both models provide engineering unit pressure data with guaranteed system accuracy. This is

achieved by readingfactory-determined pressureand temperature engineering-unit data conversion

coefficients from their transducers’ nonvolatile memories at power-up. They also allow additional

adjustment coefficients to be “fine-tuned” with a multi-point calibration under host control (e.g.,

possibly utilizing optional Pressure Systems 903x Pressure Calibrator modules).

Models9016, 9021, and 9022 provide 10-Base-TEthernet communications for their Host Port (with

TCP/UDP/IP protocol).

Pressure Systems, Inc. NetScanner™ System (9016, 9021, & 9022) User’s Manual

www.PressureSystems.com

1 - 2

NOTE: ThenewestPSIIntelligentPressureScanneristhe9022.Itsserialnumbers

beginwith 1000. The9022 is similarin function tothe 9021 (usingexternal

sensors), however, the 9022 features circular (military style connectors),

splash-proof case and connectors, antialiasing filters, and a jumper

selectable precision 5 or 10 voltexcitation voltage for use with third-party

sensors. The overall dimensions of the 9022 are slightly larger than the

9021 due to a thicker top plate.

Model 9016 Model 9021 Model 9022

Figure 1.1

NetScanner™System Models 9016, 9021, and 9022 Intelligent Pressure Scanners

Pressure Systems, Inc. NetScanner™ System (9016, 9021, & 9022) User’s Manual

www.PressureSystems.com

1 - 3

1.2 Description of Instruments

NetScanner™System family of Intelligent Pressure Scanner modules are flexible pressure

measuring devices intended for use in test and production environments. Models are available

with 12 (Model 9021/9022), or 16 (Model 9016) channels, each with individual pneumatic or all-

media transducers per channel. The most distinctive features are highlighted below:

!Pre-calibrated Transducer — a memory chip containing full calibration data is

embedded within each internal transducer (9016) or external Series 9400

transducer (9021/9022).

!Individual transducer per measurement input channel — mixed transducer ranges

may be installed in a single 9016 module or attached to a 9021/9022 module.

!Low cost per point — per-channel cost is less than a typical industrial pressure

transducer/transmitter.

!High accuracy— Model 9016 pressure scanners are capable of accuracies up to

±0.05%. Accuracy is maintained through use of built-in re-zero, span, or multi-

point calibration capabilities. Model 9021/9022 pressure scanners provide

accuracies better than ±0.10% FS. Accuracy is maintained for six (6) months after

calibration.

!Low thermal errors —each internal transducer and each external 904x transducer

contains an individual temperature sensor and thermal calibration data for internal

use by software correction algorithms. Thermal errors are reduced as low as

±0.001%FS/ºC over the calibrated temperature span.

!Re-zero upon demand (Models 9016) — an integrated calibration valve allows for

automatic re-zero adjustment calibration of dry gas transducers to null offset drift

errors.

!Ease of transducer replacement — factory calibrated transducer assemblies may

be stocked and rapidly replaced in the field. Storage of thermal coefficients

within the transducer allows for ‘plug and play’ transducer replacement.

!Ease of calibration — each 9016 module contains a pneumatic calibration

manifold and software commands to automatically perform re-zero, span, and

multi-point adjustment calibrations. New offset and gain coefficients that result

from the most recent calibration may be stored in non-volatile transducer memory.

Pressure Systems, Inc. NetScanner™ System (9016, 9021, & 9022) User’s Manual

www.PressureSystems.com

1 - 4

!Measurement flexibility — each 9021/9022 module is capable of measuring

general purpose voltage signals on any channel not populated with a 9400-type

transducer. Full-scale ranges of ±50, ±100, ±250 and ±4500 mV are supported

through programmable gain amplifier circuitry.

!Ease of use — modules have simple command sets and provide engineering units

output. They may interface directly to a desktop or laptop computer or they may

be interconnected into a large network controlled by many types of host

computers.

!Connectivity — use of industry-standard communications network protocols to

control and read data from NetScanner™System modules allows distribution to

the point of measurement and ensures compatibility with third party hardware and

software.

1.3 Options

1.3.1 Pressure Ranges

Model 9016 contains sixteen (16) DH200 transducers. These transducers are available with full

scale pressure ranges from 10" H2O (inches of water column) to 750 psid (2.5 kPa to 5200 kPa).

Transducers with different pressure ranges may be combined in a single module.

Models 9021 and 9022 can attach up to twelve (12) Series 9400 or third party external all-media

transducers. The 9400 gauge-type transducers are available with full-scale pressure ranges from

5 psi to 10,000 psi (35 kPa to 69000 kPa). The 9401 absolute-type transducers are available

with full-scale pressure ranges from 15 psia to 10,000 psia (105 kPa to 69000 kPa). The 9402

wet-wet differential type transducers are available with full scale ranges from 5 psi to 250 psi (35

kPa to 1725 kPa). Transducers with different pressure ranges may be attached to a single

module.

Please consult the Sales Department at Pressure Systems for availability of other pressure ranges

(1-800-678-SCAN (7226)).

1.3.2 Manifolds and Pressure Connections

Model 9016 sixteen-channel Intelligent Pressure Scanners are available with a true differential or

common reference pneumatic manifold, and have a standard purge and leak check manifold.

They are available with standard 1/8" or optional 1/16" and 1/4" compression fittings. All

fittings

Pressure Systems, Inc. NetScanner™ System (9016, 9021, & 9022) User’s Manual

www.PressureSystems.com

1 - 5

utilize an SAE 5/16 - 24 O-ring boss which supports a variety of other adapter compression

fittings. They are also available with a quick disconnect plate which contains 0.063" bulge

tubulation. The common differential version is available with all choices of fittings. The true

differential version is available with 0.063" bulged tubulation fittings only.

Models 9021 and 9022 12-channel Intelligent Pressure Scanners have no internal manifold or

pressure transducers. Instead, they have up to twelve (12) externally connected type 9400, 9401,

or 9402 all-media pressure transducers. 9400, 9401, and 9402 transducers maybe purchased with

a variety of standard pressure fittings. Any necessary valves and manifolds must be customer-

supplied if automatic calibration with the appropriate medium is desired at the module

installation site. Both the 9021 and 9022 scanners are designed to operate with either PSI or

third-party transducers.

Consult the Sales Department at Pressure Systems at 1-800-678-SCAN (7226) for availability of

other input fittings.

1.3.3 Communication Interfaces

All standard NetScanner™System Intelligent Pressure Scanners provide temperature

compensated and linearized pressure data in engineering units via digital methods. They have a

10Base-T Ethernet host communications interface using industry standard TCP/IP or UDP/IP

protocol. This interface provides high data transfer rates and system connectivity.

Pressure Systems, Inc. NetScanner™ System (9016, 9021, & 9022) User’s Manual

www.PressureSystems.com

1 - 6

This page intentionally left blank

Pressure Systems, Inc. NetScanner™ System (9016, 9021, & 9022) User’s Manual

www.PressureSystems.com

2 - 1

Chapter 2

Installation and Set Up

2.1 Unpacking and Inspection

The NetScanner™System product familyhas many components which may be purchased either as

an entire system, or as individual pieces of equipment. Before assembling the system, use the

shipping bill as a reference to ensure that all parts have arrived. Pressure Systems takes no

responsibility for equipment that is damaged during shipment. If containers are broken, ripped, or

damaged, contact the transportation carrier. If the equipment itself appears to be damaged, contact

the Repair Department at Pressure Systems.

Each NetScanner™System Intelligent Pressure Scanner shipment will contain the following

minimum components:

!Model 9016 or 9021/9022 Intelligent Pressure Scanner module

!Start-up software diskette(s) or CD-ROM

!NetScanner™System User’s Manual for Intelligent Pressure Scanners (Models

9016/9021/9022) (Hard copy and/or CD-ROM)

2.2 Safety Considerations

Always wear safetyglasses when operating this equipment or when working withpressurized lines.

Always ensure thathigh pressure linesare properlysecured and thatall pneumaticlinesarerated for

the proper pressure and temperature environments.

All system power should be OFF during installation (or removal) of any components in a

NetScanner™Systemmodule. FailuretoturnpowerOFFpriortoinstallationmaycausepermanent

damage to the module. Use caution and check line voltages before applying power to the module.

Pressure Systems, Inc. NetScanner™ System (9016, 9021, & 9022) User’s Manual

www.PressureSystems.com

2 - 2

WARNING: Exceeding the specified storage or operating

temperatures may result in permanent damage to the

NetScanner™System electronics.

WARNING: Improper connection of power to the Intelligent Pressure

Scanner can result in permanent damage to module electronics.

Figure 2.1

9016, 9021, 9022 Power Pin Assignments

2.3 Preparation for Use

2.3.1 Environment

All standard Intelligent Pressure Scanners are factory calibrated to be accurate over a specified

temperaturerange, butmay be operated or storedover awidertemperature range (seeNetScanner™

SystemData Sheet, published separately). Operating or storing an instrument outside its specified

range(s) will result in a loss of measurement accuracy and may cause permanent damage to the

instrument electronics.

2.3.2 Power

Models 9016, 9021, and 9022 Intelligent Pressure Scanners need only a single unregulated power

supply.

Models9016and9021/9022haveasingleround,ruggedizedconnectorthroughwhichallpowerand

input/output signals pass as shown in Figure 2.1.

Pressure Systems, Inc. NetScanner™ System (9016, 9021, & 9022) User’s Manual

www.PressureSystems.com

2 - 3

Figure 2.2

Ethernet Host Port Connector Pins

2.3.3 Mounting and Module Dimensions

Detailed mechanical drawings for each module are included in Appendix D.

2.3.4 Network Communications Hookup

Every NetScanner™System Intelligent Pressure Scanner contains a Host Port, allowing it to be

interconnectedin anetwork withothermodules anda host computer. Models 9016, 9021,and 9022

have an Ethernet Host Port using TCP/IP and UDP/IP transmission protocols.

2.3.4.1 Ethernet Host Port Hookup

The Ethernet Host ports of everymodel 9016, 9021, and 9022 Intelligent PressureScanner module,

and its host computer, may be interconnected in a “star” network via a standard 10-Base-T

interconnection hub or switch. These standard devices will have their own power requirements.

Such a hub treats the host computerconnection and all NetScanner™System module connections

alike. Ethernet communications pin assignments for the 9016, 9021, and 9022 electrical connector

are shown in Figure 2.2. See Figure 2.3 for typical network topology.

The host and each module must have a unique Ethernet Hardware Address (a.k.a. MAC Address)

and a unique IP Address. The Ethernet Hardware address is generallyfixed (at manufacturing time

of the Ethernet microprocessorboard inside the module). The Ethernet Hardware address is shown

oneachmodule’slabel. TheEthernetIntelligentPressureScannersarecapableofsupportingvarious

methods for IP address assignment, using either the factory default (static IP addressing) or user-

This manual suits for next models

2

Table of contents

Other Pressure Systems Scanner manuals