18Revision8–November2011

BASEPLATE INSTALLATION PROCEDURE

Industry standard procedures, such as API RP 686/ PIP

REIE 686, and/or the following procedure should be

followed prior to grouting the baseplate. The procedure

assumes the installer has a basic knowledge of baseplate

and foundation design and installation methods.

BASEPLATE PREPARATION

1-Inspect all surfaces of baseplate that will contact grout for

contamination (e.g. -rust, oil, grime, etc.).

1- Thoroughly clean all surfaces of the baseplate that will

contact grout with a cleaner that will not leave any residue.

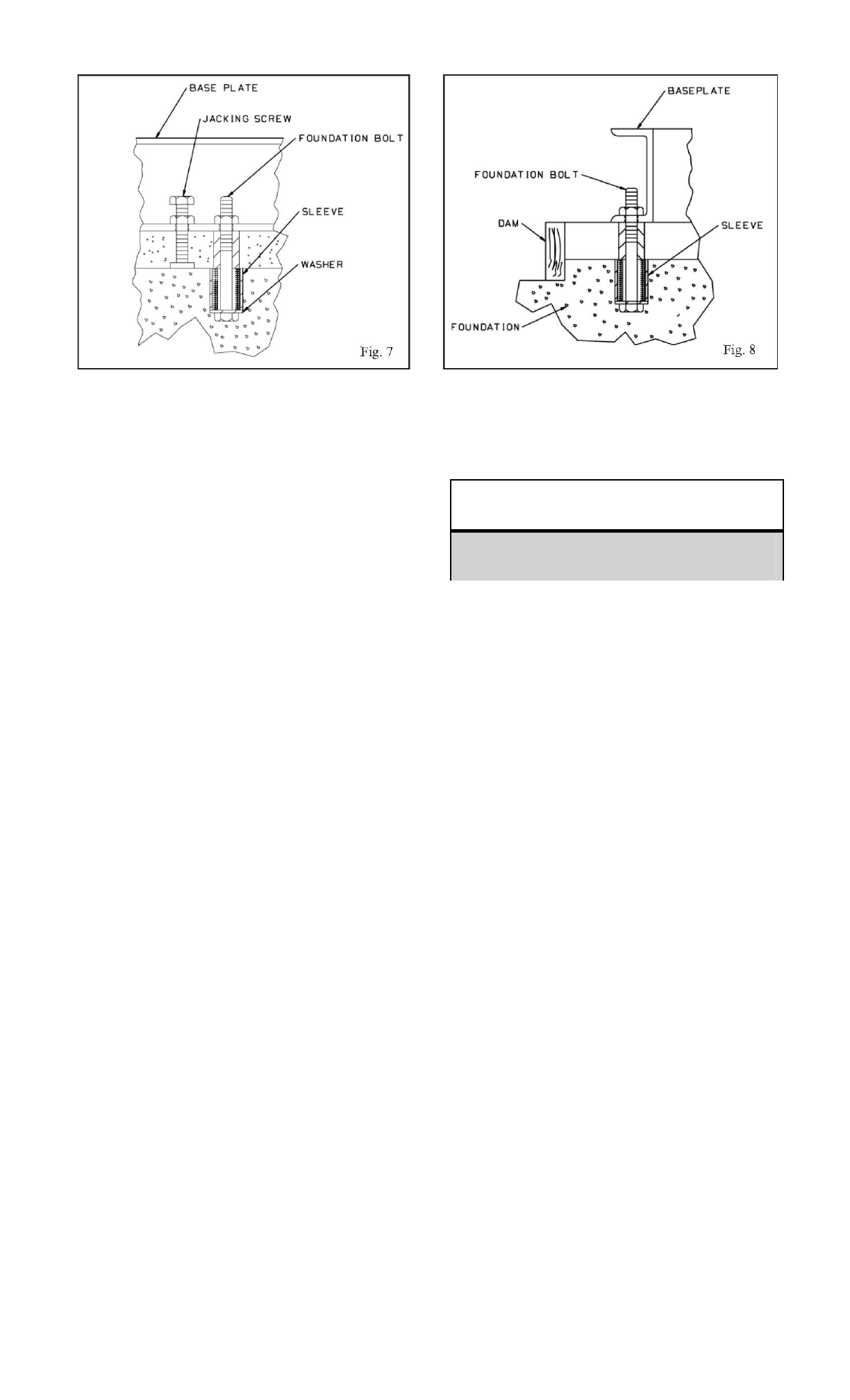

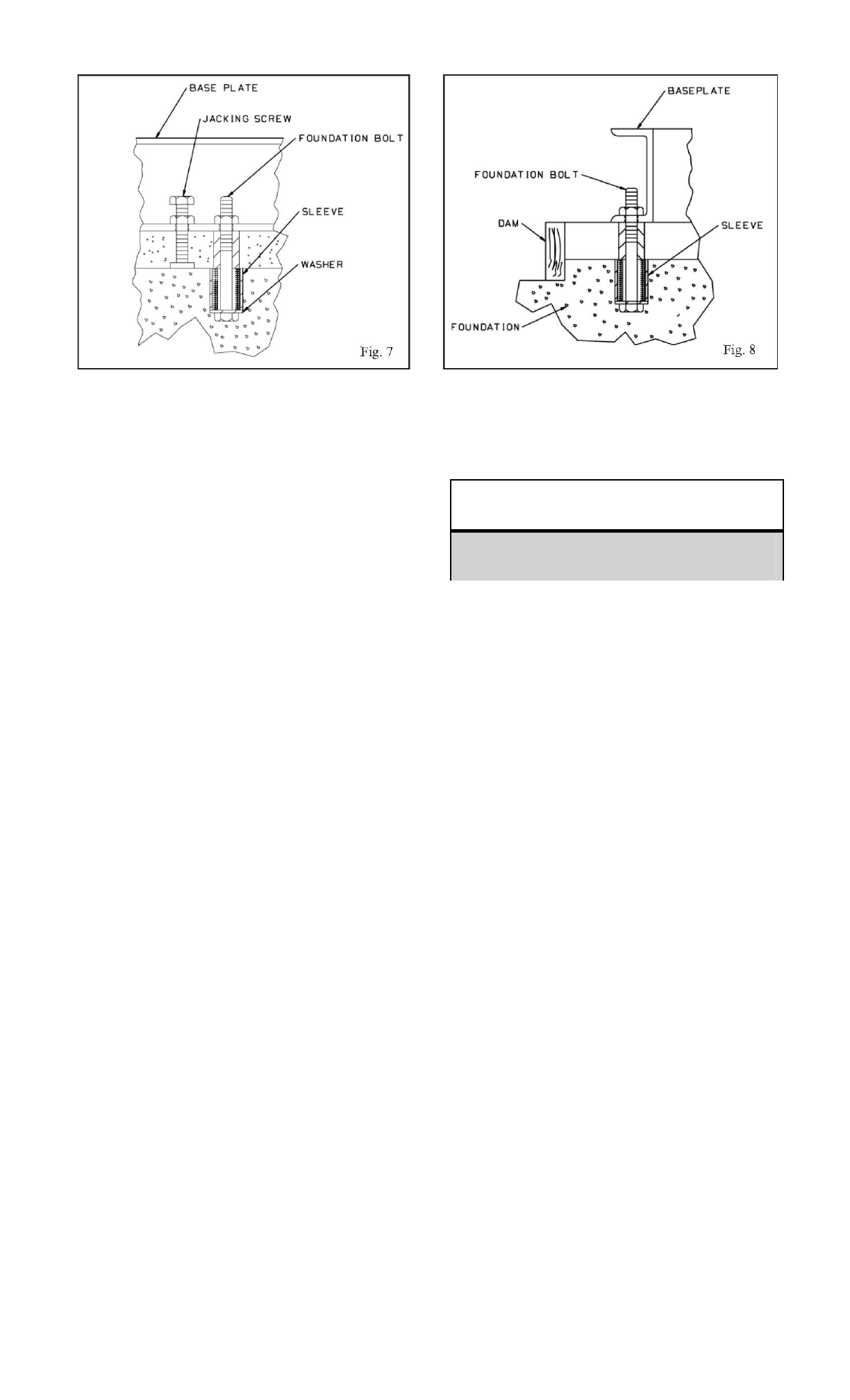

Remove water and/or debris from foundation bolt

holes/sleeves. If the sleeve type bolts are being

used, fill the sleeves with nonbinding moldable

material and seal to prevent grout from entering.

Coat exposed portion of anchor bolts with a

non-bonding compound (such as paste wax) to

prevent grout from adhering to anchor bolts.

2-Inspect all machined surfaces for burrs, rust, paint or

any other type of contamination. If necessary, use a

honing stone to remove burrs.

Chip top of foundation a minimum of 25 mm) to

remove porous or low strength concrete. If using a

pneumatic hammer, assure that it is not contaminating

the surface with oil, moisture, etc

If recommended by grout manufacturer,

coat foundation surface with a

compatible primer.

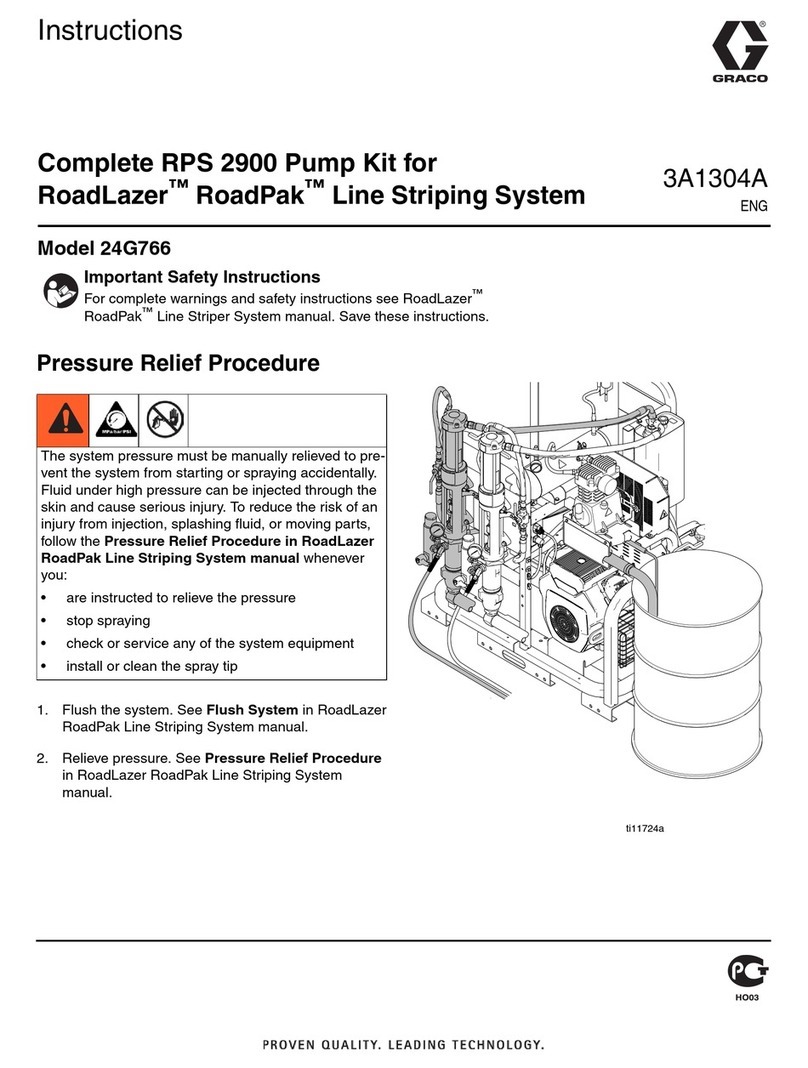

3-Coat portions of leveling screws that will contact grout

with a non-bonding (anti-seize) compound (such as paste

wax) to facilitate their removal after grouting.

4-Thread nuts on foundation bolts and hand tighten.

FOUNDATION PREPARATION

SETTING AND LEVELING BASEPLATE

Lower base onto foundation bolts. Base will rest

on top of foundation on jackscrews provided on

base (Figs. 9 & 10).

Adjust leveling jack screws, located adjacent to

the foundation bolt holes, until the baseplate rests

1-2 in. (25 -50 mm) above foundation to allow for

adequate grouting. This will provide even support

for the base once it is grouted.

Level base to within .002 in./ft. (0.20 mm/m) of

length or width of the base, respectively, by

adjusting leveling screws. Maximum total

variation from one end or side of the base to the

other is .015 in. (0.38 mm).

�CAUTION

Do not use heavy tools such as jackhammers, as they

could damage the structural integrity of the

foundation.