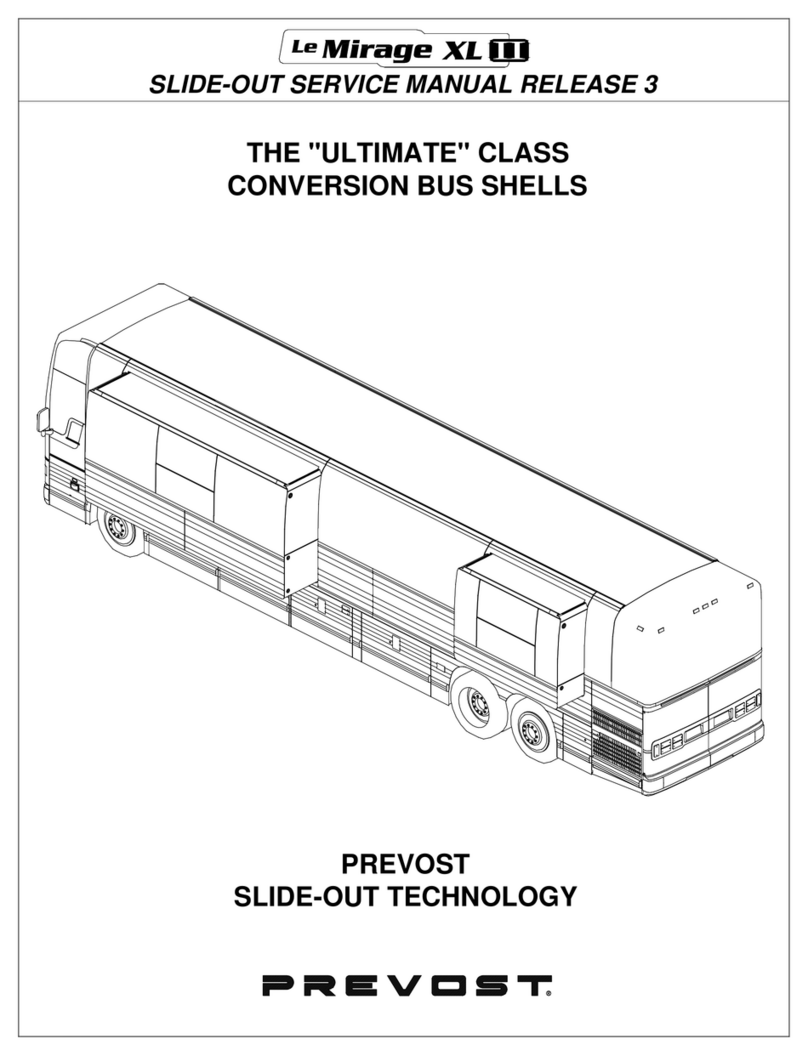

Section 26: VIP SLIDE-OUT

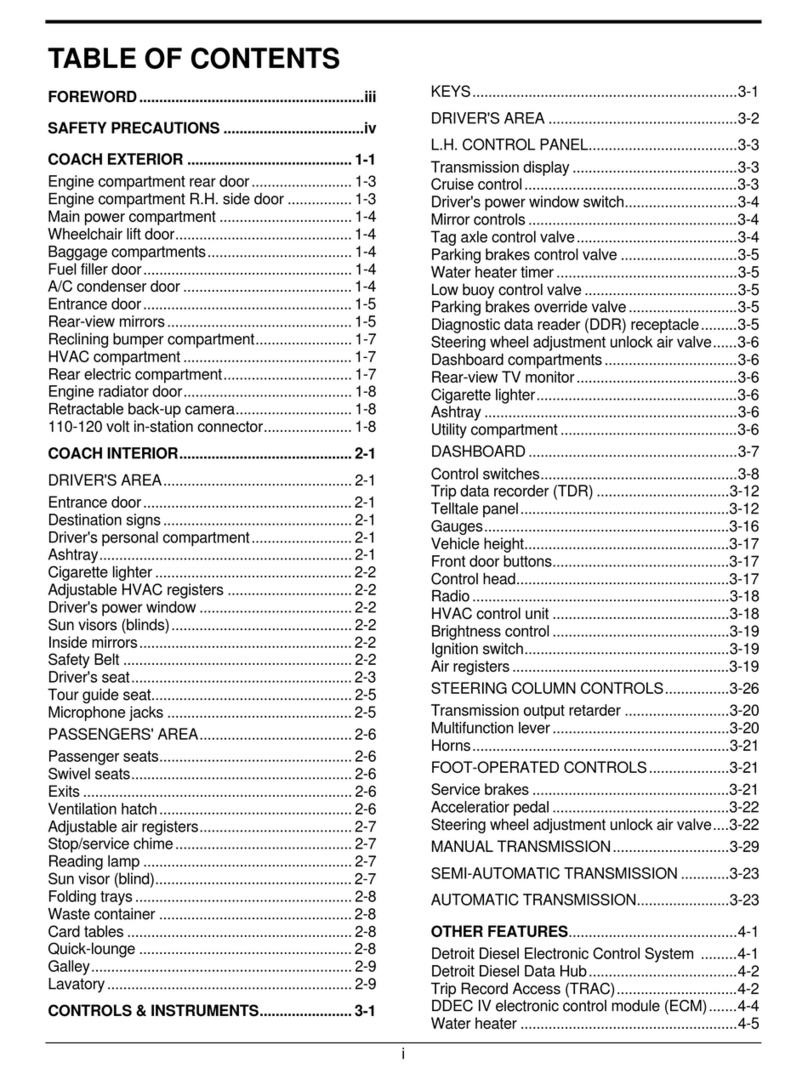

LIST OF ILLUSTRATIONS

FIGURE 1 : FRONT SLIDE-OUT ........................................................................................................................... 5

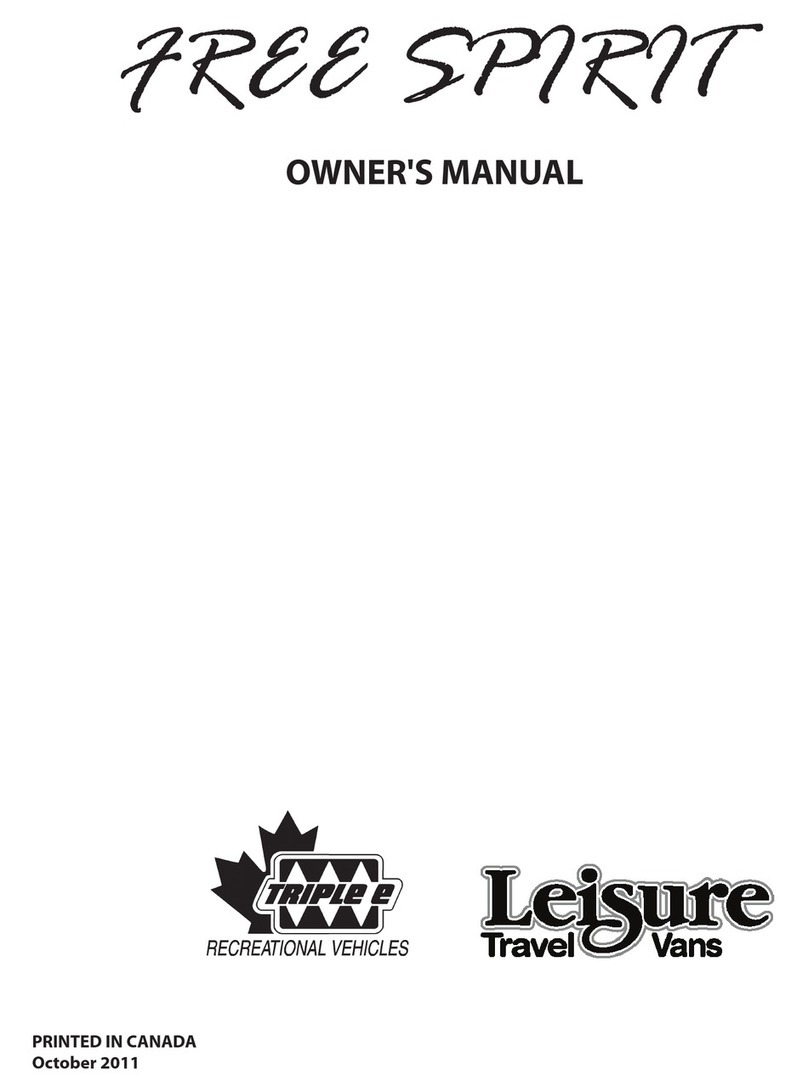

FIGURE 2 : REAR SLIDE-OUT ............................................................................................................................. 5

FIGURE 3 : SIDE INNER STOPPER ADJUSTMENT .................................................................................................. 5

FIGURE 4: UPPER INNER STOPPERS ADJUSTMENT .............................................................................................. 5

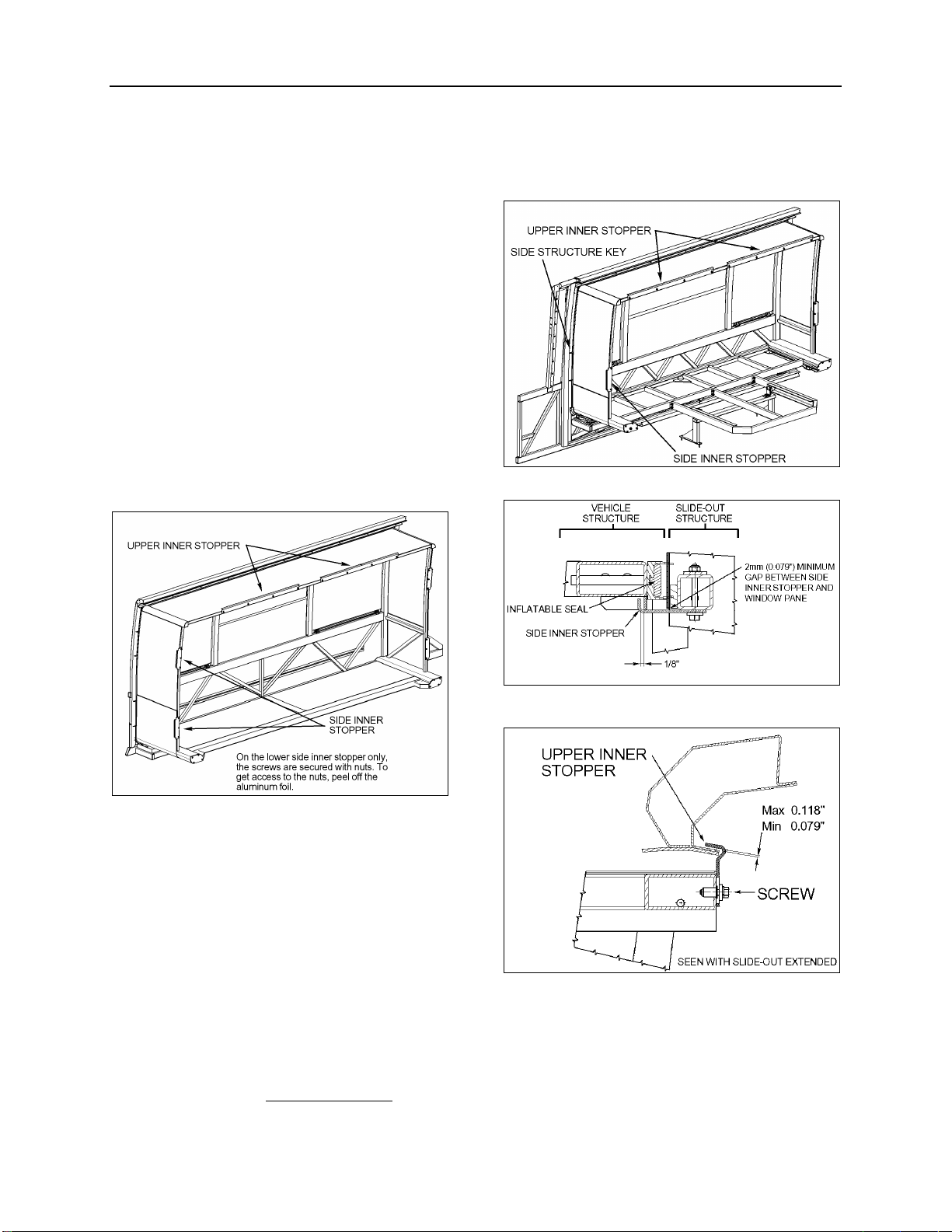

FIGURE 5: LOWER "IN LIMIT" STOPPER ............................................................................................................... 6

FIGURE 6: UPPER "IN LIMIT" STOPPER ............................................................................................................... 6

FIGURE 7 : EXTERIOR EXTRUSION ..................................................................................................................... 6

FIGURE 8: SECURITY PIN AIR CYLINDER REMOVAL .............................................................................................. 7

FIGURE 9 : FRONT SLIDE-OUT ROOF REINFORCING ROD ...................................................................................... 7

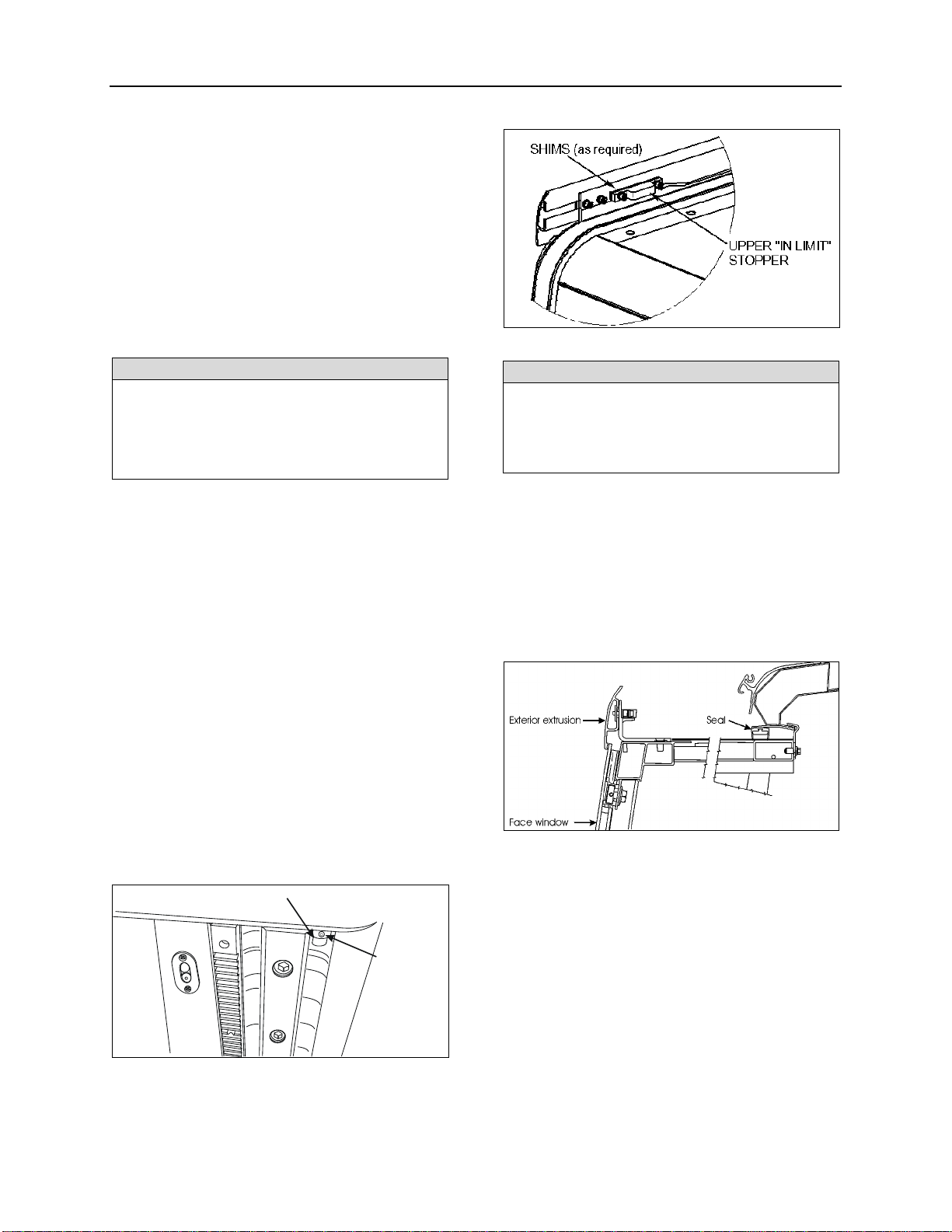

FIGURE 10 : RACK............................................................................................................................................ 8

FIGURE 11: PINION AND KEYLESS BUSHING POSITIONING .................................................................................... 9

FIGURE 12: PINION AND KEYLESS BUSHING (BOTTOM VIEW) ................................................................................ 9

FIGURE 13: MECHANICAL COMPONENTS (TYPICAL) ............................................................................................ 9

FIGURE 14 : KEYLESS BUSHING TIGHTENING .................................................................................................... 10

FIGURE 15 : TORQUE WRENCH FORMULA ........................................................................................................ 10

FIGURE 16 : KEYLESS BUSHING INSTALLATION INSTRUCTION ............................................................................ 12

FIGURE 17: ELECTRIC MOTOR AND SPEED REDUCTION GEARBOX ...................................................................... 13

FIGURE 18: MOTOR/GEARBOX ASSEMBLY MOUNTING BOLTS ............................................................................. 13

FIGURE 19: CLAMPING HUB POSITION ON SHAFTS ............................................................................................ 14

FIGURE 20: JAW COUPLING ............................................................................................................................ 14

FIGURE 21: SLIDE-OUT LEVEL ADJUSTEMENT ................................................................................................... 15

FIGURE 22 : SLIDE-OUT LEVELING ................................................................................................................... 16

FIGURE 23: TILT ADJUSTMENT ........................................................................................................................ 16

FIGURE 24 : RAIL POSITIONING ....................................................................................................................... 17

FIGURE 25: ACETAL PLASTIC BLOCKS .............................................................................................................. 17

FIGURE 26: REMOVE THE UPPER ACETAL PLASTIC BLOCKS WITH A PICKING TOOL ............................................... 17

FIGURE 27: LOWER ACETAL PLASTIC BLOCK INSERTION .................................................................................... 18

FIGURE 28 : FRONT SERVICE COMPARTMENT ................................................................................................... 19

FIGURE 29: PNEUMATIC CONTROL UNIT ........................................................................................................... 20

FIGURE 30 : SEAL ASSEMBLY .......................................................................................................................... 20

FIGURE 31: REAR SLIDE-OUT INFLATABLE SEAL AIR INLET ................................................................................. 20

FIGURE 32: WIPER SEAL CUT-OUT ................................................................................................................... 21

FIGURE 33: SLIDE-OUT 2" INSIDE – UPPER PART .............................................................................................. 22

FIGURE 34 : DASHBOARD SLIDE-OUT TELLTALE LIGHT ...................................................................................... 23

FIGURE 35: MAIN BREAKER IN MAIN POWER COMPARTMENT ............................................................................. 23

FIGURE 36 : SLIDE-OUT CONTROL PANEL ......................................................................................................... 23

FIGURE 37: FRONT SLIDE-OUT SENSORS ........................................................................................................ 24

FIGURE 38: REAR SLIDE-OUT SENSORS ........................................................................................................... 24

FIGURE 39 : MAGNETS ON SLIDE-OUT UNDERBODY .......................................................................................... 24

FIGURE 40 : SLIDE-OUT PANELS AND WINDOWS ............................................................................................... 25

FIGURE 41 : SIDE PANEL INSTALLATION ........................................................................................................... 26

FIGURE 42 : SIDE PANEL INSTALLATION ........................................................................................................... 26

FIGURE 43 : SIDE PANEL INSTALLATION – SIKA 221 APPLICATION ON STRUCTURE .............................................. 27

FIGURE 44 : SIDE PANEL INSTALLATION – SIKA 221 OR 252 APPLICATION ON STRUCTURE .................................. 27

FIGURE 45 : SIDE PANEL INSTALLATION – SIKA 206 G+P APPLICATION ............................................................... 27

FIGURE 46 : SIDE PANEL INSTALLATION – SIKA 221 OR 252 APPLICATION ON SIDE PANEL ................................... 27

FIGURE 47 : SIDE PANEL INSTALLATION – SIKA TACK+BOOSTER APPLICATION ................................................... 27

FIGURE 48 : SIDE PANEL INSTALLATION ........................................................................................................... 27

FIGURE 49 : TOP AND BOTTOM PANEL INSTALLATION - DOUBLE FACE ADHESIVE TAPE APPLICATION ..................... 28

FIGURE 50 TOP AND BOTTOM PANEL INSTALLATION - SIKA 206 G+P APPLICATION ............................................. 29

FIGURE 51 : TOP AND BOTTOM PANEL INSTALLATION - SIKA TACK+BOOSTER APPLICATION ................................. 29

FIGURE 52 : TOP PANEL INSTALLATION ............................................................................................................ 29

FIGURE 53 : BOTTOM PANEL INSTALLATION ..................................................................................................... 29

FIGURE 54 : FACE WINDOW - RUBBER SEAL INSTALLATION ................................................................................ 30

PA1217 3