Section 00 : GENERAL INFORMATION

00-2

1. FOREWORD

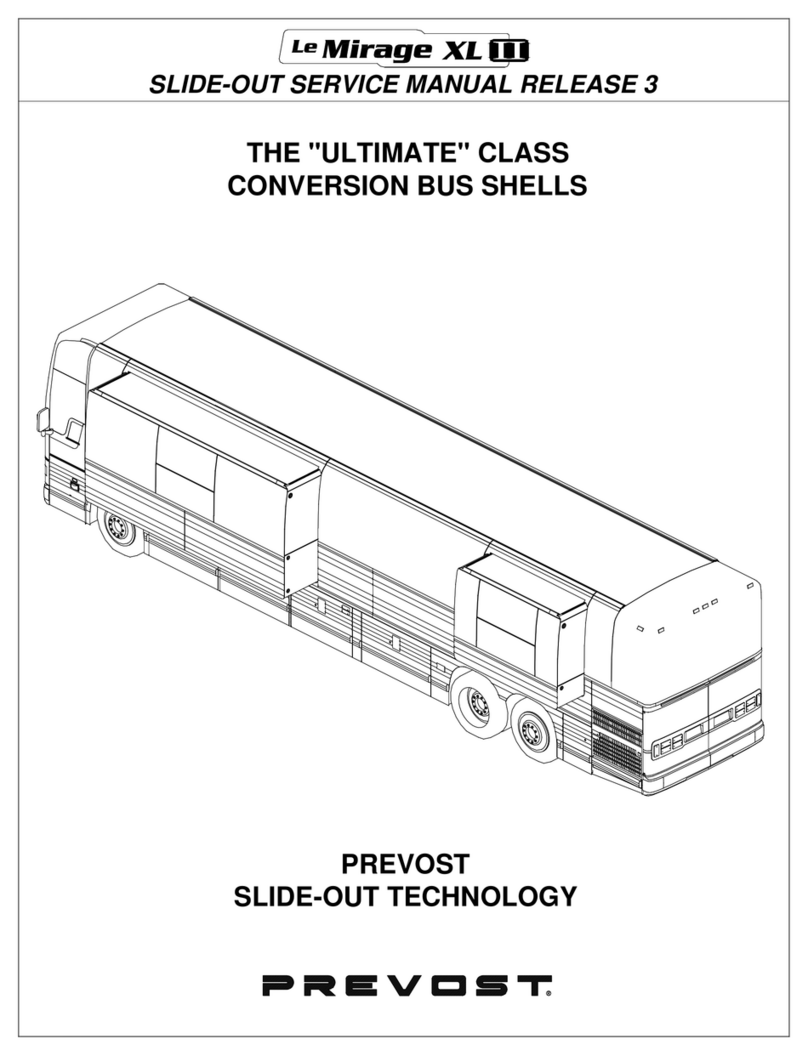

This manual includes procedures for diagnosis,

service, maintenance and repair for components

of the H3 series coaches or VIP model listed on

the front cover page.

This manual should be kept in a handy place for

ready reference by the technician. If properly

used, it will meet the needs of the technician and

owner.

Information provided in Section 1 through 24

pertains to standard equipment items, systems

and components as well as the most commonly

used optional equipment and special equipment

offered on the coach models covered by this

manual.

At the beginning of each section; a Table of

Contents and a list of illustrations give the page

number on which each subject begins and where

each figure is located.

Coach operating information is provided in a

separate Operator's Manual. Audio/Video

system operator instructions are also included in

a separate manual.

More specific information on engine and

transmission operating, maintenance, and

overhaul information is contained in the

applicable engine or transmission service

manual published by the engine or transmission

manufacturer. Engine and transmission parts

information is contained in the applicable engine

or transmission parts catalog published by the

engine or transmission manufacturer.

All information, illustrations and specifications

contained in this manual are based on the latest

product information available at the time of

publication approval. The right is reserved to

make product changes at any time without

notice.

Note: Typical illustrations may be used;

therefore minor illustration difference may exist

when compared to actual parts or other

publications.

Prévost Car occasionally sends Maintenance

Information, Warranty Bulletins, Safety Recalls

or other literature to update users with the latest

service procedures. They are issued, when

required, to supplement or supersede

information in this manual. Update sheet should

be filled out and bulletins should be filed at the

end of their respective section for future

reference.

2. SCHEMATICS

Vehicle AIR SCHEMATICS are provided at the

end of Section 12, "Brake". SUSPENSION AIR

SCHEMATICS are provided at the end of

Section 16, "Suspension". Moreover,

ELECTRICAL SCHEMATICS are provided in the

technical publications box. Refer to those

schematics for detailed circuit information or

during diagnosis.

3. PRECAUTIONS TO BE OBSERVED

BEFORE WELDING

Caution: Cut off battery power in main power

compartment using battery safety switch.

1. Disconnect “Ground” cables from battery

terminals.

Note: Disconnect “Ground” cables only.

2. If welding must be done near the dashboard

i.e. steering column, you must disconnect all

electronic control modules (radio & control

head, HVAC, TTLT cluster Volvo). You must

also disconnect alternator module located in

rear electrical compartment.

3. Disconnect three wiring harness connectors

from ECM (Electronic Control Module). The

ECM is mounted on the starter side of the

engine.

4. For vehicles equipped with an Allison

automatic transmission, disconnect three

wiring harness connectors from ECU

(Electronic Control Unit). The ECU is located

in main power compartment.

5. For vehicles equipped with a WCL system,

disconnect electronic controller connector.

6. For vehicles equipped with ABS (Anti-Lock

Brake System), disconnect wiring harness

connectors from ABS Electronic Control Unit.

The ABS Electronic Control Unit is located in

the 1st baggage compartment.

7. Cover electronic control components and

wiring to protect from hot sparks, etc.

8. Do not connect welding cables to electronic

control components.

9. Do the appropriate welding on vehicle.

Caution: Position welding machine ground

clamp as close as possible to the work.

10.When welding is complete, reconnect ECM,

ECU, ABS electronic control units, etc.

11.Terminate by reconnecting “Ground” cables

to battery terminals.