6acutherm.com | THERMA-FUSER - Manual

THERMA-FUSER

THERMA-FUSER - Manual | acutherm.com

BLOW PATTERNS (TF-C, TF-CW, AND TF-HC)

A major selling feature of the TF-C, TF-CW and TF-HC diffusers is the ability to easily

add or remove blow patterns in the field. This is done by blocking the air off behind

the blades on the appropriate sides.

DO NOT:

• Disconnect the spokes.

• Tape, screw or otherwise lock the blade closed. This unbalances the loads on

the center bearings.

• Block the four venturi nozzles.

DO block air flow behind the blades or between the standoffs. (Standoffs are the

supports between the housing and the diffusion plate.) Ways to do this are:

1. Factory installed directional baffles. These are strips of metal wrapped around

the standoffs to block one, two or three sides. These can be removed in the field

after first removing the diffusion plate assembly.

2. Field installed directional baffles. These are trapezoid pieces of metal that are laid

horizontally on top of the corner supports. Dimensions are as shown in Fig. 5.

Directional baffles can be made locally or purchased from Acutherm.

3. 1-5/8" diameter x 10" long (Armaflex) for split system refrigeration lines. Insert

between the housing and the diffusion plate/blade assembly and wedge between

the standoffs (See Fig. 6). Not supplied by Acutherm but easily available in

the field.

The rule for blocking the appropriate side is: Always block the thermostat side. (See

Fig. 7 for examples.)

NOTE: Some earlier TF-C and TF-CW models have one induction slot by the

thermostat instead of four venturi nozzles. The rule for blocking the appropriate side

for this version is: Never block the thermostat side.

When blocking for direction, the air volume for a given static pressure is reduced from

max. air volume listed in the performance guide by:

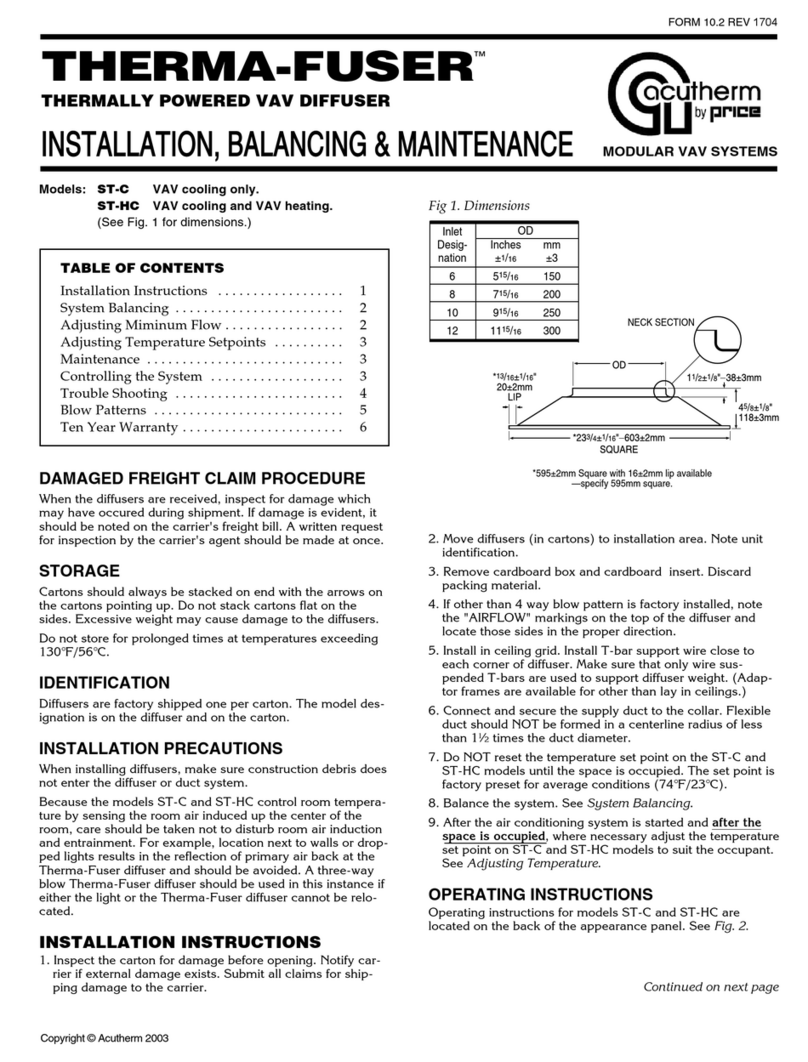

FIG. 5 FIELD INSTALLED BAFFLE

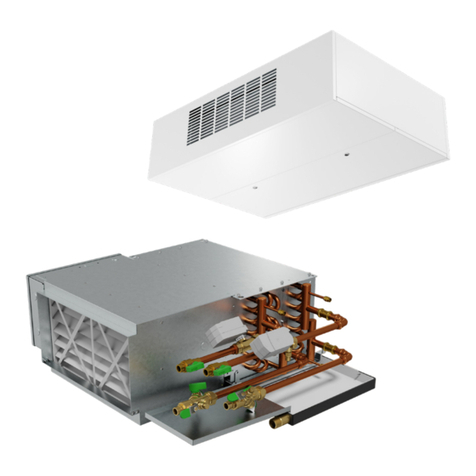

FIG. 6 FOAM DIRECTIONAL BAFFLE

Blow Patterns

3 way

2 way

1 way

Blade Opening

0.78

0.56

0.34

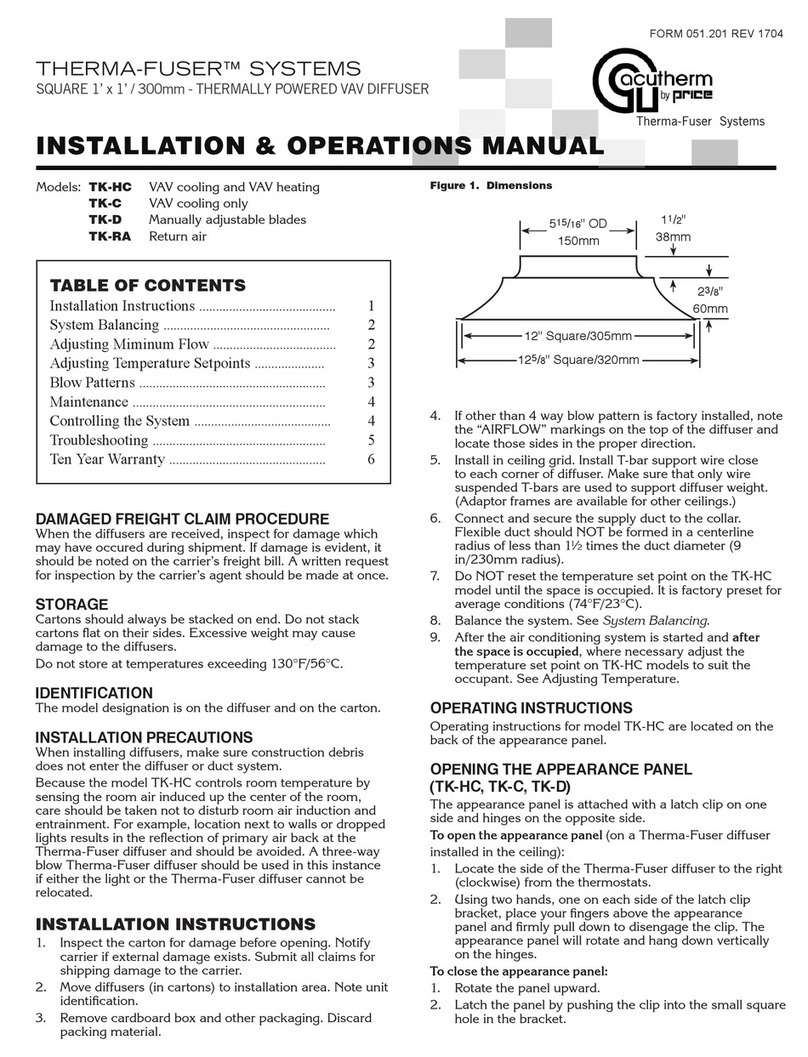

3-WAY D3 2-WAY D2 OPPOSITE 2-WAY D2C CORNER 1-WAY D1

FIG. 7 BLOW PATTERNS

The thermostats may be slightly harder to screw in or out when

warm because the shaft is extended putting more pressure on the

thermostat. If you are unable to turn the thermostat in this situa-

tion, cool the thermostat by holding an ice cube to the large end.

The shaft will then contract and the thermostat will turn easily for

adjustment.

For proper operation make sure that the extension shaft on the

cooling thermostat is in the actuator arm dimple. Check by sight-

ing through the control plate viewport. (See Fig. 4) If the shaft is

not in the dimple, cool the thermostat by holding ice to the large

end until the shafts retracts and move the shaft into the dimple.

BLOW PATTERNS (TF-C, TF-CW, AND

TF-HC)

A major selling feature of the TF-C, TF-CW and TF-HC diffusers

is the ability to easily add or remove blow patterns in the field.

This is done by blocking the air off behind the blades on the

appropriate sides.

DO NOT:

— Disconnect the spokes.

— Tape, screw or otherwise lock the blade closed. This unbalan-

ces the loads on the center bearings.

— Block the four venturi nozzles.

DO block air flow behind the blades or between the standoffs.

(Standoffs are the supports between the housing and the diffu-

sion plate.) Ways to do this are:

1. Factory installed directional baffles. These are strips of metal

wrapped around the standoffs to block one, two or three sides.

These can be removed in the field after first removing the dif-

fusion plate assembly.

2. Field installed directional baffles. These are trapezoid pieces of

metal that are laid horizontally on top of the corner supports.

Dimensions are as shown in Fig. 5. Directional baffles can be

made locally or purchased from Acutherm.

3. 1-5/8" diameter x 10" long (Armaflex) for split system refrig-

eration lines. Insert between the housing and the diffusion

plate/blade assembly and wedge between the standoffs (See

Fig. 6). Not supplied by Acutherm but easily available in the

field.

The rule for blocking the appropriate side is: Always block the ther-

mostat side. (See Fig. 7 for examples.)

Note: Some earlier TF-C and TF-CW models have one induction

slot by the thermostat instead of four venturi nozzles. The

rule for blocking the appropriate side for this version is:

Never block the thermostat side.

When blocking for direction, the air volume for a given static

pressure is reduced from max. air volume listed in the perform-

ance guide by:

Blow Patterns Reduction

3 way .78

2 way .56

1 way .34

MAINTENANCE

The moving parts of the TF Therma-Fuser diffuser have no main-

tenance or lubrication requirements. We are often asked to rec-

ommend periodic maintenance procedures and a spare parts

stock. Recommended maintenance is to clean the outer surfaces

of the Therma-Fuser diffuser—nothing else. We do not recom-

mend stocking any spare parts. Our customers also confirm that

stocking is unnecessary.

DAMPER BLADE ADJUSTMENT (TF-C,

TF-CW, AND TF-HC)

If one of the blades does not track uniformly with the others,

make a simple field adjustment to the spoke wire which connects

the blade to the control plate. A pair of needle nose pliers or sim-

ilar tool is all that is required. If the blade does not open as rap-

idly as the other blades, insert the pliers inside of the closed

loope in the spoke wire and slightly expand the loop. If the blade

opens more rapidly than the others, place the pliers outside of

the closed loop and slightly compress the loop. No other adjust-

ment is required.

Continued on next page

Fig. 5 Field installed baffle

Fig. 6 Foam directional baffle

87/16" – 214mm

1511/16" – 398mm

3/4"–19mm Dia.

19/16" – 40mm

45° TYP.

Corners Clipped – No Sharp Points

33/4" – 95mm

3/32"

2mm TYP.

3/16" – 1mm TYP.

THERMA-FUSER

DIFFUSER

THERMA-FUSER

DIFFUSER

Directional Baffle

Fig. 7 Blow Patterns

3-Way D3 2-Way D2 Opposite

2-Way D2C Corner 1-Way D1

Page 3

The thermostats may be slightly harder to screw in or out when

warm because the shaft is extended putting more pressure on the

thermostat. If you are unable to turn the thermostat in this situa-

tion, cool the thermostat by holding an ice cube to the large end.

The shaft will then contract and the thermostat will turn easily for

adjustment.

For proper operation make sure that the extension shaft on the

cooling thermostat is in the actuator arm dimple. Check by sight-

ing through the control plate viewport. (See Fig. 4) If the shaft is

not in the dimple, cool the thermostat by holding ice to the large

end until the shafts retracts and move the shaft into the dimple.

BLOW PATTERNS (TF-C, TF-CW, AND

TF-HC)

A major selling feature of the TF-C, TF-CW and TF-HC diffusers

is the ability to easily add or remove blow patterns in the field.

This is done by blocking the air off behind the blades on the

appropriate sides.

DO NOT:

— Disconnect the spokes.

— Tape, screw or otherwise lock the blade closed. This unbalan-

ces the loads on the center bearings.

— Block the four venturi nozzles.

DO block air flow behind the blades or between the standoffs.

(Standoffs are the supports between the housing and the diffu-

sion plate.) Ways to do this are:

1. Factory installed directional baffles. These are strips of metal

wrapped around the standoffs to block one, two or three sides.

These can be removed in the field after first removing the dif-

fusion plate assembly.

2. Field installed directional baffles. These are trapezoid pieces of

metal that are laid horizontally on top of the corner supports.

Dimensions are as shown in Fig. 5. Directional baffles can be

made locally or purchased from Acutherm.

3. 1-5/8" diameter x 10" long (Armaflex) for split system refrig-

eration lines. Insert between the housing and the diffusion

plate/blade assembly and wedge between the standoffs (See

Fig. 6). Not supplied by Acutherm but easily available in the

field.

The rule for blocking the appropriate side is: Always block the ther-

mostat side. (See Fig. 7 for examples.)

Note: Some earlier TF-C and TF-CW models have one induction

slot by the thermostat instead of four venturi nozzles. The

rule for blocking the appropriate side for this version is:

Never block the thermostat side.

When blocking for direction, the air volume for a given static

pressure is reduced from max. air volume listed in the perform-

ance guide by:

Blow Patterns Reduction

3 way .78

2 way .56

1 way .34

MAINTENANCE

The moving parts of the TF Therma-Fuser diffuser have no main-

tenance or lubrication requirements. We are often asked to rec-

ommend periodic maintenance procedures and a spare parts

stock. Recommended maintenance is to clean the outer surfaces

of the Therma-Fuser diffuser—nothing else. We do not recom-

mend stocking any spare parts. Our customers also confirm that

stocking is unnecessary.

DAMPER BLADE ADJUSTMENT (TF-C,

TF-CW, AND TF-HC)

If one of the blades does not track uniformly with the others,

make a simple field adjustment to the spoke wire which connects

the blade to the control plate. A pair of needle nose pliers or sim-

ilar tool is all that is required. If the blade does not open as rap-

idly as the other blades, insert the pliers inside of the closed

loope in the spoke wire and slightly expand the loop. If the blade

opens more rapidly than the others, place the pliers outside of

the closed loop and slightly compress the loop. No other adjust-

ment is required.

Continued on next page

Fig. 5 Field installed baffle

Fig. 6 Foam directional baffle

87/16" – 214mm

1511/16" – 398mm

3/4"–19mm Dia.

19/16" – 40mm

45° TYP.

Corners Clipped – No Sharp Points

33/4" – 95mm

3/32"

2mm TYP.

3/16" – 1mm TYP.

THERMA-FUSER

DIFFUSER

THERMA-FUSER

DIFFUSER

Directional Baffle

Fig. 7 Blow Patterns

3-Way D3 2-Way D2 Opposite

2-Way D2C Corner 1-Way D1

Page 3

The thermostats may be slightly harder to screw in or out when

warm because the shaft is extended putting more pressure on the

thermostat. If you are unable to turn the thermostat in this situa-

tion, cool the thermostat by holding an ice cube to the large end.

The shaft will then contract and the thermostat will turn easily for

adjustment.

For proper operation make sure that the extension shaft on the

cooling thermostat is in the actuator arm dimple. Check by sight-

ing through the control plate viewport. (See Fig. 4) If the shaft is

not in the dimple, cool the thermostat by holding ice to the large

end until the shafts retracts and move the shaft into the dimple.

BLOW PATTERNS (TF-C, TF-CW, AND

TF-HC)

A major selling feature of the TF-C, TF-CW and TF-HC diffusers

is the ability to easily add or remove blow patterns in the field.

This is done by blocking the air off behind the blades on the

appropriate sides.

DO NOT:

— Disconnect the spokes.

— Tape, screw or otherwise lock the blade closed. This unbalan-

ces the loads on the center bearings.

— Block the four venturi nozzles.

DO block air flow behind the blades or between the standoffs.

(Standoffs are the supports between the housing and the diffu-

sion plate.) Ways to do this are:

1. Factory installed directional baffles. These are strips of metal

wrapped around the standoffs to block one, two or three sides.

These can be removed in the field after first removing the dif-

fusion plate assembly.

2. Field installed directional baffles. These are trapezoid pieces of

metal that are laid horizontally on top of the corner supports.

Dimensions are as shown in Fig. 5. Directional baffles can be

made locally or purchased from Acutherm.

3. 1-5/8" diameter x 10" long (Armaflex) for split system refrig-

eration lines. Insert between the housing and the diffusion

plate/blade assembly and wedge between the standoffs (See

Fig. 6). Not supplied by Acutherm but easily available in the

field.

The rule for blocking the appropriate side is: Always block the ther-

mostat side. (See Fig. 7 for examples.)

Note: Some earlier TF-C and TF-CW models have one induction

slot by the thermostat instead of four venturi nozzles. The

rule for blocking the appropriate side for this version is:

Never block the thermostat side.

When blocking for direction, the air volume for a given static

pressure is reduced from max. air volume listed in the perform-

ance guide by:

Blow Patterns Reduction

3 way .78

2 way .56

1 way .34

MAINTENANCE

The moving parts of the TF Therma-Fuser diffuser have no main-

tenance or lubrication requirements. We are often asked to rec-

ommend periodic maintenance procedures and a spare parts

stock. Recommended maintenance is to clean the outer surfaces

of the Therma-Fuser diffuser—nothing else. We do not recom-

mend stocking any spare parts. Our customers also confirm that

stocking is unnecessary.

DAMPER BLADE ADJUSTMENT (TF-C,

TF-CW, AND TF-HC)

If one of the blades does not track uniformly with the others,

make a simple field adjustment to the spoke wire which connects

the blade to the control plate. A pair of needle nose pliers or sim-

ilar tool is all that is required. If the blade does not open as rap-

idly as the other blades, insert the pliers inside of the closed

loope in the spoke wire and slightly expand the loop. If the blade

opens more rapidly than the others, place the pliers outside of

the closed loop and slightly compress the loop. No other adjust-

ment is required.

Continued on next page

Fig. 5 Field installed baffle

Fig. 6 Foam directional baffle

87/16" – 214mm

1511/16" – 398mm

3/4"–19mm Dia.

19/16" – 40mm

45° TYP.

Corners Clipped – No Sharp Points

33/4" – 95mm

3/32"

2mm TYP.

3/16" – 1mm TYP.

THERMA-FUSER

DIFFUSER

THERMA-FUSER

DIFFUSER

Directional Baffle

Fig. 7 Blow Patterns

3-Way D3 2-Way D2 Opposite

2-Way D2C Corner 1-Way D1

Page 3

The thermostats may be slightly harder to screw in or out when

warm because the shaft is extended putting more pressure on the

thermostat. If you are unable to turn the thermostat in this situa-

tion, cool the thermostat by holding an ice cube to the large end.

The shaft will then contract and the thermostat will turn easily for

adjustment.

For proper operation make sure that the extension shaft on the

cooling thermostat is in the actuator arm dimple. Check by sight-

ing through the control plate viewport. (See Fig. 4) If the shaft is

not in the dimple, cool the thermostat by holding ice to the large

end until the shafts retracts and move the shaft into the dimple.

BLOW PATTERNS (TF-C, TF-CW, AND

TF-HC)

A major selling feature of the TF-C, TF-CW and TF-HC diffusers

is the ability to easily add or remove blow patterns in the field.

This is done by blocking the air off behind the blades on the

appropriate sides.

DO NOT:

— Disconnect the spokes.

— Tape, screw or otherwise lock the blade closed. This unbalan-

ces the loads on the center bearings.

— Block the four venturi nozzles.

DO block air flow behind the blades or between the standoffs.

(Standoffs are the supports between the housing and the diffu-

sion plate.) Ways to do this are:

1. Factory installed directional baffles. These are strips of metal

wrapped around the standoffs to block one, two or three sides.

These can be removed in the field after first removing the dif-

fusion plate assembly.

2. Field installed directional baffles. These are trapezoid pieces of

metal that are laid horizontally on top of the corner supports.

Dimensions are as shown in Fig. 5. Directional baffles can be

made locally or purchased from Acutherm.

3. 1-5/8" diameter x 10" long (Armaflex) for split system refrig-

eration lines. Insert between the housing and the diffusion

plate/blade assembly and wedge between the standoffs (See

Fig. 6). Not supplied by Acutherm but easily available in the

field.

The rule for blocking the appropriate side is: Always block the ther-

mostat side. (See Fig. 7 for examples.)

Note: Some earlier TF-C and TF-CW models have one induction

slot by the thermostat instead of four venturi nozzles. The

rule for blocking the appropriate side for this version is:

Never block the thermostat side.

When blocking for direction, the air volume for a given static

pressure is reduced from max. air volume listed in the perform-

ance guide by:

Blow Patterns Reduction

3 way .78

2 way .56

1 way .34

MAINTENANCE

The moving parts of the TF Therma-Fuser diffuser have no main-

tenance or lubrication requirements. We are often asked to rec-

ommend periodic maintenance procedures and a spare parts

stock. Recommended maintenance is to clean the outer surfaces

of the Therma-Fuser diffuser—nothing else. We do not recom-

mend stocking any spare parts. Our customers also confirm that

stocking is unnecessary.

DAMPER BLADE ADJUSTMENT (TF-C,

TF-CW, AND TF-HC)

If one of the blades does not track uniformly with the others,

make a simple field adjustment to the spoke wire which connects

the blade to the control plate. A pair of needle nose pliers or sim-

ilar tool is all that is required. If the blade does not open as rap-

idly as the other blades, insert the pliers inside of the closed

loope in the spoke wire and slightly expand the loop. If the blade

opens more rapidly than the others, place the pliers outside of

the closed loop and slightly compress the loop. No other adjust-

ment is required.

Continued on next page

Fig. 5 Field installed baffle

Fig. 6 Foam directional baffle

87/16" – 214mm

1511/16" – 398mm

3/4"–19mm Dia.

19/16" – 40mm

45° TYP.

Corners Clipped – No Sharp Points

33/4" – 95mm

3/32"

2mm TYP.

3/16" – 1mm TYP.

THERMA-FUSER

DIFFUSER

THERMA-FUSER

DIFFUSER

Directional Baffle

Fig. 7 Blow Patterns

3-Way D3 2-Way D2 Opposite

2-Way D2C Corner 1-Way D1

Page 3

The thermostats may be slightly harder to screw in or out when

warm because the shaft is extended putting more pressure on the

thermostat. If you are unable to turn the thermostat in this situa-

tion, cool the thermostat by holding an ice cube to the large end.

The shaft will then contract and the thermostat will turn easily for

adjustment.

For proper operation make sure that the extension shaft on the

cooling thermostat is in the actuator arm dimple. Check by sight-

ing through the control plate viewport. (See Fig. 4) If the shaft is

not in the dimple, cool the thermostat by holding ice to the large

end until the shafts retracts and move the shaft into the dimple.

BLOW PATTERNS (TF-C, TF-CW, AND

TF-HC)

A major selling feature of the TF-C, TF-CW and TF-HC diffusers

is the ability to easily add or remove blow patterns in the field.

This is done by blocking the air off behind the blades on the

appropriate sides.

DO NOT:

— Disconnect the spokes.

— Tape, screw or otherwise lock the blade closed. This unbalan-

ces the loads on the center bearings.

— Block the four venturi nozzles.

DO block air flow behind the blades or between the standoffs.

(Standoffs are the supports between the housing and the diffu-

sion plate.) Ways to do this are:

1. Factory installed directional baffles. These are strips of metal

wrapped around the standoffs to block one, two or three sides.

These can be removed in the field after first removing the dif-

fusion plate assembly.

2. Field installed directional baffles. These are trapezoid pieces of

metal that are laid horizontally on top of the corner supports.

Dimensions are as shown in Fig. 5. Directional baffles can be

made locally or purchased from Acutherm.

3. 1-5/8" diameter x 10" long (Armaflex) for split system refrig-

eration lines. Insert between the housing and the diffusion

plate/blade assembly and wedge between the standoffs (See

Fig. 6). Not supplied by Acutherm but easily available in the

field.

The rule for blocking the appropriate side is: Always block the ther-

mostat side. (See Fig. 7 for examples.)

Note: Some earlier TF-C and TF-CW models have one induction

slot by the thermostat instead of four venturi nozzles. The

rule for blocking the appropriate side for this version is:

Never block the thermostat side.

When blocking for direction, the air volume for a given static

pressure is reduced from max. air volume listed in the perform-

ance guide by:

Blow Patterns Reduction

3 way .78

2 way .56

1 way .34

MAINTENANCE

The moving parts of the TF Therma-Fuser diffuser have no main-

tenance or lubrication requirements. We are often asked to rec-

ommend periodic maintenance procedures and a spare parts

stock. Recommended maintenance is to clean the outer surfaces

of the Therma-Fuser diffuser—nothing else. We do not recom-

mend stocking any spare parts. Our customers also confirm that

stocking is unnecessary.

DAMPER BLADE ADJUSTMENT (TF-C,

TF-CW, AND TF-HC)

If one of the blades does not track uniformly with the others,

make a simple field adjustment to the spoke wire which connects

the blade to the control plate. A pair of needle nose pliers or sim-

ilar tool is all that is required. If the blade does not open as rap-

idly as the other blades, insert the pliers inside of the closed

loope in the spoke wire and slightly expand the loop. If the blade

opens more rapidly than the others, place the pliers outside of

the closed loop and slightly compress the loop. No other adjust-

ment is required.

Continued on next page

Fig. 5 Field installed baffle

Fig. 6 Foam directional baffle

87/16" – 214mm

1511/16" – 398mm

3/4"–19mm Dia.

19/16" – 40mm

45° TYP.

Corners Clipped – No Sharp Points

33/4" – 95mm

3/32"

2mm TYP.

3/16" – 1mm TYP.

THERMA-FUSER

DIFFUSER

THERMA-FUSER

DIFFUSER

Directional Baffle

Fig. 7 Blow Patterns

3-Way D3 2-Way D2 Opposite

2-Way D2C Corner 1-Way D1

Page 3

The thermostats may be slightly harder to screw in or out when

warm because the shaft is extended putting more pressure on the

thermostat. If you are unable to turn the thermostat in this situa-

tion, cool the thermostat by holding an ice cube to the large end.

The shaft will then contract and the thermostat will turn easily for

adjustment.

For proper operation make sure that the extension shaft on the

cooling thermostat is in the actuator arm dimple. Check by sight-

ing through the control plate viewport. (See Fig. 4) If the shaft is

not in the dimple, cool the thermostat by holding ice to the large

end until the shafts retracts and move the shaft into the dimple.

BLOW PATTERNS (TF-C, TF-CW, AND

TF-HC)

A major selling feature of the TF-C, TF-CW and TF-HC diffusers

is the ability to easily add or remove blow patterns in the field.

This is done by blocking the air off behind the blades on the

appropriate sides.

DO NOT:

— Disconnect the spokes.

— Tape, screw or otherwise lock the blade closed. This unbalan-

ces the loads on the center bearings.

— Block the four venturi nozzles.

DO block air flow behind the blades or between the standoffs.

(Standoffs are the supports between the housing and the diffu-

sion plate.) Ways to do this are:

1. Factory installed directional baffles. These are strips of metal

wrapped around the standoffs to block one, two or three sides.

These can be removed in the field after first removing the dif-

fusion plate assembly.

2. Field installed directional baffles. These are trapezoid pieces of

metal that are laid horizontally on top of the corner supports.

Dimensions are as shown in Fig. 5. Directional baffles can be

made locally or purchased from Acutherm.

3. 1-5/8" diameter x 10" long (Armaflex) for split system refrig-

eration lines. Insert between the housing and the diffusion

plate/blade assembly and wedge between the standoffs (See

Fig. 6). Not supplied by Acutherm but easily available in the

field.

The rule for blocking the appropriate side is: Always block the ther-

mostat side. (See Fig. 7 for examples.)

Note: Some earlier TF-C and TF-CW models have one induction

slot by the thermostat instead of four venturi nozzles. The

rule for blocking the appropriate side for this version is:

Never block the thermostat side.

When blocking for direction, the air volume for a given static

pressure is reduced from max. air volume listed in the perform-

ance guide by:

Blow Patterns Reduction

3 way .78

2 way .56

1 way .34

MAINTENANCE

The moving parts of the TF Therma-Fuser diffuser have no main-

tenance or lubrication requirements. We are often asked to rec-

ommend periodic maintenance procedures and a spare parts

stock. Recommended maintenance is to clean the outer surfaces

of the Therma-Fuser diffuser—nothing else. We do not recom-

mend stocking any spare parts. Our customers also confirm that

stocking is unnecessary.

DAMPER BLADE ADJUSTMENT (TF-C,

TF-CW, AND TF-HC)

If one of the blades does not track uniformly with the others,

make a simple field adjustment to the spoke wire which connects

the blade to the control plate. A pair of needle nose pliers or sim-

ilar tool is all that is required. If the blade does not open as rap-

idly as the other blades, insert the pliers inside of the closed

loope in the spoke wire and slightly expand the loop. If the blade

opens more rapidly than the others, place the pliers outside of

the closed loop and slightly compress the loop. No other adjust-

ment is required.

Continued on next page

Fig. 5 Field installed baffle

Fig. 6 Foam directional baffle

87/16" – 214mm

1511/16" – 398mm

3/4"–19mm Dia.

19/16" – 40mm

45° TYP.

Corners Clipped – No Sharp Points

33/4" – 95mm

3/32"

2mm TYP.

3/16" – 1mm TYP.

THERMA-FUSER

DIFFUSER

Directional Baffle

Fig. 7 Blow Patterns

3-Way D3 2-Way D2 Opposite

2-Way D2C Corner 1-Way D1

Page 3