Page 3

Continued on NEXT Page

CONTROLLING THE SYSTEM

(TLW-C and TLW-CW)

References:

• System Design, p 4, TLW brochure, Form 23.1.

• Chapters 2.2, 3.1 and 3.2, pp 6, 7 and 8, Designing Modular

VAV Systems, Form 5.2.

• Air Handling and Fan Coil Units Subzoned with Therma-Fuser

VAV modules, Form 6.7.

• DX Equipment Zoned with Therma-Fuser VAV Modules, Form

6.5.

SUPPLY AIR TEMPERATURE

The source of cooling is controlled from supply air temperature.

As with all VAV systems, the goals are to achieve a constant sup-

ply air temperature (may be reset to another constant supply air

temperature) and to limit the supply air temperature. Limits for

cooling supply air temperature should be between 50°F/10°C and

68°F/20°C. These objectives are best achieved by modulating

chilled water valves, and other variable equipment from supply air

temperature. On/off equipment such as DX compressors are

cycled from supply air temperature. Use a discharge air sensor

for the supply air temperature signal.

For TLW-CW models, mode change between heating,

recirculation and cooling is controlled from room temperature.

Signals from one or more room temperature sensors may be used

for mode change. When using more than one sensor, a “majority

rules” approach is recommended. Constant volume heating

temperature for TL-CW models should be as low as possible but

no lower than 80°F / 26.5° C.

STATIC PRESSURE

As with all VAV systems, the fan must run continuously during

occupied times. Goals of static pressure control are to provide

enough static pressure to obtain the required air volume

especially at the diffuser farthest from the fan, to avoid diffuser

noise by limiting static pressure at both full flow and turndown

and to provide pressure independence or consistent operation as

the system flow changes.

These objectives can be achieved with the usual methods of

automatic static pressure control: bypass dampers, discharge

dampers, zone dampers, and fan control (variable speed drives,

inlet dampers, etc.). Locate the static pressure sensor as far down

the duct as possible—at least 2/3 down the duct from the first

takeoff.

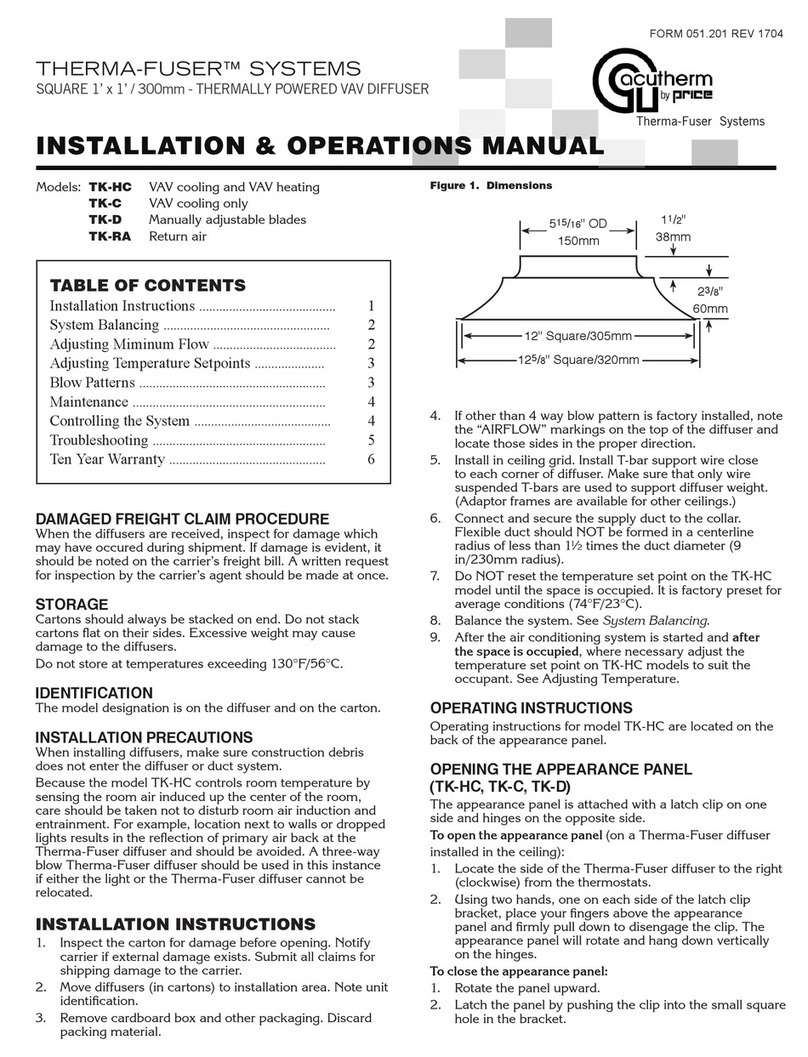

FIRE WALLS

For soffit installations, the fire wall can be extended up behind the

diffuser. See Fig. 3.

For installations with the diffuser face flush with the wall, the fire

wall should be extended beneath the diffuser and then up behind

it. See Fig. 9.

A fire damper should be installed in the supply air duct where it

penetrates the fire wall.

MAINTENANCE

The moving parts of the TLW Therma-Fuser diffuser have no

maintenance or lubrication requirements. We are often asked to

recommend periodic maintenance procedures and a spare parts

stock. Recommended maintenance is to clean the outer surfaces

of the Therma-Fuser diffuser—nothing else. We do not recom-

mend stocking any spare parts. Our customers also confirm that

stocking is unnecessary.

ADJUSTING TEMPERATURE

SETPOINT (TLW-C and TLW-CW)

The room temperature set point is adjusted by turning the phil-

lips screw with a phillips screwdriver to move the thermostat in

or out. Four slot units have two thermostats, each controlling two

slots, which are separately adjusted. The temperature scale,

located behind the thermostat slide, can be viewed at the end of

the diffuser slot. Each graduation on the temperature scale is

1°F/.55°C providing an easy way of determining the amount of

adjustment. Turning the phillips screw clockwise will move the

slide out over the temperature scale for a cooler set point. Turn-

ing the phillips screw counterclockwise moves the thermostat

slide in to a warmer setpoint. About 1½ turns will change the set-

point by 1°F/.55°C.

The diffuser is factory set to maintain approximately 74°F/23°C.

It is not necessary to adjust the temperature set point at time of

installation. Instead, make any adjustments after the system has

been started and the space is occupied. Then adjust only those

Therma-Fuser difusers where occupants are uncomfortable at

the factory set point.

Readjust to the factory set point by turning the phillips screw

clockwise (cooler set point) until the thermostat slide hits the

stop. Then turn counter clockwise (warmer) for nine turns.

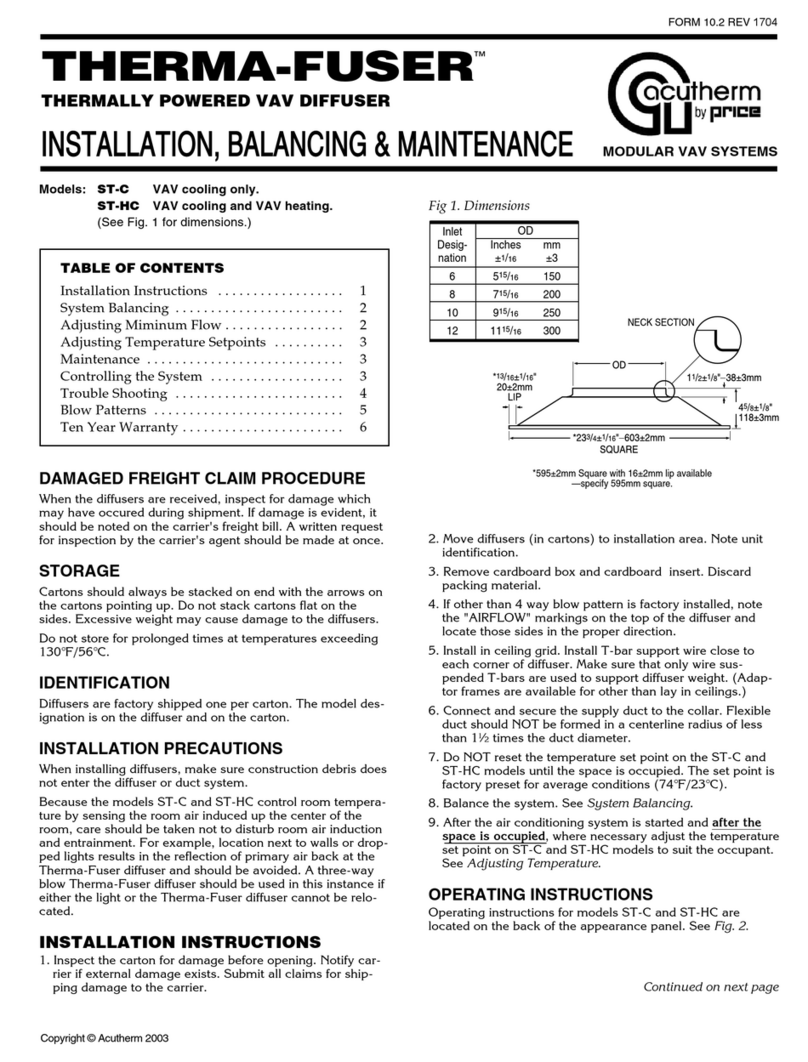

Figure 8. Adjusting Temperature

Read the temperature set point at the bottom of the thermostat slide.

C

O

O

L

E

R

W

A

R

M

E

R

Warmer

Cooler

W

C

78°F/25°C

74°F/23°C

70°F/21°C

Thermostat

Slide

Temperature

Scale

Recommended

Action

Adjust for higher room temperature set point.

Therma-Fuser diffuser is correct. Check if cooling

is still required, and if not, turn cooling unit off.

Therma-Fuser diffuser is correct. Check for lack of

air or for too warm air temperature.

Adjust for lower room temperature set point.

Reduce static pressure. Recommended static

pressure is .05 to .25 in. wg / 12 to 62 Pa at the

inlet of the diffuser.

Blade

Position

Open

Closed

Open

Closed

Any

Room

Temp.

Too

Cold

Too

Warm

Any

Mode

Cooling

TLW-C

TLW-CW

Too

Noisy

RECOMMENDED ADJUSTMENTS FOR

VARIOUS CONDITIONS

Figure 9. Fire Wall Around Diffuser

FIRE WALL