3

priceindustries.com/vavdiffusers | VARITHERM SMALL SQUARE VAV DIFFUSER - Manual

VARITHERM SMALL SQUARE VAV DIFFUSER

VAV systems are balanced for design air volume at maximum air flow and systems using Varitherm Small Square VAV VAV diffusers

are no exception. When all the Varitherm Small Square VAV diffusers are set for maximum air flow by fully opening them, the

system is really a constant air volume system and is balanced as a constant volume system. Balancing dampers are best located

at the takeoff before the runout to the Varitherm Small Square VAV diffuser.

1. Prepare the system for balancing. (Make necessarychecks

for diversity, fan capacities, fan rotation,miminum outside

air requirements, duct leaks andstatic pressure controller

design settings. Set outsideair control damper for mini-

mum air and return aircontrol damper for maximum air.)

2. Open Varitherm Small Square VAV diffusers.

a. Open appearance panel.

b. Using a flat blade screwdriver or coin, turn thedamper

opening cam clockwise until the damperblades are

fully open and the blade tips toucheach other.

See Fig. 3.

c. Close appearance panel.

3. Start fans, adjust system for 100% air flow and

makesystem checks. (Measure static pressure across

filtersand coils and at sensor for static pressure controller.

Measure supply, return and branch duct air flow.)

4. Place a direct reading diffuser balancing hood over theface

of each Varitherm Small Square VAV diffuser and adjust

damperat duct takeoff to obtain maximum design air

volume.If a velocity meter is used, measure discharge

velocityat the housing (See Fig. 3). Multiply the velocity in

fpmtimes Akof .12 ft2to get air flow in cfm.

5. Return Varitherm Small Square VAV diffusers to operating

condition.

a. Open appearance panel.

b. Turn damper opening cam to allow damper blades

to close.

c. Close appearance panel.

Balancing (VKD-D)

1. The damper blade opening is factory set at ¾inch/19mm

(See Fig. 4). Readjust where necessary byturning the

damper opening cam (See Fig. 2).

2. Place a direct reading diffuser balancing hood over theface

of each VKD-D diffuser and adjust damper at ducttakeoff

to obtain design air volume. If a velocity meteris used,

measure discharge velocity at the housing (See Fig. 3).

Multiply the velocity in fpm times Akof .12 ft2toget air flow

in cfm.

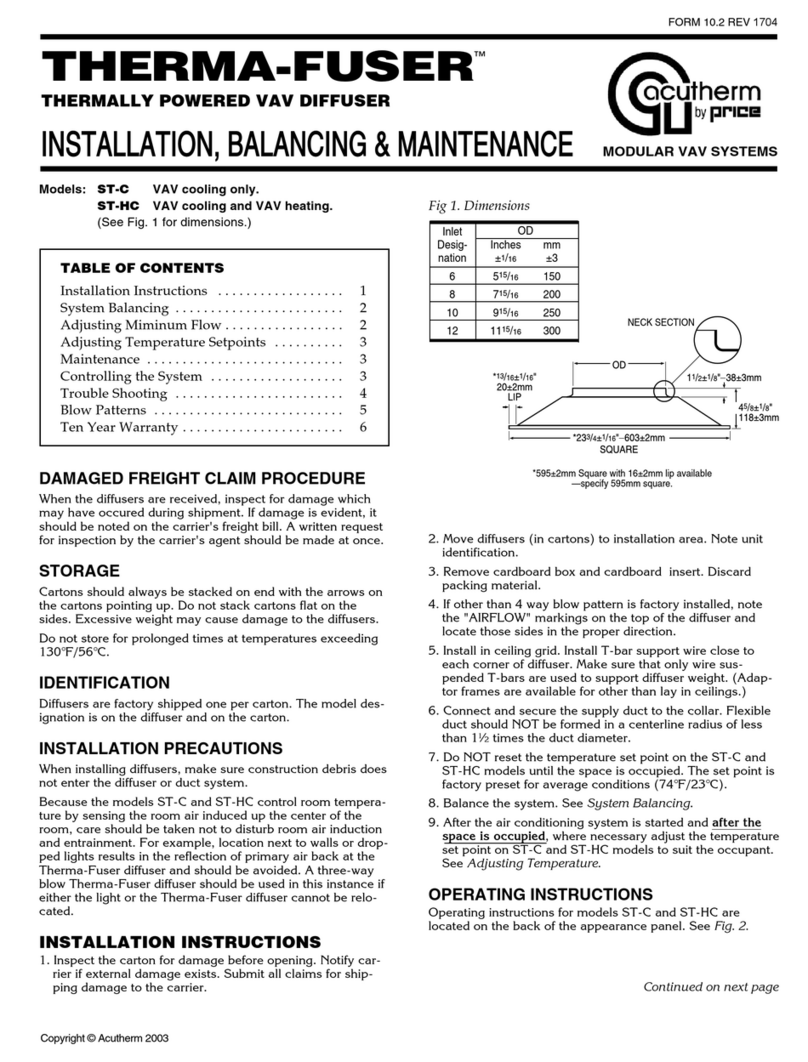

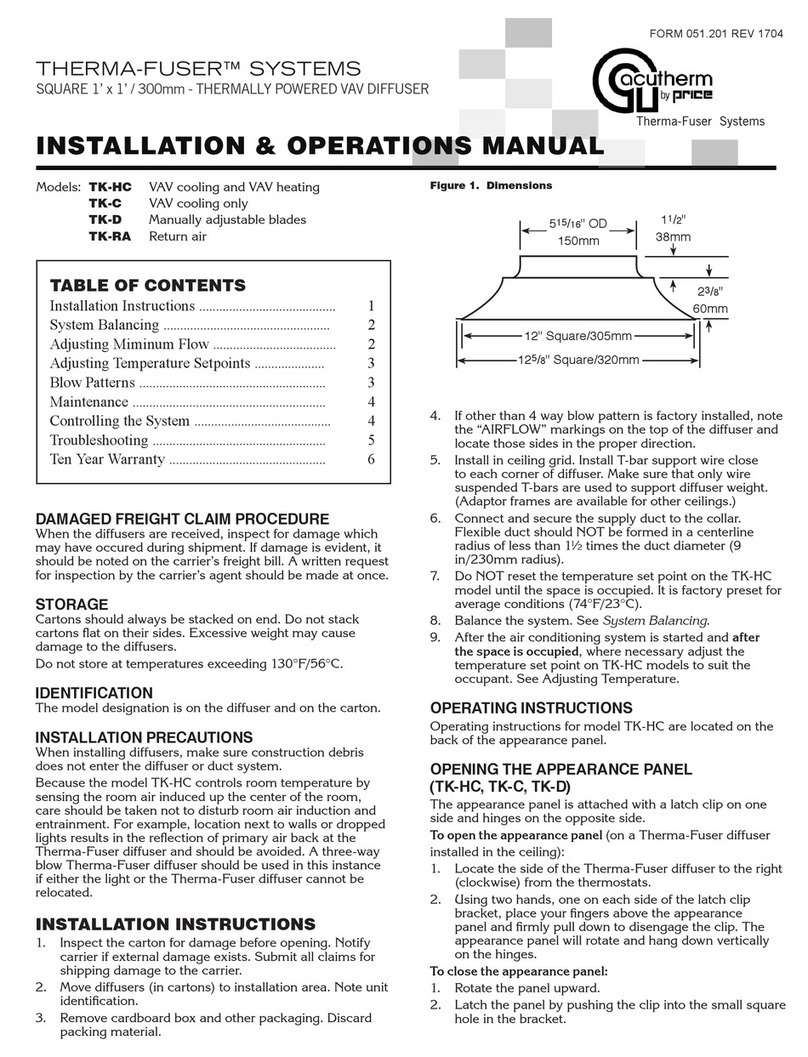

SYSTEM BALANCING (VKD-HC, VKD-C)

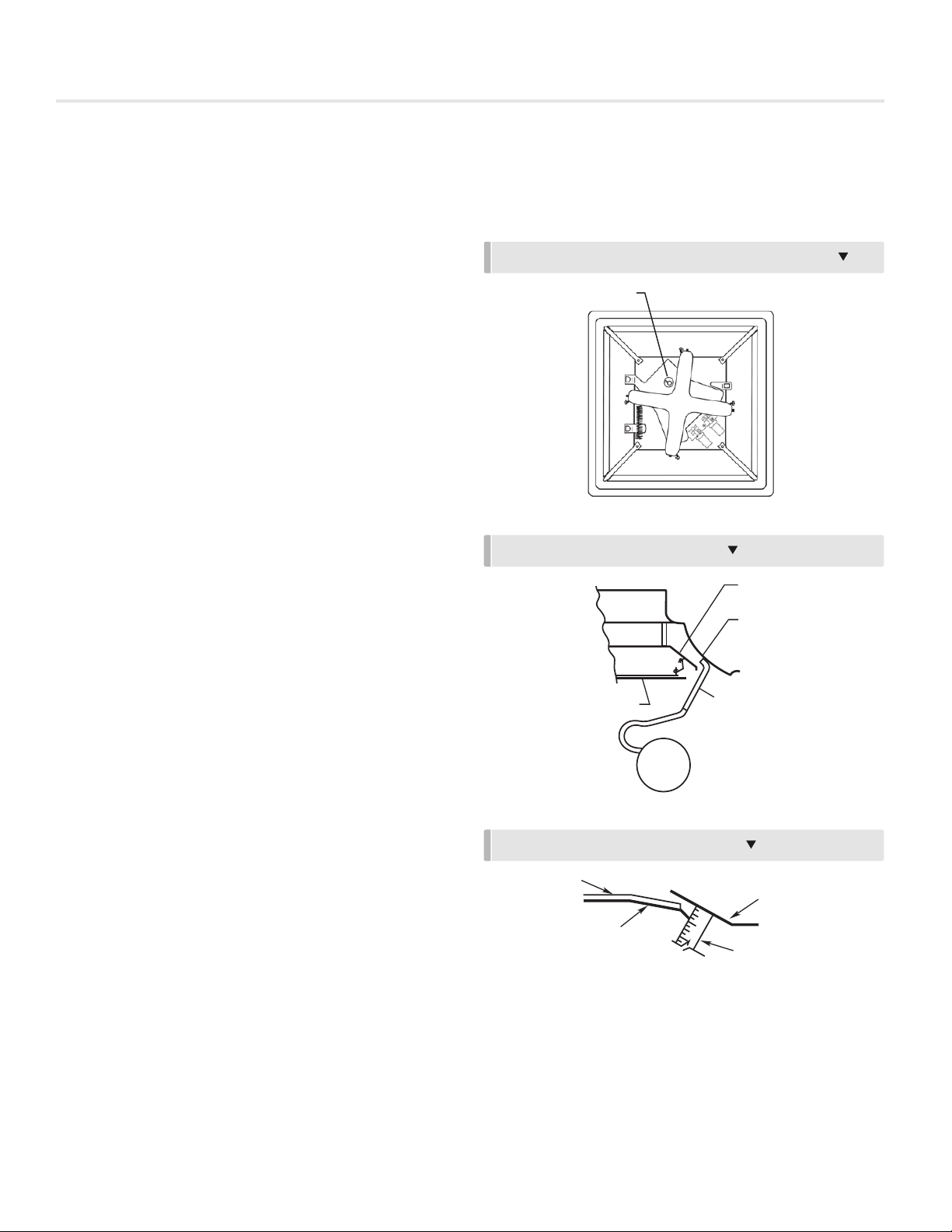

FIG. 2 TURN DAMPER OPENING CAM TO OPEN FOR BALANCING

FIG. 3 MEASURING DISCHARGE VELOCITY

FIG. 4 MEASURING DAMPER BLADE OPENING

To remove the appearance panel:

1. Open appearance panel as described above.

2. Rotate the appearance panel away from the latch clip

bracket to force the hinge hooks open on the panel.

3. Slightly lift the panel to remove from the hinges.

To reattach the appearance panel:

1. Hang the appearance panel on the hinges.

2. Press the hinge hooks against the panel to close

around the hinge brackets.

3. Close panel as described above.

SYSTEM BALANCING (TK-HC, TK-C)

VAV systems are balanced for design air volume at

maximum air flow and systems using Therma-Fuser VAV

diffusers are no exception. When all the Therma-Fuser

diffusers are set for maximum air flow by fully opening

them, the system is really a constant air volume system

and is balanced as a constant volume system. Balancing

dampers are best located at the takeoff before the

runout to the Therma-Fuser diffuser.

1. Prepare the system for balancing. (Make necessary

checks for diversity, fan capacities, fan rotation,

miminum outside air requirements, duct leaks and

static pressure controller design settings. Set outside

air control damper for minimum air and return air

control damper for maximum air.)

2. Open Therma-Fuser diffusers.

a. Open appearance panel.

b. Using a flat blade screwdriver or coin, turn the

damper opening cam clockwise until the damper

blades are fully open and the blade tips touch

each other. See Fig. 2.

c. Close appearance panel.

Fig 2. Turn damper opening cam to open for balancing

Damper Opening Cam

3. Start fans, adjust system for 100% air flow and make

system checks. (Measure static pressure across filters

and coils and at sensor for static pressure controller.

Measure supply, return and branch duct air flow.)

4. Place a direct reading diffuser balancing hood over the

face of each Therma-Fuser diffuser and adjust damper

at duct takeoff to obtain maximum design air volume.

If a velocity meter is used, measure discharge velocity

at the housing (See Fig. 3). Multiply the velocity in fpm

times Akof .12 ft2to get air flow in cfm.

5. Return Therma-Fuser diffusers to operating condition.

a. Open appearance panel.

b. Turn damper opening cam to allow damper blades to close.

c. Close appearance panel.

Fig 3. Measuring Discharge Velocity

Diffusion

Damper

Housing

Probe

Appearance

Panel

Gauge

1250 to

2300 fpm

Figure 7 @ 200%

Figure 3 @200%

BALANCING (TK-D)

1. The damper blade opening is factory set at 3/4

inch/19mm (See Fig. 4). Readjust where necessary by

turning the damper opening cam (See Fig. 2).

2. Place a direct reading diffuser balancing hood over the

face of each TK-D diffuser and adjust damper at duct

takeoff to obtain design air volume. If a velocity meter

is used, measure discharge velocity at the housing (See

Fig. 3). Multiply the velocity in fpm times Akof .12 ft2to

get air flow in cfm.

Foam

Housing

Blade

Small Steel Rule

Fig 4. Measuring damper blade opening

Fig 5. Percent Minimum Flow vs. Blade Opening

ADJUSTING MINIMUM FLOW (TK-HC, TK-C)

Minimum flow is adjusted by turning the damper opening

cam until the damper blades are open the correct amount.

Determine the correct blade opening for the required percent

minimum flow from the graph in Fig. 5. Measure the blade

opening as shown in Fig. 3 and adjust the damper opening cam.

PERCENT of AIR FLOW CAPACITY vs. BLADE OPENING

PERCENT AIR FLOW CAPACITY

100

80

60

40

20

0

0 .10 .20 .30 .40 .50 .60 .70 .80

(0) (2.5) (5.1) (7.6) (10.2) (12.7) (15.2) (17.8) (20.3)

BLADE OPENING — INCHES

(MM)

Page 2 of 6

To remove the appearance panel:

1. Open appearance panel as described above.

2. Rotate the appearance panel away from the latch clip

bracket to force the hinge hooks open on the panel.

3. Slightly lift the panel to remove from the hinges.

To reattach the appearance panel:

1. Hang the appearance panel on the hinges.

2. Press the hinge hooks against the panel to close

around the hinge brackets.

3. Close panel as described above.

SYSTEM BALANCING (TK-HC, TK-C)

VAV systems are balanced for design air volume at

maximum air flow and systems using Therma-Fuser VAV

diffusers are no exception. When all the Therma-Fuser

diffusers are set for maximum air flow by fully opening

them, the system is really a constant air volume system

and is balanced as a constant volume system. Balancing

dampers are best located at the takeoff before the

runout to the Therma-Fuser diffuser.

1. Prepare the system for balancing. (Make necessary

checks for diversity, fan capacities, fan rotation,

miminum outside air requirements, duct leaks and

static pressure controller design settings. Set outside

air control damper for minimum air and return air

control damper for maximum air.)

2. Open Therma-Fuser diffusers.

a. Open appearance panel.

b. Using a flat blade screwdriver or coin, turn the

damper opening cam clockwise until the damper

blades are fully open and the blade tips touch

each other. See Fig. 2.

c. Close appearance panel.

Fig 2. Turn damper opening cam to open for balancing

Damper Opening Cam

3. Start fans, adjust system for 100% air flow and make

system checks. (Measure static pressure across filters

and coils and at sensor for static pressure controller.

Measure supply, return and branch duct air flow.)

4. Place a direct reading diffuser balancing hood over the

face of each Therma-Fuser diffuser and adjust damper

at duct takeoff to obtain maximum design air volume.

If a velocity meter is used, measure discharge velocity

at the housing (See Fig. 3). Multiply the velocity in fpm

times Akof .12 ft2to get air flow in cfm.

5. Return Therma-Fuser diffusers to operating condition.

a. Open appearance panel.

b. Turn damper opening cam to allow damper blades to close.

c. Close appearance panel.

Fig 3. Measuring Discharge Velocity

Diffusion

Damper

Housing

Probe

Appearance

Panel

Gauge

1250 to

2300 fpm

Figure 7 @ 200%

Figure 3 @200%

BALANCING (TK-D)

1. The damper blade opening is factory set at 3/4

inch/19mm (See Fig. 4). Readjust where necessary by

turning the damper opening cam (See Fig. 2).

2. Place a direct reading diffuser balancing hood over the

face of each TK-D diffuser and adjust damper at duct

takeoff to obtain design air volume. If a velocity meter

is used, measure discharge velocity at the housing (See

Fig. 3). Multiply the velocity in fpm times Akof .12 ft2to

get air flow in cfm.

Foam

Housing

Blade

Small Steel Rule

Fig 4. Measuring damper blade opening

Fig 5. Percent Minimum Flow vs. Blade Opening

ADJUSTING MINIMUM FLOW (TK-HC, TK-C)

Minimum flow is adjusted by turning the damper opening

cam until the damper blades are open the correct amount.

Determine the correct blade opening for the required percent

minimum flow from the graph in Fig. 5. Measure the blade

opening as shown in Fig. 3 and adjust the damper opening cam.

PERCENT of AIR FLOW CAPACITY vs. BLADE OPENING

PERCENT AIR FLOW CAPACITY

100

80

60

40

20

0

0 .10 .20 .30 .40 .50 .60 .70 .80

(0) (2.5) (5.1) (7.6) (10.2) (12.7) (15.2) (17.8) (20.3)

BLADE OPENING — INCHES

(MM)

Page 2 of 6

To remove the appearance panel:

1. Open appearance panel as described above.

2. Rotate the appearance panel away from the latch clip

bracket to force the hinge hooks open on the panel.

3. Slightly lift the panel to remove from the hinges.

To reattach the appearance panel:

1. Hang the appearance panel on the hinges.

2. Press the hinge hooks against the panel to close

around the hinge brackets.

3. Close panel as described above.

SYSTEM BALANCING (TK-HC, TK-C)

VAV systems are balanced for design air volume at

maximum air flow and systems using Therma-Fuser VAV

diffusers are no exception. When all the Therma-Fuser

diffusers are set for maximum air flow by fully opening

them, the system is really a constant air volume system

and is balanced as a constant volume system. Balancing

dampers are best located at the takeoff before the

runout to the Therma-Fuser diffuser.

1. Prepare the system for balancing. (Make necessary

checks for diversity, fan capacities, fan rotation,

miminum outside air requirements, duct leaks and

static pressure controller design settings. Set outside

air control damper for minimum air and return air

control damper for maximum air.)

2. Open Therma-Fuser diffusers.

a. Open appearance panel.

b. Using a flat blade screwdriver or coin, turn the

damper opening cam clockwise until the damper

blades are fully open and the blade tips touch

each other. See Fig. 2.

c. Close appearance panel.

Fig 2. Turn damper opening cam to open for balancing

Damper Opening Cam

3. Start fans, adjust system for 100% air flow and make

system checks. (Measure static pressure across filters

and coils and at sensor for static pressure controller.

Measure supply, return and branch duct air flow.)

4. Place a direct reading diffuser balancing hood over the

face of each Therma-Fuser diffuser and adjust damper

at duct takeoff to obtain maximum design air volume.

If a velocity meter is used, measure discharge velocity

at the housing (See Fig. 3). Multiply the velocity in fpm

times Akof .12 ft2to get air flow in cfm.

5. Return Therma-Fuser diffusers to operating condition.

a. Open appearance panel.

b. Turn damper opening cam to allow damper blades to close.

c. Close appearance panel.

Fig 3. Measuring Discharge Velocity

Diffusion

Damper

Housing

Probe

Appearance

Panel

Gauge

1250 to

2300 fpm

Figure 7 @ 200%

Figure 3 @200%

BALANCING (TK-D)

1. The damper blade opening is factory set at 3/4

inch/19mm (See Fig. 4). Readjust where necessary by

turning the damper opening cam (See Fig. 2).

2. Place a direct reading diffuser balancing hood over the

face of each TK-D diffuser and adjust damper at duct

takeoff to obtain design air volume. If a velocity meter

is used, measure discharge velocity at the housing (See

Fig. 3). Multiply the velocity in fpm times Akof .12 ft2to

get air flow in cfm.

Foam

Housing

Blade

Small Steel Rule

Fig 4. Measuring damper blade opening

Fig 5. Percent Minimum Flow vs. Blade Opening

ADJUSTING MINIMUM FLOW (TK-HC, TK-C)

Minimum flow is adjusted by turning the damper opening

cam until the damper blades are open the correct amount.

Determine the correct blade opening for the required percent

minimum flow from the graph in Fig. 5. Measure the blade

opening as shown in Fig. 3 and adjust the damper opening cam.

PERCENT of AIR FLOW CAPACITY vs. BLADE OPENING

PERCENT AIR FLOW CAPACITY

100

80

60

40

20

0

0 .10 .20 .30 .40 .50 .60 .70 .80

(0) (2.5) (5.1) (7.6) (10.2) (12.7) (15.2) (17.8) (20.3)

BLADE OPENING — INCHES

(MM)

Page 2 of 6