PRIER Products, Inc.

4515 E 139th St.

Grandview, MO 64030

800-362-9055

www.PRIER.com/P-754

Installation, Operation & Maintenance Instructions for the

PRIER P-754 Hot & Cold Commercial Wall Hydrant

*Please leave this sheet for the property owner*

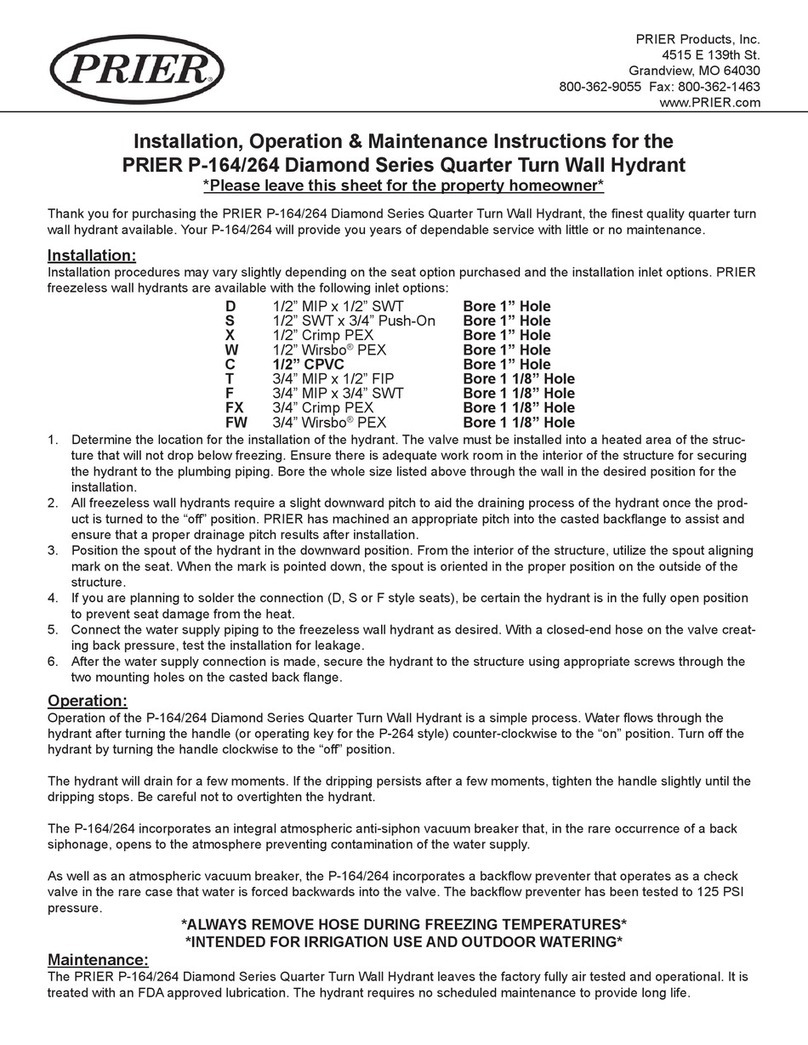

Thank you for purchasing the PRIER P-754 Hot & Cold Commercial Wall Hydrant, the nest quality commercial

hydrant available. Your P-754 will provide you years of dependable service with little or no maintenance.

Please note: Your P-754 hydrant has drain holes under the packing nut. After shuto, the drain holes will allow water to

drain for a few moments to prevent freezing. This is normal and according to design.

Installation:

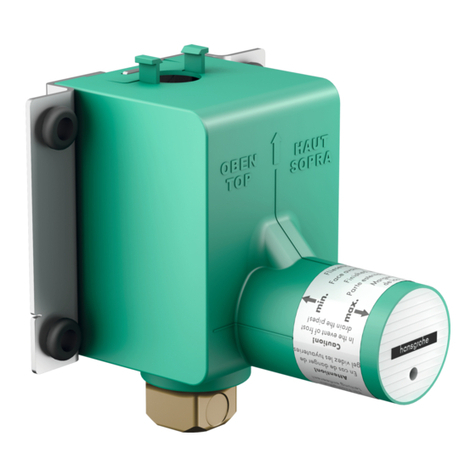

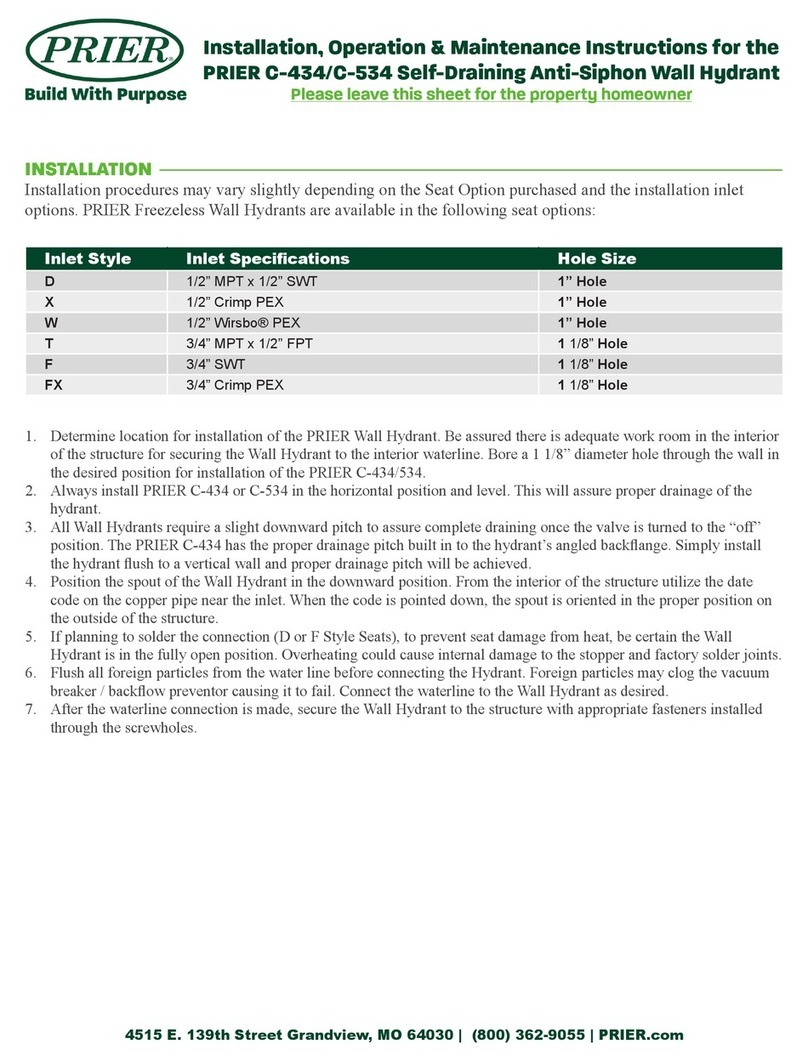

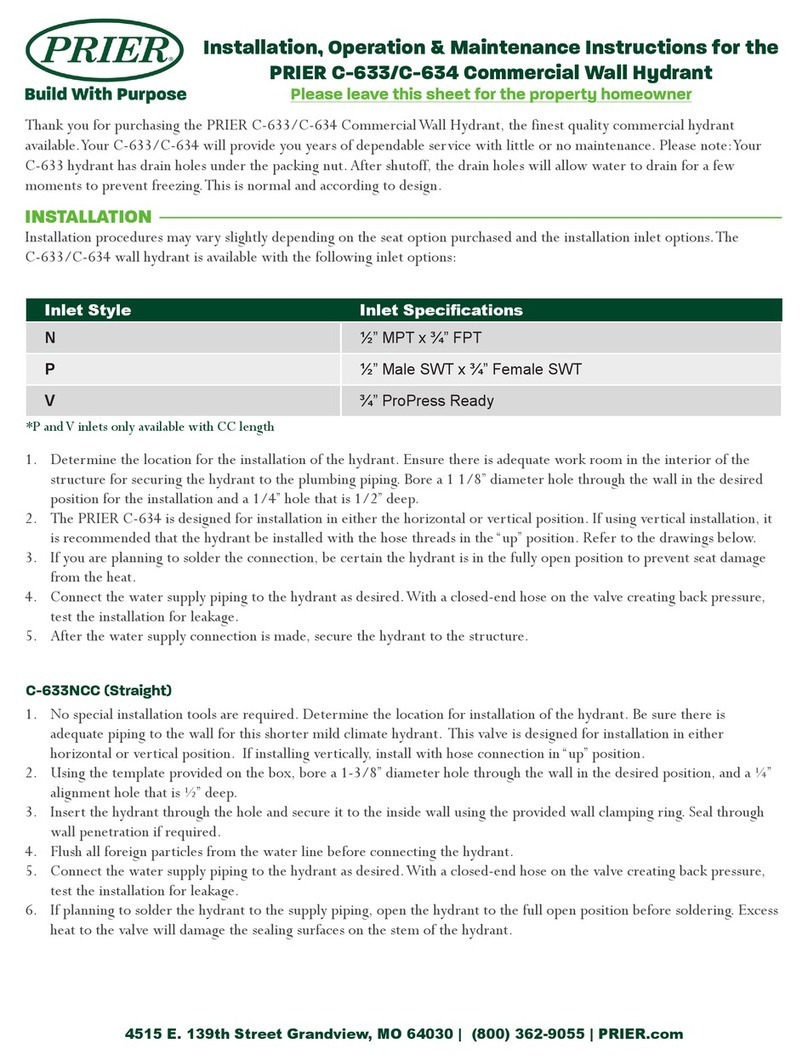

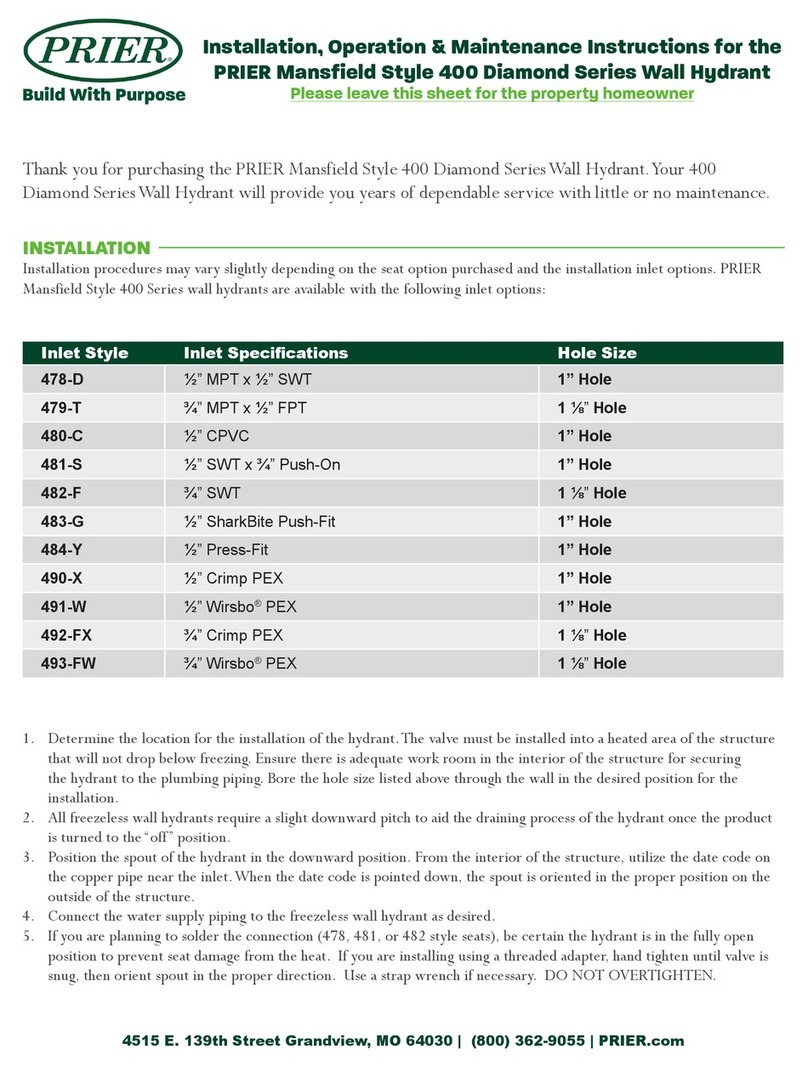

Installation procedures may vary slightly depending on the application and choice to use the P-754BX1 hydrant box. The

P-754 wall hydrant is available only in the M inlet (¾” MPT):

Operation:

Operation of the P-754 Commercial Wall Hydrant is a simple process. Water ows through the hydrant after turning the

loose key one full turn counter-clockwise to the “on” position. The hydrant will achieve maximum ow at 2 1/2 full turns.

At any time during the “on” position the temperature dial can be rotated clockwise (to the right) for cold water or counter-

clockwise (to the left) for hot water. Turn o the hydrant by turning the loose key fully clockwise to the “o” position. The

hydrant will drain for a few moments. If the dripping persists after a few moments, tighten the key slightly until the dripping

stops. Be careful not to overtighten the hydrant.

The P-754 incorporates an integral ASSE 1052 atmospheric anti-siphon vacuum breaker that, in the rare occurrence of a

back siphon- age, opens to the atmosphere preventing contamination of the water supply.

As well as an atmospheric vacuum breaker, the P-754 incorporates a check valve in the rare case that water is forced

backwards into the valve.

*ALWAYS REMOVE HOSE DURING FREEZING TEMPERATURES*

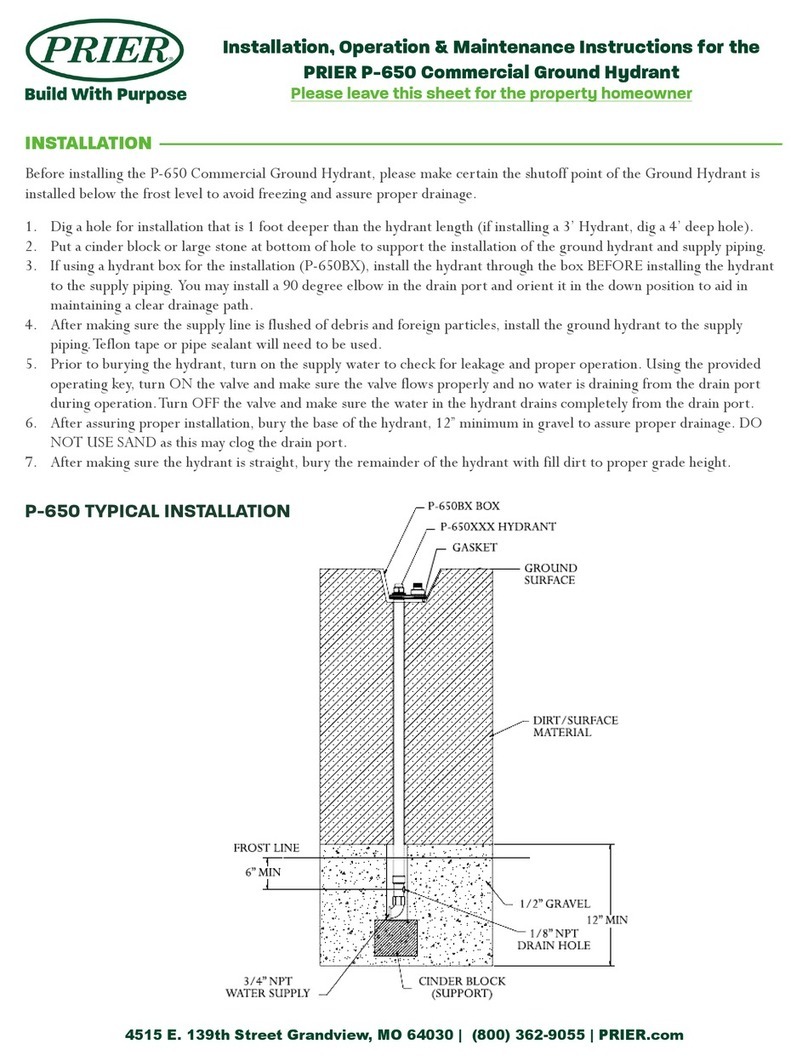

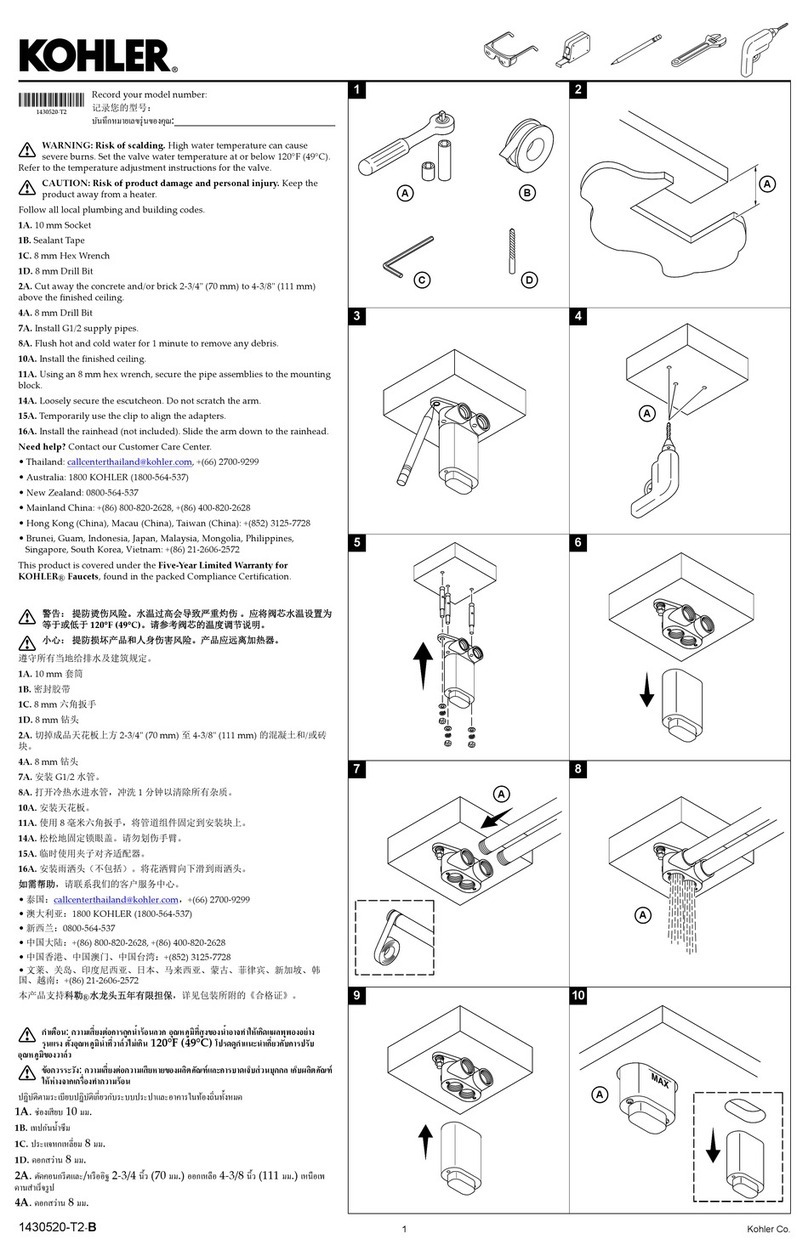

1. Determine the location for the installation of the hydrant. Ensure there is adequate work room in the interior of the

structure for securing the hydrant to the plumbing piping.

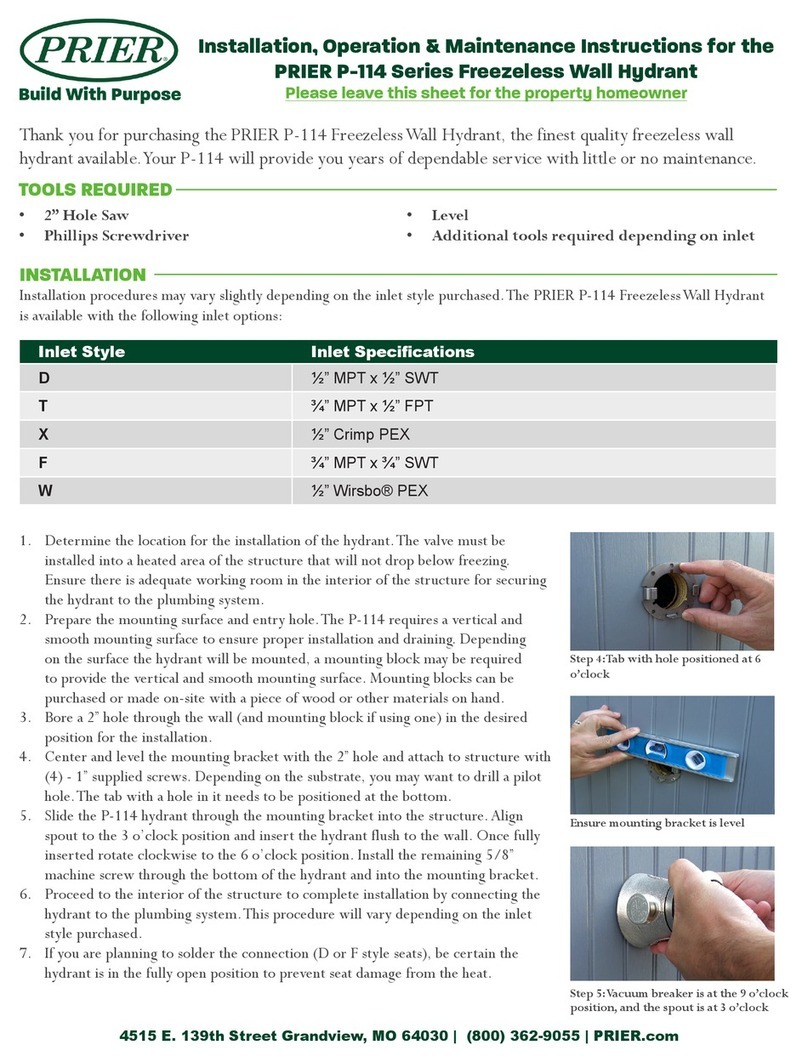

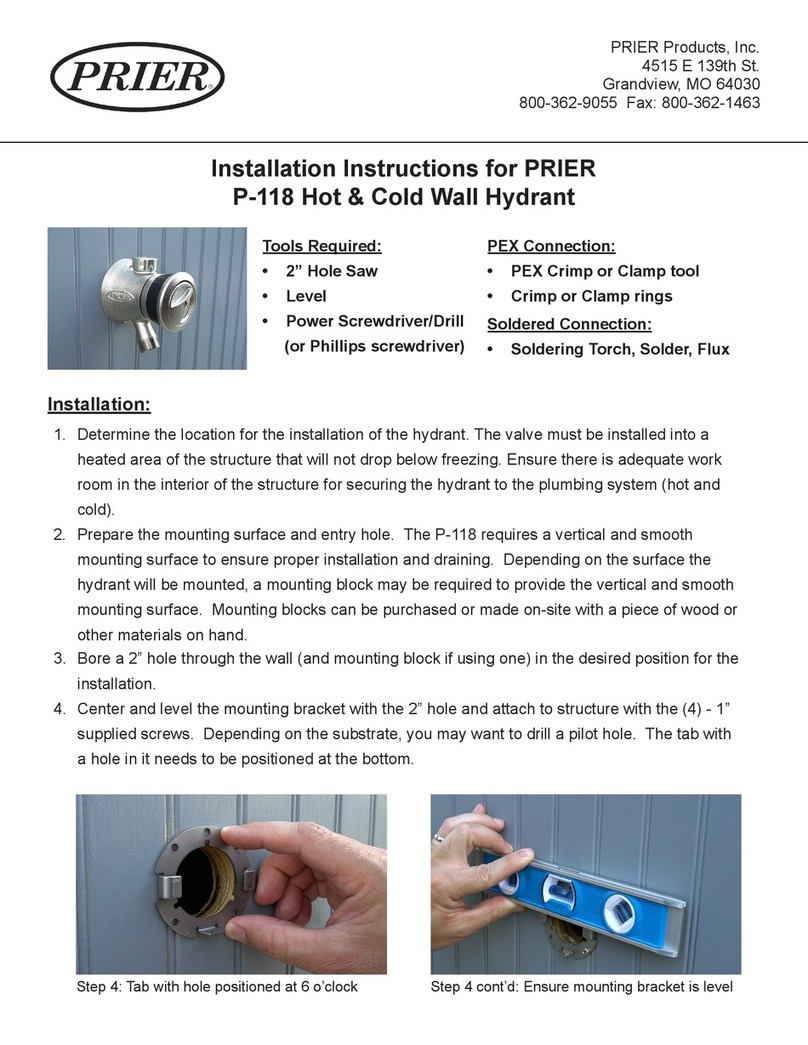

2. For installation without a box, use the cardboard template located on the hydrant box, cut a 4” Wide x 4 1/2” Tall open-

ing through the wall in the desired position for the installation.

3. For installation with a box, use the cardboard template located on the box, cut a 6” Wide x 7 1/2” Tall opening through

the wall in the desired position for the installation.

4. Insert the hydrant into the cutout and temporarily secure to connect the water supply. If using a box, fully secure the

box to the structure (can use the optional (4) 3/8-16 lugs on the back of the box), loosely install the stainless steel

mounting plate and hydrant to the box using the (4) #10-24 screws provided.

5. If you are planning to solder the connection, be certain to keep heat away from the threaded connection as there is a

plastic check valve installed to prevent thermal migration.

6. Connect the water supply piping to the hydrant as desired. Make sure to connect the hot supply to the inlet marked

with RED. With a closed-end hose on the valve creating back pressure, test the installation for leakage.

7. After the water supply connection is made, secure the mounting plate to the structure with appropriate fasteners, or if

using a box secure the (4) screws to hold the hydrant to the box.

Maintenance:

The P-754 Heavy Commercial Wall Hydrant leaves the factory fully air tested and operational. It is treated with an FDA

approved lubrication. The hydrant requires no scheduled maintenance to provide long life. If the stem is removed, the

bypass O-Ring needs to be replaced and lubricated with an FDA approved lubricant to avoid tearing.