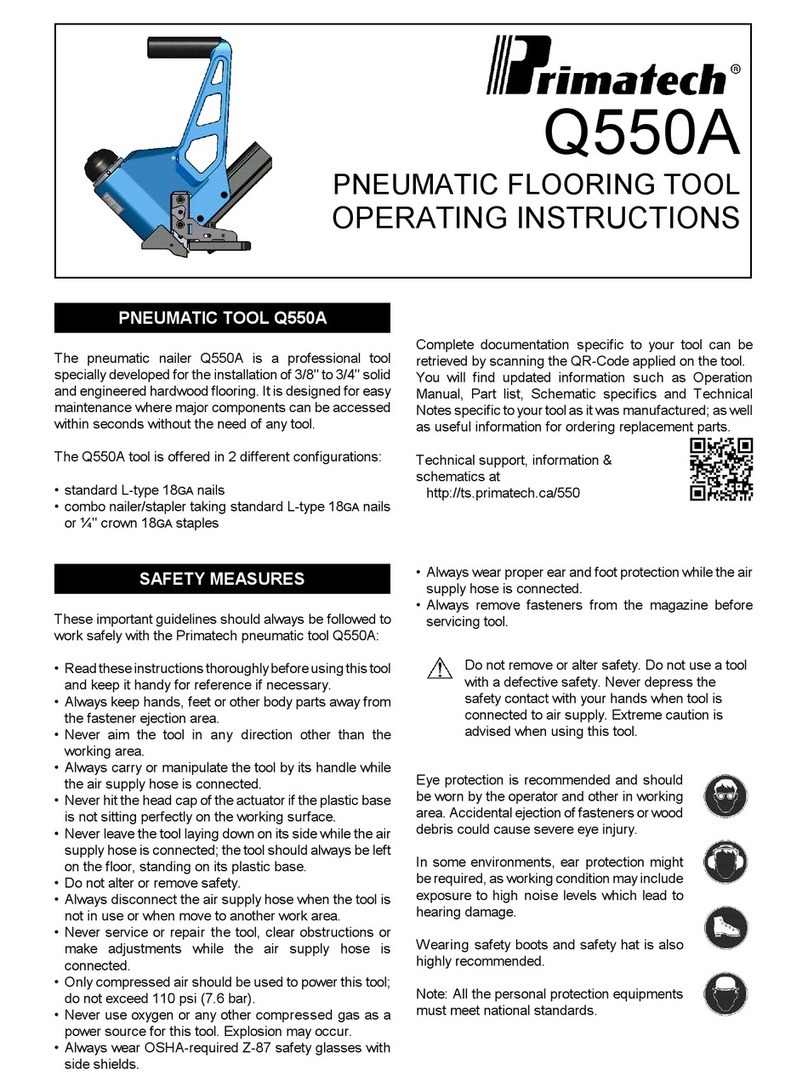

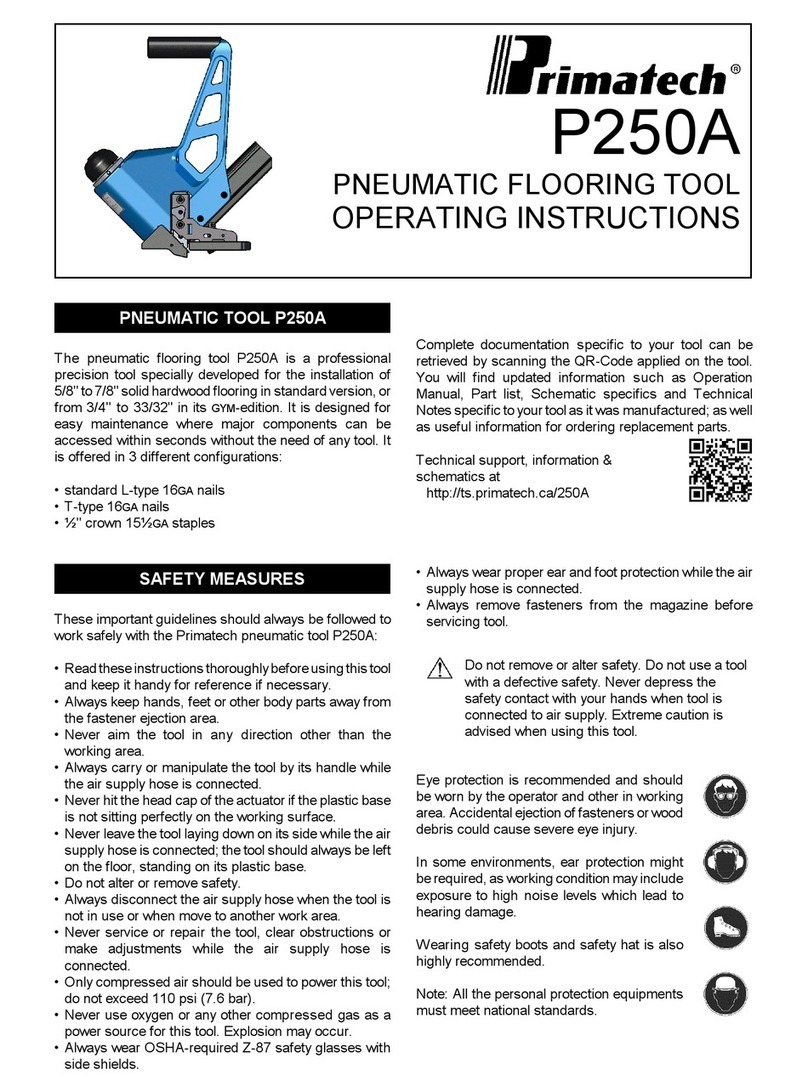

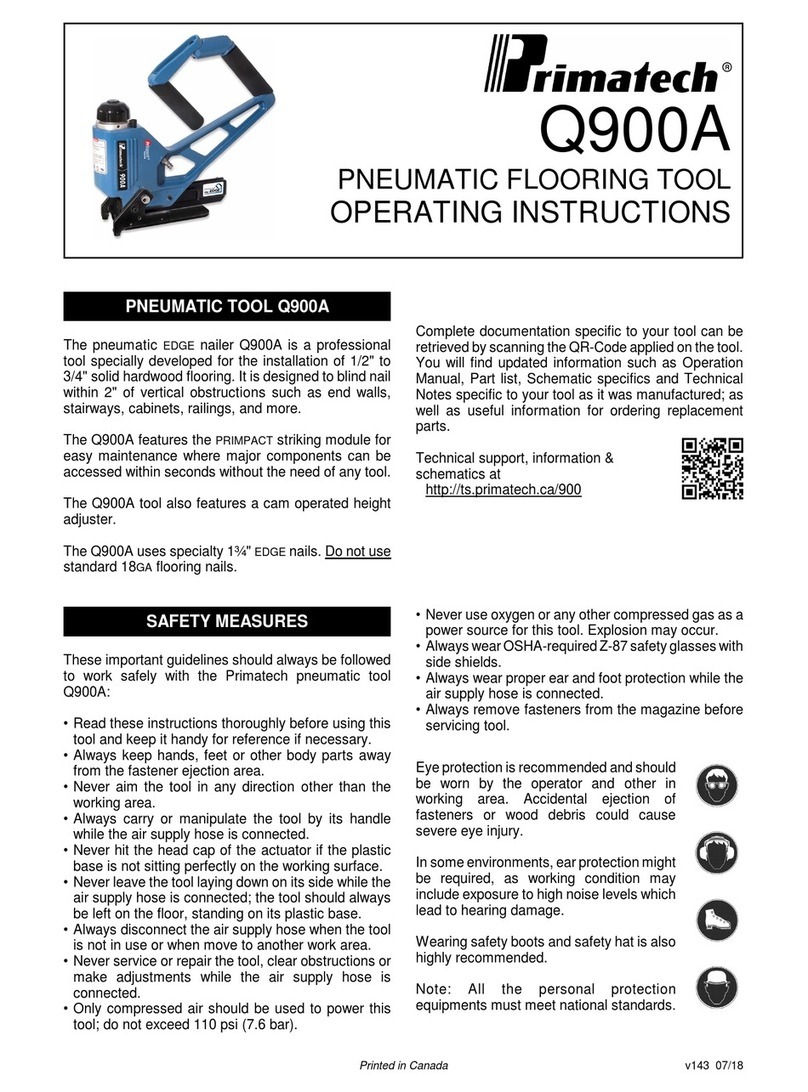

PRIMATECH PNEUMATIC NAILER Q550

The pneumaticnailerQ550 isaprofessional precision tool

speciallydeveloped forthe installationof3/8"to3/4"solid and

engineered hardwood flooring.It hasbeen designed foreasy

maintenancewheremajorcomponentscan be accessed within

secondswithoutthe need ofanytool.Weighting only8.7pounds

(4kg),thisergonomicallydesigned tool makesthe installation of

hardwood floorveryeasy,allowing theoperatortosetand nail

the boardsin the standing position.It usesstandard L-type 18GA

cleatsavailable in lengthsof1¾"(45 mm),1½"(38 mm) and 1¼"

(32 mm).Forbestresult, onlyPRIMATECH cleatsshould be used.

Read carefullytheseinstructionsbeforeoperating thistool.It is

importanttounderstand warnings/cautionsand the safety

measurestoensuresafeuseof thistool.

The Q550 isbuilt around the

Primpact valveengine, a

breakthrough technologyfor

pneumatictools. Primpact main

featuresare:

•short noseand compact valvedesign withan all-

around striking surface

•high-speed action and fewmoving parts, fora

powerful yet soft strokeand increased precision.

•reciprocal striking systemthat regulatesthe depth

of penetration independentlyfromthe mallet impact

•finelythreaded screw-in cartridge assembly

Additional information isavailable directlyfromthe manufacturer:

1135 Jeremie-Fortin, Quebec, QC

Canada, G1J1R8

Phone: 1 (800)363-1962 or1(418)522-7744

Fax: 1(418)522-7466

email: support@primatech.ca

web: www.primatech.ca/support

SAFETYMEASURES

Theseimportantguidelinesshouldalwaysbe followed towork

safelywiththe PRIMATECH pneumaticnailermodel Q550:

1. Read theseinstructionsthoroughlybeforeusing thistool

and keep it handyforreferenceif necessary.

2. Alwayskeep hands,feetorotherbodypartsawayfromthe

nail ejection area.

3. Neveraimthe tool in anydirection otherthan the working

area.

4. Alwayscarryormanipulatethe tool byitshandle while the

airsupplyhoseisconnected.

5. Neverhit the head cap of the actuatorifthe plasticbaseis

not sitting perfectlyon the working surface.

6. Neverleavethe tool laying downon itsside while the air

supplyhoseisconnected;the tool should alwaysbe left on

the floor, standing on itsplasticbase.

7. Do not alterorremovesafety.

8. Alwaysdisconnect the airsupplyhosewhen the tool isnot

in useorwhen movetoanotherworkarea.

9. Neverserviceorrepairthe tool,clearobstructionsormake

adjustmentswhile the airsupplyhoseisconnected.

10. Onlycompressed airshould be used topowerthistool ;do

not exceed 110 psi(7.6bar).

11. Neveruseoxygen oranyothercompressed gasasapower

sourceforthistool.

12. AlwayswearOSHA-required Z-87 safetyglasseswithside

shields.

13. Alwayswearproperearand feetprotection while the air

supplyhoseisconnected.

14. Alwaysremovecleatsfromthefeederchannel before

servicing tool.

DO NOTREMOVE ORALTERSAFETY.NEVERDEPRESS

THE SAFETY CONTACTWITHYOUR HANDS WHENTOOLIS

CONNECTEDTO AIRSUPPLY.EXTREME CAUTIONIS

ADVISEDWHENUSING THIS TOOL.

CONNECTION & AIR SUPPLYSYSTEM

Toensuremaximumperformanceand efficiency,and alsoa

minimumofcare,the PRIMATECH pneumaticnailerrequiresclean,

dryair. It isnecessarytouseafilterand apressureregulator.

Thistool needsadetachable male couplerwith3/8"NPTmale

treads.The useofa3/8"(1cm) diameterairsupplyhoseis

recommended. Asmallerhoseorahoselongerthan 50'(15 m)

could causeapressuredrop when the tool isactivated

repeatedly.

ALWAYS USE AFREE-FLOWCONNECTIONFORTHE

COMPRESSEDAIRSUPPLY TO PREVENTTHATTHE TOOL

STAYS CHARGEDAFTERDISCONNECTING THE AIRSUPPLY

HOSE.

UNLOADTOOLBEFORE CONNECTING AIRTO PREVENT

ACCIDENTALDISCHARGE.

AFTERMOVING TOOLTO ADIFFERENTWORK AREA,OR

AFTERANY MAINTENANCE TO THE TOOL,ALWAYS

ENSURE PROPEROPERATIONBY ACTUATING TOOL

SEVERALTIMES WITHOUTCLEATS OVERTHE

SUBFLOORING .

Dirt, dust, and otherparticlesin the airsupplycan causesluggish

operation orprematurewearofmanycomponentsofthe tool.

Drain waterfromthe compressortankregularly.The compressor

start-stop limitsshould be settodeliveran airpressureofatleast

100 psi(7bar) atall time.Consultthecompressormanual or

dealerforinstructionson howtomakethisadjustment.

At80 psi(5.5bar) and 100 hitsperminute,the tool consumes

approximately3.8cu.ft (110 )ofairperminuteat70°F(21°C).

Higherairpressurewill increasethe consumption ofcompressed

air.

The tool isdesigned tobe operated withacompressed air

pressureof80 psi(5.5bar).Occasionally,ahigherpressure

could be necessary,forexample tousethe tool withdifferent

speciesofharderwood.Inthesemoredifficultcases,the

compressed airpressurecan be increased up to100 psi

(7.0bar).It isveryimportantnottoexceed thismaximum

pressuretopreventleaks,prematurewearordamagestothe

tool.

Checkthe compressed airsupplyhosebeforeconnecting to

ensurethattheyarefree fromdirtorparticlesthatcan alterthe