primatech P240 User manual

Revision 06/05 Printed inCanada

PNEUMATICFLOORINGNAILER

P240

OPERATINGINSTRUCTIONS

WARNING

Read theseinstructionsthoroughlybeforeusingthistooland keep it

handyforreference.

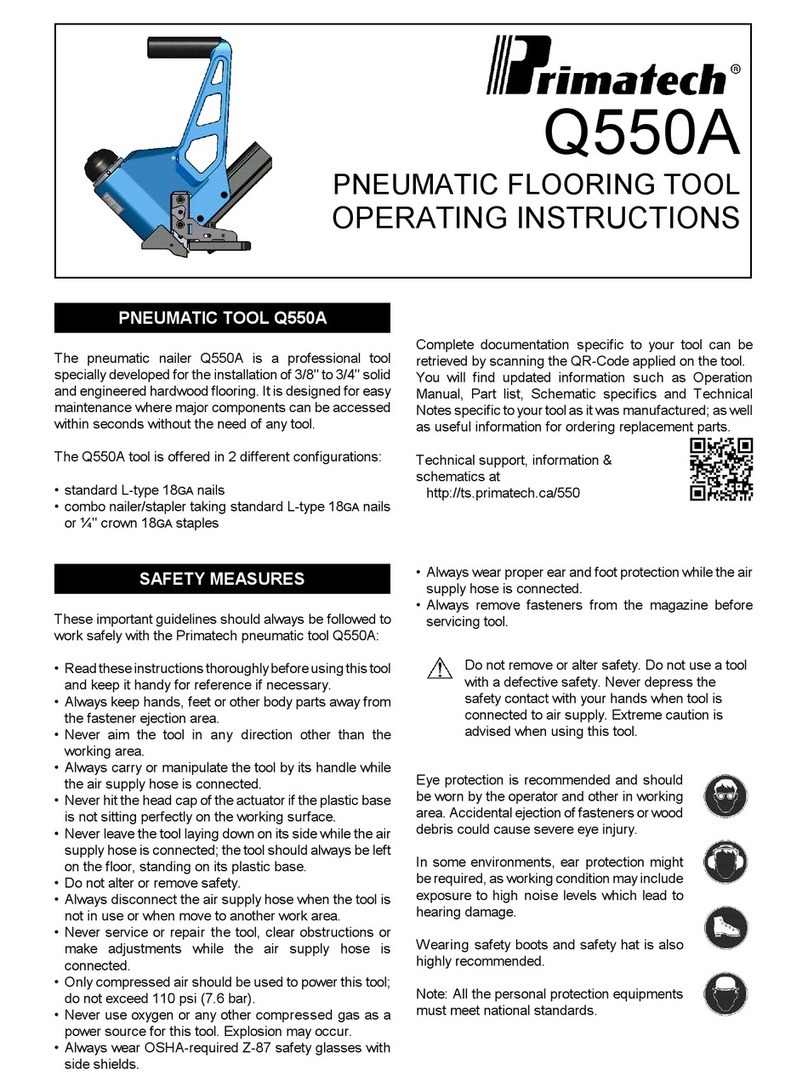

PRIMATECH PNEUMATIC NAILER P240

isaheavydutyprecision toolspeciallydeveloped forthe installation

ofhardwood flooring.Weighting only11 pounds (5kg), thisergono-

micallydesigned tool makes the installation ofhardwood floor very

easy,allowing the operatortosetand nail the boards inthe standing

position.It uses standard"L"type cleatsavailableinlengths of1½"

(38 mm), 1¾" (44 mm)or2"(50 mm)cleats;oroptionallythe 1½"

(38 mm)or2"(50 mm)"T"type cleats.Forbestresult, only

PRIMATECH cleatsshouldbe used. For maximumperformance,the

manufacturerguidelines shouldbe followed.Read carefullythese

instructions beforeoperating thistool. It isimportant tounderstand

warnings/cautions and the safetymeasures toensuresafeuse of

thistool.

Additional information isavailabledirectlyfromthe manufacturer:

1135 de Lorraine, Québec, QC

Canada, G1J 1R8

Phone: 1 (800) 363-1962, 1(418) 522-7744

Fax: 1(418) 522-7466

email: support@primatech.ca

web: www.primatech.ca/support

SAFETYMEASURES

These importantguidelines shouldalwaysbe followed toworksafely

withthe PRIMATECH pneumaticnailer model P240:

1. Read these instructions thoroughlybeforeusing thistooland

keep it handyfor reference ifnecessary.

2. Alwayskeep hands,feetorotherbodypartsawayfromthe nail

ejection area.

3. Neveraimthe toolinanydirection otherthan the working area.

4. Alwayscarryormanipulatethe toolbyitshandlewhilethe air

supplyhose isconnected.

5. Neverhit the head cap ofthe actuatorifthe plasticbase isnot

sitting perfectlyon the working surface.

6. Neverleave the toollaying down on itsside whilethe air supply

hose isconnected;the toolshouldalwaysbe lefton the floor,

standing on itsplasticbase.

7. Do not alter or remove safety.

8. Alwaysdisconnectthe air supplyhose when the toolisnotin

use or when move toanother workarea.

9. Neverservice orrepair the tool, clearobstructions ormake

adjustmentswhilethe air supplyhose isconnected.

10.Onlycompressed air shouldbe used topowerthistool(110 psi,

7.6bar maximum).

11.Neveruseoxygen oranyothercompressed gas as apower

source for thistool.

12.AlwayswearOSHA-required Z-87 safetyglasses withside

shields.

13.Alwayswearproperearand feetprotection whilethe air supply

hose isconnected.

DO NOTREMOVE OR ALTER SAFETY.NEVER

DEPRESS THESAFETYCONTACTWITH YOUR HANDS

WHEN TOOLISCONNECTED TO AIR SUPPLY.EXTREME

CAUTION ISADVISED WHEN USING THISTOOL.

CONNECTION&AIRSUPPLYSYSTEM

To ensuremaximumperformance and efficiency,and also a

minimumofcare,the PRIMATECH pneumaticnailerrequires clean,

dryair. It isnecessarytouse afilter and apressureregulator.

Thistoolneeds adetachablemalecouplerwith3/8"NPT male

treads.Use a3/8"(1cm)minimumdiameterair supplyhose.A

smallerhose orahose longerthan 50'(15 m)couldcause a

pressuredrop when the tool isactivated repeatedly.

ALWAYSUSE AFREE-FLOWCONNECTION FOR THE

COMPRESSED AIR SUPPLYTO PREVENTTHATTHE

TOOLSTAYSCHARGED AFTER DISCONNECTING THE

AIR SUPPLYHOSE.

UNLOAD TOOLBEFORECONNECTING AIR TO

PREVENTACCIDENTALDISCHARGE.

AFTER MOVING TOOLTO ADIFFERENTWORK AREA,

OR AFTER ANYMAINTENANCETO THETOOL,ALWAYS

ENSUREPROPER OPERATION BYACTUATING TOOL

SEVERALTIMES WITHOUTCLEATS OVER THE

SUBFLOORING .

Dirt, dust, and otherparticles inthe air supplycan cause sluggish

operation orprematurewearofmanycomponentsofthe tool. Drain

waterfromthe compressortank regularly.The compressorstart-stop

limitsshouldbe settodeliveran air pressureofatleast100 psi

(7bar) atall time.Consult the compressormanualordealerfor

instructions on how tomake thisadjustment.

At80 psi(5.5bar) and 100 hitsperminute,the toolconsumes

approximately4.5cu.ft(125 )ofair perminuteat70°F(21°C).

Higherair pressurewillincrease the consumption ofcompressed air.

The toolisdesigned tobe operated withacompressed air pressure

of80 psi(5.5bar). Occasionally,ahigherpressurecouldbe

necessary,forexampletouse the toolwithdifferentspecies of

harderwood.Inthese moredifficult cases,the compressed air

pressurecan be increased up to110 psi(7.6bar). It isvery

importantnottoexceed thismaximumpressuretopreventleaks and

risk ofdamage tothe tool.

The toolmaybe fitted withthe optionalP-055 pressurerelease

valve.thisvalve will produce aloud noise ifthe maximumair

pressureisexceeded.

Check the compressed air supplyhose beforeconnecting toensure

thattheyarefree fromdirt orparticles thatcan alterthe performance

ofthe tool. Payspecialattention toanyair leaks.Do notuse a

compressed air pressurehigherthan 110 psi(7.6bar). Higher

pressurecan cause prematurewearordamage tocertain

components.Afterassembly,check allthe connections toprevent

the leaks and tohave maximumefficiency.

TO PREVENTACCIDENTALDAMAGETO THEFINISHED

SURFACEOFTHEINSTALLED FLOOR,RESTTHETOOL

ONTO THESUBFLOORING WHEN CONNECTING AIR,

LOADING TOOLOR PERFORMING ANYMAINTENANCE

TO THETOOL.

LOADING THE TOOL

Insert arow ofPRIMATECH'scleatsinside the feederchanneland pull

back on the plastictab gentlyuntil it engages behind the cleats.To

release,simplysqueezethe tab withyourthumband indexand

allow the spring torecoil slowly.The clipmustbe released slowlyto

preventdamage.For MAXIMUMPERFORMANCE,alwaysuse P RIMATECH

cleats.The PRIMATECH modelP240 comes standardwiththe P-148

feederchanneltoaccommodate1½" (38 mm), 1¾" (44 mm)or2"

(50 mm)L-type cleats.It maybe ordered orconverted withthe

P-951 kit toaccommodate2"or1½" T-type cleats.Longerfeeder

channelsforthe L-type cleatsarealso available.Make surethatthe

proper type ofcleatsisused.

USE ONLY THETYPE OFCLEATSIDENTIFIED ON THE

FEEDER CHANNEL.THEUSE OFANYOTHER TYPE OF

CLEATSWILL DAMAGETHETOOL.

Alwaysoperatethe toolwithcleatsinfeederchannel. Damage may

occur ifthe tool isoperated without cleats.

OPERATION

Place the toolontothe subflooring,unload tooland connectthe

hose.Afterloading the toolwithPRIMATECH cleats,the PNEUMATIC

NAILER model P240 isreadyfor use.

A2.5lbs (1.1kg)hammerissupplied withthe tool.

Use the rubberface tohelpposition

the boards.Use the steelwith

caution topreventdamage tothe

boards.

Press the flooring firmlyinplace.The

lipofthe plasticbaseP-433 should

restsnuglyagainstthe tongueofthe flooring.

Downwardpressureshouldbe applied toensure

properseating ofthe cleat. To activatethe tool,

strike lightlythe head cap P-501 withthe RUBBER

FACE ofthe 2.5lbs (1.1kg)hammersupplied withthe tool. Never

strike the toolwiththe metalend ofthe hammer.Ifwood is

slightlytwisted,hitting the toolwithmoreforce will assistinpulling

the boardup snugly. NEVER strike the head cap when the toolisnot

sitting on the working surface.

USE ONLYTHE RUBBER FACE OFTHEHAMMER.

USING THESTEELEND WILL DAMAGETHETOOLAND

VOID THEWARRANTY.

OPERATING THETOOLWHEN THESAFETYCONTACT

ISNOTFULLYDEPRESSED WILL CAUSE PREMATURE

WEAR OR DAMAGETO THEDRIVING BLADE,PISTON

AND CYLINDER.

Eyeprotection isrecommended and shouldbe

wornbythe operatorand otherinworking area.

Accidentalejection ofnailsorwood debriscould

cause severeeyeinjury.

Insomeenvironments, ear protection might be

required, as working condition mayinclude

exposuretohigh noise levelswhich lead to

hearing damage.

Wearing safetybootsand safetyhatisalso highly

recommended.

NOTE:All the personalprotection equipmentsmust

meet national standards.

ADJUSTING FORHARDWOODTHICKNESS

To fasten 3/4"or25/32"

flooring,no adjustmenttothe

toolisrequired.Use the

standardP-433 plasticbase

supplied withthe tool.

To fasten 1/2"flooring,install

optionaladapterkit P-188.If

necessary,useone ortwo

shims(supplied)toinsurethat

thegate/footdo notsit on the

tongue.Insert shimsbetween

mainbodyand plasticbase as

shown.

To fasten 33/32"flooring,

remove plasticbase as shown.

You mayapplythe optional

self-adhesivebase P-986 to

protectthe finished surface of

the flooring.

BEFORESTARTING AN INSTALLATION,NAILDOWN

FEW BOARDSTO ASCERTAIN THATYOU AREUSING

THERIGHTTOOLAND FASTENER.

PREVENTIVE MAINTENANCE

Thistoolrequires minimallubrication.Use only

detergent-free oil such as Primatech P-090.Few drops

ofoil weeklyinthe air inletissufficient. Othertypes of

lubricant maydegrade the seals.

Check periodicallytomake surethatall screws aretight. Pay

particularattention tothe two screws holding the feederchannelas

well as the screws and nutson the feederchannelassemblywho

might loosen up overtime.Be carefulnottostripthe threads when

tightening.The use ofan mediumstrengthadhesive sealantsuch as

the Loctite242 isrecommended for those screws and nuts.

MAINTENANCE &REPAIR

Disassemblyofthe toolmustbe done inaclean environment. Some

partscan be easilydamaged ifdisassembled withimpropertoolsor

byinadequatemethods.Maintenance shouldonlybe performed by

trained personnel. Use onlygenuine PRIMATECH replacementparts.

TO PREVENTINJURY,ALWAYS DISCONNECTTHE

AIR SUPPLYHOSE WHEN SERVICING OR

DISASSEMBLING THETOOL.

When assembling the tool, make surethatall hexcap screws P-005

holding the casing on the base aretight.Inspectthese screws

regularly. Do not use anysubstitutetogasket P-107.

When servicing the tool, do nottwistorforce anyparts.Damage

mayresult fromsuch abuse.Ifpartsdo notcomeloose easily,

contact your PRIMATECH distributor for moreinformation.

When opening the toolformaintenance,alwaysclean all

componentsofdirt, grit, orparticles.Inspectthe toolcarefullyfor

broken partsorexcessive wear, and replace ifnecessary.When

ordering parts,be suretospecifythe rightpart number, and also the

tool serial number.

AFTER ANYMAINTENANCETO THETOOL,REMOVE

ALL CLEATS BEFORECONNECTING AIR AND

ACTUATETHETOOLREPEATEDLYOVER APIECEOF

WOOD OR SUBFLOORING TO INSUREPROPER

OPERATION.

CLEANING THE VALVE

Ifthe tool becomes sluggish, does notsetthe cleat, it mayindicate

excessive dirt inthe head of thetool, therebyimpeding the cycling

ofthe valve P-543.Thismaybe caused bydirt,dustorother

particles,oreven waterinthe compressed air. Insuch case,remove

the six(6)screws P-015 and take the head assemblyoff the tool.

Remove the valve mainscrew P-544B withan 3/16"Allen keyand

take outboththe valve P-543 and the actuatorP-542.It isgenerally

notnecessarytoremove the head cap P-501. Check all sealsand

replace ifnecessary.Clean the interiorand lightlylubricatewithnon-

detergentoil P-090.Othertypes oflubricantmaydegrade the seals.

Ifcareistaken,the gasketP-107 shouldrequireonlyinfrequent

replacement.

ASSEMBLING THE VALVE

1. First, make surethatall assemblies have all their seals

installed.

2. Holdthe actuatorhead assemblyP-541 inplace.It isnot

necessarytoremove head cap P-501 ifalreadyinstalled.

3. Insert actuator assemblyP-542. It shouldslide smoothly.

4. Insert mainvalve assemblyP-543 .

5. Carefullyput actuator cap assemblyP-544 inplace.

6. Assemblewithscrew P-544B, using a3/16"Allen key.

7. Snap head cap P-501 inplace.

8. IMPORTANT -Pull outthe valve P-543 downwardbeforeclosing

the head assembly.

ALWAYSPULL OUTTHEVALVE ASSEMBLYTO ITS

EXTENDED POSITION BEFORECLOSING THEHEAD

ASSEMBLY.AFTER REASSEMBLY,ALWAYSACTUATE

THETOOLREPEATEDLY WITHOUT CLEATS

AGAINSTAPIECEOFWOOD TO INSUREPROPER

OPERATION.

REPLACING THE DRIVING BLADE

1. Remove the plasticbase P-433 byremoving the (4)screws and

washersP-034.

2. Remove the fourhexcap screws P-005 holdingthe casing to

the base P-235 and remove it.

3. Remove the reinforcement plateP-226.

4. Pull outthe bumperP-125;remove anydebrisfrombumperand

re-use.

5. Pull outthe mainpiston P-522 bypulling the driving blade

P-223.

6. Remove anydebrisand dispose ofthe broken driving blade

and screw.Atthistimeassess condition ofcylinderP-518.If

marked orgrouged,use arat-tail filetosmoothoutwalls.The

piston P-522 must be allowed tomove without restriction.

7. Lock the piston inavise,using arag topreventscoring.Open

the split ring and use along 3/16"Allen wrench toremove the

broken blade. Discardthe oldscrew.

8. Install the new driving blade firmlyinposition,using the new

screw supplied. It isimportant that the blade be perpendicular

tothe piston.Use ofamediumstrengthadhesive sealantsuch

as Loctite242 and tighten withas much force as possible.

Follow the instructions supplied withthe new driving blade.

9. Reverse the order ofinstructions toreassemble.

TROUBLESHOOTING

Thissection will helptodiagnose problemsthatmightalterthe

qualityofworkdone bythe operator, orthe tool, and will give

suggestions on how tosolve them.Follow the orderofthese

instructions.

TO PREVENTINJURY,ALWAYS DISCONNECT

THE AIR SUPPLY HOSE WHEN ADJUSTING,

SERVICING OR DISASSEMBLING THETOOL.

(1) FIRST:CHECKTHE COMPRESSED AIR SUPPLY

Manyofproblemscomefromafaultyorinadequate

compressed air supplysystem.Beforeattempting torepair the

tool, the following pointsshouldbe checked:

a)check the pressureat the output ofthe compressor; adjust

to80-110 psi (5.5-7.6bar) as required

b)checkthe tank pressureofthe compressor&adjustthe

start/stop limits

c)check the air deliverysystem, use ahose ofat least 3/8"

d)use fewertoolssimultaneously;do notexceed the capacity

ofthe compressor or ofthe deliverysystem

e)drainwater fromthe compressor

(2) SECOND:CHECKFOR AIR LEAKS

Atrest, thistoolshouldnothave anyair leak.Beforeattempting

torepair the tool and replace parts, check the following:

a)Tighten screws P-015 or replace gasket P-107

b)Check rectangularrings P-009 &P-543A;replace if

necessary

c)Check sealP-543D;replace ifnecessary;the topedge of

maincylinder P-518 shouldbe free ofdents.

d)Check seal P-516B

e)Clean &lubricatethe head assembly;re-assemblethe head

assemblycarefully

f) Check interior ofhead P-506 for scratches

g)Check top ring P-014; replace ifnecessary

(3) TOOLDOES NOTDRIVE CLEATS

a)Check that therearecleatsinthe feeder channel

b)Make surethe feeder clipisengaged behind the cleats

c)Check the frontend ofthe feederchannelforburrsor

damages

d)Check the safetyelement

e)Check ifthe driver isstuck indown position (see 6below)

f) Check for obstruction inthe cleat ejection area

(4) CLEATSARENOTSETCOMPLETELY

a)First, verifyair supply(see 1above)

b)Clean tooland lubricatetool; particularlythe head assembly

c)Increase air pressurewhen working withharderwoods;

never exceed 110 psi (7.6bar)

d)Check the driving blade for broken end

e)Ensurethe tool iswell seated on the floor whileejecting

(5) TOOLDOES NOTACTIVATE

a)Check the air supply

b)Inspectthe head assemblyand check all seals;reassemble

carefully

(6) DRIVING BLADEDOES NOTRETURN

a)Check for jammed cleat or obstruction

b)Check gate/footand end offeederchannelfordamages or

burrs.

c)Check the driving blade P-223

d)Inspectthe head assemblyand check all seals;clean &

lubricate

e)Check for damaged or missing bottomO-ring P-014

f) Tighten reinforcement plate

g)Check that the bumper isinplace.

(7) BROKEN OR WORN DRIVING BLADE

Replace the driving blade P-223.Failuretofollow the

instructions carefullywill result inrepeated breakage ofthe

driving blade.

(8) POOR FEED OR TOOLJAMMING

a)Make surethe feeder clipengages behind the cleats

b)Check the gateand foot for damages or wear

c)Check the frontend ofthe feederchannelforburrsor

damages

(9) OTHER PROBLEMS

Contact Primatech:

byphone 1 (800) 363-1962

1(418) 522-7744

byemail support@primatech.ca

consult our on-line Technical Support siteat

http://www.primatech.ca/support

ACCESSORIES

P-149 18"(45 cm) "L"feeder channel

P-951 "T"type cleatsconversion kit

P-080 Hammer

H-082 Double-head hammer

P-084 Whiterubber cap

P-188 Adapter for 1/2"to5/8"(13 to17mm) solid

P-288 Adapter for 3/4"to33/32"(19 to26mm)

P-090 Non detergent oil

TrakEdge

Adapter plates for factoryfinished floorings.

A-001 for standard3/4"floorings

A-004 for 9/16"&5/8"floorings

Customfitstoflooring manufacturersspecifications also

available. Contact us for moreinformation.

A-800 Extension Handle

The A-800 extension handleallows tooperatethetoolata

higherorlowerposition.Il provides abettertoolcontrol,

improve ease and stabilitywhen sliding the tool sideways.

OTHER PRIMATECH NAILERS

PRIMATECH offersafull line of professionaltoolsforthe installation

ofhardwood flooring:

H300 standardmodel, manual operation

H330 standardmodel, 'Multiple-Hits'manual operation

Q500 manualoperation,forsolidwood 1/2"(1.25 cm)or3/8"

(1cm) thick

R610 manual operation, for engineered flooring

PRIMATECH CLEATS

For best results, alwaysuse PRIMATECH cleats:

2"(50 mm) "L"or "T"type

1¾" (44 mm) "L"type

1½" (38 mm) "L"or “T” type

Table of contents

Other primatech Nail Gun manuals

Popular Nail Gun manuals by other brands

Hitachi

Hitachi NT65M2 - to 2-1 16 Gauge Finish Nailer Instruction and safety manual

Campbell Hausfeld

Campbell Hausfeld SB323200 operating instructions

Grizzly

Grizzly H5527 owner's manual

Rapid

Rapid Airtac PB131 Operating instructions - Original

Milwaukee

Milwaukee 7100-20 Operator's manual

Numax

Numax SFN64 manual