In the manual mode:

After pushing the press icon on the screen (picture 13), the foot-operated

switch, or the green START switch, situated on the same side of the

machine as the heating plate, the heat plate will go down. In order to

change position of the heating plate, push the green START switch,

situated on the opposite side of the heating plate position.

Example 1:

The heating plate is situated above the left base plate.

After pushing the press icon on the screen (picture 13), foot-operated

switch or green START switch, situated on the left side of the machine,

the press will close on the left base plate.

Example 2:

The heating plate is situated above the left base plate. After pushing the green START switch, situated on the right side of the

machine, the heating plate will move to the right. After renewed pushing of the same START switch, the press will close on

the right base plate.

In order to reak the pressing process efore the programmed time is up, use the foot-operated switch or one of the green START

uttons situated on the machine.

In the automatic mode, without prepressing and postpressing:

After pushing the press icon on the screen (picture 13), foot-operated switch or one of the START uttons:

1. The heating plate will move to the new position

2. The heating plate will go down and the pressing process will start

3. The heating plate will go up and stop.

In the automatic mode, with prepressing and postpressing:

After pushing the press icon on the screen (picture 13), foot-operated switch or one of the START uttons:

1. The heating plate will move to the new position

2. The heating plate will go down, prepressing process will start

3. The heating plate will go up, and move to the start position

4. Renewed pushing of the START switch

5. The heating plate will move to the new position, pressing process will start

6. The heating plate will go up and move to the start position

7. Renewed pushing of the START switch

8. The heating plate will move to the new posistion, pospressing process will start

9. The heating plate will go up and stop.

3.2 Application range and sample adjustments of the heat press

The heat press is designed for pressing transfer foils on textiles. To get good achievements get in contact with the producer of the

textiles. Here are example settings:

Film FlexS 155°C – 160°C time 15 seconds

Film A-Flex 155°C – 160°C time 15 seconds

Film Flock 160°C – 180°C time 15 seconds

Su limation 190°C – 205°C time 50 seconds

Before each work sequence it is needed to do tests for pressing transfers and to check the resistance on washing. Use cotton

textiles, polyester or mixed textiles according to the specifiaction of the foil.

3.3 Position adjustment of the heating plate

If the heating plate moves too far or not enough to the new position, the settings of the positions have to e adjusted. Press the

settings utton (picture 1). Then enter the settings (picture 2). Change the chosen parameters using uttons „+” and „-”. Then save

the changes y pushing the green utton (picture 3). After every change the test has to e performed.

3. Pressure adjustment

On the Swing S Pneu press, the pressure setting can e adjusted precisely. The pressure force can e adjusted with the kno

situated on the left side of the machine. The pressure force has to e adjusted to the size of the ase plate. After every new

adjustment, close the heat press to check the new settings. If the heat press gets damaged because of too big pressure, the

terms and conditions of warranty are not more valid. The manufacturer does not response for damages caused by wrong

adjustment of the pressure force.

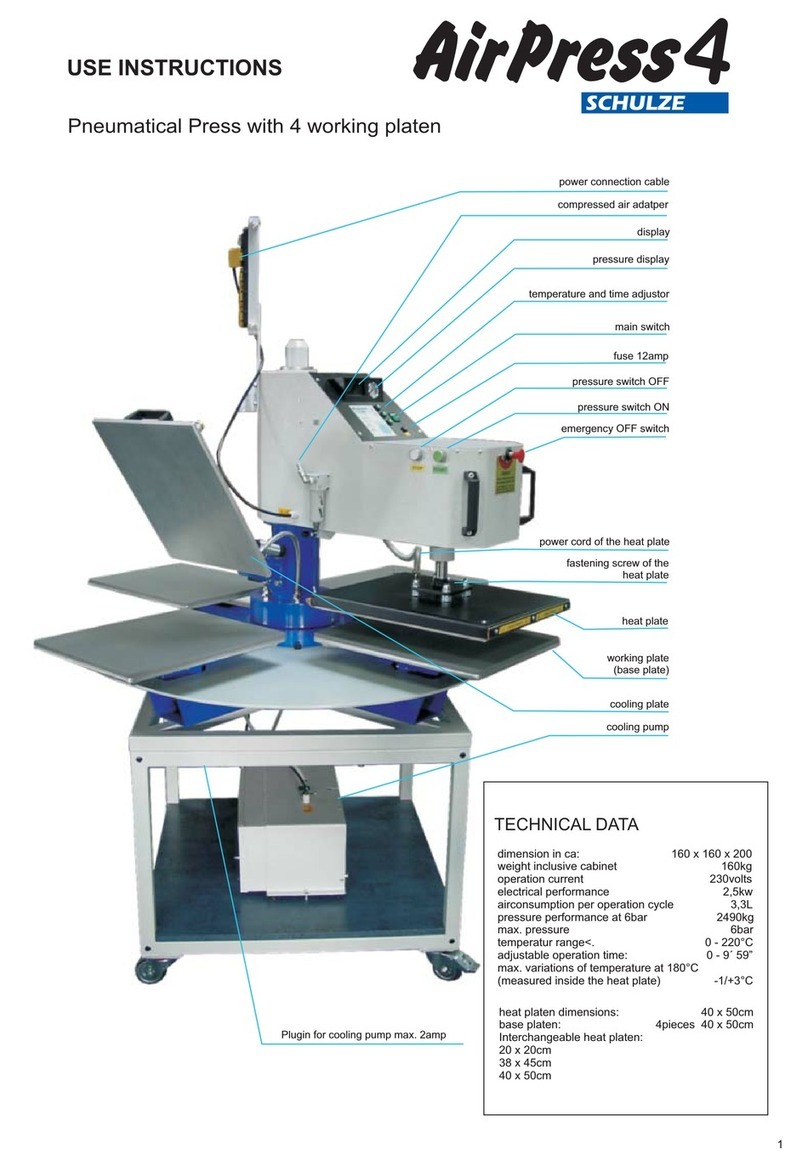

The pressure force can e checked on the manometer which is situated in the upper part of the machine.

Version 18.04 9/14