5

Tightenscrew1to80%,nextTightenscrew2to

80%,nextTightenscrew3to80%,andnext

Tightenscrew4to80%.Onceallscrewsare80%,

startprocessovertillscrewsare100%.

NOTE:DONOTOVERTIGHTEN.Thisreservoirdoes

notrequirealargeamountoftorquetowork

properly,sodonotwrenchdownonthescrewsor

theacrylicwillcrackandleak.

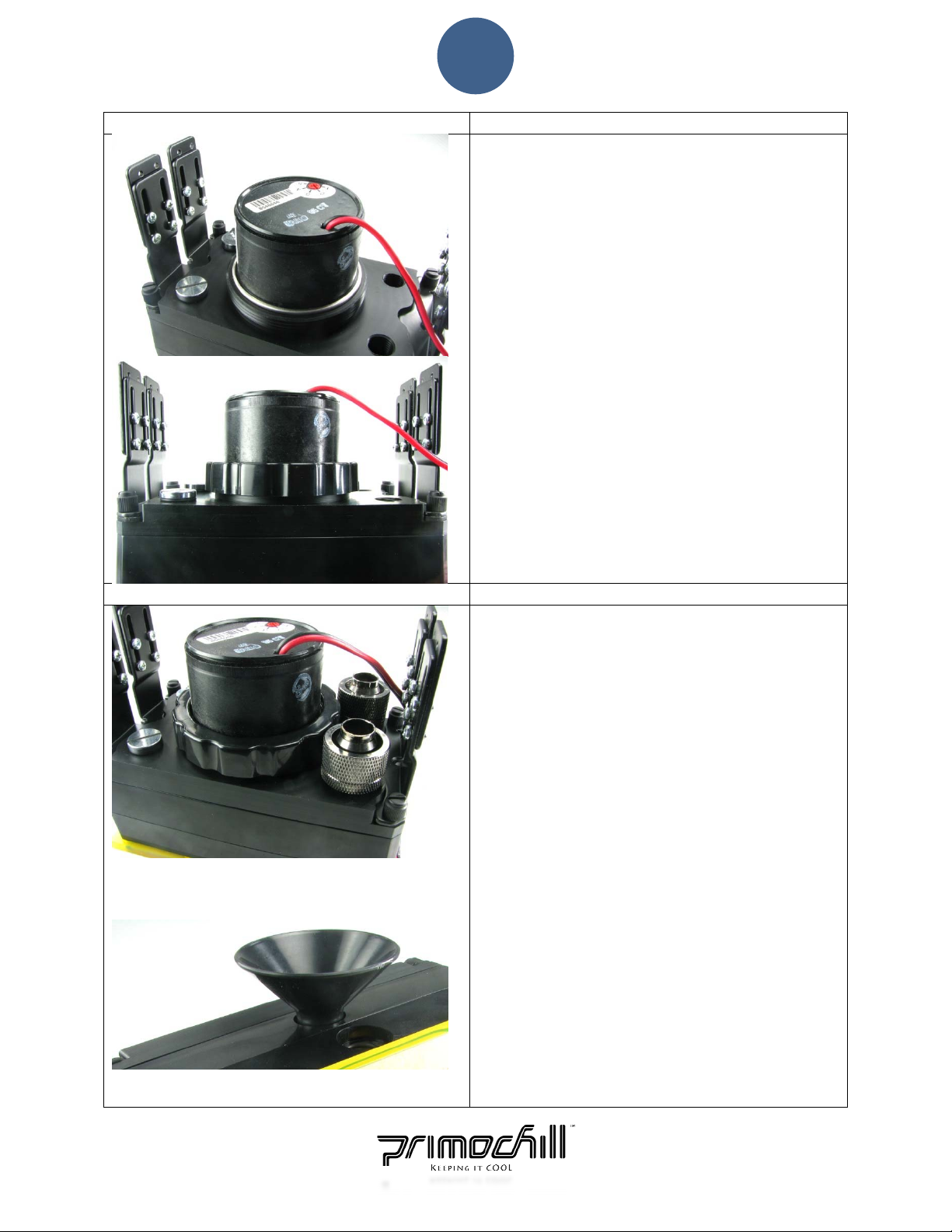

Oncethecentralframeisproperlyfittedtothe

pumphousing,removetherestoftheprotective

paperofftheacrylicfaceplateandlaygentlyonthe

frame.MakesuretheO‐ringisstillinthechannel

andnotprotrudingoutANYWHERE.

Oncethefaceplateisinplace,locatethefourpack

ofM4screwsinthebagWITHOUTtheplasticcaps.

(Seepicturetotheleft).

Gentlyplacethescrewsintotheholes.These

screwsaretobeusedinthecenter4holesONLY.

Gentlytightenthescrewsintheordershowninthe

pictureto80%,thenrepeatto100%.100%should

betheequivalenttohandtighttension.DONOT

OVERTIGHTEN.

ProceedtoStep8.

Step8 MountingBracketThroughScrews–4Corners

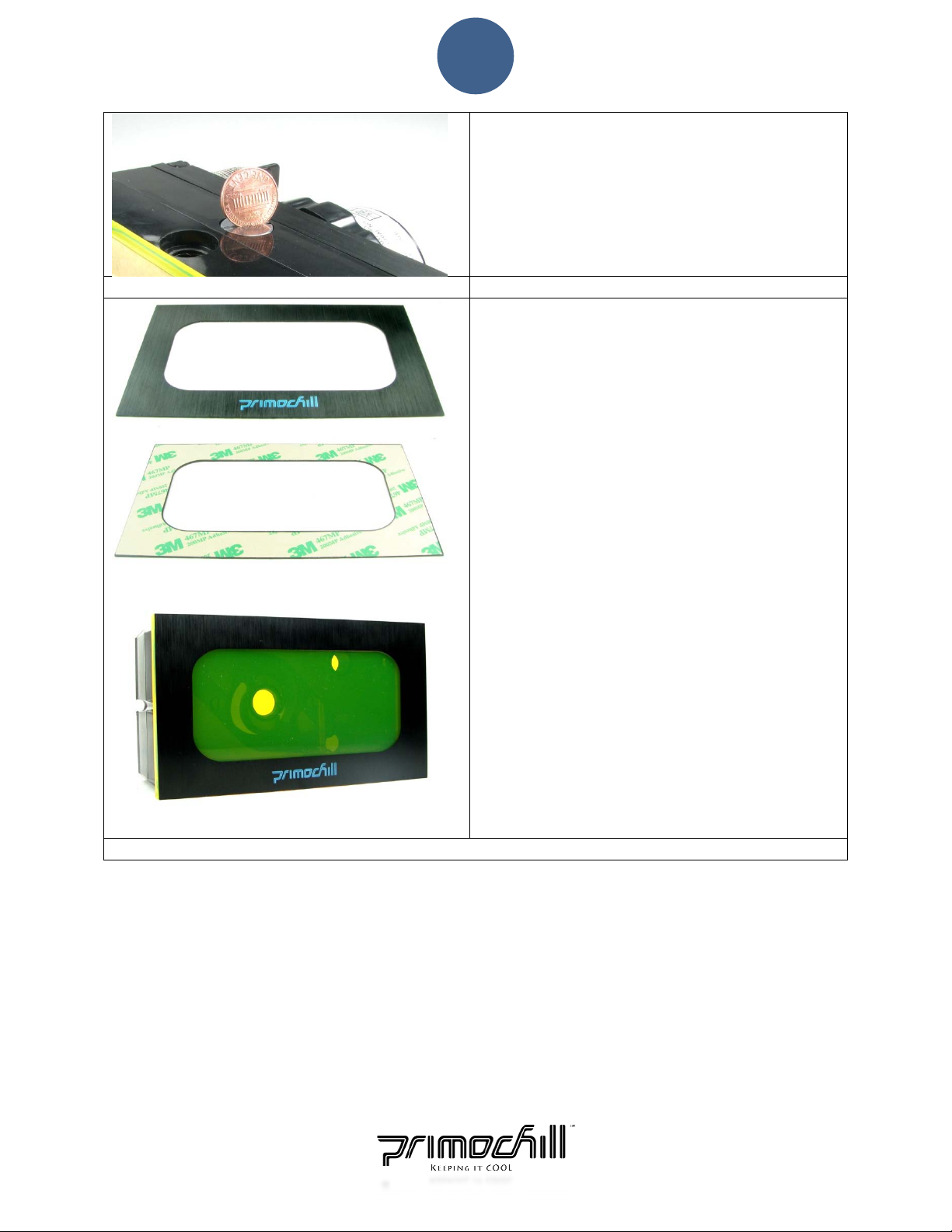

Withthe4centerscrewsinplace,proceedtopeel

offthepaperonthetwoedgesnexttotheLED

Lightchannel.Leavethecenterpieceunpeeledfor

now.

Onceyoupeeloffthepaperontheedgesyouwill

seetheO‐ringmakingcontactwiththeacrylicface

plateiftheO‐ringhasbeeninstalledproperly.

Locatethe6‐32screwswiththe4plasticcaps.

Insertthescrewsintotheholesandbeginto

tighten.Followthesametighteningprocessasyou

didinStep7.

Tighteningthesescrewstohandtighttensionjust

likethecenterscrewsisadequatetomakeawater

tightseal.IfthesescrewsareovertighteneditWILL

CAUSETHEACRYLICTOCRACK.