PRINCO L2000 User manual

Instrumentation designed

with the user in mind

INSTRUCTION MANUAL

PRINCO MODEL L2000

POINT LEVEL CONTROLLER

with NULL-KOTE™

PRINCO INSTRUMENTS INC.

1020 INDUSTRIAL BLVD.

SOUTHAMPTON, PA 18966

TEL: 800-221-9237, 215-355-1500

FAX: 215-355-7766

WEB SITE: www.princoinstruments.com

E-MAIL: [email protected]

Rev 1, 12 Nov 01

Table of Contents

i

Section 1. Description

A. General Description 1-1

B. Functional Description 1-1

C. L840 Series Probe Description 1-3

Section 2. Specifications

A. 1. L2000 Level Controller 2-1

A. 2. L840 Series Probes 2-1

Section 3. Installation

A. Inspection 3-1

B. Grounding 3-1

C. Probe Mounting 3-1

D. Electrical Connections 3-3

E. Installation in Hazardous Areas 3-5

Section 4. Adjustments and Operation

A. Initial Checkout 4-1

B. Calibration 4-1

C. Alarm Action 4-5

D. Delay Operations and Adjustments 4-5

E. Troubleshooting Guide4-5

Section 5. Equipment Service 5-1

Illustrations

Figure 1-1. Typical Explosion-Proof Installation 1-3

Figure 1-2. Standard L843 Probe, Dimensional Drawing 1-4

Figure 1-3. Standard L843 Probe, Descriptive Drawing 1-5

Figure 3-1. Standard Installation 3-2

Figure 3-2. Extended Guard Installation 3-3

Figure 3-3. Electrical Connections, 115 Vac and 230 Vac Units 3-4

Figure 3-4. Electrical Connections, 24 Vdc Unit 3-4

Figure 3-5. Ground Continuity Test 3-5

Figure 4-1. L2000 Adjustment and Indicator Locations 4-1

Figure 4-2. Conductive Process Calibration Procedure 4-3

Figure 4-3. Non-Conductive Process Calibration Procedure 4-4

Section One

Description

1-1

A. General Description

The Princo Model L2000 is a low-cost, adjustable, RF Impedance point level controller. It may

be used, in conjunction with any Princo L840 Series Sensor Probe, to detect the presence or

absence of process material within a storage vessel.

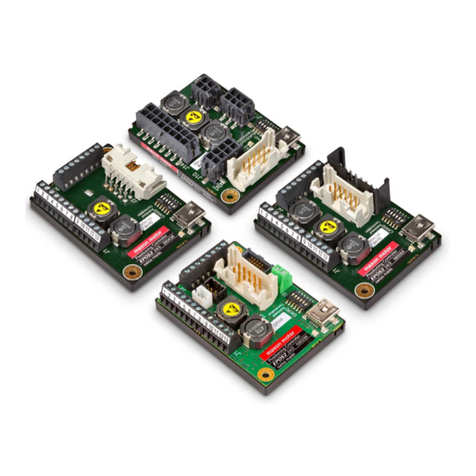

The basic instrument consists of an electronic chassis within a heavy-duty, cast aluminum,

weatherproof, explosion-proof housing. The housing has a removable lid which exposes the

electronic chassis. The chassis is composed of two circular printed circuit boards which are held

together by a removable system of mechanical spacers and electrical interconnects. The

chassis is easily removed from the instrument housing, allowing convenient replacement,

should troubleshooting be required.

The housing, with internal electronic chassis, attaches directly to any one of the Princo L840

Series point level probes. An electrical and mechanical probe connection is made by simply

screwing the housing directly onto the probe upper hub NPT fitting. The probe lower hub NPT

fitting threads directly into the storage vessel, thus allowing probe entry into the vessel, as well

as, mechanically and electrically fixturing the electronic housing and probe to the vessel

construction.

The electronic chassis performs the RF impedance measurement, and compares the

measurement with a set-point established by the coarse and fine sensitivity adjustments on the

top of the chassis. The set-point adjustment is established by making adjustments with actual

presence and absence of process material in the storage vessel. When the vessel's condition

changes relative to the set-point, two control relays are switched and the Probe Status LED

changes state.

B. Functional Description

The basic function of the device is to detect the presence or absence of process material within

a storage tank or holding vessel, and to announce the process material detection in the form of

an “alarmed” set of relay contacts.

The Model L2000, used in conjunction with an L840 Series Sensor Probe, can detect the

presence or absence of a wide variety of process materials, from electrical insulators with low

dielectric constants, to highly conductive electrical conductors. The mechanical nature of these

materials can range from dry powders or granulars, to liquid materials with virtually any

consistency -even thick, viscous materials that severely coat the sensor probe.

1. Basic Features

•RF Impedance Sensing Measurement Technology with Null-KoteTM

The L2000 uses RF impedance technology proven in tens of thousands of applications. The

principle of operation is very simple: an L840 Series Sensor Probe is mounted in the storage

vessel. As the process material changes from not contacting the probe to contacting the

probe, a corresponding change in electrical impedance occurs between the probe and the

metal storage vessel wall. (For non-metallic storage vessels, a "dual element" probe is

used. In this case, the impedance change occurs between the "active" and "ground"

elements of the probe.)

The highly sensitive impedance measurement circuits inside the L2000 detect and measure

this impedance change by means of a low level, radio frequency current that flows from the

Section One

Description

1-2

sensor, through the process material and back to the electronics via the metal storage

vessel wall (or via the probe ground element). This change in radio frequency current is

converted to a proportional DC signal. The electronics compares this DC signal to a set-

point determined by the coarse and fine sensitivity adjustments, and triggers a change in the

state of the Probe Status LED and the Output Control Relay when the signal level traverses

the set-point level.

•Coating Cancellation

A coating of process material on a probe can effectively simulate a presence condition, even

when the process level is well below the probe. Princo point level probes incorporate a

"guard" element which negates this problem. Driven by the electronic circuitry, the guard

produces a correction signal, allowing the electronics to respond only to level changes

above and below the "active" element of the probe. The unit must be calibrated with the

probe coated for the guard to function correctly.

•Heavy Duty Control Relay

Two sets of Form C (DPDT) contacts are provided via a terminal block located on the top

printed circuit board of the L2000. The contacts are rated at 10 amps at 115 Vac.

•Probe Status Indicator

The status of the process material at the sensor probe is indicated by the color of the

PROBE STATUS LED. The two color (Red/Green) LED is located on the top printed circuit

board of the L2000. Green indicates material contacting the probe; Red indicates no

contact.

•Coarse and Fine Sensitivity Adjustments

Two linearly scaled, single turn potentiometers (SENS, C & F) are provided on the top

printed circuit board of the L2000. These adjustments are used to establish a repeatable

switch point that is calibrated to the given application.

•Selectable Alarm Action

A jumper select switch is provided for programming the alarm action as either high acting, or

low acting. The Alarm Select (FAIL SAFE) is located on the top printed circuit board of the

L2000.

A high acting alarm condition occurs when the process material contacts the probe

(presence). A low acting alarm condition occurs when the process material is removed from

the probe (absence). In both cases the alarm condition is defined as a de-energized control

relay.

•Fail Safe Alarm Action

The L2000 is in normal, non-alarmed state when its control relay is energized. If the unit

were to lose power, the control relay would de-energize. Thus a power failure would

produce an alarm condition, alerting the operator that a problem exists.

•Time Delay Adjustment

The L2000 senses the process material level change instantaneously. However, a delay

can be inserted between the instant the instrument senses the level change, and the time

the control relay correspondingly changes state. A single turn Time Delay (DLY) pot is

Section One

Description

1-3

provided on the top printed circuit board of the unit. This potentiometer allows an adjustment

of 0 to 30 seconds of time delay.

The time delay feature is useful when process material wave action causes the control relay

to continually change state. It can also be used to suit a particular control timing application.

Note that the PROBE STATUS LED changes immediately, even when a delay is applied.

Figure 1-1

Typical Explosion-Proof Installation with L2000 Dimensions

C. L840 Series Probe Description

L840 Series Sensor Probes are the probes commonly used with the L2000. (Refer to Figure 1-

2 for a dimensional drawing of the standard L843 Probe.) These probes have three stainless

steel electrical contacts -active, guard and ground -which are separated from each other by

Teflon insulators. See Figure 1-3 for location of these contacts on the L843 probes. Electrical

contact between the probe elements and the electronic unit is made by simply threading the

probe into the electronic housing. The "active" element contacts the L2000 circuit board by

means of the spring-loaded pin projecting from the top of the probe. The guard contact is made

by means of a ½ inch diameter spring which projects from the bottom of the L2000 bottom

circuit board. This spring fits concentrically around the spring-loaded pin and touches the guard

contact on the probe. The hub of the probe serves as the ground element. It contacts both the

electronic housing and the metal storage vessel through its threaded connections with them.

The guard element cancels the effect of any process coating between the ground and active

elements, allowing the electronics to respond only to changes in the process material level.

All of the L840 Series Probes have these same three elements, varying only in physical

dimensions and configuration as required for various applications.

The L844 Probe (not shown) has a built-in ground reference and is referred to as a "dual

element" probe. It is suitable for low viscosity liquids in various low dielectric and non-metallic

Section One

Description

1-4

tank applications. The L844 has a ¾ inch diameter stainless steel tube concentrically

surrounding the standard active/guard rod. The tube itself serves as the ground element.

Probes are available in custom guard lengths and overall lengths, above and below the

standard lengths. Teflon and Kynar sheathed probes are available for applications where

stainless steel is incompatible with the process material. Consult the factory for specific

application questions.

Figure 1-2

Standard L843 Probe, Dimensional Drawing

Figure 1-3

Standard L843 Probe, Descriptive Drawing

Section Two

Specifications

2-1

A. Specifications

1. L2000 LEVEL CONTROLLER

•TYPE

Point type (on/off), solid state electronic, high frequency (RF), impedance sensing, level

controller.

•POWER REQUIREMENTS

95 to 135 Vac, 50 to 60Hz, 1.3 watts; or 205 to 250 Vac, 1.3 watts; or 17/34 Vdc, <1 Watt.

•AMBIENT TEMPERATURE RANGE

-40 to 150 °F (-40 to 66 °C)

•SENSITIVITY

Senses capacitance as low as 0.5pF and materials with dielectric constants as low as 1.5.

Sensitivity may be decreased to approximately 500pF.

•TEMPERATURE STABILITY

Temperature coefficient of 0.025pf/°F (4.75 pf over ambient temperature range).

•ALARM TYPE

Selectable as either High Acting or Low Acting.

High Acting: Alarm occurs upon presence of process material.

Low Acting: Alarm occurs upon absence of process material.

•ALARM ACTION

Fail Safe Alarm: Control relay de-energizes (drops out) upon alarm.

•CONTROL RELAY CONTACTS

Two sets of form C contacts, rated at 10 amperes, 115 Vac or 26 Vdc, resistive load.

•DELAY TIME AND MODE

Standard delay time is adjustable from 0 to 30 seconds. Standard mode is delay both ways

(turn-on alarm and turn-off alarm). Consult factory for optional times and modes.

•ELECTRONIC HOUSING

Heavy duty, cast aluminum.

Explosion-proof for: Class I, groups C & D; Class II, groups E, F & G.

Weather proof: NEMA 4.

2. L840 SERIES PROBES

•TYPE

Point level, single or dual element.

Section Two

Specifications

2-2

•PRESSURE / TEMPERATURE RATINGS

PSI @TEMP °F

1000 @-300

1000 @100

450 @300

350 @400

0@500

•WETTED SURFACES

Teflon and 316 Stainless Steel are standard. Probes fully sheathed in Teflon or Kynar are

also available.

•VESSEL CONNECTION SIZE

3/4" NPT.

•PHYSICAL DIMENSIONS

Refer to Figure 1-2.

Section Three

Installation

3-1

A. Inspection

The L2000 Level Controller is normally supplied with one of the Princo L840 Series Level

Probes. The L2000 and probe are shipped in separate packages.

Carefully remove each package's contents and check each item against the packing list. Inspect

each item for shipping damage. In particular, check the spring-loaded pin, located on the

threaded hub end of the probe (see Figure 1-3). This pin provides the necessary electrical

connection from the L2000 bottom printed circuit board, to the active element of the probe.

Make sure this pin is not missing, bent, jammed, or otherwise damaged.

If the probe is Teflon or Kynar sheathed, then carefully inspect the condition of the sheathing.

Make sure the sheathing forms a smooth, continuous coverage over the probe. Discontinuities

in the sheathing material which breach through to the active element may render the probe

useless in certain applications. Report any such damage immediately to the factory.

CAUTION !

Care must be exercised when handling probes which incorporate an insulating sheath. Do not

allow the sheathed sensing element to come in contact with a rough or sharp surface, as this

may cause a breach in the insulating sheath, and render the probe inoperable.

B. Grounding

Reliable operation of the L2000 Level Controller will only occur through proper installation. The

most important installation consideration is a proper sensor ground return.

If the process storage tank is metal, and the probe is a single element type, the ground return

connection is made when the probe is properly mounted in the vessel (see C. Probe Mounting).

Dual-element probes are available for non-metallic tanks. They provide a built-in ground return

rod. In this case, external grounding is not required.

If the vessel is non-metallic (eg. plastic, concrete, etc.), and the probe is a single element type,

a separate ground return should be provided. The ground return should consist of a metal rod,

equal in length to the probe. The rod should be mounted parallel to the length of the probe, no

greater than 6 to 8 inches from it.

The ground return rod must be electrically connected to the L2000 housing or to the ground

position of the terminal block with 18 AWG or heavier wire. See Figure 3-3 & 3-4. See Figure

3-5 for ground continuity testing.

C. Probe Mounting

The probe is mounted by its NPT hub or flange. Refer to Figure 1-1 for dimensions.

If the process material in the storage vessel is electrically conductive, the probe can be mounted

in either a vertical or horizontal orientation. If the probe is mounted vertically, and the process

material is electrically conductive, the L2000 will be tip sensitive (i.e. the L2000 trip point will

occur when the process material just contacts the tip of the probe).

If the process material in the storage vessel is electrically non-conductive (i.e. non-conductive

liquid, dry powder or granular), it is recommended that the probe be mounted in a horizontal

orientation.

Section Three

Installation

3-2

A vertically installed probe in a non-conductive process material, may require up to six inches of

probe immersion before a stable trip point is reached.

In horizontal mount applications, it is recommended that the probe be mounted at a shallow

downward angle (not critical) off the horizontal axis for optimum process liquid drainage (refer to

Figure 3-1).

In applications where the probe is installed through a nozzle, the guard element should extend

two inches into the vessel, beyond any process material coating build-up on the vessel inner

wall (see Figure 3-2).

To mount the equipment, screw the NPT hub of the probe into the NPT mounting collar which is

welded into the wall or top of the storage vessel.

After mounting the probe, screw the electronic housing onto the terminal end of the probe. This

is all the support it requires.

NOTE

Do not use any type of thread lubricant on the NPT probe mounting threads or the NPT threads

which mount the electronic housing. Application of thread lubricant may cause faulty or improper

ground connection. If required, Teflon tape may be used as a thread seal for either threaded

connection. If Teflon tape thread sealant is used, the installer should make an electrical

continuity check with a hand held ohm meter. Continuity should exist between the storage

vessel and the equipment electronic housing. Less than 1 ohm resistance should exist between

these two points. Refer to Figure 3-5.

Figure 3-1

Standard Installation

Section Three

Installation

3-3

Figure 3-2

Extended Guard Installation

D. Electrical Connections

Remove the lid of the L2000 electronic housing in preparation for connection of input and output

wires. Before drawing wires into the equipment housing, it may be necessary to remove the

electronic chassis. To do so, unfasten the two 8-32 mounting screws which are located on either

side of the electronic chassis. Once screws are unfastened, the chassis may be lifted or

removed from the housing. The power and relay contact wires may now be pulled through the

¾ inch NPT wiring port.

Connect the 115 Vac or 230 Vac power line wires: Hot (H), Neutral (N), and Ground (G)

respectively, to the terminal block as shown in Figure 3-3. If the unit requires 24 Vdc for power,

the terminal block is labeled as plus (+), minus (-) and ground (G). Connect 24 Vdc power

accordingly (See Figure 3-4).

Connect the normally open (NO), normally closed (NC) and common (C), relay wires to the

terminal block as shown in Figure 3-3, and Figure 3-4, and as required by the specific circuit

application.

NOTE

The relay contact configuration, as shown on the terminal block labeling and in Figures 3-3 and

3-4, is identified as such with the relay in the de-energized (shelf) state. Fail safe operation

requires relay to be normally in the energized (non-shelf) state. Upon alarm, configured as

either HIGH or LOW, the relay then becomes de-energized (shelf state).

Replace the electronic circuit board chassis with the flat side of the printed circuit boards facing

the wiring port. Replace the 8-32 mounting screws and tighten.

Section Three

Installation

3-4

NOTE

The two 8-32 mounting screws MUST be fastened securely. These two screws provide the

ground connection to the printed circuit board electronics. If not fastened securely, faulty

equipment operation may occur.

Verify that all connections were made correctly.

Figure 3-3

Electrical Connections, 115 Vac and 230 Vac Units

Figure 3-4

Electrical Connections, 24Vdc Unit

Section Three

Installation

3-5

E. Installation in Hazardous Areas

The outline which follows points out some of the major requirements of the NEC's (National

Electric Code) Section 501, as it relates to typical level control installations.

WARNING !

For applications which MUST BE explosion-proof and/or weatherproof, it is the customer's

responsibility to install the required conduit, seals, wiring, etc., which meet national, as well as

applicable local and plant safety codes. See Figure 1-1.

For Class 1 locations, rigid metal conduit must be used. At least five full threads of the conduit

must be tightly engaged in the enclosure. Conduit seal fittings must also be used. These seal

fittings, must be filled with an approved sealing compound and must be installed within 18

inches (or closer) of the enclosure. Conduit seals are also required when the conduit passes

from a hazardous area into a non-hazardous area. Water drain seal fittings eliminate or

minimize the effect of water which tends to collect in the conduit or enclosure due to

condensation.

Approved wire type, such as mineral-insulated wire, is required for use in Division 1

installations. Certain types of metal-clad cable or shielded non-metallic sheathed cable are

permitted in Division 2 installations. When multiconductor cables are used in the conduit, the

outer jacket must be cut away in such a manner that allows the sealing compound to surround

each insulated wire as well as the jacket.

The preceding information should act as guide to assist the customer/installer in satisfying their

responsibility for producing safe installations in hazardous area.

Ground Continuity Test:

With unit power off, using an ohmmeter on

the lowest range, a check between the

following points should read less than one

ohm.

1. Point A (posts) to point B.

2. Point B to point C.

3. Point C to point D (except in non-

metallic tank).

Figure 3-5

Ground Continuity Test

Section Four

Adjustments and Operation

4-1

A. Initial Checkout

1. Refer to Figure 4-1 for L2000 adjustment and indicator locations.

2. Install the L2000 Level Controller with Probe as presented in Section 3 of this manual.

3. Apply power to the unit and allow a 15 minute warm-up time before performing the

calibration procedure as outlined below.

4. Perform step H.1: Basic Electronic Checks.

Figure 4-1

L2000 Adjustment and Indicator Locations

B. Calibration

The Coarse (C) and Fine (F) sensitivity (SENS) pots must be properly adjusted in order to

establish a repeatable switch point that is calibrated to the given process material application.

If the process material is electrically conductive, then adjustments can be made under simulated

or "bench test" conditions.

To make adjustments under simulated conditions, perform the following outlined procedure by

raising and lowering the L2000, with attached probe, into and out of a small metallic vessel filled

with the conductive process material. Perform the procedure making certain that nothing but the

process material, contacts the probe. A clip lead must be connected from the L2000 metal

housing to the metal wall of the vessel used.

Whether adjustments are made under simulated conditions, or in the actual proper installation,

the following procedure must be performed.

NOTE

A Green PROBE STATUS indicator denotes presence of material at the probe, and a Red

indicator denotes absence of material at the probe, when sensitivity potentiometers are properly

adjusted.

Section Four

Adjustments and Operation

4-2

1. ADJUSTMENT PROCEDURE -Conductive Process Materials

a) Refer to Figure 4-1 for adjustment and indicator locations. Refer to Figure 4-2 for a pictorial

outline of this procedure.

b) Perform Section 4.A., Initial Checkout, as outlined above.

c) Allow the unit to warm up (thermally stabilize) for approximately 15 minutes before

proceeding with steps d through f below.

d) Turn the Time Delay (DLY) pot to the fully counterclockwise position (No Delay).

e) With process material NOT contacting the probe, adjust both the Coarse (C) and Fine (F)

Sensitivity (SENS) pots fully counter-clockwise. The Probe Status LED should be Red.

f). Immerse probe in process material. The LED should switch to Green and the relays should

change state upon contact with the process material. This completes the adjustment

procedure.

NOTE

Conductive process materials will tend to "trip" near the tip of the probe when the storage tank is

metallic. This same procedure may be used even though the probe is to be mounted

horizontally.

Figure 4-2

Conductive Process Calibration Procedure

Section Four

Adjustments and Operation

4-3

2. ADJUSTMENT PROCEDURE -Non-Conductive (Insulating) Process Materials:

a) Refer to Figure 4-1 for adjustment and indicator locations. Refer to Figure 4-3 for a pictorial

outline of this procedure.

b) Perform Section 4.A., Initial Checkout, as outlined above.

c) Allow the unit to warm up (thermally stabilize) for approximately 15 minutes before

proceeding with following steps.

d) Preset the Fine (F) Sensitivity (SENS) pot full clockwise and the Coarse ( C ) pot to its mid-

point position (12 o'clock).

e) Turn the Time Delay (DLY) pot to the fully counter-clockwise position (No Delay).

f) If a coating is likely to build up on the probe in actual use, pre-coat the probe with the

process material before proceeding. The coating must cover the entire length of the probe,

including the guard element. This may be done by raising the level or by other means.

g) With process material NOT contacting the probe, adjust the Coarse (C) sensitivity such that

the Probe Status LED "just turns" Green and stays. Don't touch the Coarse (C) sensitivity

pot again.

NOTE

Clockwise rotation increases sensitivity for both Coarse (C) and Fine (F) potentiometers.

h). Adjust the Fine (F) sensitivity pot counter-clockwise, such that the PROBE STATUS LED

"just turns" Red, and then back clockwise until it "just turns" Green. Mark the position of the

Fine (F) sensitivity pot.

i). Immerse probe in process material to the desired level of "trip point". For a vertically

installed sensor probe in a non-conductive process material, this trip point should typically

be half way up the probe active section.

NOTE

Horizontal probe mounting is preferred (see Section 3C). The procedure must be done with the

L2000 properly installed in the intended storage tank, and with the intended process material.

All or most of the probe may need to be covered. The angle between the adjustment marks may

be quite small with non-conductive process materials.

j). With probe immersed, adjust the Fine (F) sensitivity pot counter-clockwise, such that the

PROBE STATUS LED "just turns" Red and stays. Mark or mentally note position of

screwdriver slot.

k). Turn the Fine (F) sensitivity pot until the screwdriver slot is midway between the marks from

steps h and j. The Probe Status LED should now be Green (probe immersed in same

position). If not repeat steps d through k.

Section Four

Adjustments and Operation

4-4

Figure 4-3

Non-conductive Process Calibration Procedure

Section Four

Adjustments and Operation

4-5

C. Alarm Action

The L2000 is in the normal “non-alarmed” state when it’s control relay is energized. The unit is

in the “alarm” state when its internal control relay is de-energized. Hence, if the unit lost power,

the internal control relay would de-energize, and an “alarm” condition would occur.

This type of “Fail-Safe” operation is based on the fact that most major malfunctions, including a

power failure, would cause the control relay to de-energize.

1. Fail Safe Low Operation (Low Acting Alarm):

The control relay contacts de-energize (shelf state) upon Low Alarm. When process material

absence is detected, a Low Alarm condition occurs, and the relay changes from the normal

"non-alarmed" (energized) state to the “alarmed” (de-energized) state.

2. Fail Safe High Operation (High Acting Alarm):

The control relay contacts de-energize (shelf state) upon High Alarm. When process

material presence is detected, a High Alarm condition occurs, and the relay changes from

the normal "non-alarmed" (energized) state to the “alarmed” (de-energized) state.

This action is controlled by a small plastic jumper selector switch (FAIL SAFE) located on the

top of the unit (see Figure 4-1). The L circuit pad designates Low Acting Alarm. The H circuit

pad designates High Acting Alarm. The center pad is the common, and always connects to one

position of the jumper selector.

Unless otherwise specified this unit is set for High Acting Alarm operation. If Low Acting Alarm

operation is desired, remove the jumper switch currently connected between center pin and H,

and re-locate it between center pin and L.

D. Delay Operations and Adjustments

Time delay is useful in preventing control relay "chatter" caused by agitation of the process

material within the storage vessel. It is also useful in certain process control timing applications.

The three types of time delay are as follows: delayed turn-on alarm, delayed turn-off alarm, and

delayed turn-on alarm/turn-off alarm.

The first two modes are normally used to suit a particular timing application. The third mode

(turn-on/turn-off) is best suited to prevent relay chatter. This mode (on/off) is factory configured

in the standard L2000 unit.

A single turn Time Delay (DLY) pot is provided on the L2000 (see Figure 4-1). Most applications

require no time delay. Therefore, adjust the Time Delay pot to the maximum counterclockwise

direction (zero time delay).

If there is significant agitation of the process material within the storage vessel, then time delay

may be required. In this case, adjust the Time Delay pot clockwise, just enough to prevent

control relay chatter. Use the smallest amount of delay possible.

The maximum standard delay time is 30 seconds full scale. Consult Factory for optional delay

times and modes.

H. Trouble-Shooting Guide

1. Basic Electronic Checks

Section Four

Adjustments and Operation

4-6

üThe Probe Status LED should be lit to either Red or Green at all times. If not, check that

proper power is applied to the Power terminals.

üWith the Probe dry (no contact with process material):

With both the Coarse (C) and Fine (F) sensitivity potentiometers turned fully clockwise, the

LED should be Green. With both potentiometers turned fully counter-clockwise the LED

should be Red. (With the Probe immersed in a conductive liquid, the LED should remain

Green at all times.)

üThe LED should switch crisply from Green to Red or from Red to Green. It should never

hang in between in an orange color.

If the unit fails any of the above checks, return the L2000 electronic chassis to the factory for

repair or replacement.

2. Adjustment Problems

•After performing the adjustment procedure, the unit fails to shut off or on properly.

üCheck ground continuity (refer to Figure 3-5).

üCheck that the spring-loaded pin (refer to Figure 1-3) on the top of the probe is making

contact with the silver pad on the bottom of the electronic circuit board. The pin normally

projects about 1¼ inch above the NPT fitting on the probe. It may be stretched out further

with a pair of pliers without causing damage.

üBe sure that non-immersed and immersed conditions really exist when making the

appropriate adjustments

•Unit switches correctly once or several times and then fails to switch correctly.

üA progressively thicker coating may be building up on the probe. This would result in a

narrower span between the non-immersed and immersed positions of the sensitivity

potentiometer when performing the adjustment procedure.

Solution: This condition will require performing the adjustment procedure over again when

the coating is at its thickest point.

üThere may have been a change in the dielectric constant of the process material. This

would change the flow of RF current through the probe, effectively shifting the switch point.

Solution: RF impedance technology is designed to operate with materials having a constant

dielectric constant (therefore, a constant RF conductivity). It may be possible, through trial

and error, to find a switch point that works for some changes in dielectric constant; but

extreme changes, like oil to water, may be impossible to compensate for. As a general rule,

a unit adjusted to a low dielectric constant material will switch correctly when a higher

dielectric constant material is applied (although at a point closer to the tip of the Probe).

However, changes in the coating characteristics could negate this.

Section Five

Equipment Service

5-1

Getting Help

If your Princo equipment is not functioning properly, and attempts to solve the problem have

failed, contact the closest Princo sales representative in your area, or call the factory direct and

ask for service assistance. The factory telephone number is 1-800-221-9237.

To assist us in providing an efficient solution to the particular problem, please have the following

information available when you call:

1. Instrument Model Number

2. Probe Model Number

3. Purchase Order Number

4. Date of Purchase Order

5. Process Material being Measured

6. Detailed Description of the Problem

If your equipment problem cannot be resolved "over the phone"; then it may be necessary to

return the equipment for checkout/repair.

Do not return equipment without first contacting the factory for a Return Authorization Number

(RMA #).

Any equipment, which is returned, MUST include the following information in addition to the list

above.

7. RMA Number

8. Person to contact at your Company

9. Return (Ship to) Address

Princo level instruments are covered by a 10-year limited warranty. You will not be charged if it

is determined that the problem is covered under warranty. Please return your equipment with

freight charges prepaid. If repair is covered under warranty, Princo will pay return freight

charges.

If telephone assistance or equipment return is not a practical solution to the problem, then it

may be necessary for field assistance. Trained field servicemen are available from the factory

on a time/expense basis to assist in these instances.

Table of contents

Popular Controllers manuals by other brands

Friedrich

Friedrich VRPXEMWRT2 instruction manual

Siemens

Siemens AEROGYR RWI65.02 manual

Elan

Elan Z-600 owner's manual

Dontek

Dontek AQUATEK instruction manual

Ducasa

Ducasa Smart Command Installation and operating manual

Yisutongma Network Technology

Yisutongma Network Technology ESM-9013 instruction manual